Grade-E series ship plate steel and preparing method thereof

A ship plate steel, series technology, applied in the field of E-class ship plate steel and its preparation, can solve the problems of poor low temperature toughness and high non-plastic transition temperature of ship plate steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

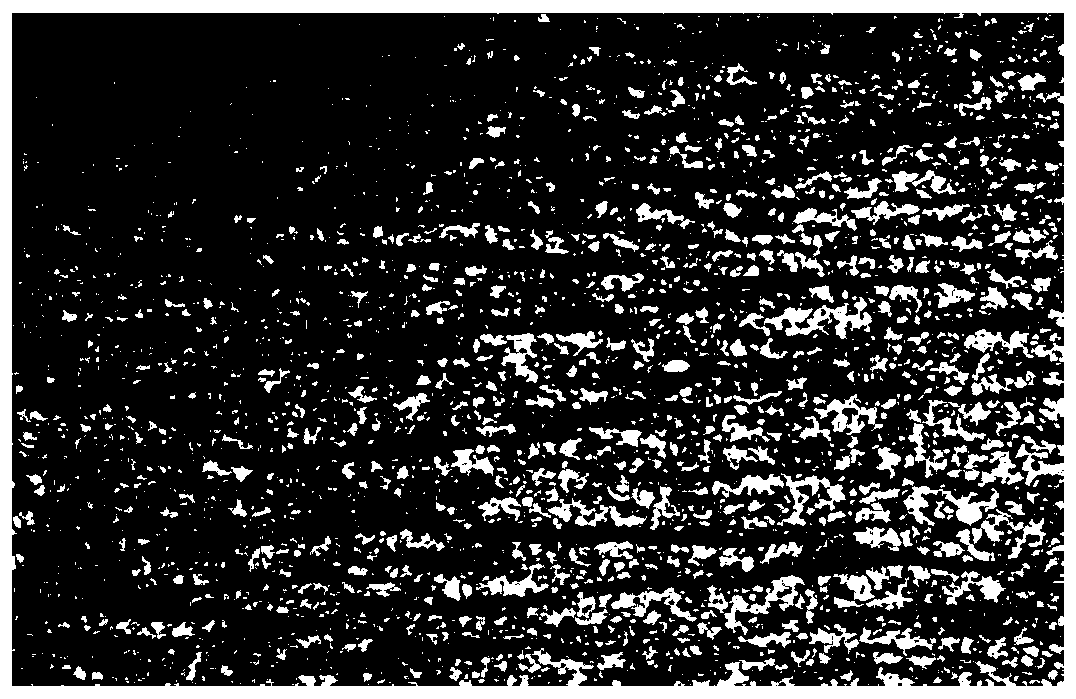

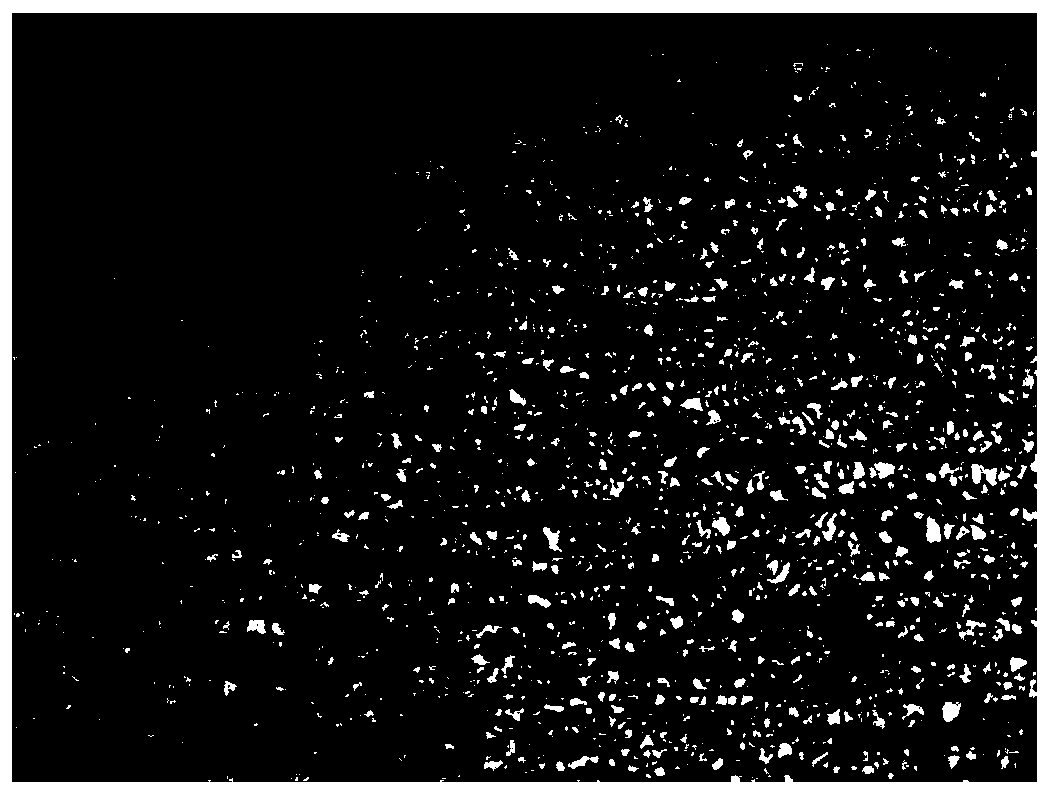

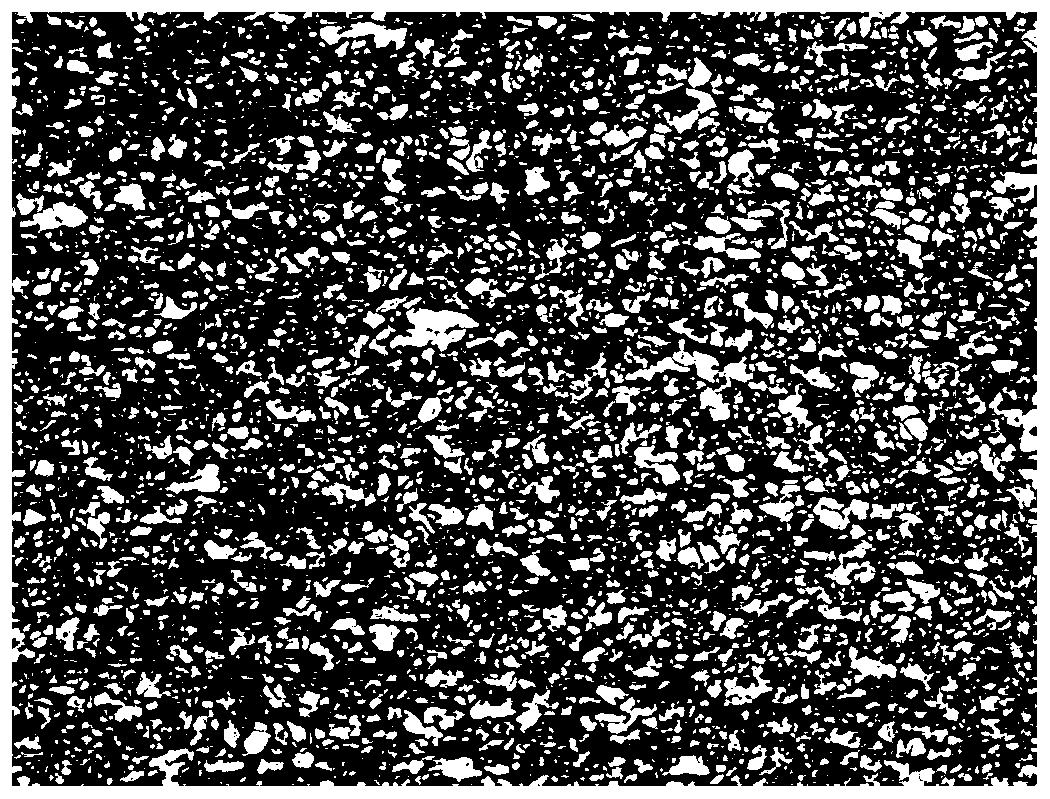

[0061] The preparation method of the E-class series ship plate steel includes: casting slab heating, controlled rolling and controlled cooling, and finishing finished products. The inventors of the present application found that during the implementation of the controlled cooling technology, due to the inappropriate regulation of the rolling temperature and the large difference in the cooling rate between the surface and the core of the steel plate during the rolling and laminar cooling process, the metallographic structure of the steel plate is uneven , affecting the mechanical properties of the steel plate. Through creative research and experiments, the inventors of the present application propose to limit the starting rolling temperature, finishing rolling temperature and finishing cooling temperature in the controlled rolling and controlled cooling step. It should be noted that the heating of the slab and the finishing of the finished product in the preparation method of t...

Embodiment 1

[0071] This embodiment provides a kind of E grade series ship plate steel, the specification is E36 ship plate steel with a thickness of 50mm, and its chemical composition (wt%) is as follows: C: 0.1079wt%, Si: 0.4205wt%, Mn: 1.544wt%, P: 0.0200wt%, S: 0.0038wt%, Cr: 0.013wt%, Ni: 0.044wt%, Mo: 0.116wt%, Cu: 0.015wt%, Als: 0.0228wt%, W: 0.001wt%, Ti: 0.0152wt%, V: 0.0299wt%, Nb: 0.0483wt%, and the balance is Fe. 0.5(V+Als)+Nb+Ti=0.090wt%.

