U shaft and V shaft structure for sliding table type taper head device of linear cutting machine tool

A wire cutting machine tool and taper head technology, applied in the field of U-axis and V-axis combined structure, can solve the problems of poor protection ability, small transmission torque, and low transmission accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

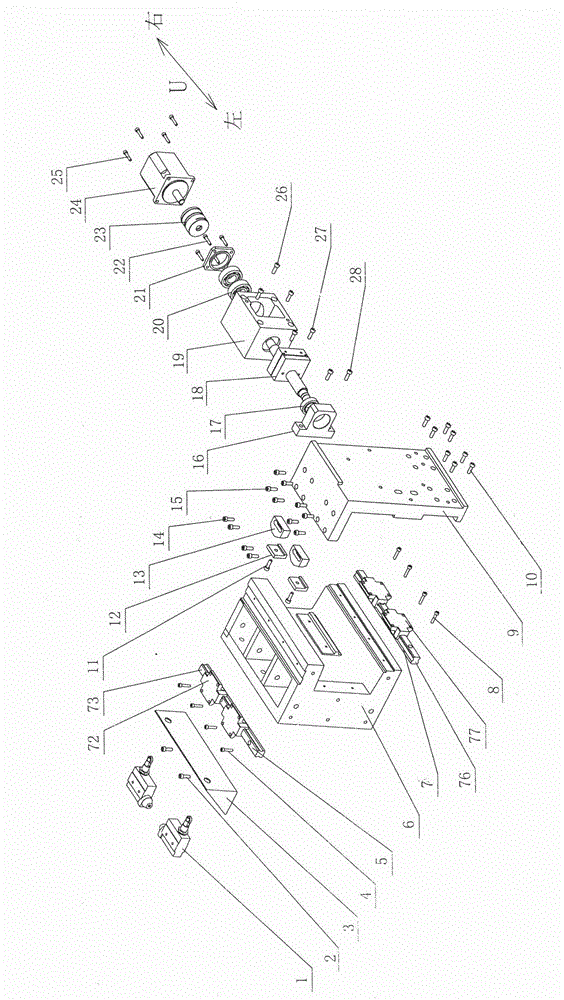

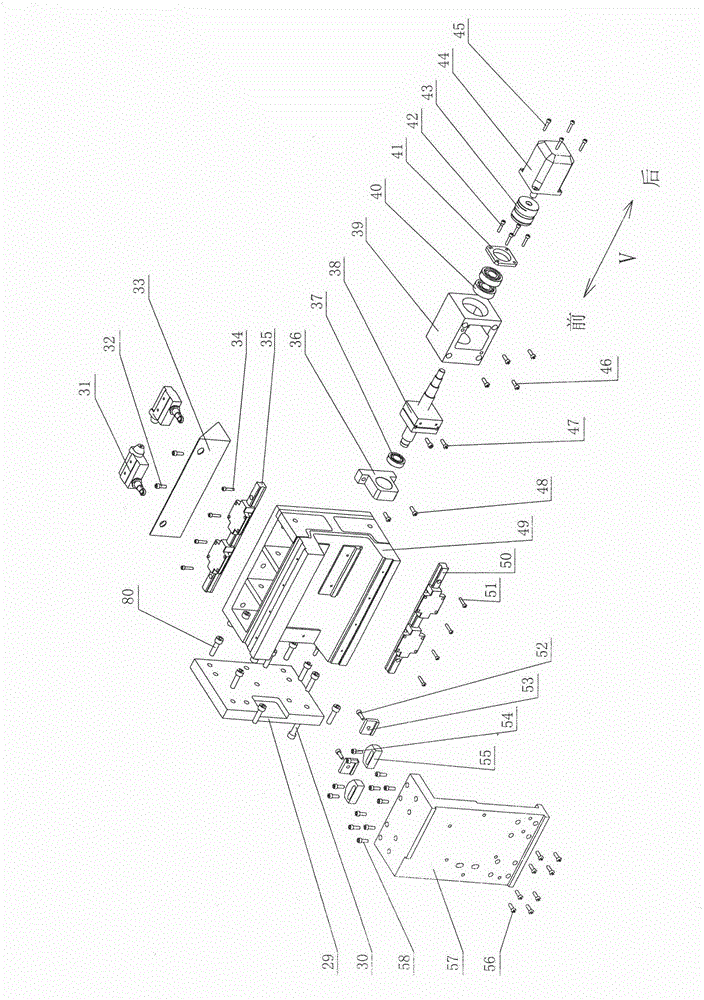

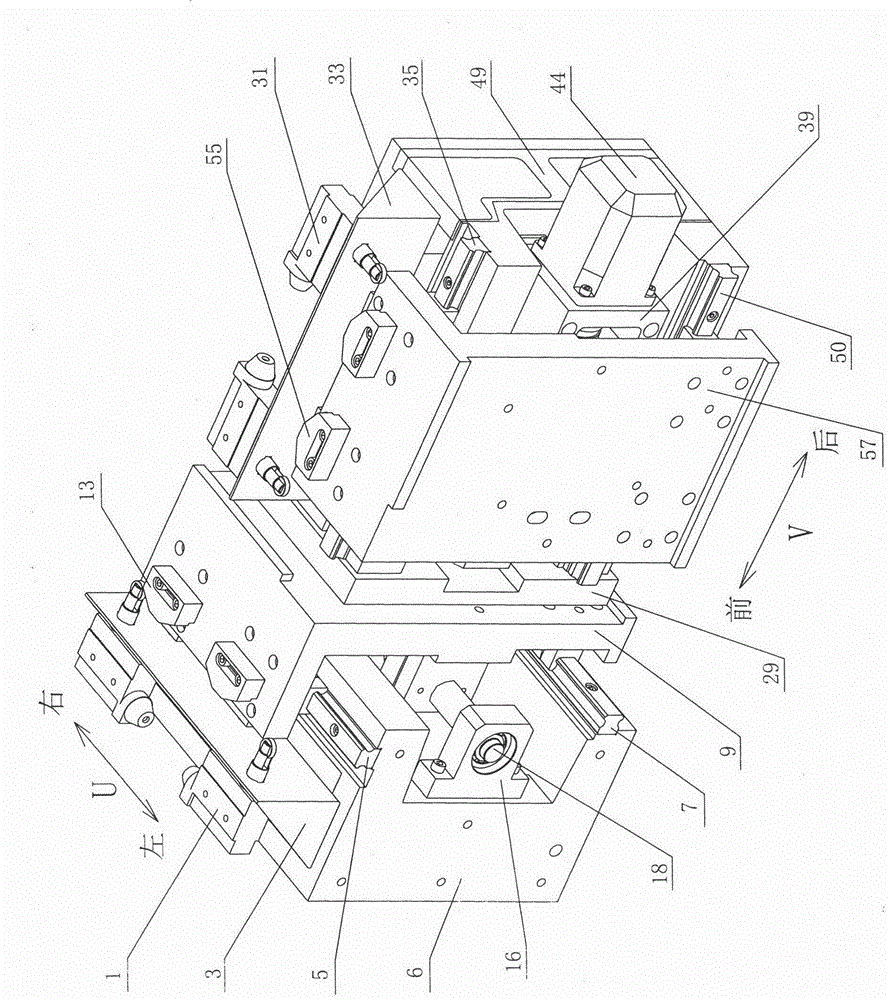

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and other related drawings, described below:

[0026]The U-axis and V-axis structure of the sliding table type taper head device for wire cutting machine tools, the U-axis consists of U-axis travel switch 1, U-axis switch bending plate 3, U-axis vertical linear guide rail slider assembly 5, U-axis slide seat 6, U-axis Axis side linear guide rail slider assembly 7, U-axis connecting bending plate 9, U-axis elevation guide rail slider pressure plate 12, U-axis travel bumper 13, U-axis tail end bearing seat 16, U-axis screw support bearing 17, U-axis screw nut pair 18, U-axis motor drive seat 19, special bearing for U-axis screw rod 20, U-axis bearing flange cover 21, U-axis coupling 23 and U-axis servo motor 24, V-axis is composed of V-axis Stroke switch 31, V-axis switch bending plate 33, V-axis elevation linear guide rail slider assembly 35, V-axis slide seat 49, V-axis side linear guide rail slider assembly 50, V-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com