Patents

Literature

31results about How to "Affect precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

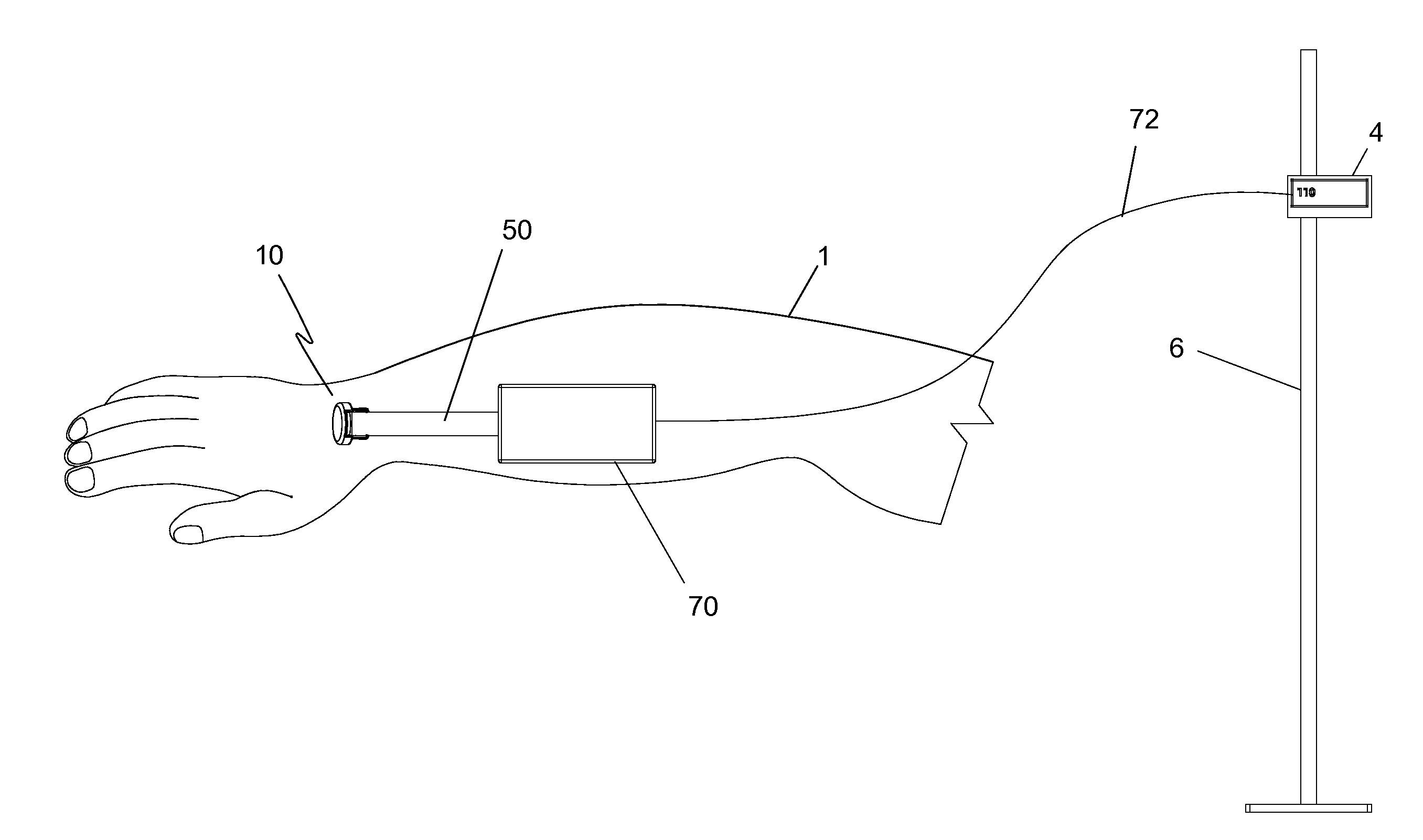

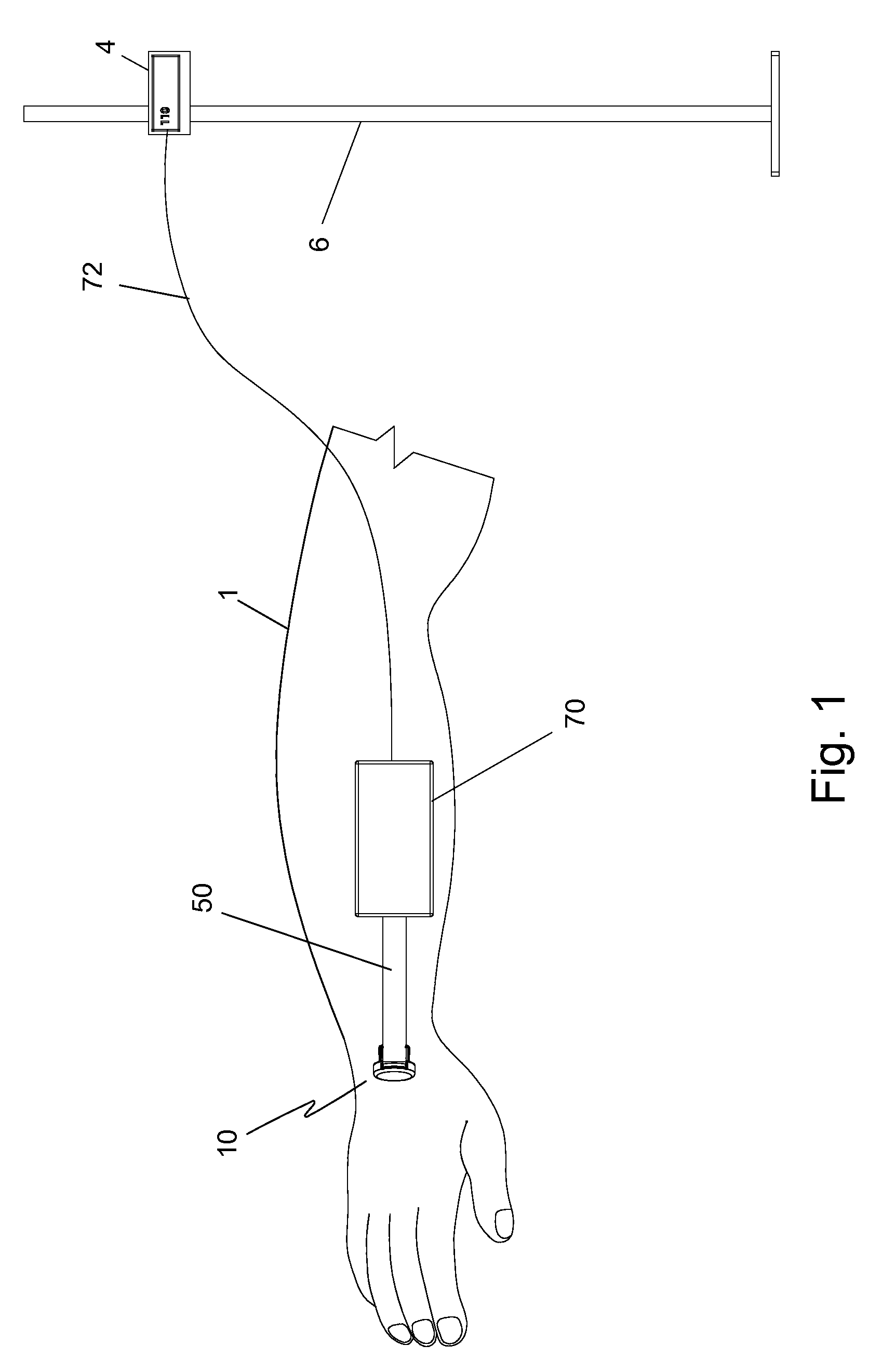

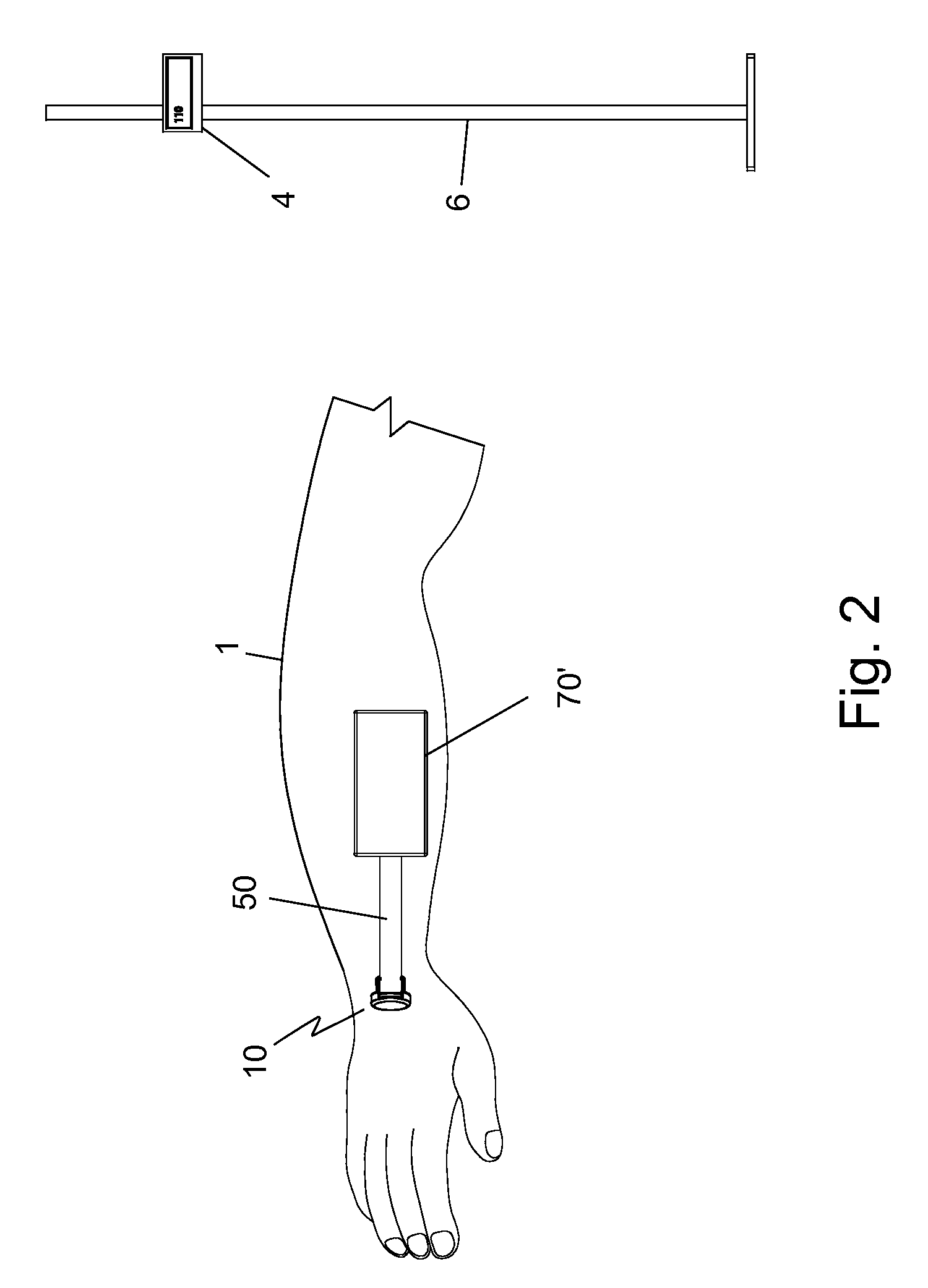

Temperature-compensated in-vivo sensor

InactiveUS20090275815A1Accurate analyte measurementBody temperature can fluctuateCatheterDiagnostic recording/measuringAnalyteCoupling