[0072] The preparation method includes: pre-desulfurizing the molten iron after the blast furnace molten iron enters the mixing furnace, smelting the pre-desulfurized molten iron in a 120t converter, then performing LF furnace refining and RH refining, and passing the refined molten steel through a continuous casting machine for continuous casting of slabs. After the slab is heated, it is rolled, laminar flow cooled and finished, and the finished product is put into storage.

[0073] Wherein, rolling cooling comprises the following steps ...

Embodiment 2

[0078] This embodiment provides a kind of E grade series ship plate steel, the specification is the E ship plate steel with a thickness of 50mm, and its chemical composition (wt%) is as follows: C: 0.085wt%, Si: 0.416wt%, Mn: 1.5481wt%, P: 0.0042wt%, S: 0.011wt%, Cr: 0.014wt%, Ni: 0.001wt%, Mo: 0.112wt%, Cu: 0.014wt%, Als: 0.021wt%, W: 0.001wt%, Ti: 0.012wt%, V: 0.037wt%, Nb: 0.0483wt%, and the balance is Fe. 0.5(V+Als)+Nb+Ti=0.089wt%.

[0079] The preparation method includes: pre-desulfurizing the molten iron after the blast furnace molten iron enters the mixing furnace, smelting the pre-desulfurized molten iron in a 120t converter, then performing LF furnace refining and RH refining, and passing the refined molten steel through a continuous casting machine for continuous casting of slabs. After the slab is heated, it is rolled, laminar flow cooled and finished, and the finished product is put into storage.

[0080] Wherein, rolling cooling comprises the following steps car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com