A kind of white water treatment flocculant and using method thereof

A technology of flocculant and white water, which is applied in processing process wastewater treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the complicated process of chemical flocculant treatment, obstacles in papermaking system, and dehydration of wire part Load increase and other problems, to achieve the effect of easy control of the amount added, uniform flocculant composition, and reduced content of particulate impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

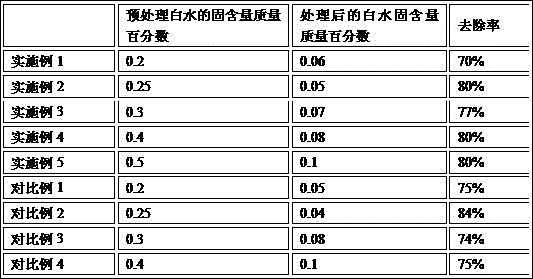

Examples

Embodiment 1

[0028] A flocculant for white water treatment, the flocculant includes raw soybean milk. The solid content of soybean active ingredients in raw soybean milk per liter of the flocculant is 0.5 g, and the balance is water.

[0029] A method for using a flocculant for white water treatment, comprising the following steps: step A, tailings white water purification and recovery pretreatment, to obtain pretreated white water for use as a standby; step B, performing dissolved air treatment on clarified white water, and completely clarifying by dissolved air treatment The white water is placed in the air-dissolving tank for standby; Step C, the pretreated white water obtained in step A and the clarified white water in the dissolving tank are added to the air flotation tank, and flocculant is added to the white water inlet of the air flotation tank at the same time; Step D, Scrape off the floating pollutants that float up to the water surface of the air flotation tank, and the qualifie...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is:

[0041] A flocculant for white water treatment, the flocculant includes raw soybean milk. Each liter of the flocculant also includes 0.1 g of calcium chloride, 0.05 g of polyaluminum chloride, and 1 mg of polyacrylamide. The solid content of soybean active ingredients in soybean milk per liter of the flocculant is 2 g, and the balance is water.

[0042] The mass percentage of the solid content of the pretreated white water measured in this embodiment is 0.25%.

[0043] The equipment for the dissolved air treatment in the step B is a dissolved air pump, and the dissolved air pressure of the dissolved air pump is 55 psi.

[0044] The volume ratio of the clarified white water added to the air flotation tank in the step C to the pretreated white water is 12:100.

[0045] The control standard of the amount of flocculant added in the step C is the weight of soybean active ingredients added per liter of pretreated ...

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is:

[0050] A flocculant for white water treatment, the flocculant includes raw soybean milk. Each liter of the flocculant also includes 0.3g of calcium chloride, 0.1g of polyaluminum chloride, and 2mg of polyacrylamide. The solid content of soybean active ingredients in soybean milk per liter of the flocculant is 3g, and the balance is water.

[0051] The mass percentage of the solid content of the pretreated white water measured in this embodiment is 0.3%.

[0052] The equipment for the dissolved air treatment in the step B is a dissolved air pump, and the dissolved air pressure of the dissolved air pump is 60 psi.

[0053] The volume ratio of the clarified white water added to the air flotation tank in the step C to the pretreated white water is 15:100.

[0054] The control standard of the amount of flocculant added in the step C is the weight of soybean active ingredients added per liter of pretreated white ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com