A high toughness zirconia ceramic block

A technology of zirconia and porcelain blocks, which is applied in the field of high-toughness zirconia porcelain blocks, which can solve problems such as unsatisfactory lifting effect, inability to meet consumers' aesthetic needs for dentures, thin teeth and edge collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Two, the preparation method of the zirconia porcelain block that the present invention relates to

[0028] In the case of not adding a titanium nitride protective film, the preparation method of the zirconia ceramic block is: weighing each component except titanium nitride, mixing, pre-pressing and forming, and then isostatic pressing, Then pre-sintering and high-temperature sintering are carried out to complete the preparation.

[0029] If it is necessary to add a titanium nitride protective film, the specific preparation method is as follows:

[0030] (1) After the pre-sintering is completed, the zirconia ceramic block is taken out, machined to the desired shape and size, and then the zirconia ceramic block is ultrasonically cleaned and dried with acetone and alcohol in sequence.

[0031] (2) Sputtering the cleaned zirconia ceramic block with a low-energy ion beam.

[0032] (3) In a vacuum environment and an Ar atmosphere, Ti particles with a purity of 99.99% are us...

Embodiment 1

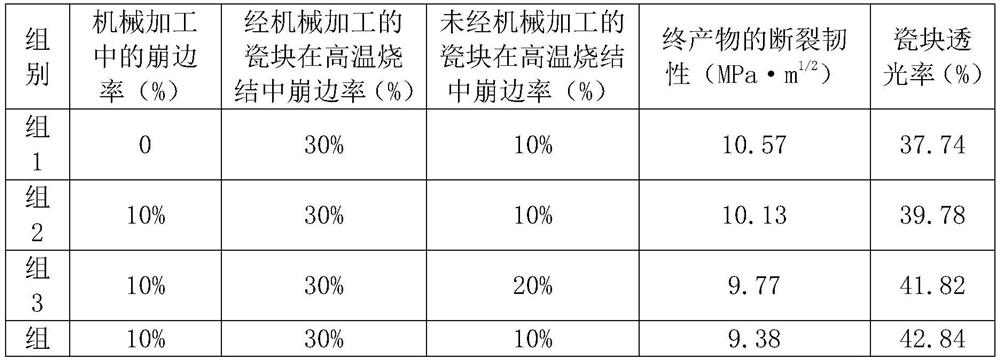

[0035] Example 1: Performance demonstration of zirconia ceramic block without titanium nitride coating

