Glass ceramic for making dental prosthesis and preparation method thereof

A technology for glass ceramics and restorations, which is applied in the field of glass ceramics for making dental restorations and its preparation, can solve the problem that the balance and unity of mechanical properties and optical properties of dental aesthetics cannot be satisfied, the aesthetics and simulation properties of restorations are poor, and they are not suitable for prefabrication. Tooth aesthetic restoration and other issues, to improve the anti-crack growth ability, reduce the scattering effect, and achieve the effect of good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh according to mass ratio: 58% SiO 2 , 29% Li 2 CO 3 , 3.7% of K 2 CO 3 , 2.8% Al 2 o 3 , 2.4% ZrO 2 , 1.5% CeO 2 and 2.6% P 2 o 5 A total of 500g of ingredients are set aside.

[0027] The above ingredients were mixed and ball milled for 8 hours, mixed evenly, put into an oven, and dried at 80°C for 24 hours to obtain a mixed powder.

[0028] Preheat the quartz crucible in a resistance furnace, pour the mixed powder into the preheated quartz crucible, raise the temperature to 1480°C at a rate of 10°C / min, melt at 1480°C in a program-controlled resistance furnace for 2 hours, and then melt the obtained The slurry was quickly poured into deionized water and quenched to obtain glass particles.

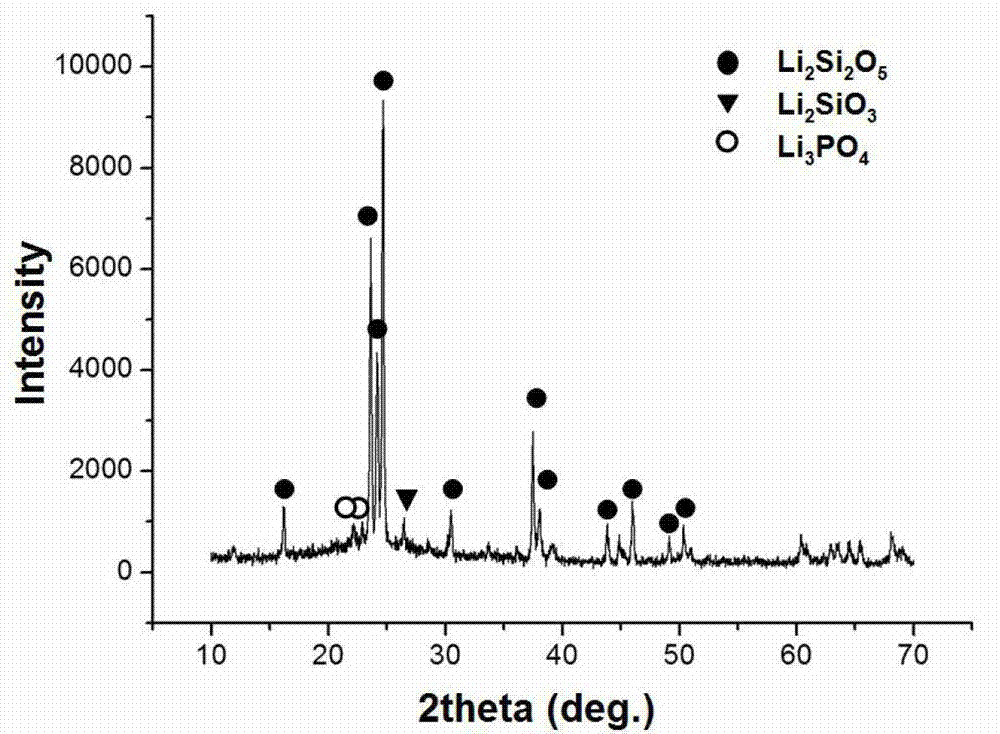

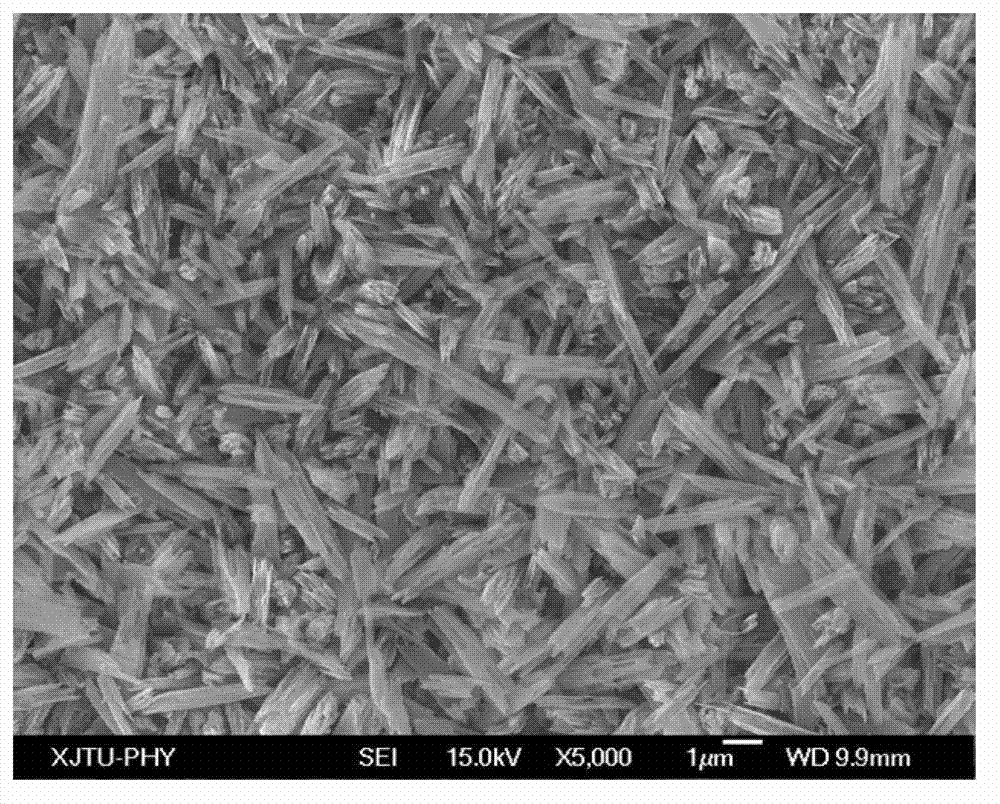

[0029] The obtained glass particles were milled in an agate ball mill jar for 12 hours, and dried to obtain glass powder; the glass powder was put into a prefabricated box, and subjected to cold isostatic pressing at a pressure of 250 MPa to form a green body. Carr...

Embodiment 2

[0033] Weigh according to mass ratio: 59% SiO 2 , 28.2% Li 2 CO 3 , 3.7% of K 2 CO 3 , 2.7% Al 2 o 3 , 2.3% ZrO 2 , 1.6% CeO 2 , 2.5% P 2 o 5 A total of 500g of ingredients are set aside.

