A Method of Eliminating Wrinkling of Large Curved Surface Based on Gradient Gap Die

A mold and curved surface technology, which is applied in the field of eliminating wrinkling in the thermoforming prefabrication process of large curved aircraft titanium alloy skin, can solve the problems of unsuitable high-strength materials, uncontrollable springback, poor continuous production, etc., to shorten the product cycle, Fast design and manufacture, eliminate wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

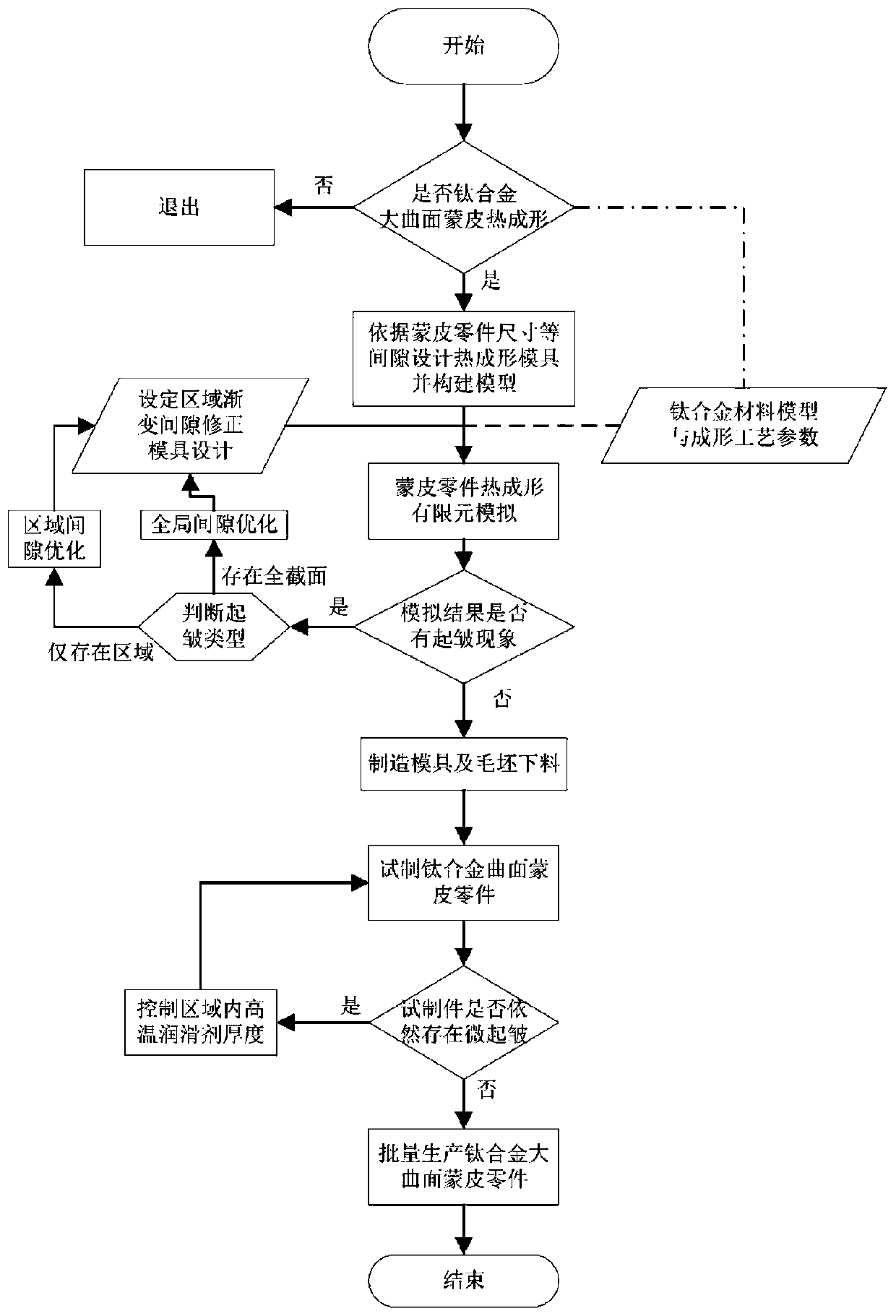

[0045] The invention is a method for eliminating wrinkling of large curved surface skin based on gradual gap mold, and proposes a design method for thermoforming mold of titanium alloy large curved surface skin parts. The thermoforming blank of titanium alloy large curved surface skin is the national standard titanium Alloy plate adopts the process of mold hot forming, and the method process is as follows: figure 1 As shown, the implementation steps of the present invention are described in detail below taking the TA32 titanium alloy large curved surface skin part as an example.

