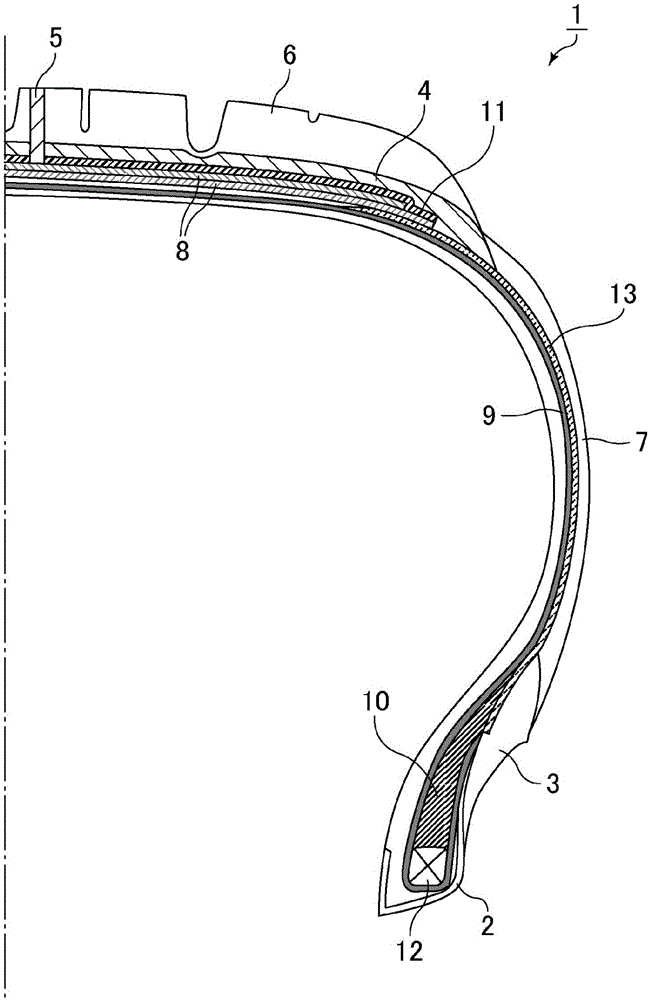

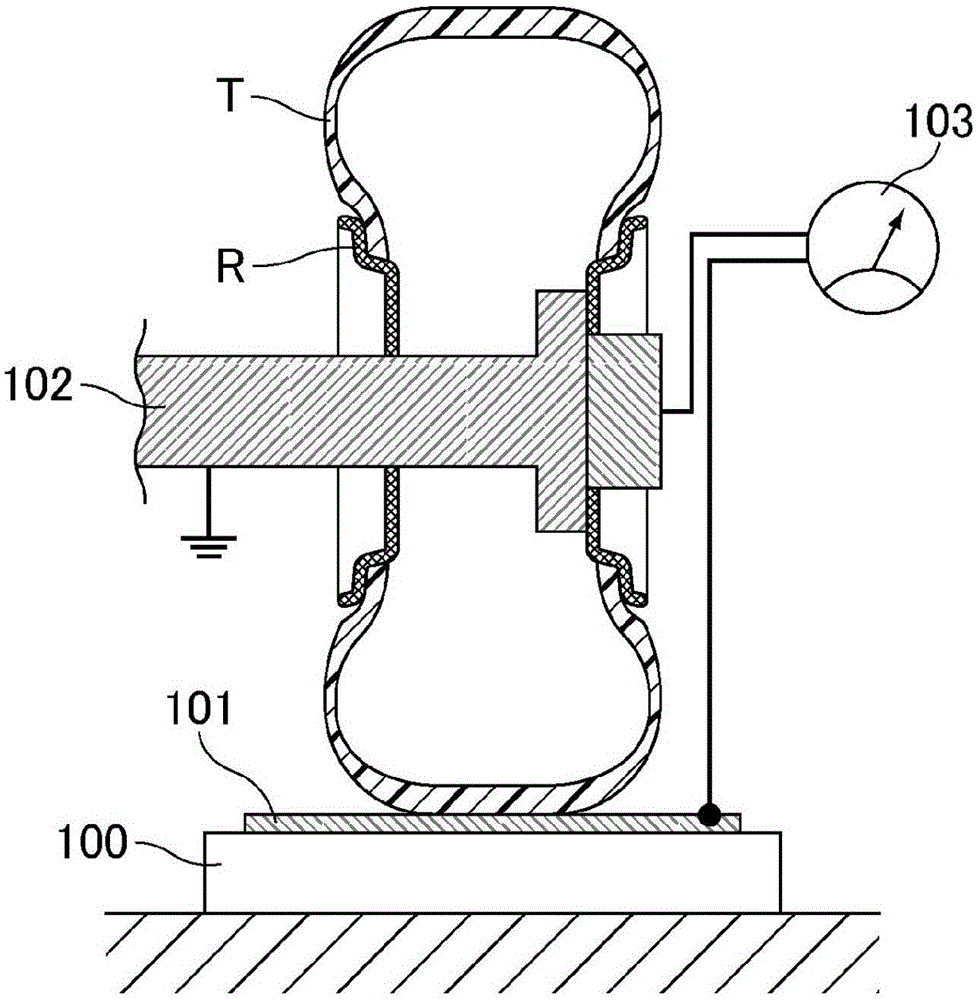

Pneumatic tire

A technology of pneumatic tires and carcass, which is applied to special tires, tire parts, tire edges, etc., to achieve the effect of excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

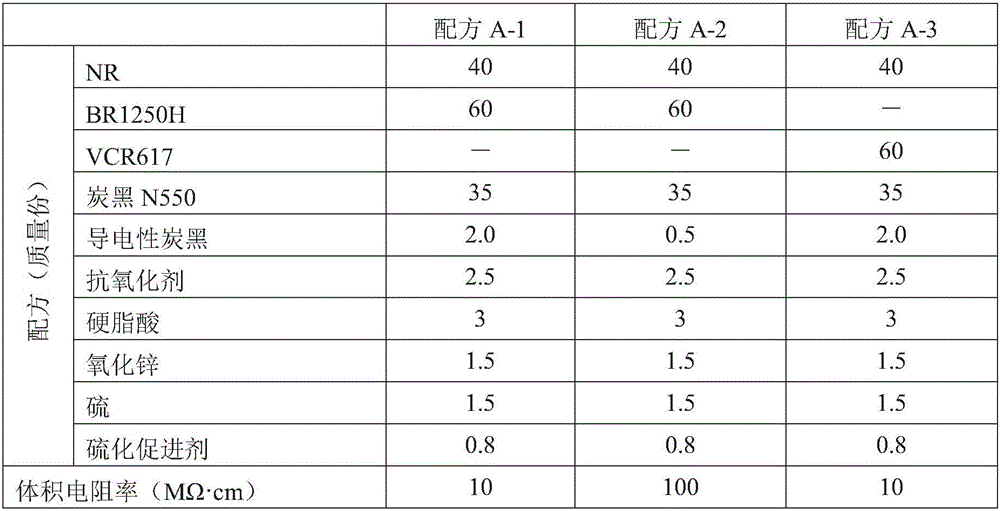

[0124] The present invention is specifically described with reference to examples, but the present invention is not limited to these examples.

[0125] The chemicals used in the examples are as follows.

[0126]

[0127] NR:TSR20

[0128] BR51: JSR BR51 manufactured by JSR Corporation (high cis BR, BR synthesized using Nd catalyst, cis content: 95% by mass)

[0129] BR1250H: BR1250H manufactured by Zeon Corp. (low cis BR, BR synthesized using Li catalyst)

[0130] VCR617: UBEPOL VCR617 (BR containing syndiotactic polybutadiene crystal) manufactured by Ube Industries, Ltd.

[0131] BR150B: UBEPOL BR150B manufactured by Ube Industries, Ltd. (high cis BR, BR synthesized using Ni catalyst, cis content: 95% by mass, Mooney viscosity (100°C): 40, Mw / Mn: 2.78, vinyl Content: 2.0% by mass)

[0132] SBR1502: SBR1502 manufactured by Sumitomo Chemical Co., Ltd. (styrene content: 23.5% by mass)

[0133] Carbon black N220: Shoblack N220 (N 2 SA: 114m 2 / g, DBP: 114ml / 100g)

[013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com