Ultralow-temperature piston actuating type high-pressure valve with buffer function

A high-pressure valve, temperate zone technology, used in engine components, fuel valves for turbine/propulsion devices, and fuel delivery systems for turbine/propulsion, etc., to achieve good repairability and testability, short processing cycles, and reduced size and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

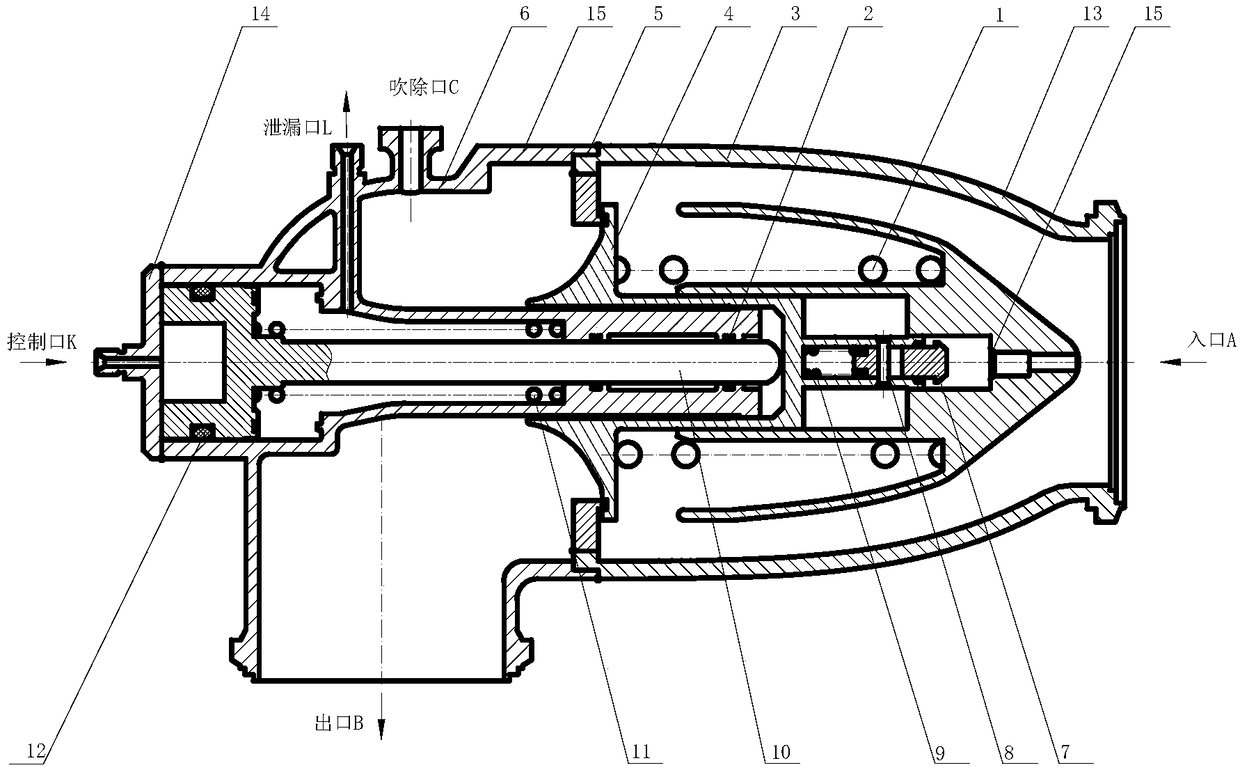

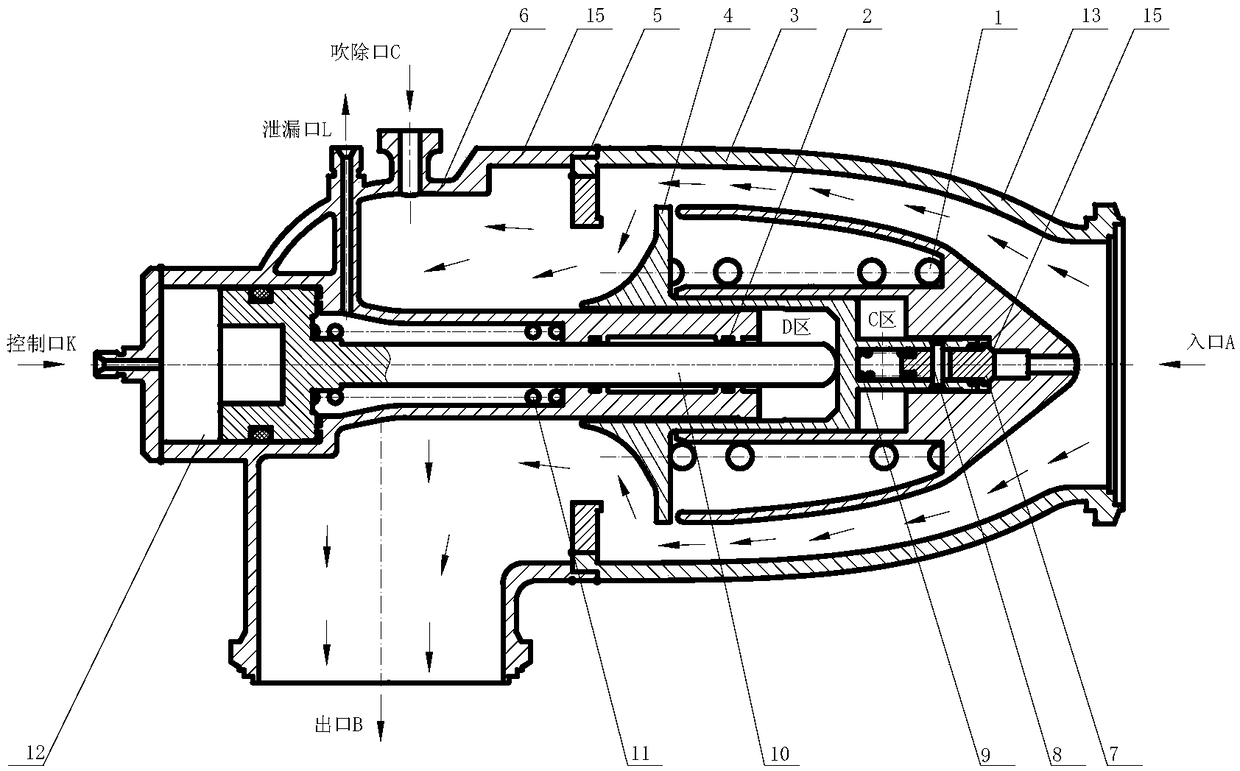

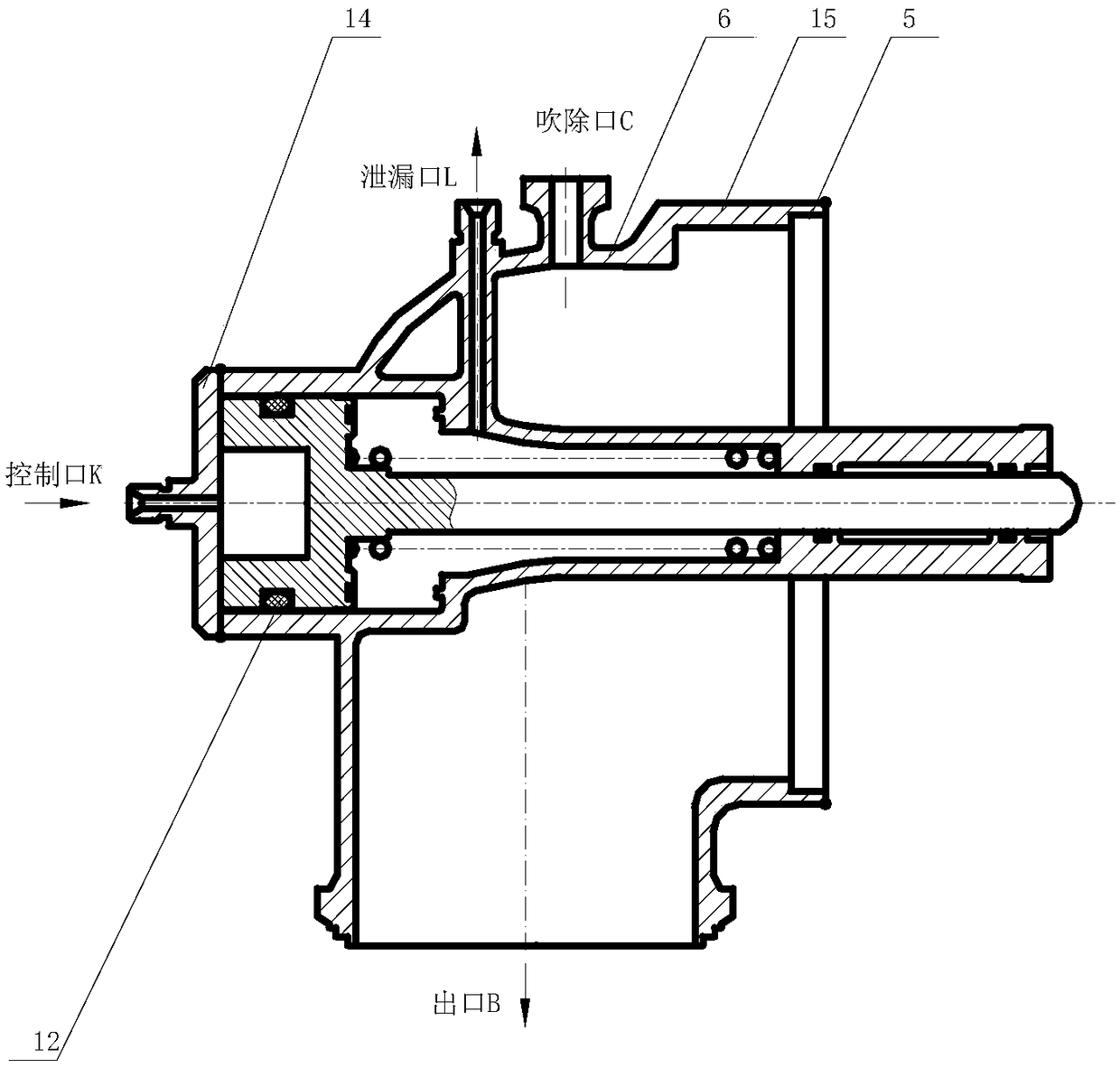

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0049] like figure 1 As shown, a piston-actuated high-pressure valve with ultra-low temperature and cushioning function includes two parts: an inlet multi-layer housing assembly 3 and an outlet housing assembly 6, which are connected and statically sealed by threads and aluminum gaskets. The whole valve adopts split assembly. After the two components are installed and tested at room temperature, they are welded to ensure the reliability of static sealing at low temperature.

[0050] like Figure 9As shown, the inlet multilayer casing 13 includes: casing outer wall 131 , guide cone 132 , main valve guide wall 133 , secondary guide wall 134 and several ribs 1311 . Wherein, the housing outer wall 131 is connected to the diversion cone 132 through several ribs 1311 . During specific implementation, the outer wall 131 of the housing, several ribs 1311 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com