Magnesium and aluminum metal-matrix composite material enhanced through waste fluorescent powder and preparation method of magnesium and aluminum metal-matrix composite material enhanced through waste fluorescent powder

An aluminum-based composite material and a composite material technology are applied in the fields of waste phosphor recycling and metal-based composite material preparation, which can solve the problems of large environmental pollution and complicated technological process, and achieve a simple preparation method, wide application prospect and short process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

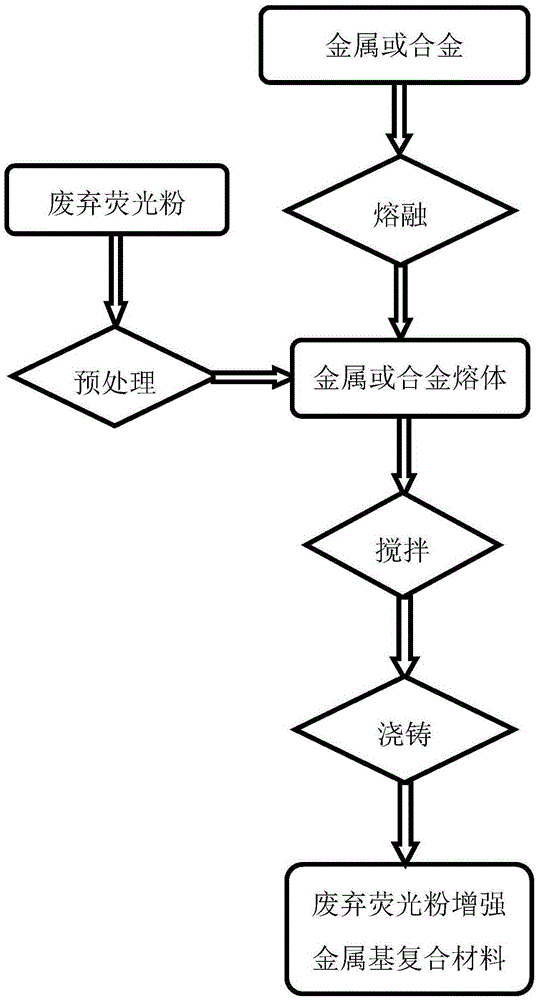

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, the process for preparing waste fluorescent powder reinforced pure magnesium-based composite materials is carried out according to the following steps:

[0019] (1) Weigh 1 g of waste fluorescent powder (red powder 50wt.%, green powder 35wt.%, blue powder 15wt.%), and keep it in a drying oven at 100° C. for 24 hours.

[0020] (2) Weigh 999g of pure magnesium (the composition is 0.005wt.% Al, 0.001wt.% Zn, 0.01wt.% Mn, 0.01wt.% Si, and the balance is Mg), put it into a graphite crucible for heating and melting to liquid state, when the temperature of the melt rises to about 660°C (the superheat of the melt is 10°C at this time), take out the phosphor powder treated in step (1), add it to the melt, and stir with a stirring blade at a speed of 1500rpm After 5 minutes of the melt in the molten state, the temperature of the melt was heated to about 700° C., the slag on the surface of the melt was scooped out, and cast into a sand mold to obtain a waste ph...

Embodiment 2

[0023] In this embodiment, the process of preparing waste fluorescent powder reinforced Mg-Al-Zn-based composite material is carried out according to the following steps:

[0024] (1) Weigh 10 g of waste fluorescent powder (red powder 55wt.%, green powder 40wt.%, blue powder 5wt.%), and keep it in a drying oven at 200° C. for 12 hours.

