Remanufacturing method of high strength die steel

A die steel, high-strength technology, applied in the field of die steel, can solve the problems that die steel cannot adapt to high strength and excellent machining performance, and achieve the effects of excellent machining performance, easy realization and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

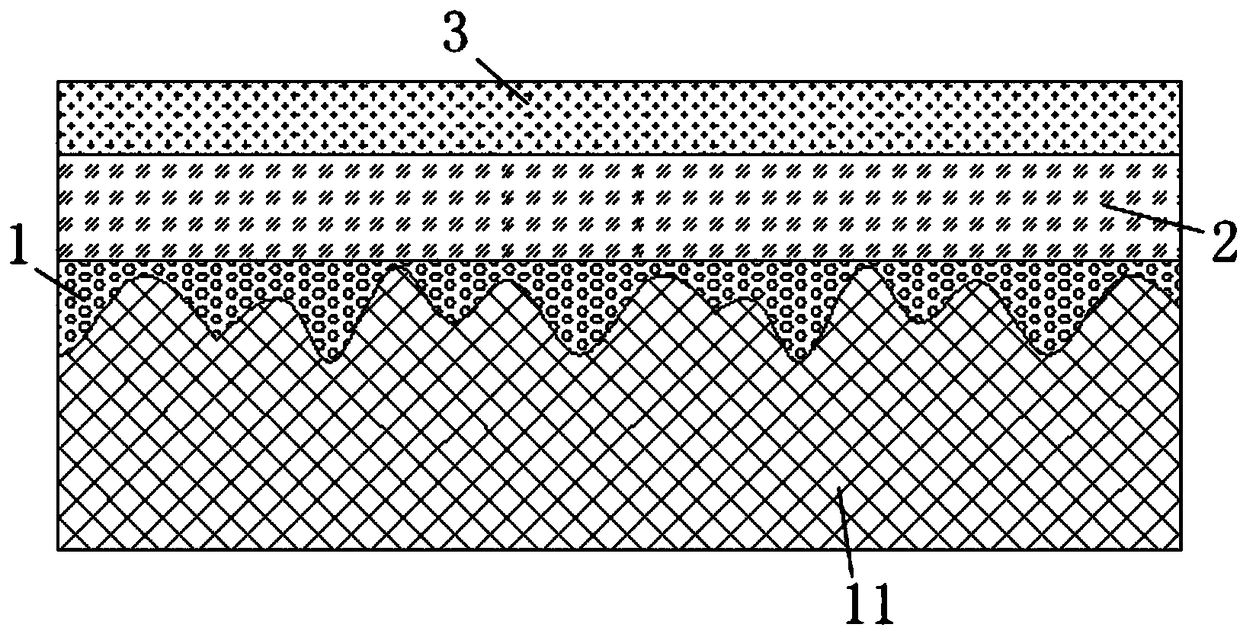

[0037] First, a plurality of micro-nano grooves with different depths are formed on the surface of the high-strength mold steel 11 to be processed, and then metal nanoparticles with an average particle size of 7nm are consolidated in the multiple micro-nano grooves by PVD technology to form a transition The bottom layer 1, the material of the metal nanoparticles is mold steel with a Cr content that is 0.5% more than the high-strength die steel 11 to be processed, and then the iron-based alloy powder is fused on the transition bottom layer 1 by laser cladding technology to form a cladding middle layer 2. Finally, a silicon nitride layer is provided on the cladding intermediate layer 2 as the outermost protection layer 3 .

Embodiment 2

[0039] First, a plurality of micro-nano grooves with different depths are formed on the surface of the high-strength mold steel 11 to be processed, and then metal nanoparticles with an average particle size of 10nm are consolidated in the multiple micro-nano grooves by PVD technology to form a transition The bottom layer 1, the material of the metal nanoparticles is mold steel with a Cr content that is 0.9% more than the high-strength die steel 11 to be processed, and then the iron-based alloy powder containing ceria is fused on the transition bottom layer 1 by laser cladding technology A cladding intermediate layer 2 is formed, and finally a silicon carbide layer is provided on the cladding intermediate layer 2 as the outermost protective layer 3 .

Embodiment 3

[0041]First, a plurality of micro-nano grooves with different depths are formed on the surface of the high-strength mold steel 11 to be processed, and then metal nanoparticles with an average particle size of 15nm are consolidated in the multiple micro-nano grooves by PVD technology to form a transition The bottom layer 1, the material of the metal nanoparticles is mold steel with a Cr content that is 0.3% more than the high-strength die steel 11 to be processed, and then the iron-based alloy powder containing diyttrium trioxide is fused to the transition bottom layer 1 by laser cladding technology A cladding intermediate layer 2 is formed on the cladding intermediate layer 2, and finally a silicon nitride layer is provided on the cladding intermediate layer 2 as the outermost protective layer 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com