High-strength semi-solid double-phase die-casting magnesium-lithium alloy and preparation method thereof

A semi-solid and lithium alloy technology, which is applied in the field of high-strength semi-solid two-phase die-casting magnesium-lithium alloy and its preparation, can solve the problem of narrow temperature range of solid-liquid two-phase region, low mechanical properties of as-cast magnesium-lithium alloy, low ignition point, etc. problems, to achieve the effect of widening the temperature range, improving the mechanical properties of the as-cast state, and shortening the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

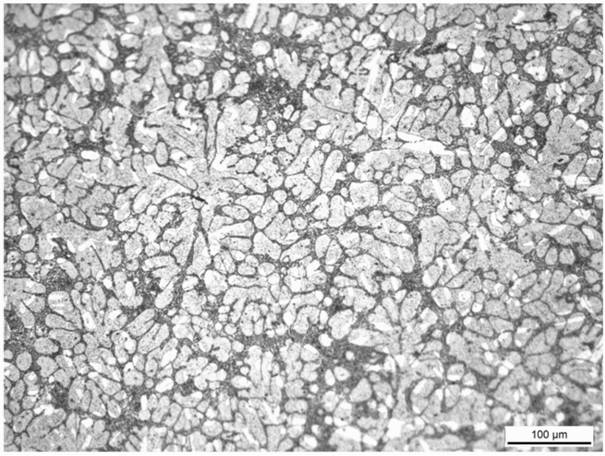

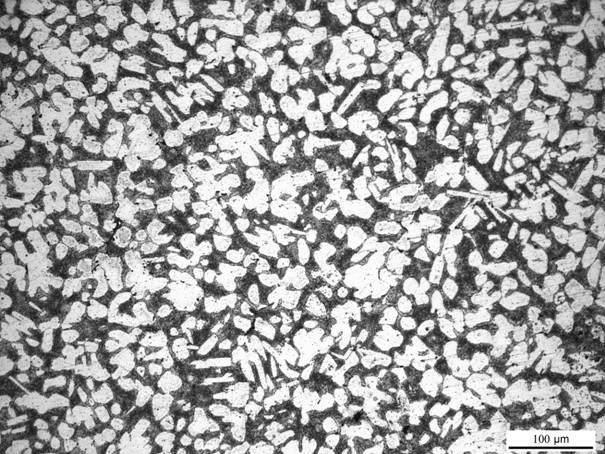

Image

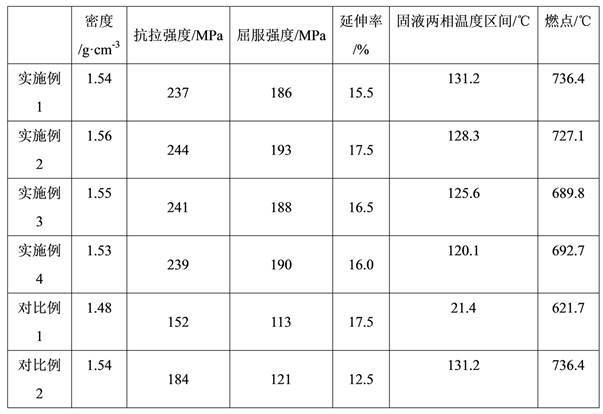

Examples

Embodiment 1

[0026] A high-strength semi-solid dual-phase die-casting magnesium-lithium alloy, mainly composed of the following components in mass percentage: Li 8%, Al 7%, Zn 1%, Ca 3%, the mass ratio of Al to Ca is 2.33:1, and the rest The amount is Mg and other unavoidable impurity elements; among them, the impurity element Na content is less than 0.001%, each of the other impurity elements is less than 0.05%, and the total amount of other impurity elements is less than 0.3%.

[0027] The preparation method of the high-strength semi-solid dual-phase die-casting magnesium-lithium alloy includes three stages of vacuum smelting, ingot blanking and cutting, and semi-solid die-casting. The specific steps are as follows:

[0028] (1) Melting and pouring: batching is carried out according to the mass percentage of each component in the alloy. After batching, a vacuum furnace is used for alloy melting. During the melting process, the vacuum degree in the vacuum furnace is first pumped to 0.5Pa, ...

Embodiment 2

[0032] A high-strength semi-solid dual-phase die-cast magnesium-lithium alloy, mainly composed of the following components in mass percentage: Li7.5%, Al 8%, Zn 1%, Ca 2.5%, the mass ratio of Al to Ca is 3.2:1, The balance is Mg and other unavoidable impurity elements, wherein the impurity element Na content is less than 0.001%, each of the other impurity elements is less than 0.05%, and the total amount of other impurity elements is less than 0.3%.

[0033] The preparation method of the high-strength semi-solid dual-phase die-casting magnesium-lithium alloy includes three stages of vacuum smelting, ingot blanking and cutting, and semi-solid die-casting. The specific steps are as follows:

[0034] (1) Melting and pouring: batching is carried out according to the mass percentage of each component in the alloy. After batching, the alloy is melted in a vacuum furnace. Pure argon, followed by heating, when the metal is completely melted, the temperature is raised to 740°C for 8 mi...

Embodiment 3

[0038]A high-strength semi-solid dual-phase die-casting magnesium-lithium alloy, mainly composed of the following components in mass percentage: Li8.5%, Al 7.5%, Zn 1.2%, Ca 2.0%, the mass ratio of Al to Ca is 3.75:1, The balance is Mg and other unavoidable impurity elements, among which the impurity element Na content is less than 0.001%, each of the other impurity elements is less than 0.05%, and the total amount of other impurity elements is less than 0.3%.

[0039] The preparation method of the high-strength semi-solid dual-phase die-casting magnesium-lithium alloy includes three stages of vacuum smelting, ingot blanking and cutting, and semi-solid die-casting. The specific steps are as follows:

[0040] (1) Melting and pouring: batching is carried out according to the mass percentage of each component in the alloy. After batching, a vacuum furnace is used for alloy melting. During the melting process, the vacuum degree in the vacuum furnace is first pumped to 1.3Pa, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com