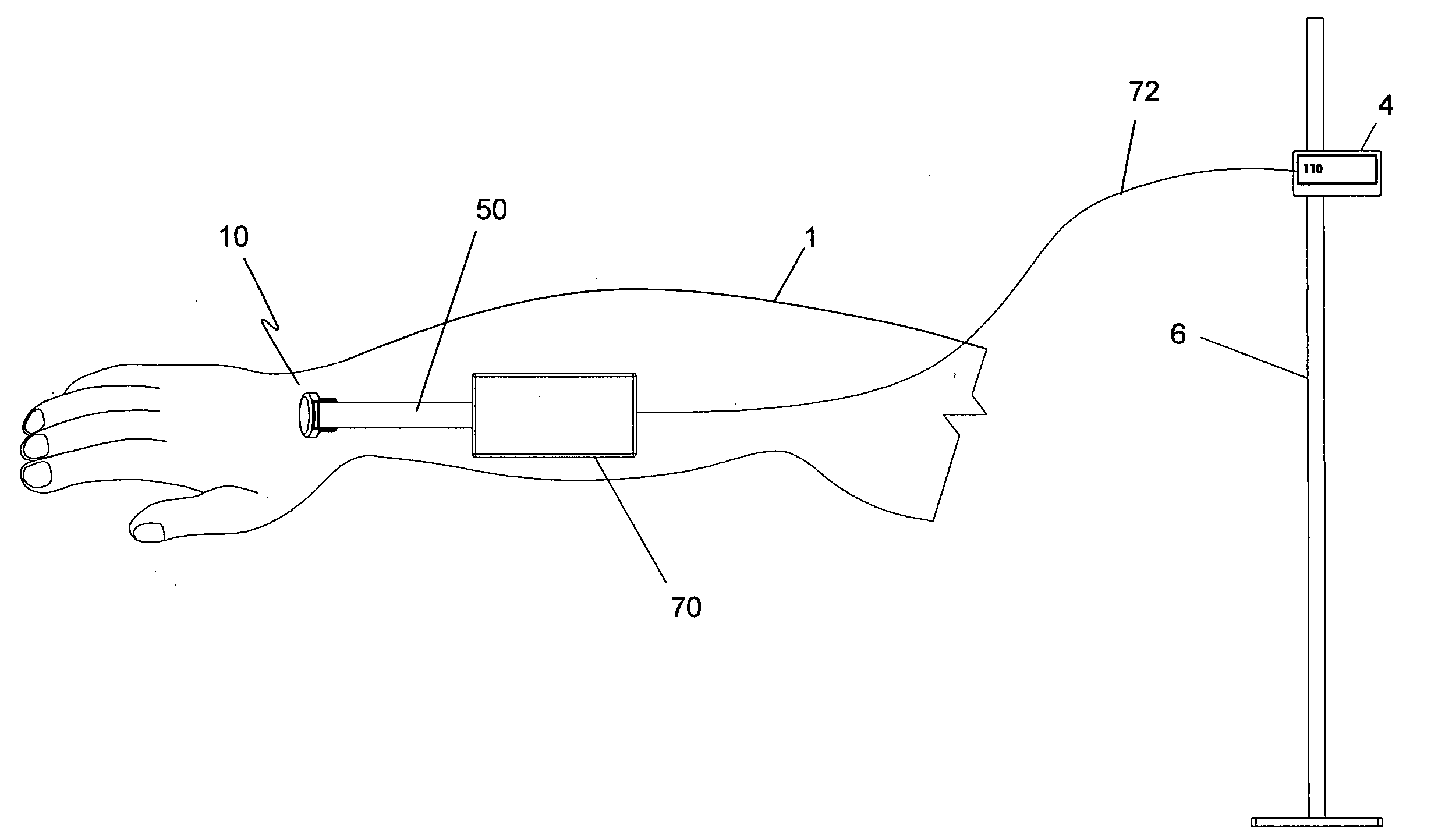

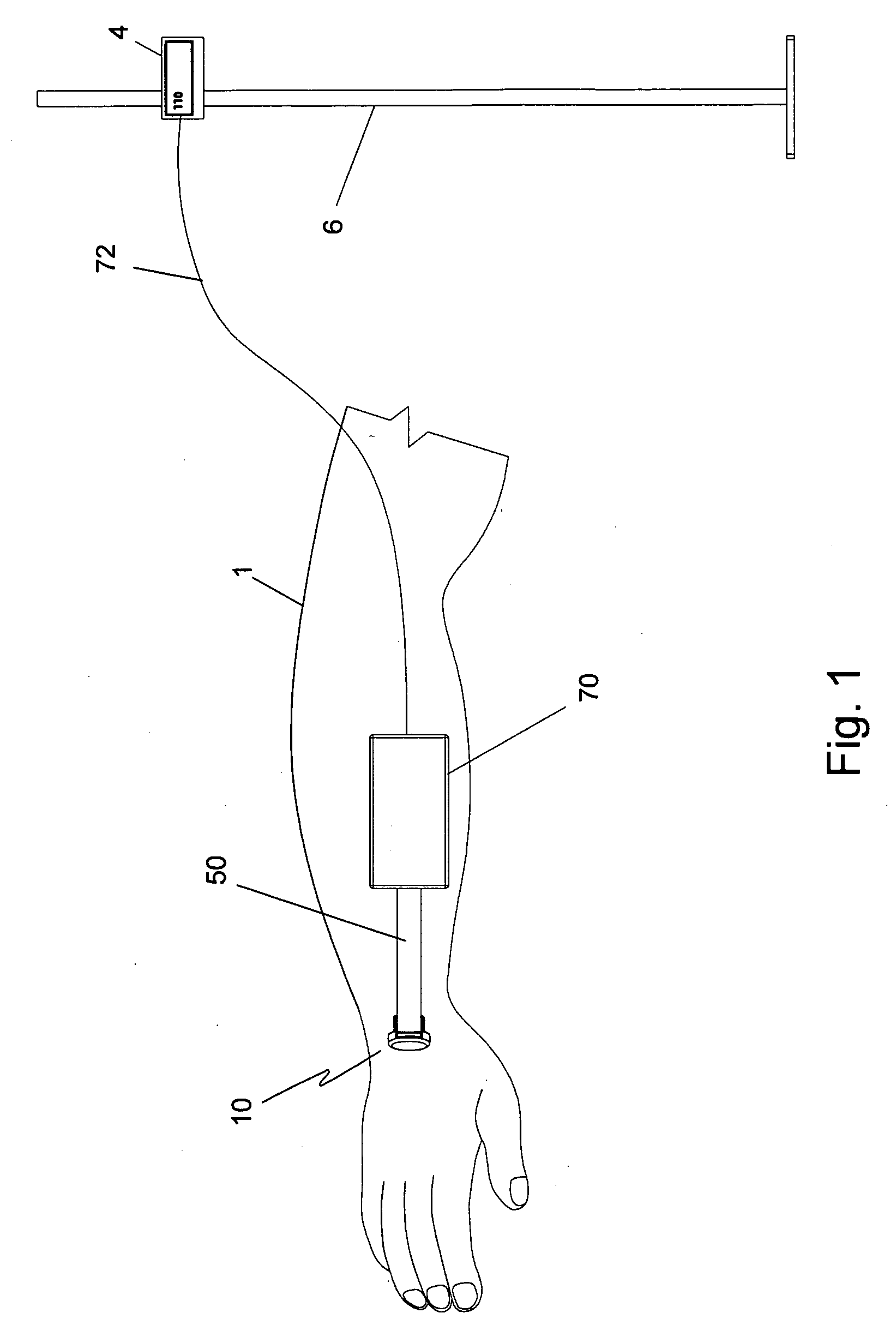

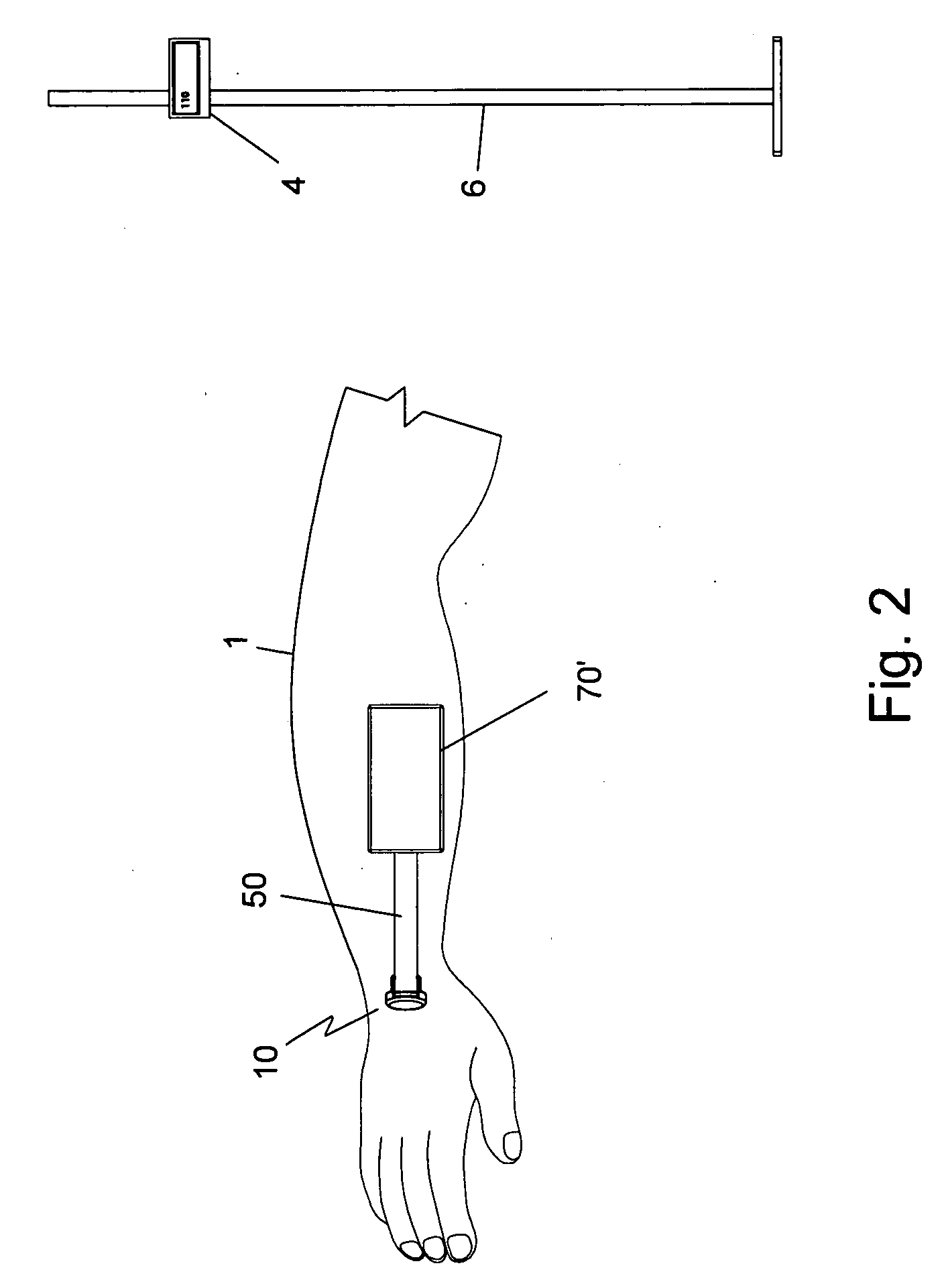

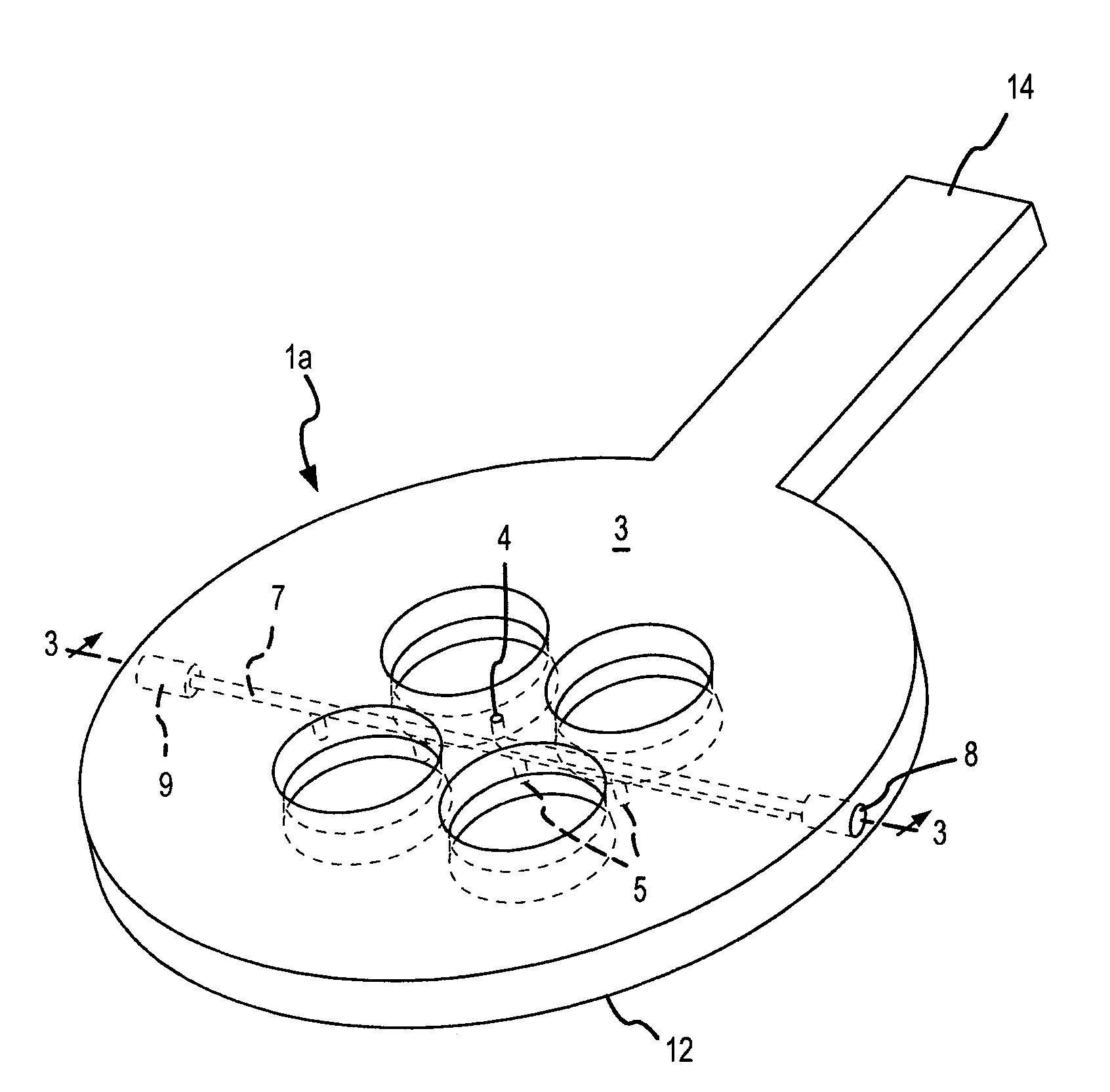

An in-vivo sensor assembly includes an assembly body having a body proximal end and a body distal end, a plurality of sensor elements including at least an analyte sensor element containing an enzyme that is a substrate of the analyte to be measured, a reference sensor element and a temperature sensor element disposed at or near the body distal end wherein the at least an analyte sensor element and the reference sensor element are exposed to the sample fluid and the temperature sensor is capable of measuring the temperature of and adjacent to the analyte sensor element, and an electrical coupling means disposed at the body proximal end and configured to couple to the at least an analytical sensor element, the reference sensor element and the temperature sensor element.

