Erosion-resistant fluorine rubber nanometer composite material with graphene and method for preparing erosion-resistant fluorine rubber nanometer composite material

A nano-composite material and graphene technology, which is applied in the field of erosion-resistant fluororubber nano-composite materials and its preparation, can solve problems affecting the comprehensive performance of composite materials, poor process stability, and poor graphene dispersion, and achieve enhanced crack resistance Expansion ability, excellent mechanical properties, and the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

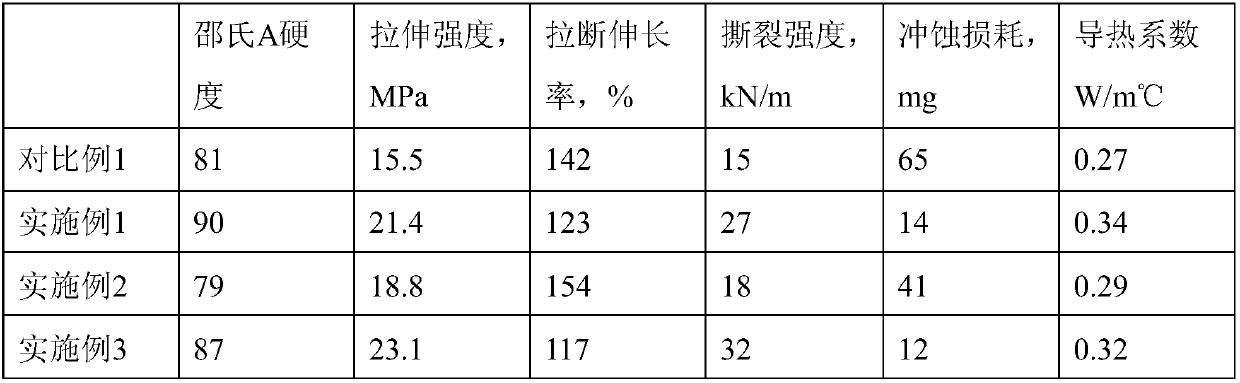

Examples

preparation example Construction

[0026] The nanocomposite material is prepared by a mechanical blending method, and its preparation method comprises the following steps:

[0027] (1) Graphene, carbon black and carbon fiber are put into the ball mill according to the ratio of mass and number of parts, and the ball milling medium is weighed according to a certain ball-to-material ratio (3:1). composition. Add a certain amount of absolute ethanol (subject to the submerged material), seal the lid and turn on the cooling cycle button, and set the temperature to 10°C. The revolution speed is 200-400r / min, the rotation speed is 500-800r / min, and the grinding time is 0.5-4h. Prepare ethanol solution of silane coupling agent with a concentration of 0.5%-5%, then fill the prepared ethanol solution of silane coupling agent into the ball mill, turn off the cooling circulating water and continue grinding for 0.5-2h, and then grind at no higher than 80 ℃ environment to obtain a graphene / carbon black / carbon fiber mixed po...

Embodiment 1

[0033] The anti-erosion fluororubber nanocomposite material containing graphene is composed of 100 parts by mass of fluororubber, 15 parts of graphene, 0.5 part of carbon black, 0.5 part of carbon fiber, 5 parts of magnesium oxide, vulcanizing agent Shuangfen 2 parts, 4 parts of TAIC, 1 part of silane coupling agent.

[0034] Put the graphene, carbon black and carbon fiber mixture into the ball mill, the revolution speed is 300r / min, the rotation speed is 500r / min, grind for 3h, prepare the silane coupling agent ethanol solution with a concentration of 1%, and then mix the prepared silane Add the ethanol solution of the coupling agent to the ball mill, turn off the cooling circulating water and continue grinding for 1 hour, and dry it for later use; then add the powder and fluororubber to the internal mixer within 10 minutes, and banbury at 60°C for 40 minutes.

[0035] Then the nanocomposite blend, vulcanizing agent and co-crosslinking agent were mixed evenly on a two-roller ...

Embodiment 2

[0037] The anti-erosion fluororubber nanocomposite material containing graphene is composed of 100 parts by mass of fluororubber, 0.5 parts of graphene, 20 parts of carbon black, 5 parts of carbon fiber, 3 parts of zinc oxide, vulcanizing agent Shuangfen 3.5 parts, 2 parts of TAIC, 0.5 parts of silane coupling agent.

[0038] Graphene, carbon black and carbon fiber mixture are put into ball mill, revolution speed is 800r / min, rotation speed is 250r / min, grind for 2.5h, the preparation concentration is the silane coupling agent ethanol solution of 0.5%, then the prepared Fill the ethanol solution of silane coupling agent into the ball mill, turn off the cooling circulating water and continue grinding for 2 hours, and dry it for later use; then add the powder and fluororubber into the internal mixer within 10 minutes, and banbury at 80°C for 30 minutes.

[0039] Then the nanocomposite blend, vulcanizing agent and co-crosslinking agent were mixed evenly on a two-roller rubber mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com