Rapid coloring process of lithium disilicate microcrystalline glass

A technology of glass-ceramics and lithium disilicate, which is applied in the field of dental materials, can solve the problems of affecting the color matching effect and easy wear of the dyed layer, and achieves the effects of wide application range, low production cost and good semi-permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

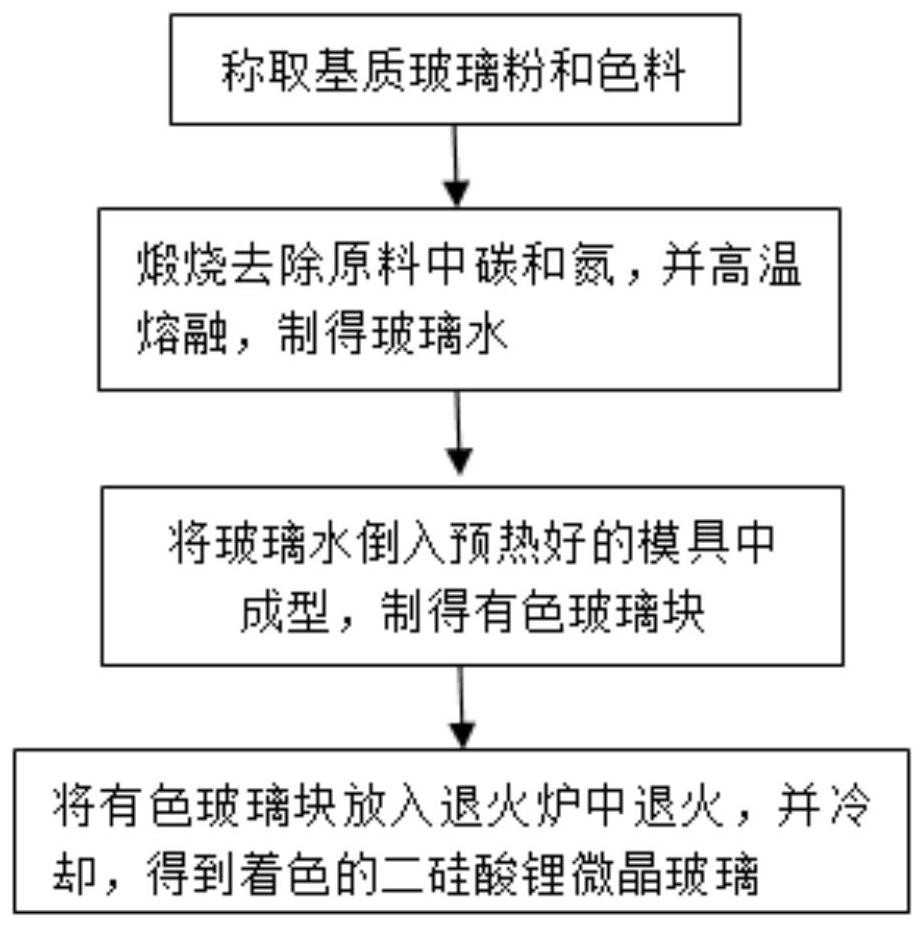

Method used

Image

Examples

Embodiment 1

[0026] a Weighing: Weigh the matrix glass powder and colorant, then put them into a ball mill jar for ball milling, mix well to obtain the matrix glass powder and colorant mixture; wherein, the molar percentage of matrix glass powder and colorant is 99:1, The molar percentages of each component in the matrix glass powder are potassium oxide 34%, silicon dioxide 41%, lithium oxide 1%, aluminum oxide 5%, phosphorus oxide 5%, zirconium oxide 11%, and sodium oxide 2%;

[0027] b Melting: put the matrix glass powder and colorant mixture obtained in step a into a muffle furnace for calcination, the calcination temperature is 800°C, and the calcination time is 30min, remove the carbon and nitrogen in the matrix glass powder and colorant mixture, and The calcined matrix glass powder and colorant mixture are melted in a high-temperature program-controlled furnace at a melting temperature of 1600°C and a melting time of 30 minutes to obtain a fully melted glass liquid for later use;

[...

Embodiment 2

[0031] a Weighing: Weigh the matrix glass powder and colorant, then put them into a ball mill jar for ball milling, mix well to obtain the matrix glass powder and colorant mixture; wherein, the molar percentage of matrix glass powder and colorant is 99:1, The molar percentages of each component in the matrix glass powder are potassium oxide 34%, silicon dioxide 41%, lithium oxide 1%, aluminum oxide 5%, phosphorus oxide 5%, zirconium oxide 11%, and sodium oxide 2%;

[0032] b Melting: put the matrix glass powder and colorant mixture obtained in step a into a muffle furnace for calcination, the calcination temperature is 800°C, and the calcination time is 30min, remove the carbon and nitrogen in the matrix glass powder and colorant mixture, and The calcined matrix glass powder and colorant mixture are melted in a high-temperature program-controlled furnace at a melting temperature of 1600°C and a melting time of 120 minutes to obtain a fully melted glass liquid for later use;

...

Embodiment 3

[0036] a Weighing: Weigh the matrix glass powder and colorant, then put them into a ball mill jar for ball milling, mix well to obtain the matrix glass powder and colorant mixture; wherein, the molar percentage of matrix glass powder and colorant is 99:1, The molar percentages of each component in the matrix glass powder are potassium oxide 34%, silicon dioxide 41%, lithium oxide 1%, aluminum oxide 5%, phosphorus oxide 5%, zirconium oxide 11%, and sodium oxide 2%;

[0037] b Melting: put the matrix glass powder and colorant mixture obtained in step a into a muffle furnace for calcination, the calcination temperature is 800°C, and the calcination time is 30min, remove the carbon and nitrogen in the matrix glass powder and colorant mixture, and The calcined matrix glass powder and colorant mixture are melted in a high-temperature program-controlled furnace at a melting temperature of 1600°C and a melting time of 30 minutes to obtain a fully melted glass liquid for later use;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com