Manufacture of fine-type stainless steel plate heat exchanger

A technology of plate-fin heat exchanger and fin heat exchanger, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of high pressure resistance, high temperature resistance and corrosion resistance of the heat exchanger, etc. Achieve the effects of good air tightness, less impurity content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

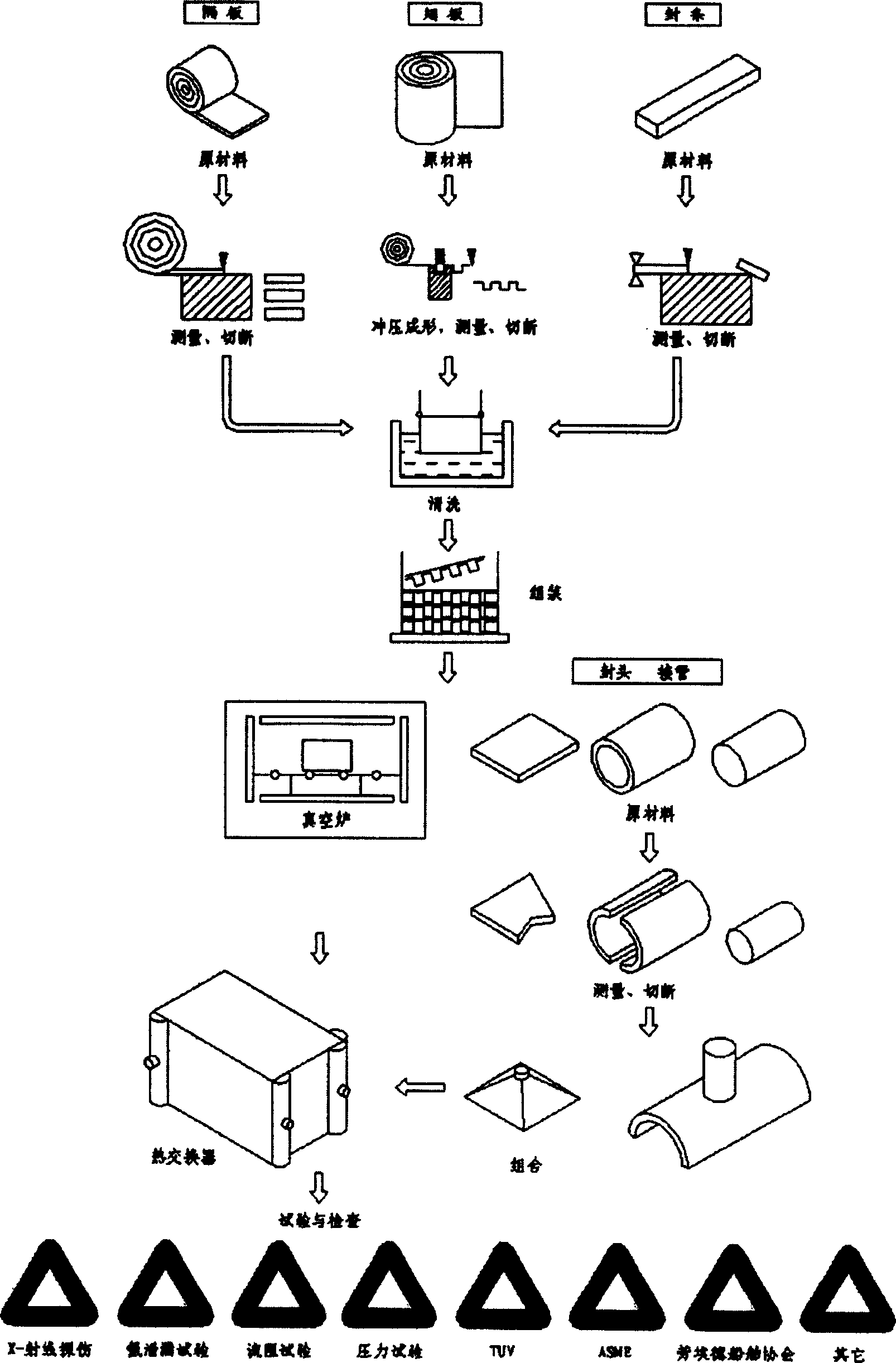

[0014] Refer to attached figure 1 , the manufacturing process of stainless steel plate-fin heat exchanger is:

[0015] 1. Parts preparation

[0016] (1) Partition. It is produced by a special manufacturer, and the material is cut according to the required length when manufacturing the plate-fin heat exchanger. The separator is generally a thin plate of 0.2 mm.

[0017] (2) Seals. It is a special profile, which can be obtained by cold drawing or hot extrusion. It is produced by a special manufacturer, and it is cut according to the required length when manufacturing the plate-fin heat exchanger.

[0018] (3) Fins. Its main forming methods are stamping and rolling, each with its own characteristics, and automatic forming machine tools are used in mass production. The fins are made of stainless steel sheets with a thickness of 0.1-0.4 mm, stamped into a blank shape with a forming die on an automatic forming machine, and then shaped with a concave and convex die. Feeding, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com