A grain refinement method for mg or mg alloy

A technology of grain refinement and alloying, which is applied in the field of grain refinement of Mg or Mg alloys, can solve the problems of many by-products and complicated preparation process, and achieve the effect of excellent effect, wide sources and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Grain refinement treatment of pure Mg

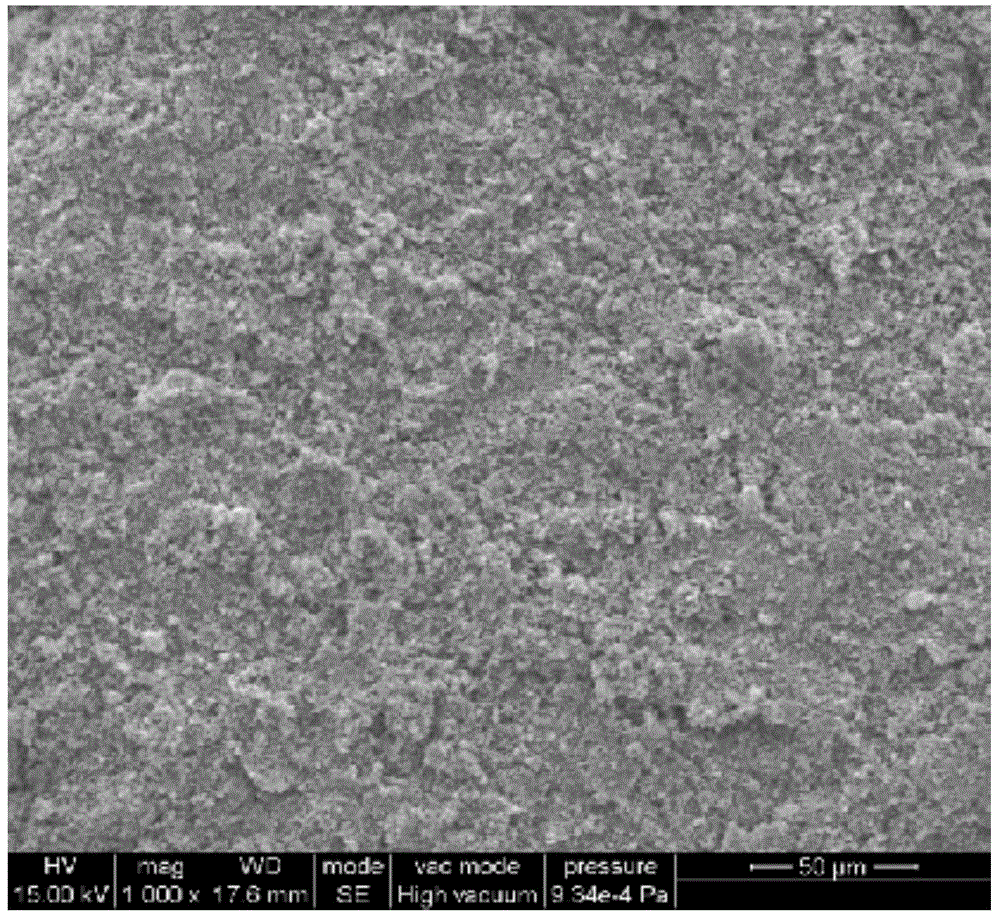

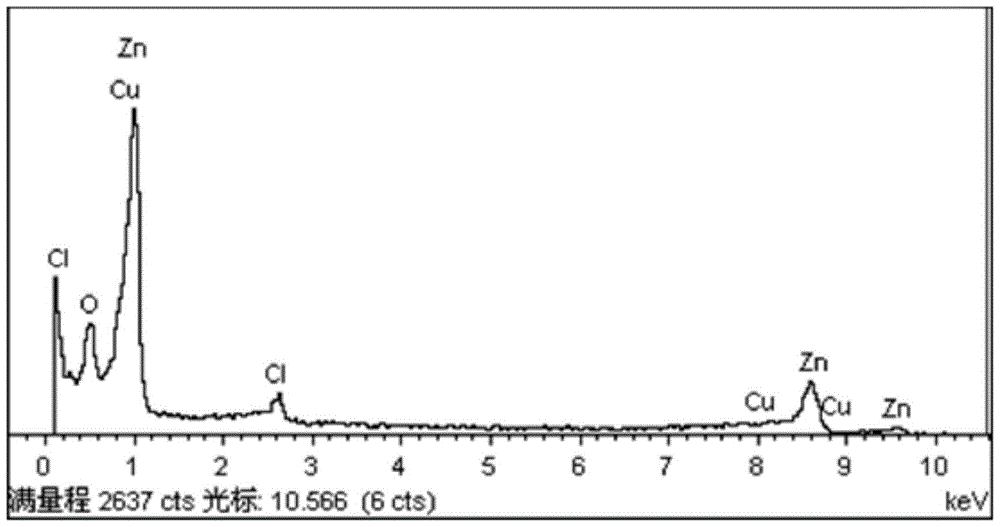

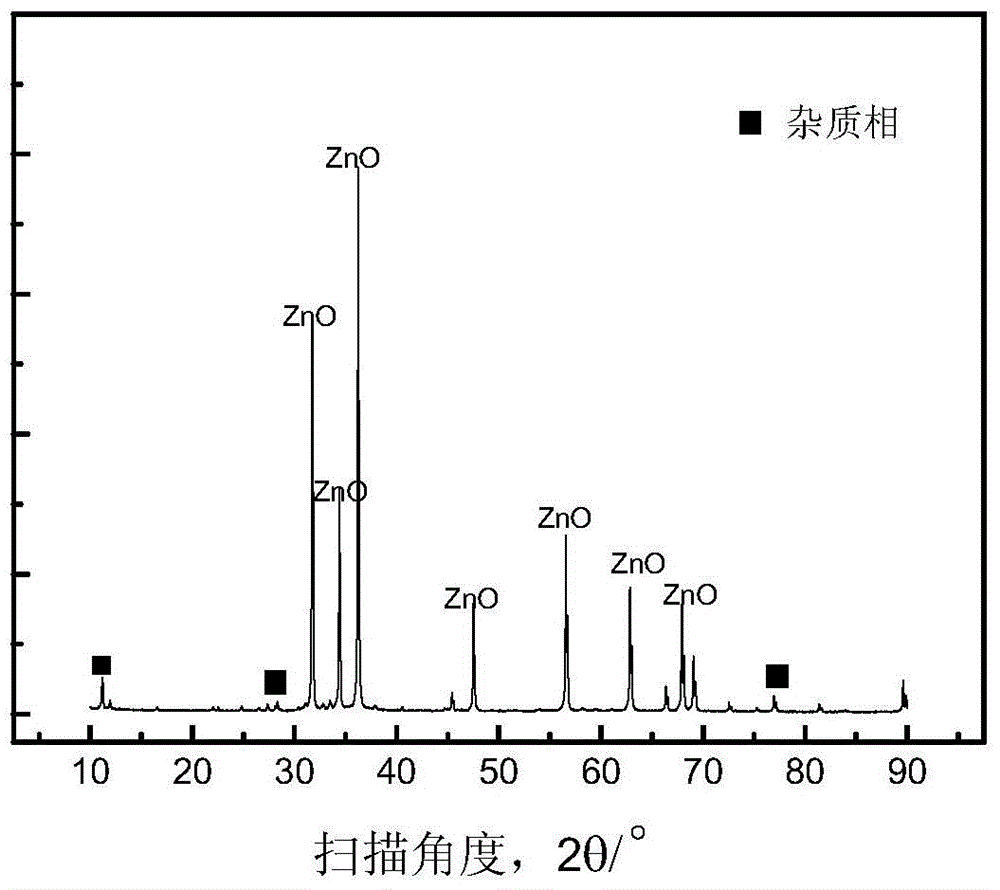

[0036] The powder of industrial zinc ash is observed by scanning electron microscope and its shape is like figure 1 As shown, the energy spectrum analysis chart is as figure 2 As shown, the main composition is Zn and O, in addition to a small amount of Cu and Cl, the specific composition is shown in Table 1. Among them, Cu should be caused by the sublimation of Cu in Zn alloy smelting, and Cl should be caused by the volatilization and deposition of the melt refining agent at high temperature in zinc alloy smelting. The XRD phase analysis results are as image 3 As shown, the phase composition is mainly ZnO with a small amount of impurity phase.

[0037] Table 1 Composition of industrial zinc ash

[0038]

[0039] In order to facilitate the addition of industrial zinc ash to the Mg melt, the industrial zinc ash is mixed with Mg powder and then pressed into an intermediate carrier containing industrial zinc ash. The preparatio...

Embodiment 2

[0051] Example 2 Grain refining treatment of Mg-3Al alloy

[0052] This embodiment is used to illustrate the refining effect of industrial zinc ash on the Mg-3Al alloy. The Mg-3Al alloy is prepared by using metallic aluminum (purity ≥99.0%) and metallic magnesium (purity ≥99.0%) as raw materials.

