Light ceramsite co-sintered on surface by virtue of magnesium chloride and preparation method of light ceramsite

A surface-assisted sintering and lightweight ceramsite technology, which is applied in the field of new building materials, can solve the problems of reducing ceramsite sintering temperature, high energy consumption, and increasing the specific gravity of ceramsite. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

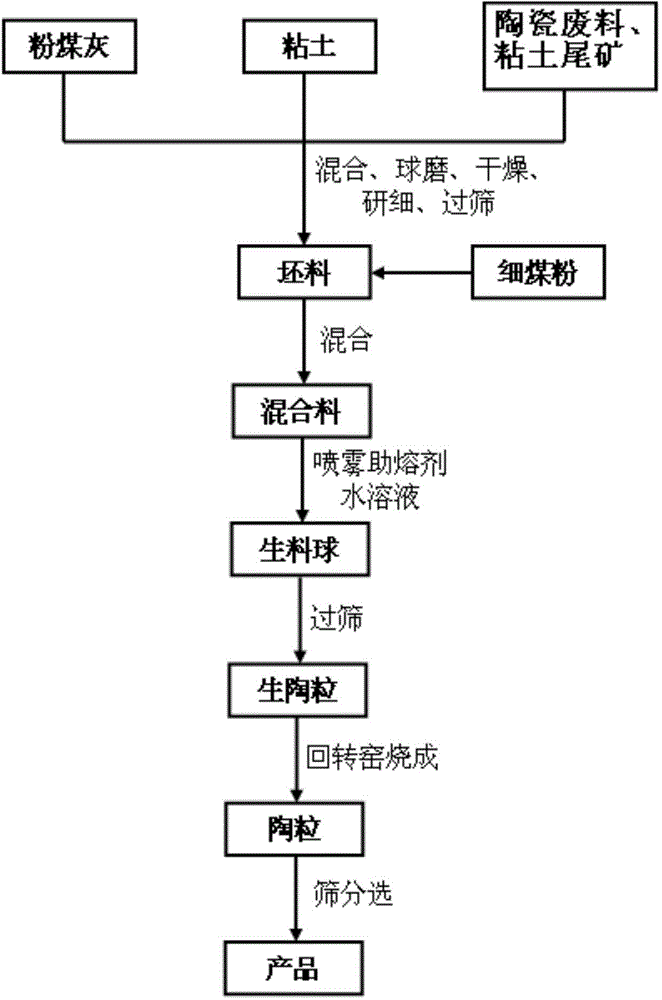

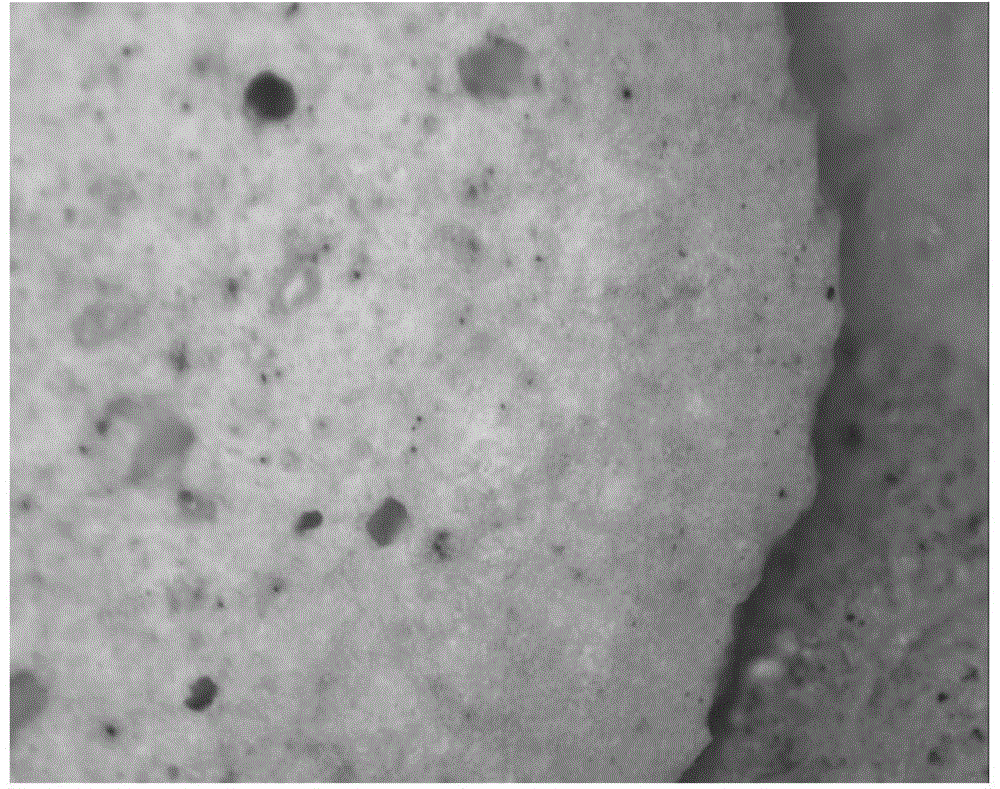

[0021] see figure 1 and 2 A method for preparing lightweight ceramsite assisted by sintering on the surface of magnesium chloride comprises the following steps:

[0022] 1) Take the raw materials in terms of mass percentage: 0%-65% of fly ash, 35%-95% of clay, 0-65% of ceramic waste and 0-65% of clay tailings; mix the raw materials and perform ball milling , dry and finely grind the blanks for later use; wherein the blanks with a particle size of less than 65 μm account for more than 90% of the total mass of the blanks;

[0023] 2) Mixing the blank prepared in step 1) and a pore-forming agent with a particle size of less than 0.125mm at a mass ratio of 100:(5-20) to obtain a mixture;

[0024] 3) Put the mixed material prepared in step 2) into the sugar coating machine for balling treatment to obtain raw meal balls. During the balling process, add the mixed material intermittently according to the balling situation, and in the balling process, add the mixed material with a co...

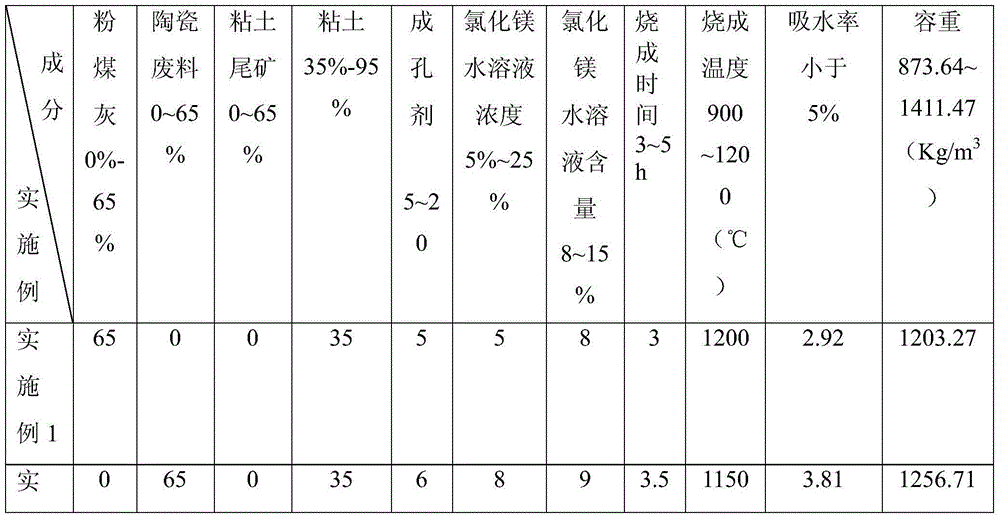

Embodiment 1

[0035] 1) Take the raw materials in terms of mass percentage: 65% of fly ash and 35% of clay; after mixing the raw materials, carry out ball milling, drying and grinding to obtain a billet for subsequent use; wherein the billet with a particle size less than 65 μm accounts for 10% of the total mass of the billet more than 90 percent;

[0036] 2) mixing the blank prepared in step 1) with a pore-forming agent with a particle size of less than 0.125 mm at a mass ratio of 100:5 to obtain a mixture;

[0037] 3) Put the mixed material prepared in step 2) into the sugar coating machine for balling treatment to obtain raw meal balls. During the balling process, add the mixed material intermittently according to the balling situation, and in the balling process, add the mixed material with a concentration of 5 % of the magnesium chloride aqueous solution is intermittently sprayed onto the mixture, and the content of the magnesium chloride aqueous solution in the obtained raw meal balls...

Embodiment 2

[0042] 1) Take the raw materials in terms of mass percentage: a mixture of 35% clay and 65% ceramic waste; after mixing the raw materials, perform ball milling, drying and grinding to obtain a blank for later use; wherein the blank with a particle size of less than 65 μm accounts for the total mass of the blank More than 90% of;

[0043] 2) mixing the blank prepared in step 1) with a pore-forming agent with a particle size of less than 0.125mm at a mass ratio of 100:6 to obtain a mixture;

[0044] 3) Put the mixed material prepared in step 2) into the sugar coating machine for balling treatment to obtain raw meal balls. During the balling process, add the mixed material intermittently according to the balling situation, and in the balling process, add the mixed material with a concentration of 8 % of the magnesium chloride aqueous solution is intermittently sprayed onto the mixture, and the content of the magnesium chloride aqueous solution in the obtained raw meal balls accou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com