Nanocrystalline composite material for 3C product and preparation method

A composite material and nanocrystalline technology, which is applied in the field of nanocrystalline composite materials and preparations for 3C products, can solve the problem that processed materials cannot meet high strength and high hardness, and achieve enhanced crack resistance and transverse fracture The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

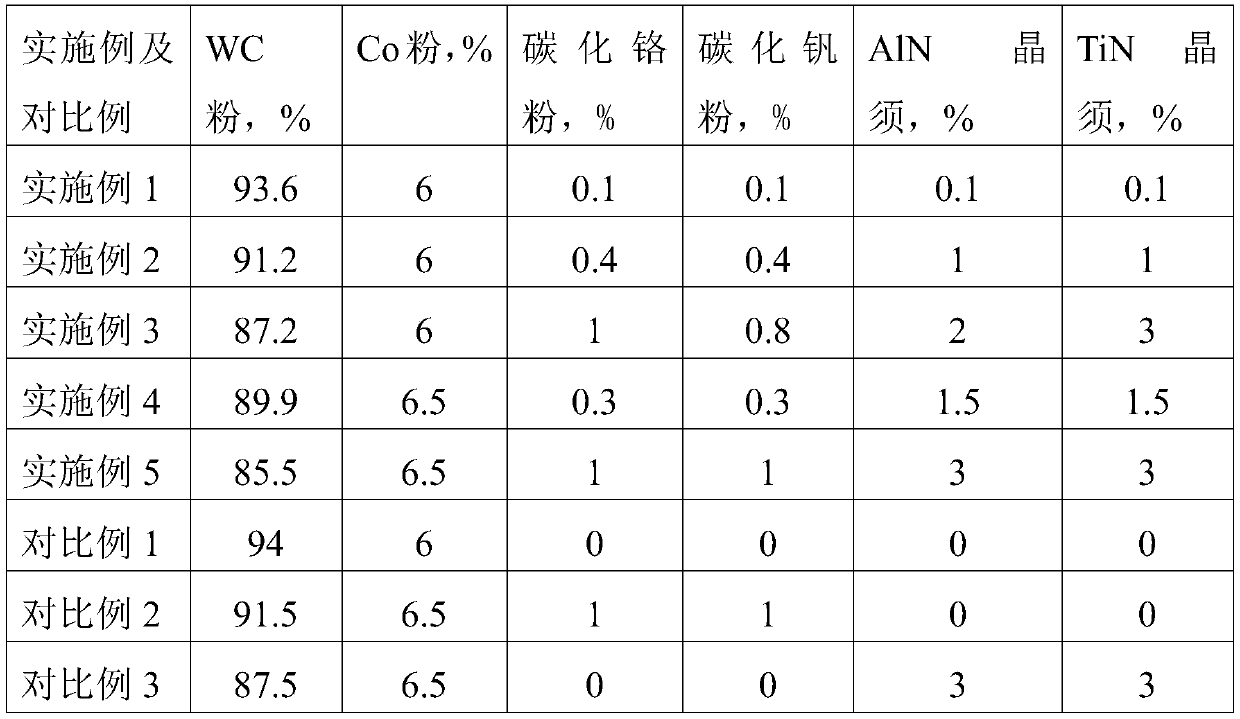

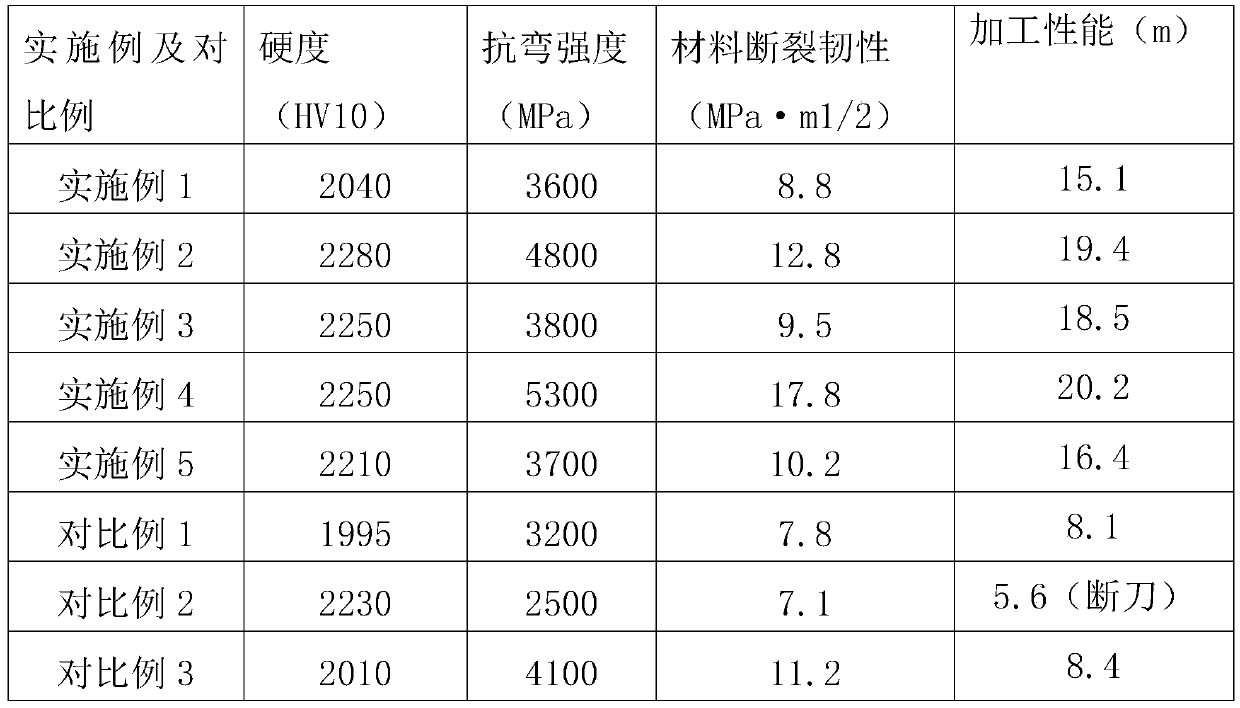

Embodiment 1

[0034] 1. Accessories:

[0035] The forming agent adopts powdered paraffin wax, and the amount of paraffin wax added is 2.5% of the total weight of the main ingredients (Co powder, AlN whisker, TiN whisker, chromium carbide powder, vanadium carbide powder and WC powder);

[0036] The dispersant adopts ethanol, and the addition of ethanol is 35% of the total weight of the main ingredients (Co powder, AlN whisker, TiN whisker, chromium carbide powder, vanadium carbide powder and WC powder);

[0037] 2. The preparation method comprises the following steps:

[0038] (1) Wet grinding (the ratio of ball to material is 5:1):

[0039] ① Add paraffin and ethanol to the ball mill, and pre-grind the paraffin in ethanol for 2 hours;

[0040] ②Put vanadium carbide powder and chromium carbide powder into the ball mill, and continue ball milling for 2 hours;

[0041] ③Put WC powder and Co powder into the ball mill and continue ball milling for 74 hours;

[0042] ④ Add AlN whiskers and Ti...

Embodiment 2

[0047] 1. Accessories:

[0048] The molding agent adopts PEG, and the addition amount of PEG is 2.2% of the total weight of the main ingredients (Co powder, AlN whisker, TiN whisker, chromium carbide powder, vanadium carbide powder and WC powder);

