Anti-aging, tearing-resistant and crack growth-resistant rubber composition for all-steel tire sidewall and preparation method and application thereof

A rubber composition, anti-aging technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems that affect the service life and retreadability of tires, unavoidable sidewall scratches, and can not take into account the tear performance and other problems , to achieve the effects of improving tear resistance and crack growth resistance, improving heat aging resistance and crack growth resistance, and slowing down the crack extension speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

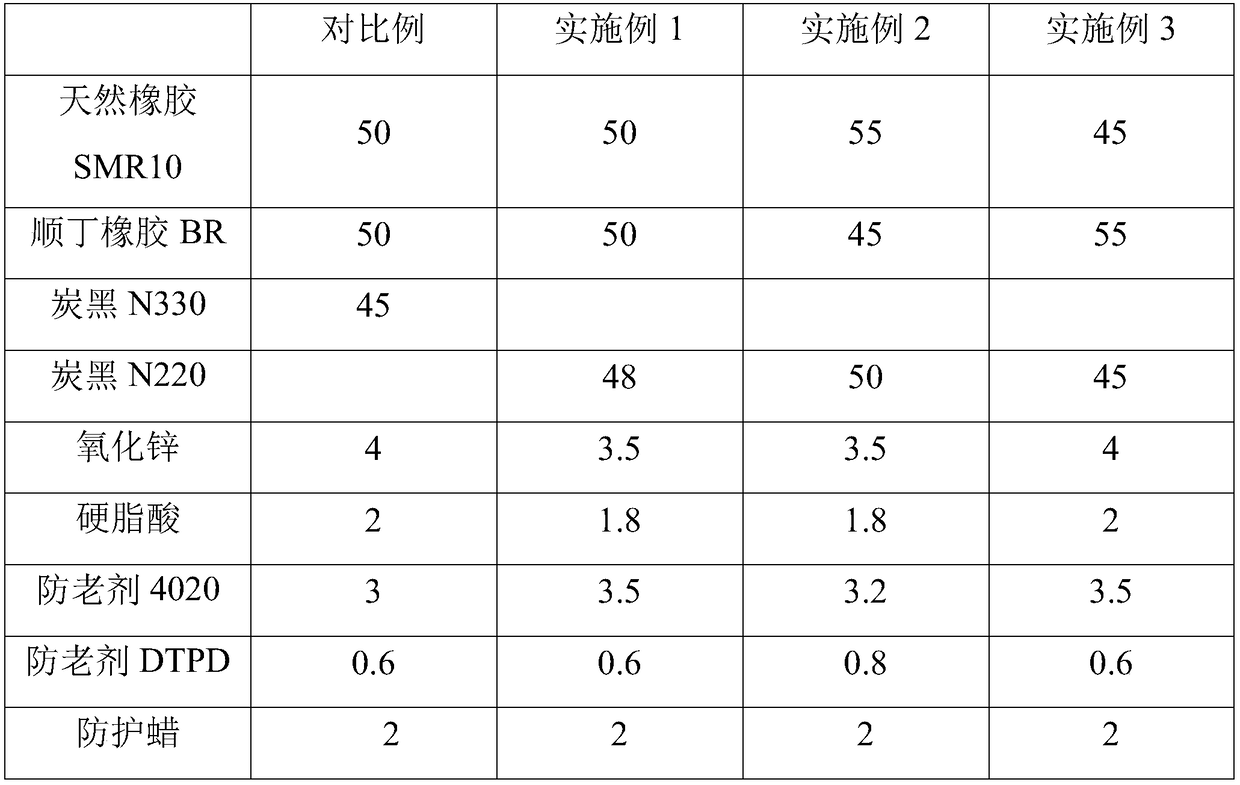

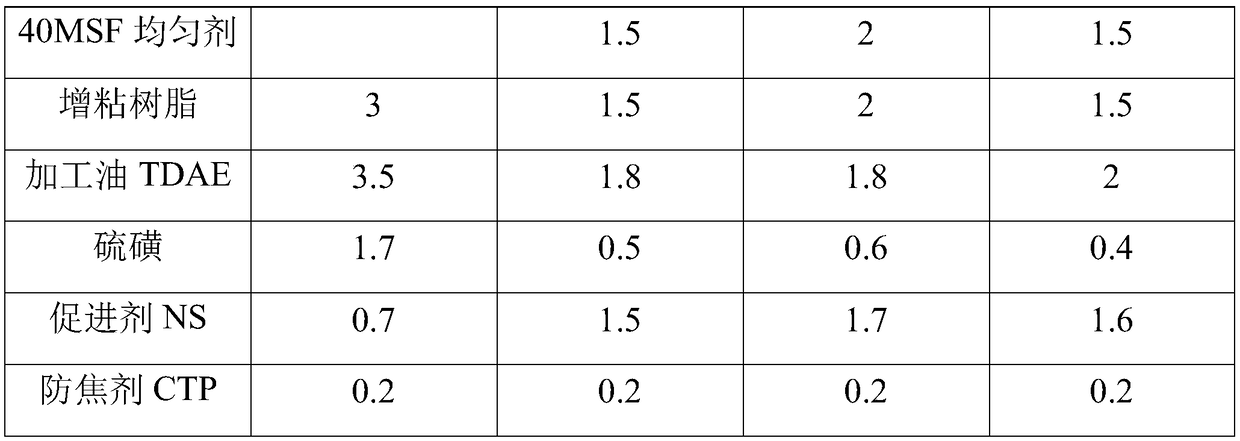

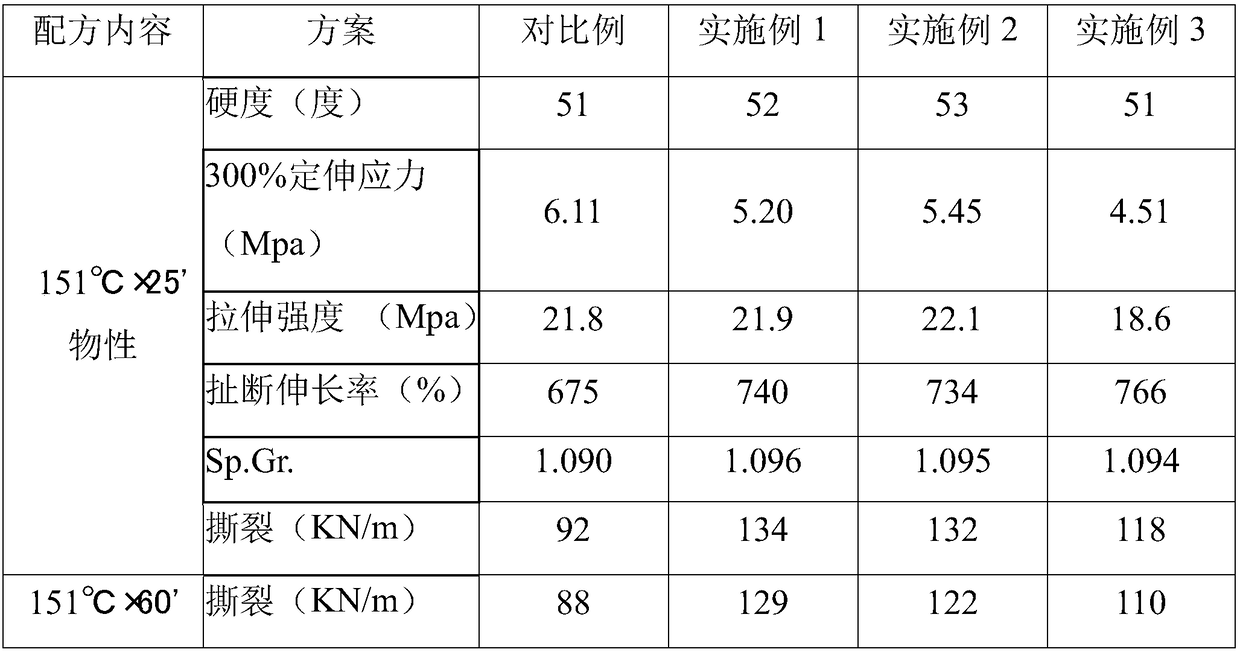

Method used

Image

Examples

Embodiment

[0032] A method for preparing an aging-resistant, tear-resistant and crack-growth-resistant rubber composition for all-steel sidewalls, comprising the following steps:

[0033] (1) Master batch mixing

[0034] Master batch mixing is carried out in an internal mixer, the internal mixer speed is 40-50rpm, the pressure is 90-110Bar, according to the proportion, add natural rubber, butadiene rubber, dispersant, protective wax, anti-aging agent, tackifying resin, zinc oxide , stearic acid, processing oil, pressurize the top bolt and keep it for 20-40S, lift the bolt and add carbon black, pressurize for 60-70S or when the temperature reaches 120℃, lift the bolt, inject processing oil, pressurize and keep for 20-40S Lift the plug, and then pressurize to 160°C-170°C to discharge the glue to prepare a section of masterbatch, and park a section of masterbatch at room temperature for 4-6 hours, and then carry out final mixing;

[0035] (2) Final mixing and mixing

[0036] The final mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com