[0034] The above ingredients were mixed and ball milled for 8 hours, mixed evenly, put into an oven, and dried at 80°C for 24 hours to obtain a mixed powder.

[0035] The quartz crucible is preheated in a resistance furnace, the mixed powder is poured into the preheated quartz crucible, the temperature is raised to 1500 °C at a rate of 10 °C / min, and 1500 °C is melted in a program-controlled resistance furnace for 1.5 hours, and then the obtained The molten slurry is quickly poured into deionized water and quenched to obtain glass particles.

[0036]The obtained glass particles were milled in an agate ball mill jar for 12 hours, and dried to obtain glass powder; the glass powder was put into a prefabricated box, and subjected to cold isostatic pressing at a pressure of 250 MPa to...

Embodiment 3

[0040] Weigh according to mass ratio: 58% SiO 2 , 29% Li 2 CO 3 , 3.8% of K 2 CO 3 , 2.7% AL 2 o 3 , 2.4% ZrO 2 , 1.5% CeO 2 , 2.6% P 2 o 5 A total of 500g of ingredients are set aside.

[0041] The above ingredients were mixed and ball milled for 8 hours, mixed evenly, put into an oven, and dried at 80°C for 24 hours to obtain a mixed powder.

[0042] Preheat the quartz crucible in a resistance furnace, pour the mixed powder into the preheated quartz crucible, raise the temperature to 1450°C at a rate of 10°C / min, melt at 1450°C in a program-controlled resistance furnace for 2 hours, and then melt the obtained The slurry was quickly poured into deionized water and quenched to obtain glass particles.

[0043] The obtained glass particles were milled in an agate ball mill jar for 12 hours, and dried to obtain glass powder; the glass powder was put into a prefabricated box, and subjected to cold isostatic pressing at a pressure of 250 MPa to form a green body. Carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com