A catalytic titanium dioxide treatment system and method thereof

A technology of salt treatment and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of low catalytic efficiency, weak catalytic force, and rapid failure, and achieve high catalytic efficiency, controlled addition, and slow failure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

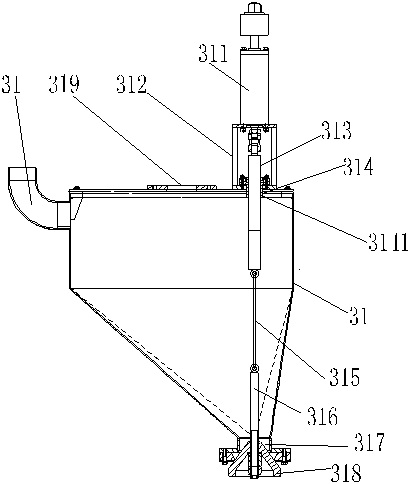

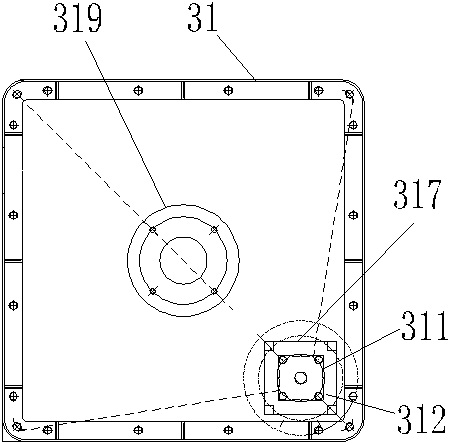

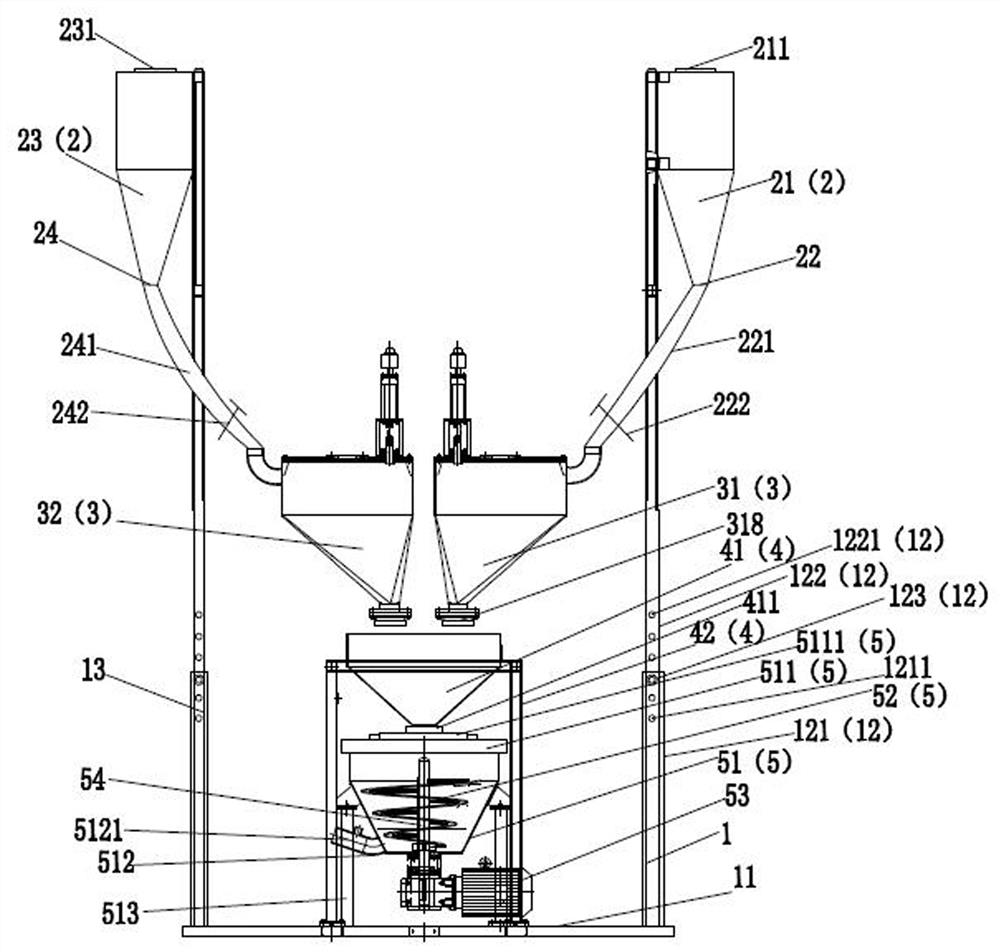

[0025] Such as Figure 1-3 The catalytic titanium white salt processing system shown includes a support 1, a storage mechanism 2, a first discharge mechanism 3, a second discharge mechanism 4 and a stirring mechanism 5, and the storage mechanism 2 is symmetrically arranged on both sides of the support 1 , the lower part of the first discharge mechanism 3 is correspondingly provided with a second discharge mechanism 4, the second discharge mechanism 4 is correspondingly arranged with the stirring mechanism 5, the stirring mechanism 5 coincides with the central axis of the second discharge mechanism 4, and the stirring mechanism 5

[0026] The support 1 comprises a base support 11, a first vertical support 12 and a second vertical support 13, the base support 11 is a rectangular m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com