[0049] The dispersant is ethanol, and the amount of ethanol added is 30% of the total weight of the main ingredients (Co powder, AlN whisker, TiN whisker, chromium carbide powder, vanadium carbide powder and WC powder);

[0050] 2. The preparation method comprises the following steps:

[0051] (1) Wet grinding (the ratio of ball to material is 5:1):

[0052] ① Add PEG and ethanol to the ball mill, and pre-grind PEG in ethanol for 2 hours;

[0053] ②Put vanadium carbide powder and chromium carbide powder into the ball mill, and continue ball milling for 3 hours;

[0054] ③Put WC powder and Co powder into the ball mill and continue ball milling for 49 hours;

[0055] ④ Add AlN whiskers and TiN whiskers into the ball mill, and con...

Embodiment 3

[0060] 1. Accessories:

[0061] The molding agent adopts stearic acid, and the addition of stearic acid is 2.0% of the total weight of the main ingredients (Co powder, AlN whisker, TiN whisker, chromium carbide powder, vanadium carbide powder and WC powder);

[0062] The dispersant adopts hexane, and the addition of hexane is 25% of the total weight of the main ingredients (Co powder, AlN whisker, TiN whisker, chromium carbide powder, vanadium carbide powder and WC powder);

[0063] 2. The preparation method comprises the following steps:

[0064] (1) Wet grinding (the ratio of ball to material is 5:1):

[0065] ① Add stearic acid and hexane into the ball mill, pre-grind stearic acid in hexane for 2 hours;

[0066] ②Put vanadium carbide powder and chromium carbide powder into the ball mill, and continue ball milling for 4 hours;

[0067] ③Put WC powder and Co powder into the ball mill and continue ball milling for 88 hours;

[0068] ④ Add AlN whiskers and TiN whiskers into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com