Owner:SANVITA MEDICAL CORPORATION

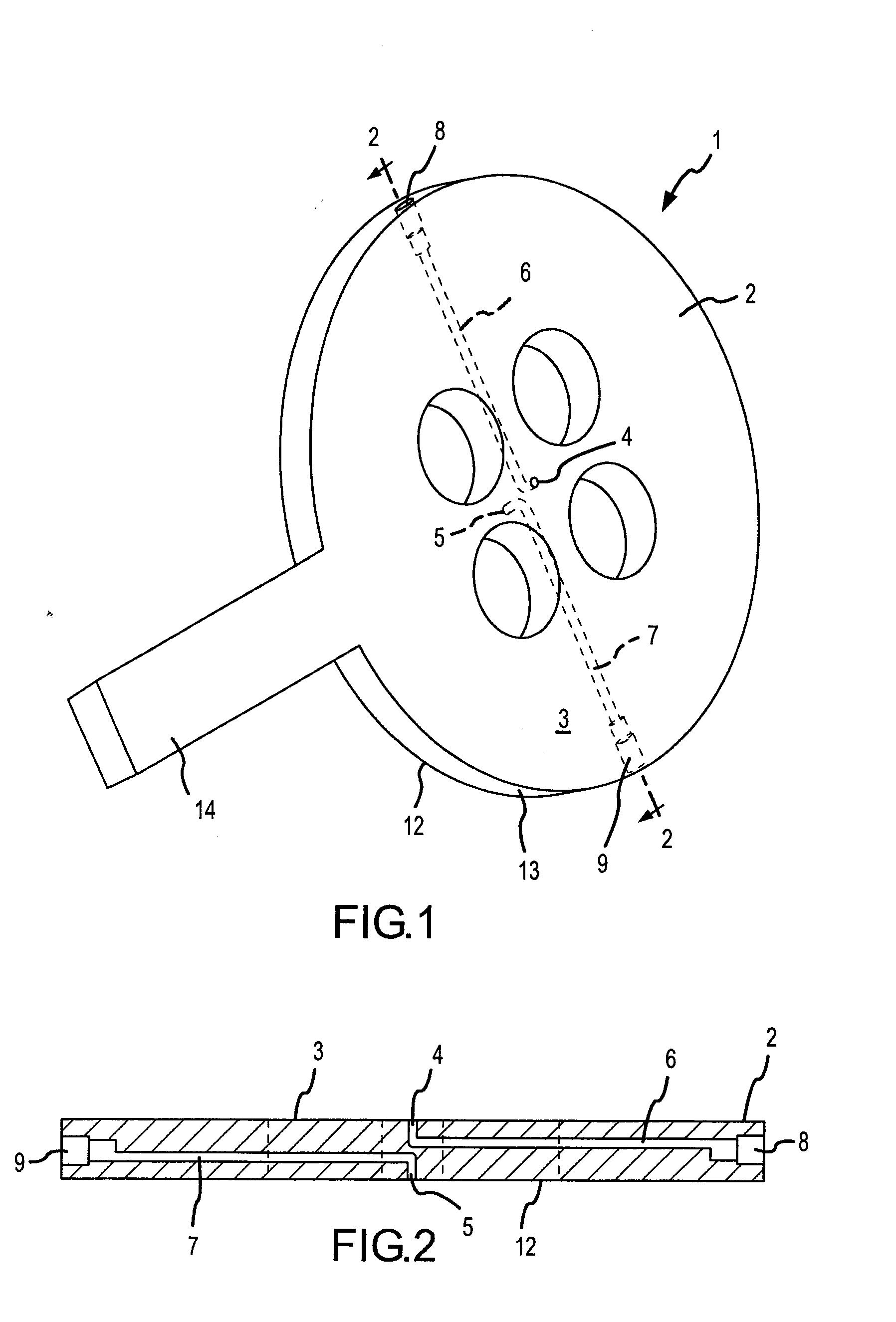

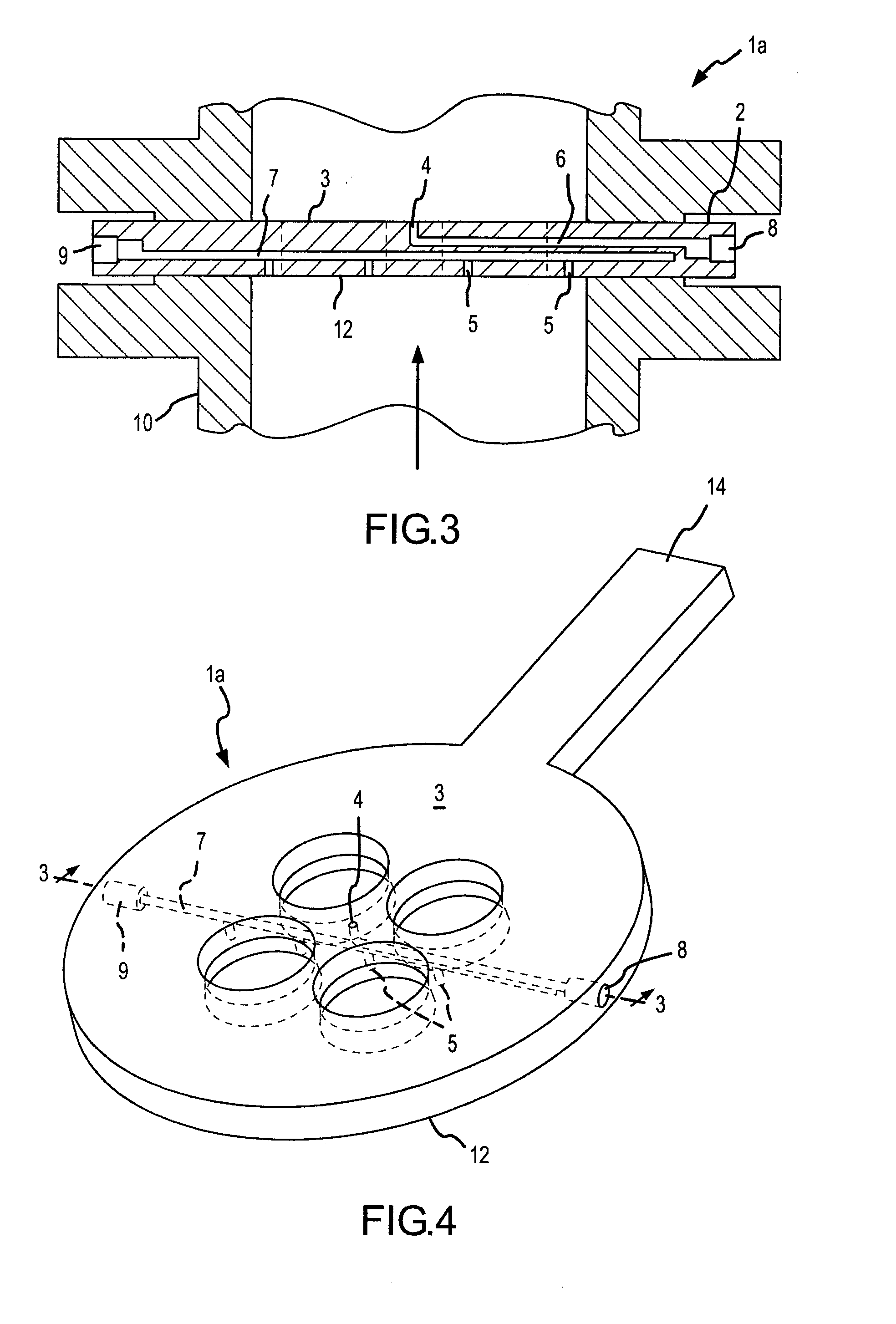

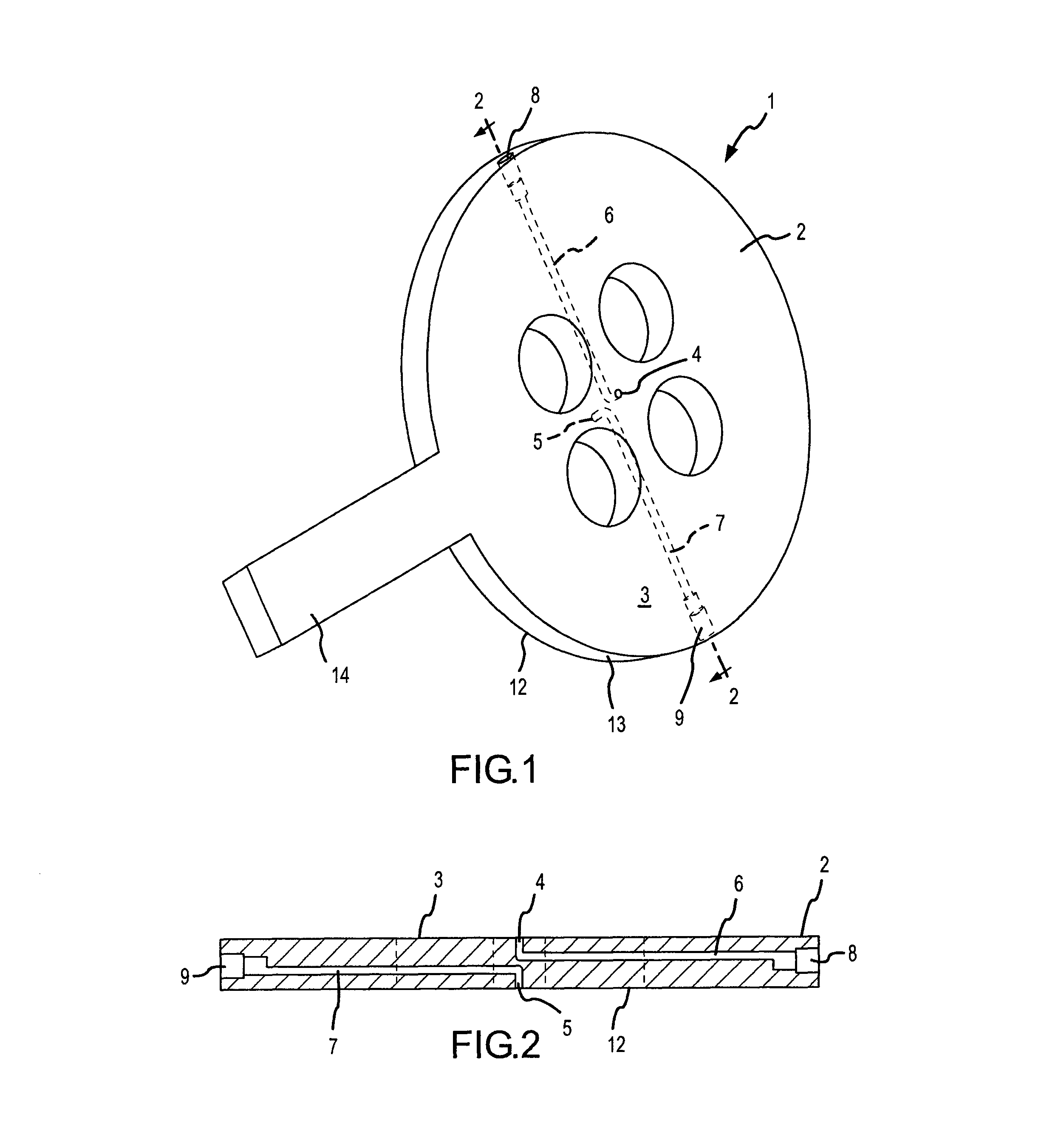

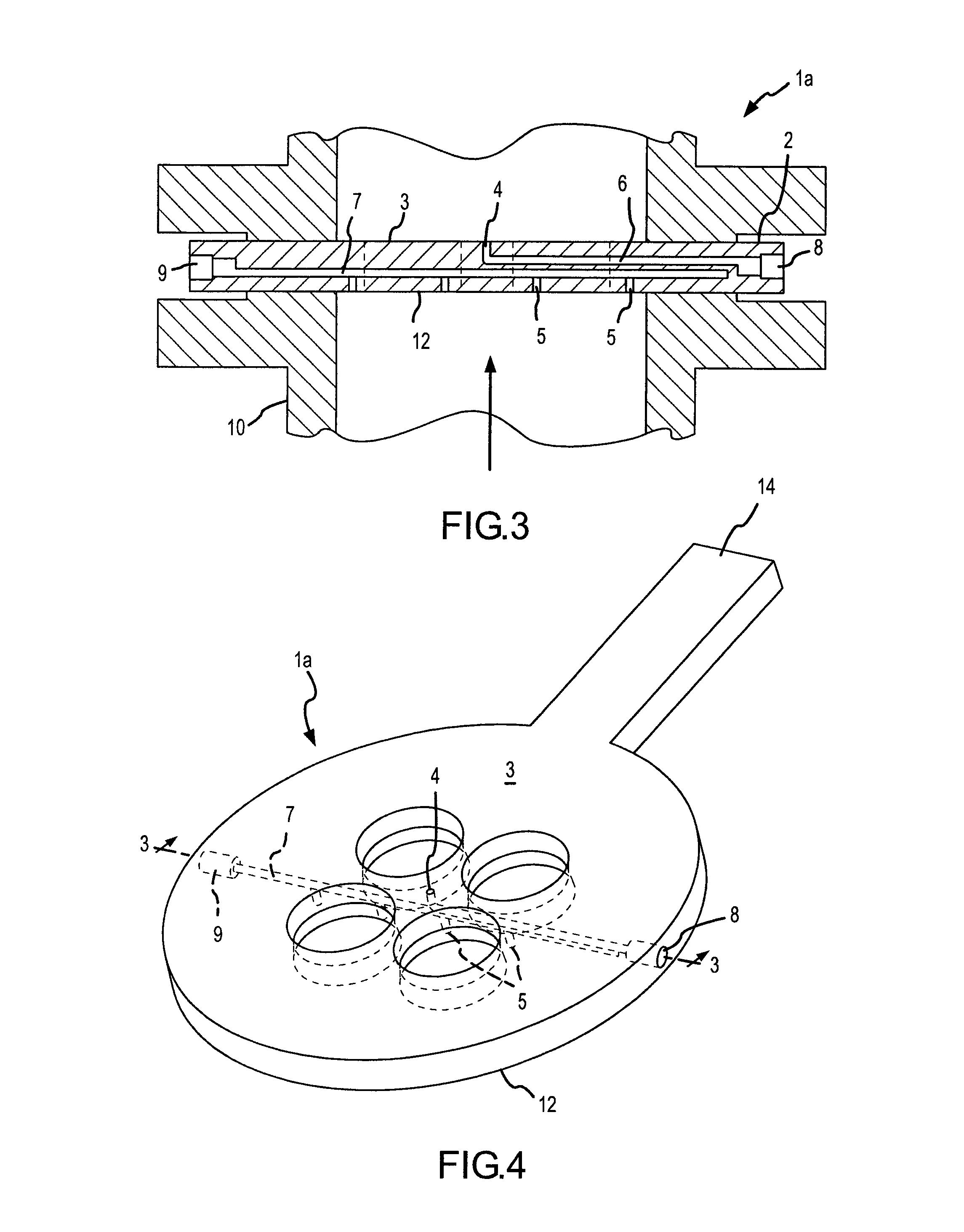

Locating Of Pressure Taps On Face Of Orifice Plate Device

ActiveUS20080307896A1Accurate measurementHigh speedVolume/mass flow by differential pressureOrifice plateImage resolution

A process flow device that includes a self-averaging orifice plate type of primary flow element with a high pressure tap located on or incorporated into its upstream surface, and a low pressure tap located on or incorporated into its downstream surface, for measuring, by a differential pressure process, the volumetric rate of fluid flow at a point in a fluid carrying conduit where the velocity profile of the fluid is asymmetric with respect to the longitudinal axis of the conduit. The improved pressure tap configuration consists of two fluid conduits, one carried by each of the downstream and upstream faces of the orifice plate, establishing fluid communication between openings in the downstream and upstream faces of the orifice plate and their respective terminal pressure ports. Location of the pressure taps on the faces of the orifice plate in this manner allows for increased resolution of the pressure signals by minimizing the effects of upstream pipe flow disturbances on pressure taps used in conjunction with conditioning orifice plate primary flow elements, especially those with higher beta ratios.

