Laser melting deposition-based automobile clutch facing and preparation method thereof

A clutch face, laser melting technology, used in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of the degree of carburization is not easy to control, the face is prone to breakage, etc., to avoid carburization, good physical Mechanical properties, the effect of good friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

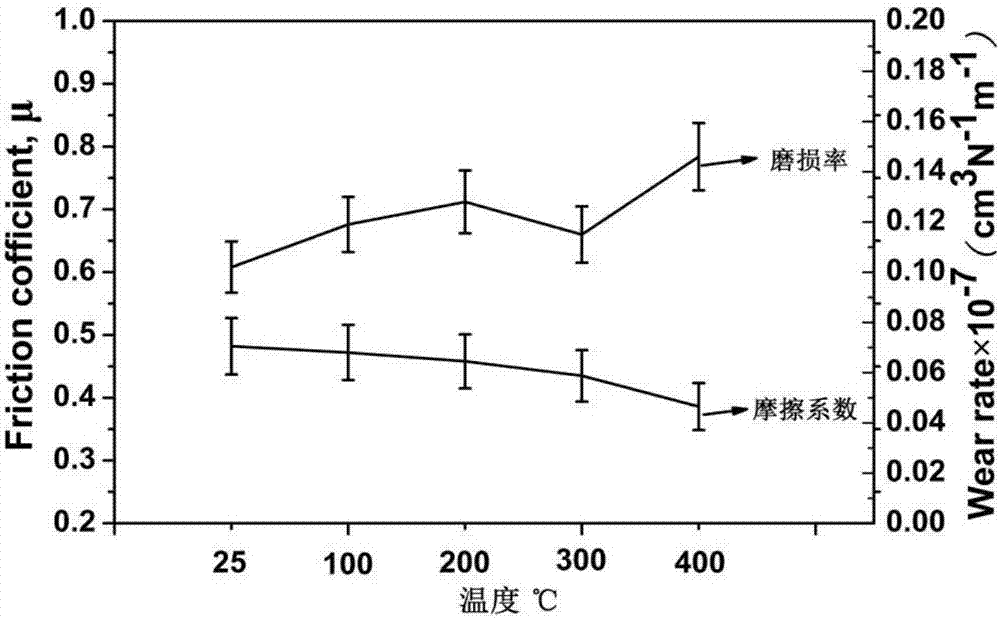

Embodiment 1

[0031] A kind of preparation based on the automobile clutch surface of laser fusion deposition, its preparation method comprises the steps:

[0032] 1) Take 10.88g of TiC powder, 5.44g of hBN powder, 0.816g of B powder, 118g of Ni powder and 18g of Al powder as raw materials, weigh each raw material according to the proportion, wherein the molar ratio of Ni powder to Al powder is 3:1, TiC The addition amount of powder is 8.0% of the total mass of Ni powder and hBN powder, the addition amount of hBN powder is 4.0% of the total mass of Ni powder and Al powder, and the addition amount of B powder is 0.6% of the total mass of Ni powder and Al powder;

[0033] 2) Place the weighed raw materials in a vibratory mixer for vibratory mixing. The vibration frequency used is 35 Hz, the vibration force is 9000 N, and the vibration time is 30 minutes, and the raw materials are fully mixed evenly;

[0034] 3) Evacuate the high-temperature melting furnace to a vacuum degree of <0.01MPa, and fil...