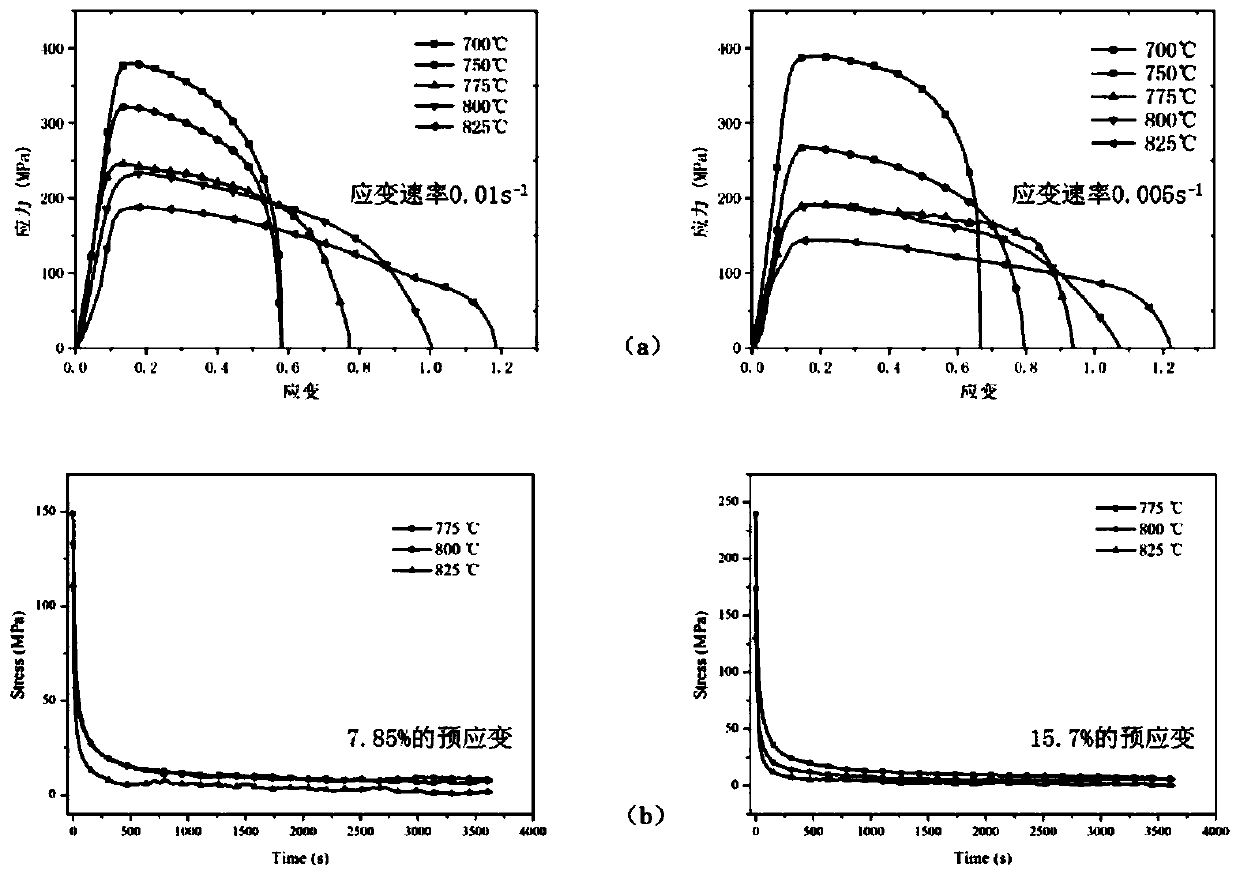

[0046] Step 1: Judging that TA32 is a titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com