Owner:DIETERICH STANDARD

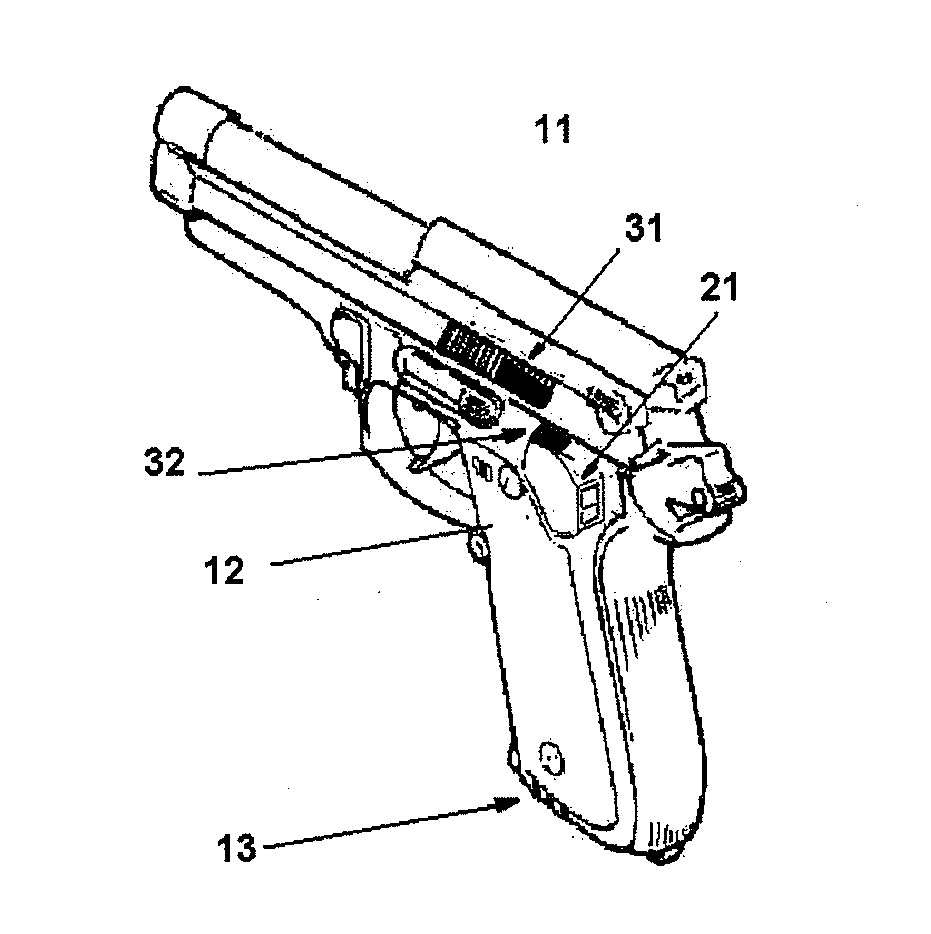

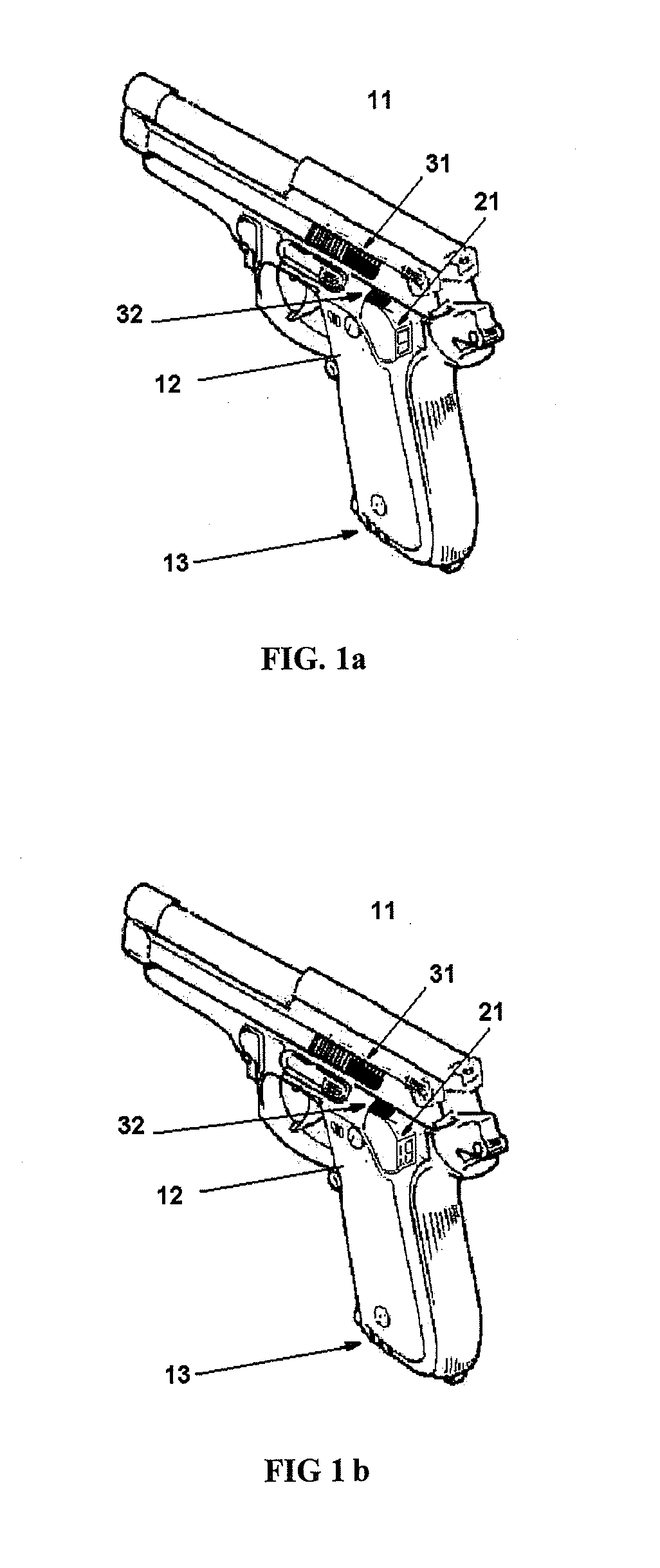

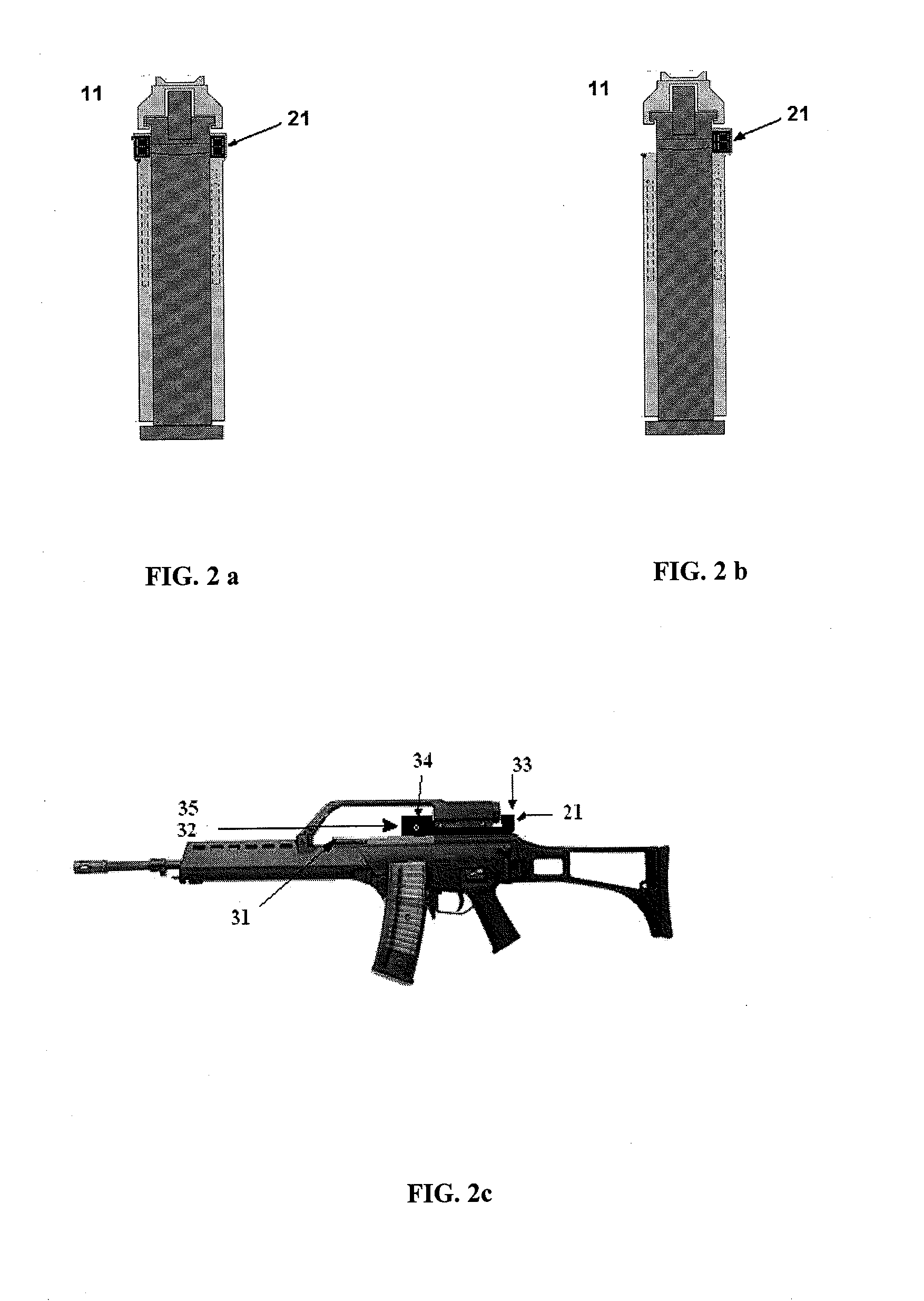

Device for controlling ammunition consumption in real time

InactiveUS20100299985A1Affect firearm 's precisionAffect precisionFiring/trigger mechanismsAmmunition loadingEngineeringBiological activation

Device (12) for counting the total number of shots fired by a firearm (11) and those fired with a same loader mounted on the weapon by means of the acquisition, analysis and interpretation of physical parameters relating to its firing cycle, in such a way that the information obtained is shown in real time on a visual display unit with the activation, visual display and setting to zero being automatic actions without intervention from the user, by means of a computer programme, with it being possible to carry out such operations manually as well. The visual display unit may show other parameters of the firearm's operation (11) such as the temperature of those points most likely to overheat so that the weapon may be used with safety and precision.

