Modified nanoparticle dispersion strengthened copper alloy, preparation method and application thereof, electronic element and mechanical element

A technology for dispersion strengthening of copper and nanoparticles, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Dispersion, good mechanical strength, large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

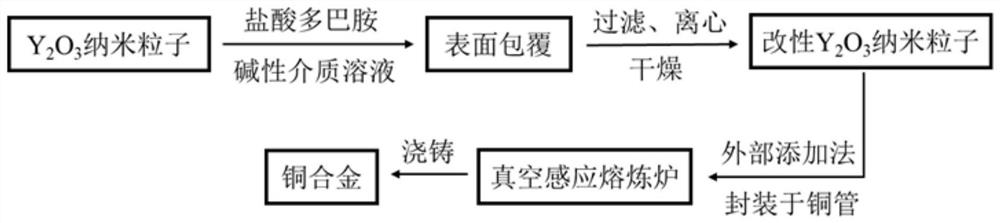

[0047] According to another aspect of the present invention, there is provided a method for preparing the above modified nanoparticle dispersion strengthened copper alloy, comprising the following steps: (a) reacting the nanoparticle and dopamine hydrochloride under alkaline conditions to obtain the modified nanoparticle (b) adding the modified nanoparticles into the copper liquid, mixing uniformly, and then casting to obtain the modified nanoparticles dispersion-strengthened copper alloy.

[0048] The preparation method is scientific and simple. First, the method of surface coating is used to oxidize dopamine hydrochloride under alkaline conditions to form polydopamine, which is coated on the surface of nanoparticles, so that the modified nanoparticles have better high temperature stability, Wettability and dispersion distribution can play the effect of dispersion strengthening copper alloy, and the product quality is easy to control; while if nanoparticles are directly used, ...

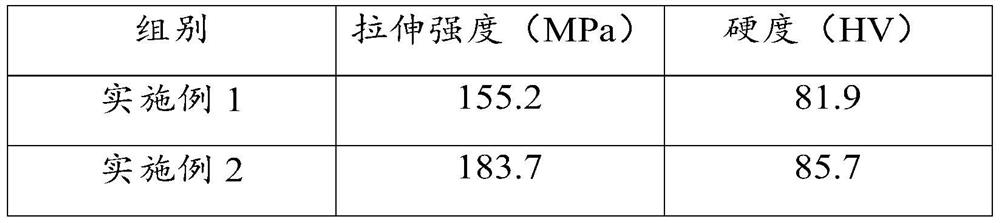

Embodiment 1

[0066] A modified nanoparticle dispersion strengthened copper alloy, including copper and modified nanoparticles dispersed in copper, the modified nanoparticles include nanoparticles and polydopamine coated on the surface of the nanoparticles, the nanoparticles are Y 2 o 3 , the average particle diameter of the nanoparticles is 30nm, the thickness of the polydopamine coated on the surface of the nanoparticles is 0.1wt% of the modified nanoparticles;

[0067] The preparation method of the copper alloy comprises the following steps: (a) mixing nanoparticles, dopamine hydrochloride and 0.01mol / L tris buffer solution, adjusting pH=9.5 after mixing, and then reacting under magnetic stirring, Obtain modified nanoparticles; wherein, the mass ratio of nanoparticles and dopamine hydrochloride is 3:8, the reaction temperature is 25°C, and the reaction time is 10h; (b) the modified nanoparticles are packaged in copper tubes, and then placed in a vacuum In the feeding funnel of the induc...

Embodiment 2

[0069] A modified nanoparticle dispersion-strengthened copper alloy. The difference from Example 1 is that in this example, the content of the modified nanoparticle is 0.03wt%. In step (a) of the preparation method, the nanoparticle, dopamine hydrochloride Mix with tris buffer solution of 0.05mol / L, adjust pH=9 after mixing, react under magnetic stirring then, obtain modified nanoparticles; wherein, the mass ratio of nanoparticles and dopamine hydrochloride is 4:10 , the reaction temperature was 25°C, and the reaction time was 18h; the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com