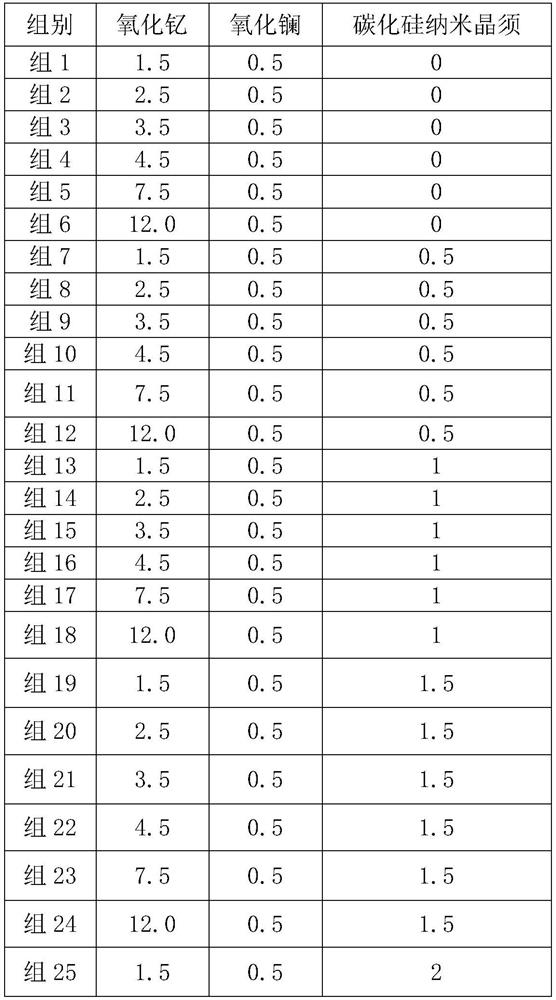

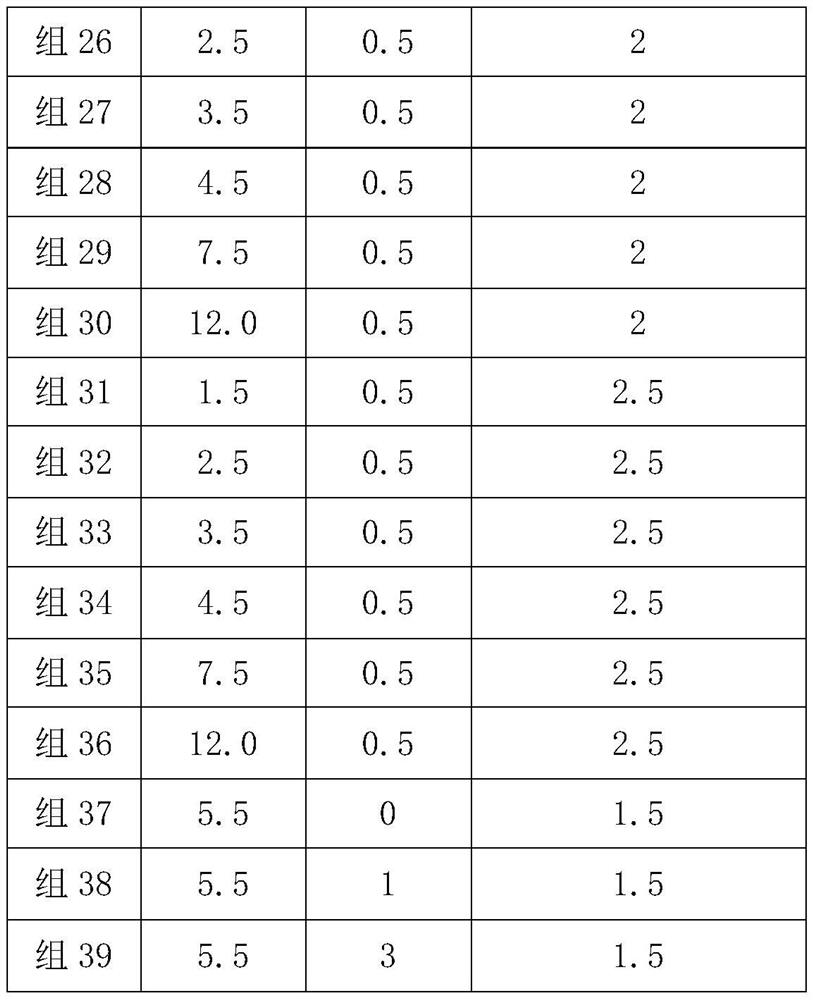

[0036] 1. Prepare 39 groups of zirconia ceramic blocks according to the above formula and method, with 20 repetitions for each group. The specific formulations of each group of zirconia ceramic blocks are shown in Table 1. The values in the table are all mass fractions, and the balance is all zirconia powder. The ST zirconia block purchased from Changsha Pengdeng Bio-porcelain Block Co., Ltd. was used as the control group. It should be noted that the applicant did not only conduct the experiments in Table 1, but because of space limitations, only selected the most representative sets of data for display.

[0037] The specific preparation method of each group of zirconia ceramic blocks is as follows: weigh each component, mix well, hold the pressure at 150MPa for 10 minutes, and carry out isostatic pressing; then hold the temperature at 1050°C for 2 hours, and carry out p...

Embodiment 2

[0046] Example 2: Performance demonstration of zirconia ceramic block with titanium nitride added

[0047] 1. Select the formula of Group 19 in Example 1 to prepare 20 groups of zirconia ceramic blocks: after pre-sintering according to the method of Example 1, take out 10 groups of zirconia ceramic blocks, machine them to the desired shape and size of the denture, and another 10 groups Group is not machined. Subsequently, each group of zirconia ceramic blocks was sequentially immersed in acetone and absolute alcohol, ultrasonically cleaned and dried.

[0048] 2. Use a low-energy ion beam to perform sputter cleaning on each group of zirconia ceramic blocks after cleaning. The specific sputtering cleaning conditions are as follows: the zirconia ceramic block is sputtered for 5 minutes with a low-energy ion beam of 300eV and 50mA.

[0049] 3. Use an electron beam evaporation coating machine to perform Ti coating on the sputtered zirconia ceramic block. Control the vacuum degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com