Owner:DELGADO ACARRETA RAL

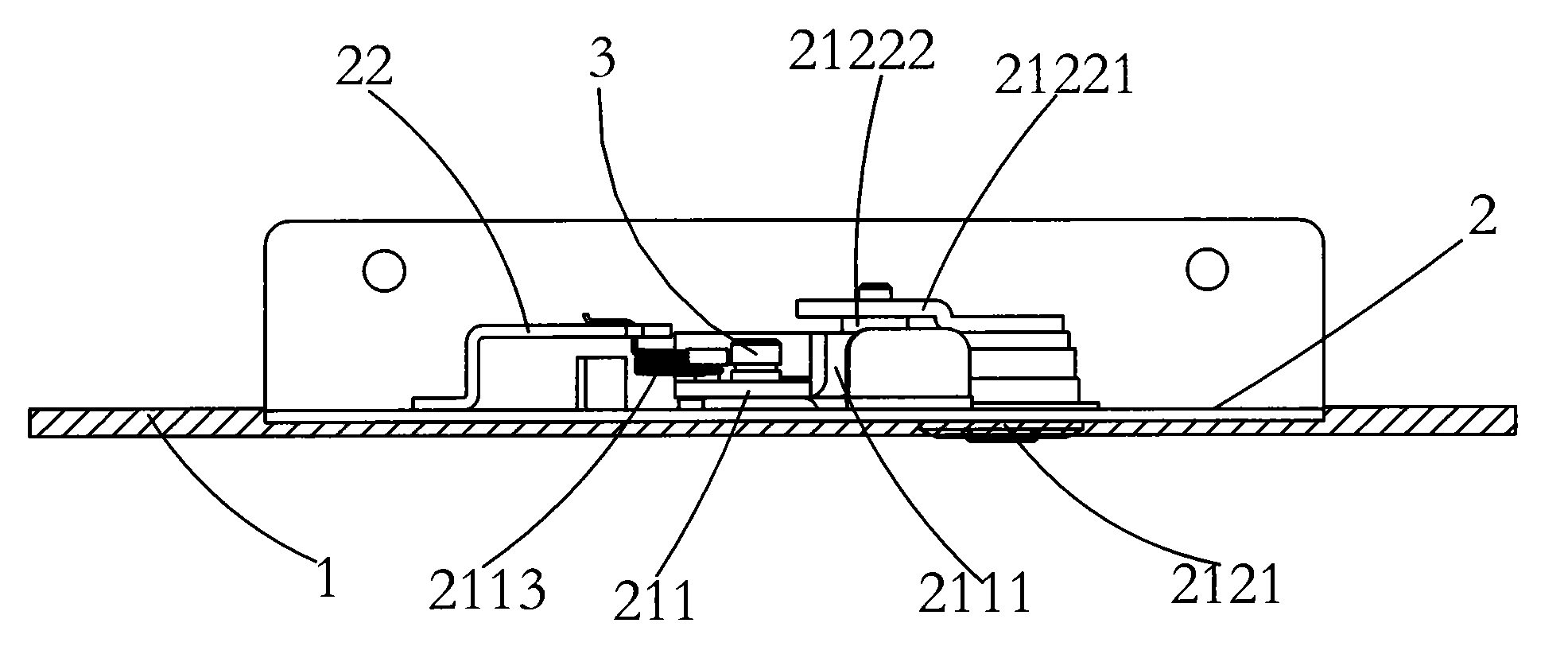

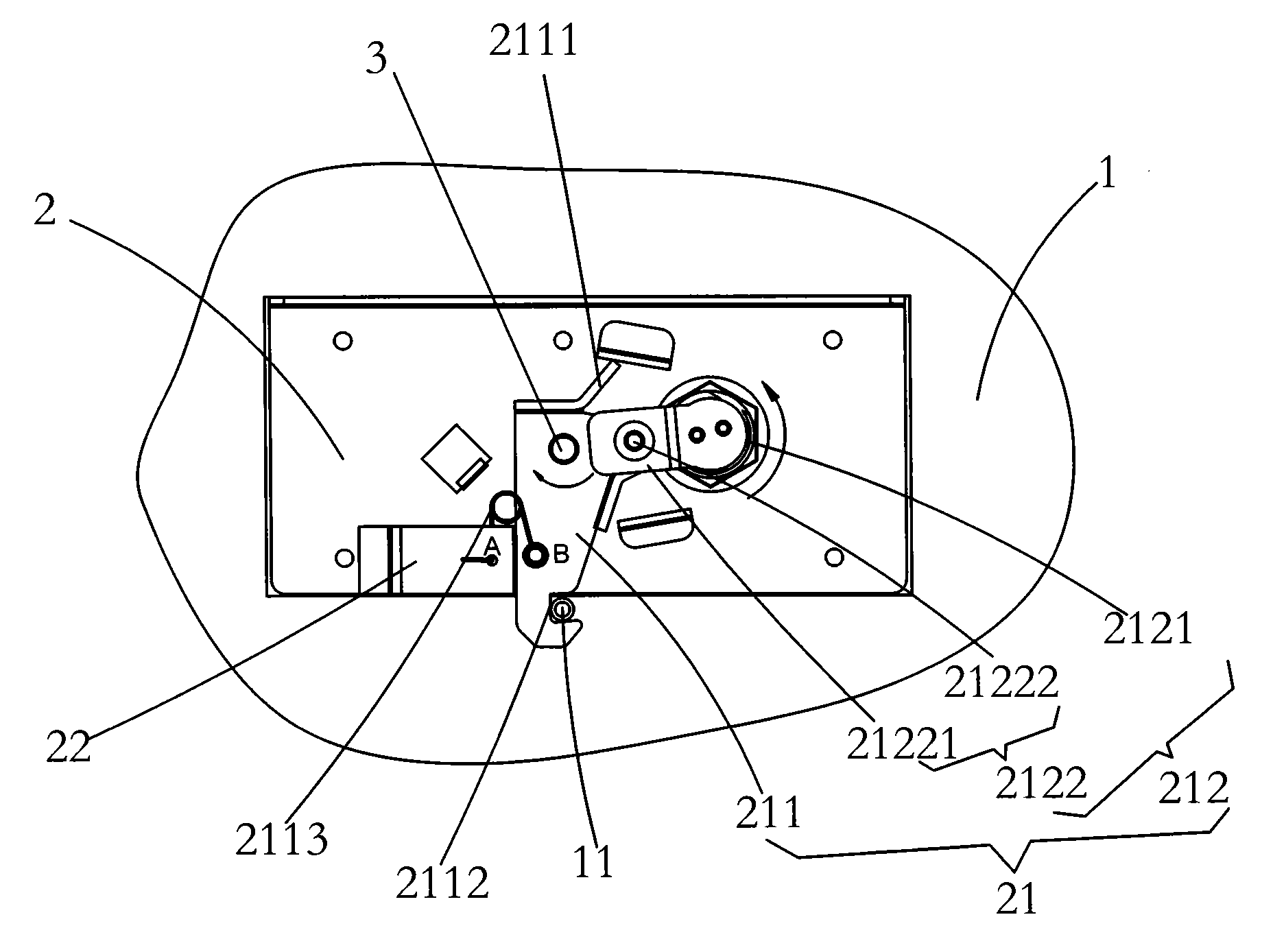

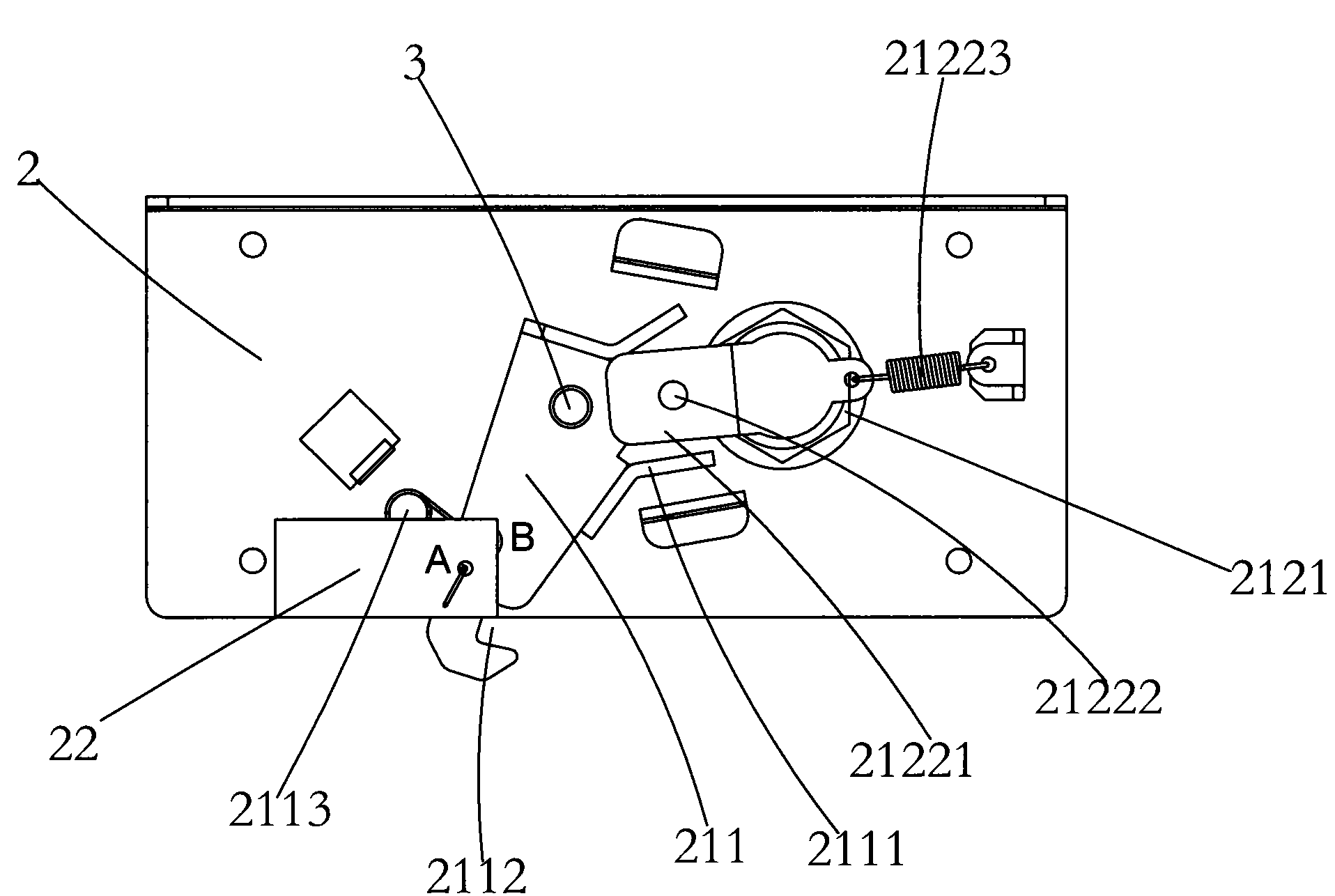

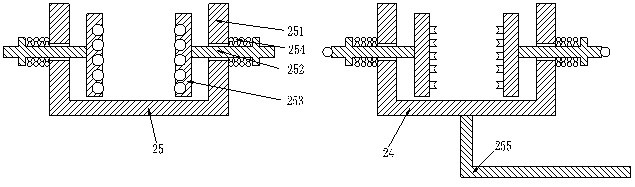

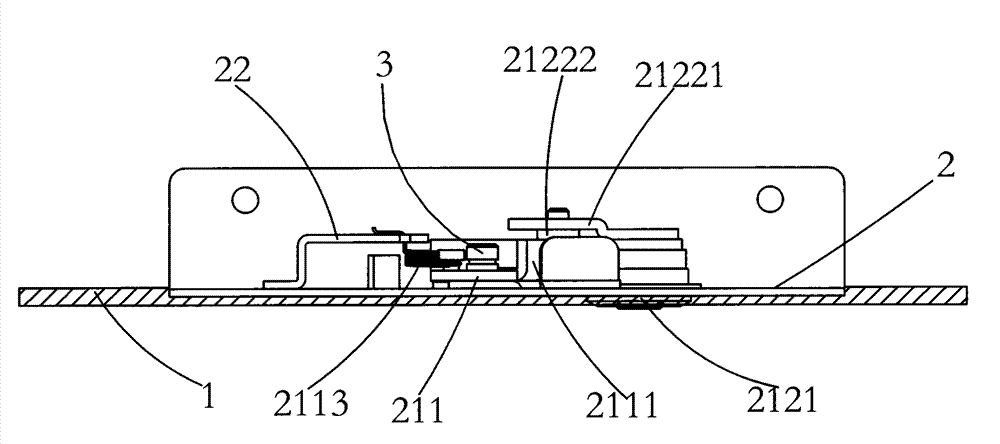

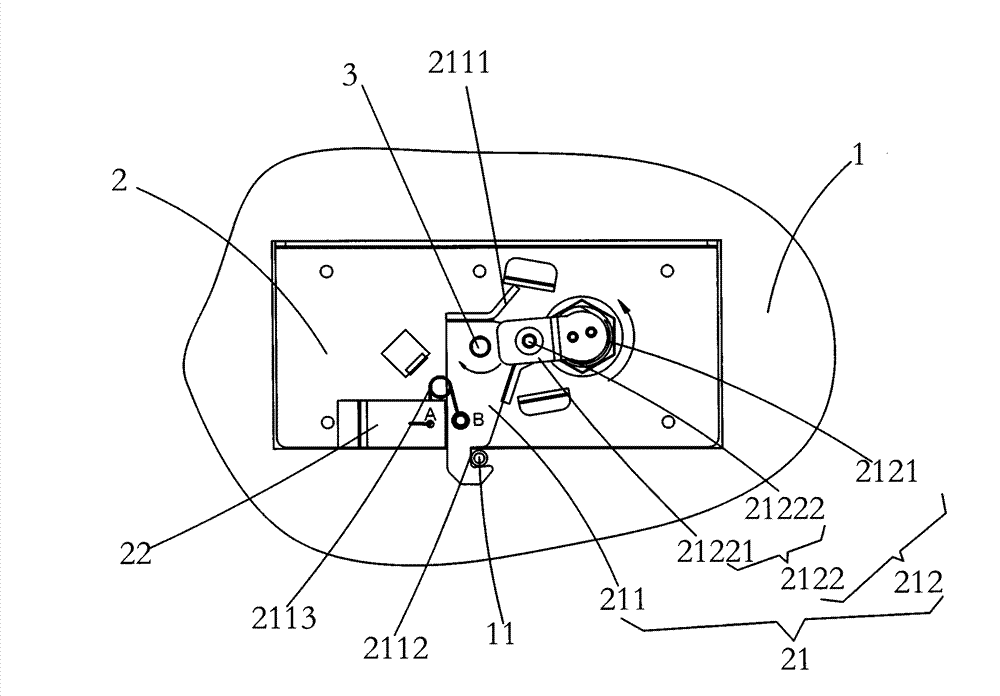