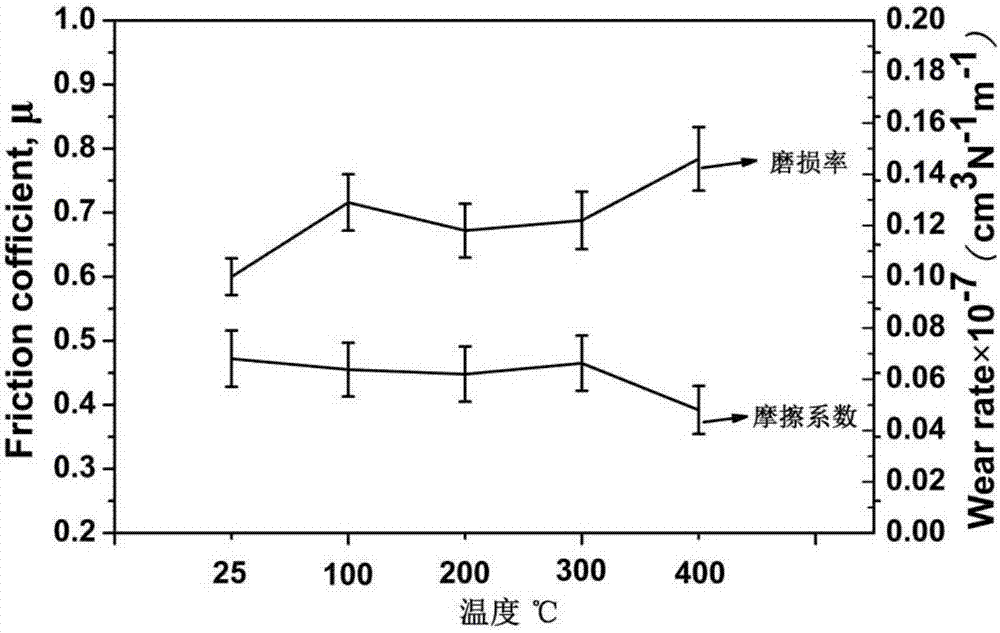

Embodiment 2

[0039] A kind of preparation based on the automobile clutch surface of laser fusion deposition, its preparation method comprises the steps:

[0040] 1) Take 14.96g of TiC powder, 6.80g of hBN powder, 0.952g of B powder, 118g of Ni powder and 18g of Al powder as raw materials, weigh each raw material according to the proportion, wherein the molar ratio of Ni powder to Al powder is 3:1, The addition amount of TiC powder is 11% of the total mass of Ni powder and Al powder, the addition amount of hBN powder is 5.0% of the total mass of Ni powder and Al powder, and the addition amount of B powder is 0.7% of the total mass of Ni powder and Al powder ;

[0041] 2) Place the weighed raw materials in a vibratory mixer for vibratory mixing. The vibration frequency used is 40 Hz, the vibration force is 10000 N, and the vibration time is 25 minutes, and the raw materials are fully mixed evenly;

[0042] 3) Evacuate the high-temperature melting furnace to a vacuum degree of <0.01MPa, fill...

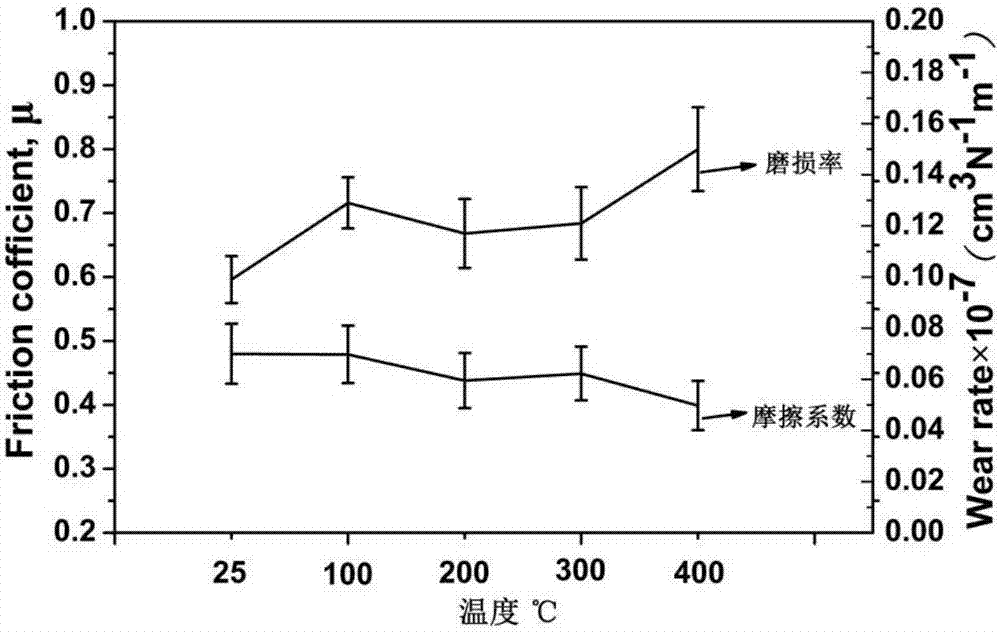

Embodiment 3

[0047] A kind of preparation based on the automobile clutch surface of laser fusion deposition, its preparation method comprises the steps:

[0048] 1) Take 16.32g of TiC powder, 8.16g of hBN powder, 1.088g of B powder, 118g of Ni powder and 18g of Al powder as raw materials, weigh each raw material according to the proportion, wherein the molar ratio of Ni powder to Al powder is 3:1, TiC The addition amount of powder is 12.0% of the total mass of Ni powder and Al powder, the addition amount of hBN powder is 6.0% of the total mass of Ni powder and Al powder, and the addition amount of B powder is 0.8% of the total mass of Ni powder and Al powder;

[0049] 2) Place the weighed raw materials in a vibratory mixer for vibratory mixing. The vibration frequency used is 45 Hz, the vibration force is 11000 N, and the vibration time is 20 minutes, and the raw materials are fully mixed evenly;

[0050] 3) Evacuate the high-temperature melting furnace to a vacuum degree of <0.01MPa, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com