[0053] The metal aluminum and metal magnesium are prepared according to the required ratio, and the surface oxide scale, water stains and oil stains are removed, and the Mg-3Al alloy is obtained by smelting.

[0054] The industrial zinc ash and Mg powder are mixed and pressed into an intermediate carrier containing industrial zinc ash. The preparation method is as follows: mix 24g magnesium powder and 6g industrial zinc ash uniformly, press it into a Φ30mm round cake under a pressure of 100MPa, and then heat the intermediate carrier of industrial zinc ash to 150°C and press it under a pressure of 60MPa. Its densification is an intermediate carrier for industrial zinc ash.

[0055] Melting ...

Embodiment 3

[0056] Example 3 Grain refining treatment of Mg-3Al alloy

[0057] The alloy material used in this embodiment is the same as that in the second embodiment.

[0058] The molding process of the master alloy carrier containing industrial zinc ash is the same as that of Example 2.

[0059] Melting Mg-3Al alloy, melting temperature is 730℃. After melting, add an intermediate carrier containing industrial zinc ash. The added amount of industrial zinc ash is 2.0%, which corresponds to 2#Mg-3Al alloy. Use RJ-2 flux to protect the melt, manually stir the melt for about 1 min, and then let it stand for 2 min after stirring, then pull the slag out of the furnace for casting. The casting mold is made of carbon steel, and the mold preheating temperature is 250°C.

[0060] Figure 8 Shown is the microstructure photo of 2#Mg-3Al alloy, and its grain size is 86μm after analysis. Compared Figure 7 It can be seen that industrial zinc ash can significantly refine the grains of Mg-3Al alloy, with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com