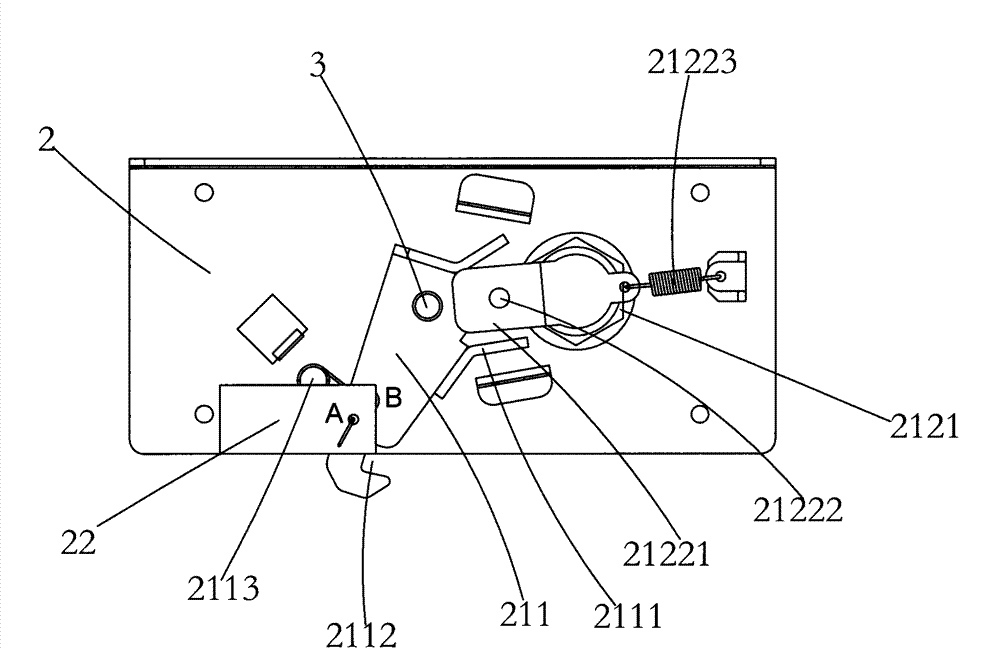

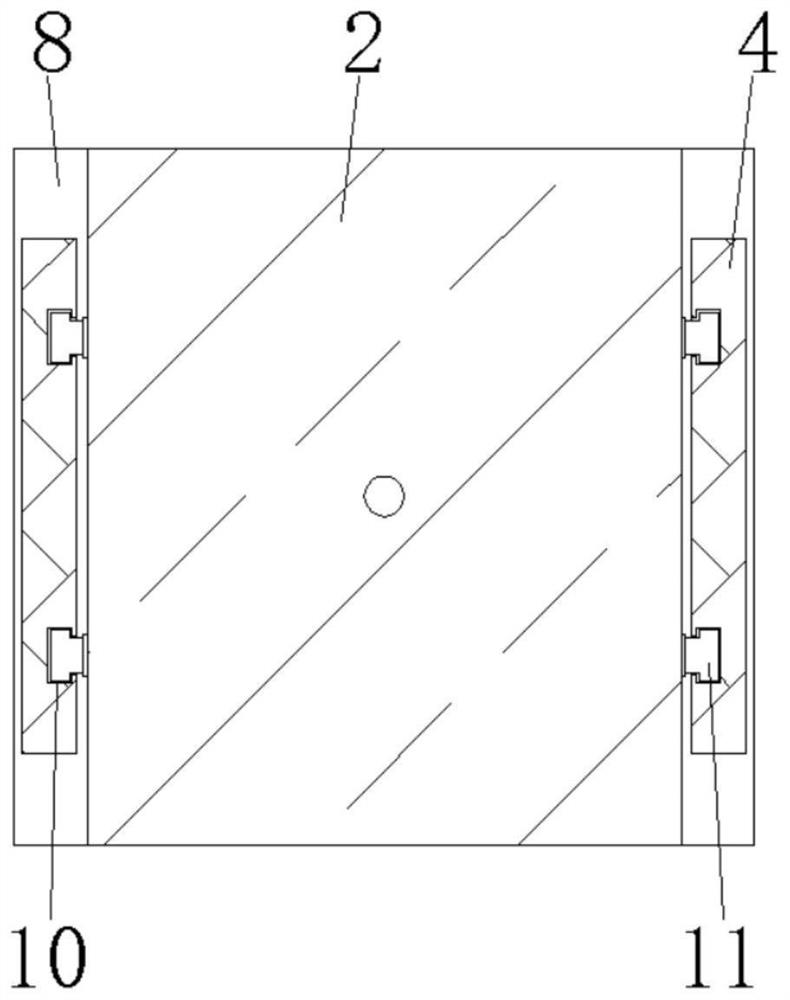

Box lock mechanism

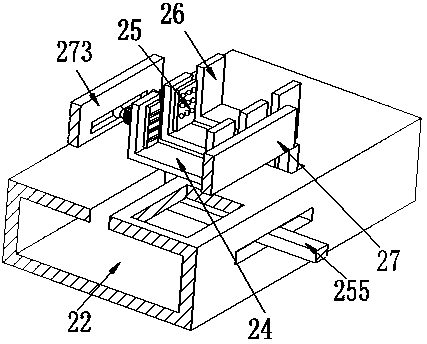

ActiveCN101974997AExtended service lifeImprove securityComplete banking machinesBuilding locksLocking mechanismEngineering