[0025] (2) Weigh 990g of AZ31 alloy (composition is 3.0wt.%Al, 0.8wt.%Zn, 0.15wt.%Mn, the balance is Mg), put it into graphite crucible and heat and melt to liquid state, wait for the melt The temperature rises to about 650°C (at this time, the superheat of the melt is 20°C), take out the phosphor powder treated in step (1), add it to the melt, and stir the molten melt with a stirring blade at a speed of 1500rpm for 10 minutes , heating the temperature of the melt to 680° C., scooping up the slag on the surface of the melt, and casting it in a metal mold to obtain a waste phosphor powder-reinforced magnesium-based composite material with a pho...

Embodiment 3

[0028] In this embodiment, the process of preparing waste fluorescent powder reinforced pure aluminum matrix composite material is carried out according to the following steps:

[0029] (1) Weigh 50 g of waste fluorescent powder (red powder 55wt.%, green powder 40wt.%, blue powder 5wt.%), and keep it in an oven at 200° C. for 12 hours.

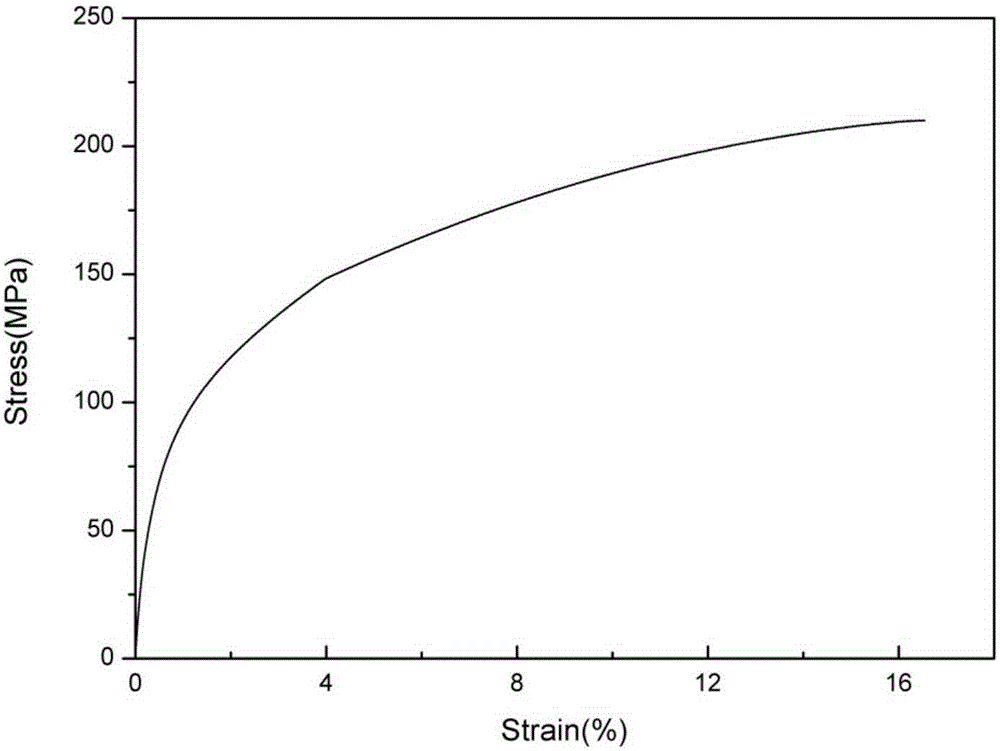

[0030] (2) Weigh 950g of pure aluminum (the composition is 1.1wt.% Mg, 0.62wt.% Si, 0.65wt.% Fe, 0.29wt.% Cu, 0.13wt.% Mn, 0.22wt.% Zn, 0.10wt. %Cr, 0.15wt.%Ti, and the balance is Al), put it into a graphite crucible and heat and melt it to a liquid state, and when the temperature of the melt rises to about 810°C (at this time, the degree of superheat of the melt is 150°C), take out the step (1) After the phosphor powder is processed, add it to the melt, stir the molten melt with a stirring paddle at a speed of 1000rpm for 15 minutes, wait until the temperature of the melt drops to 700°C, scoop out the slag on the surface of the melt, and cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com