Owner:GRG BAKING EQUIP CO LTD

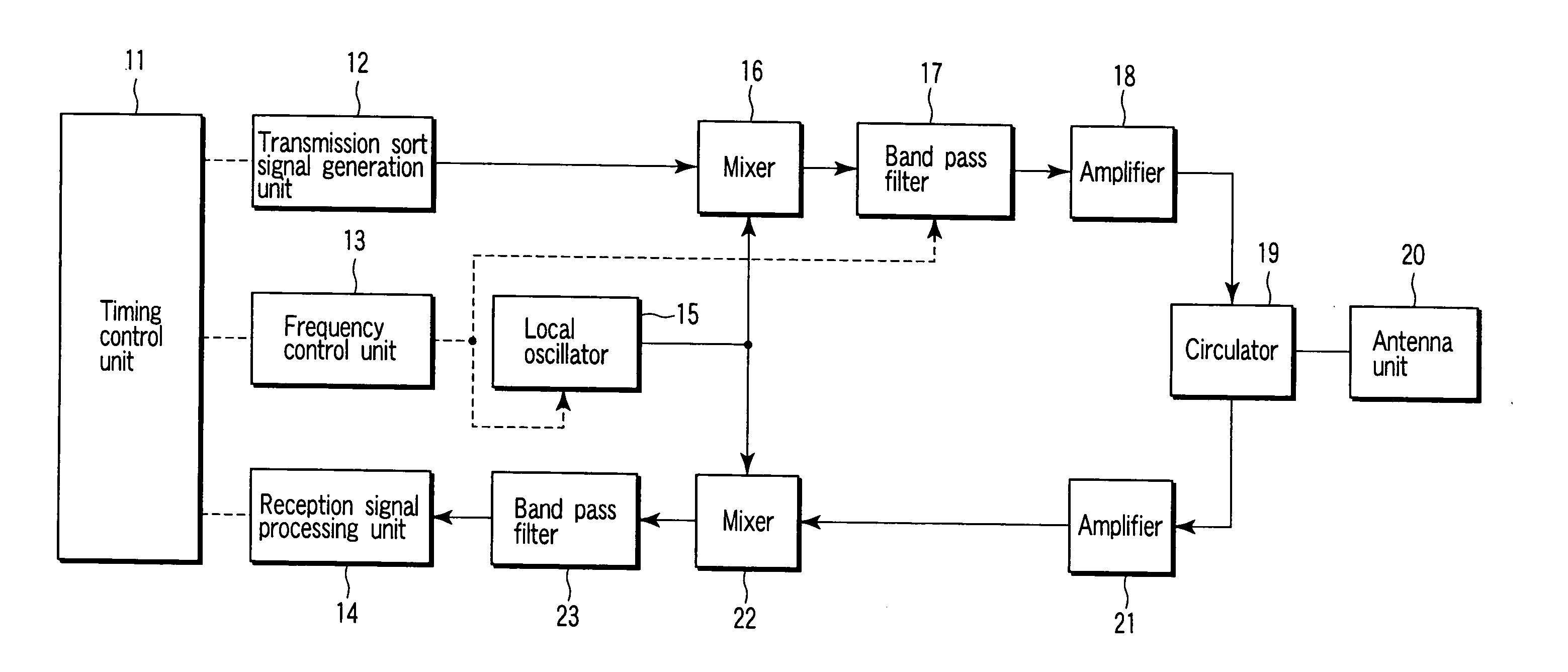

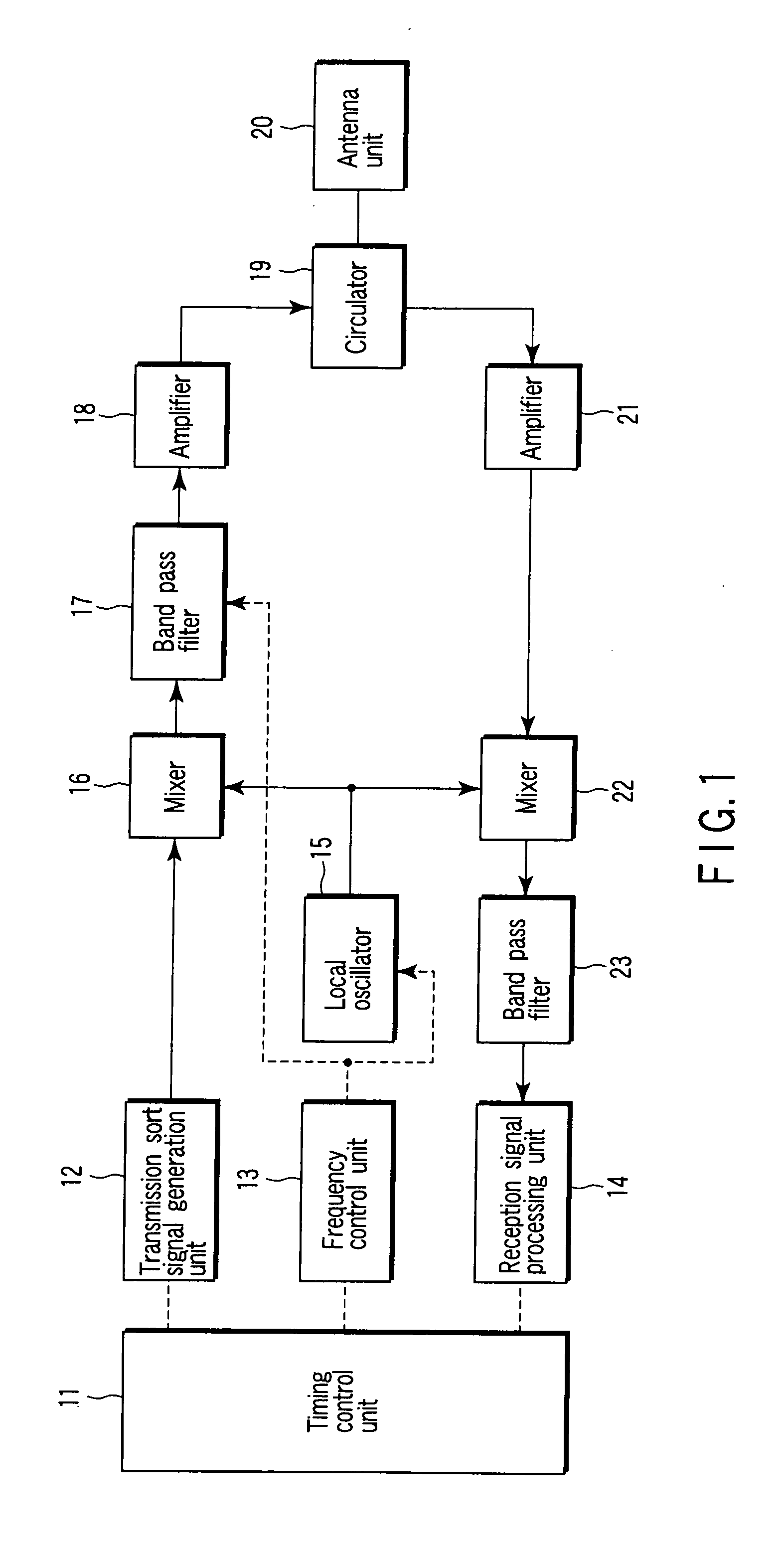

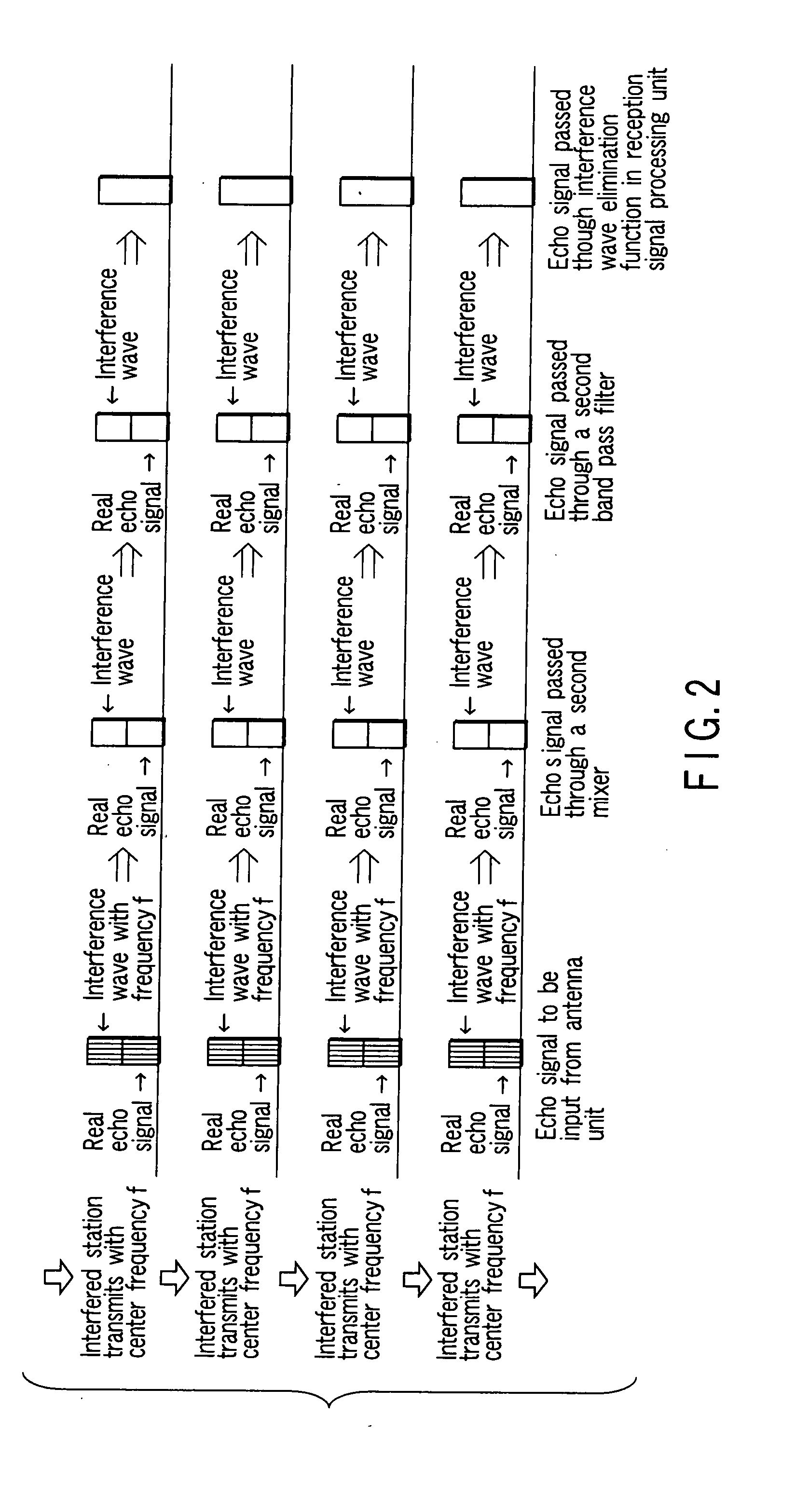

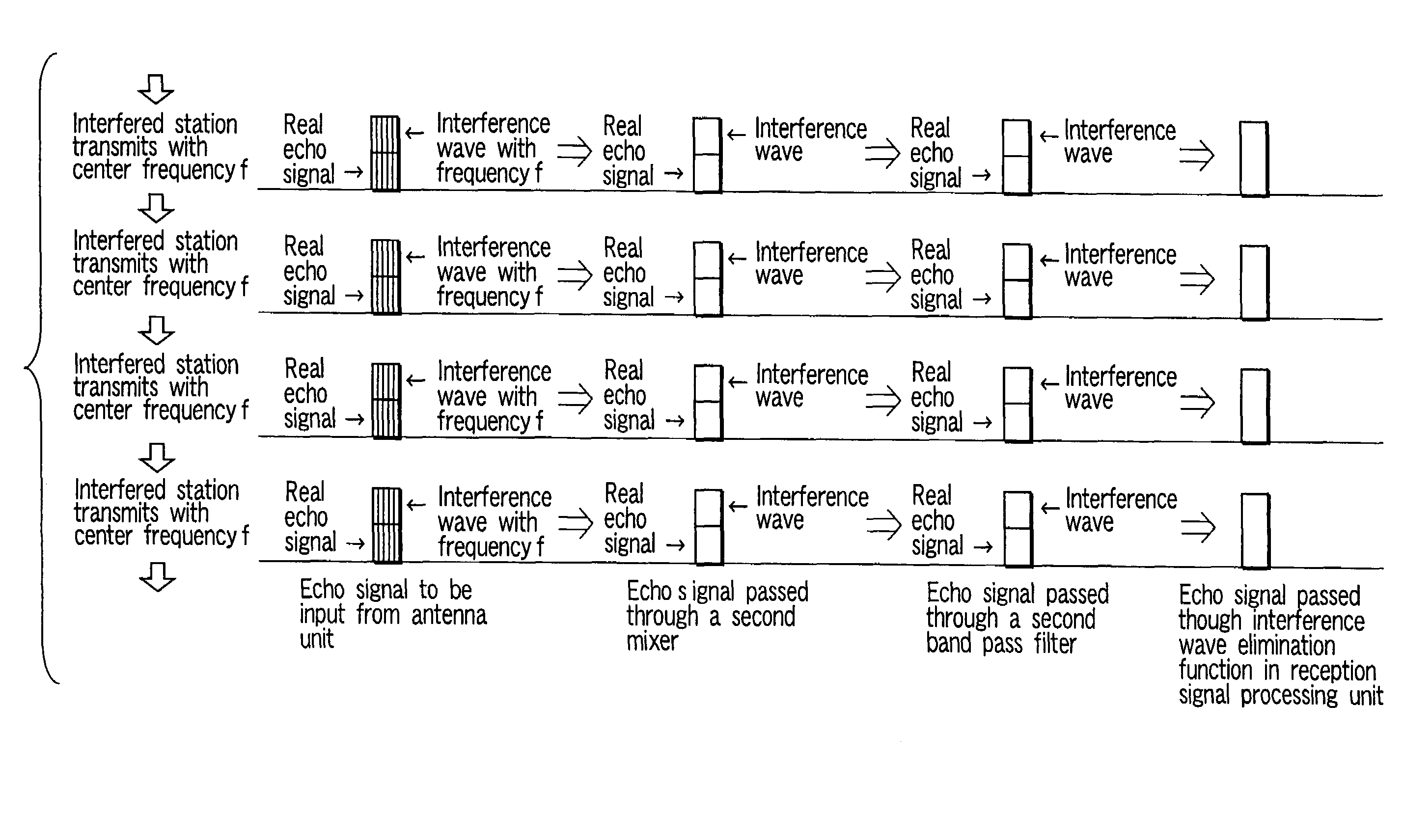

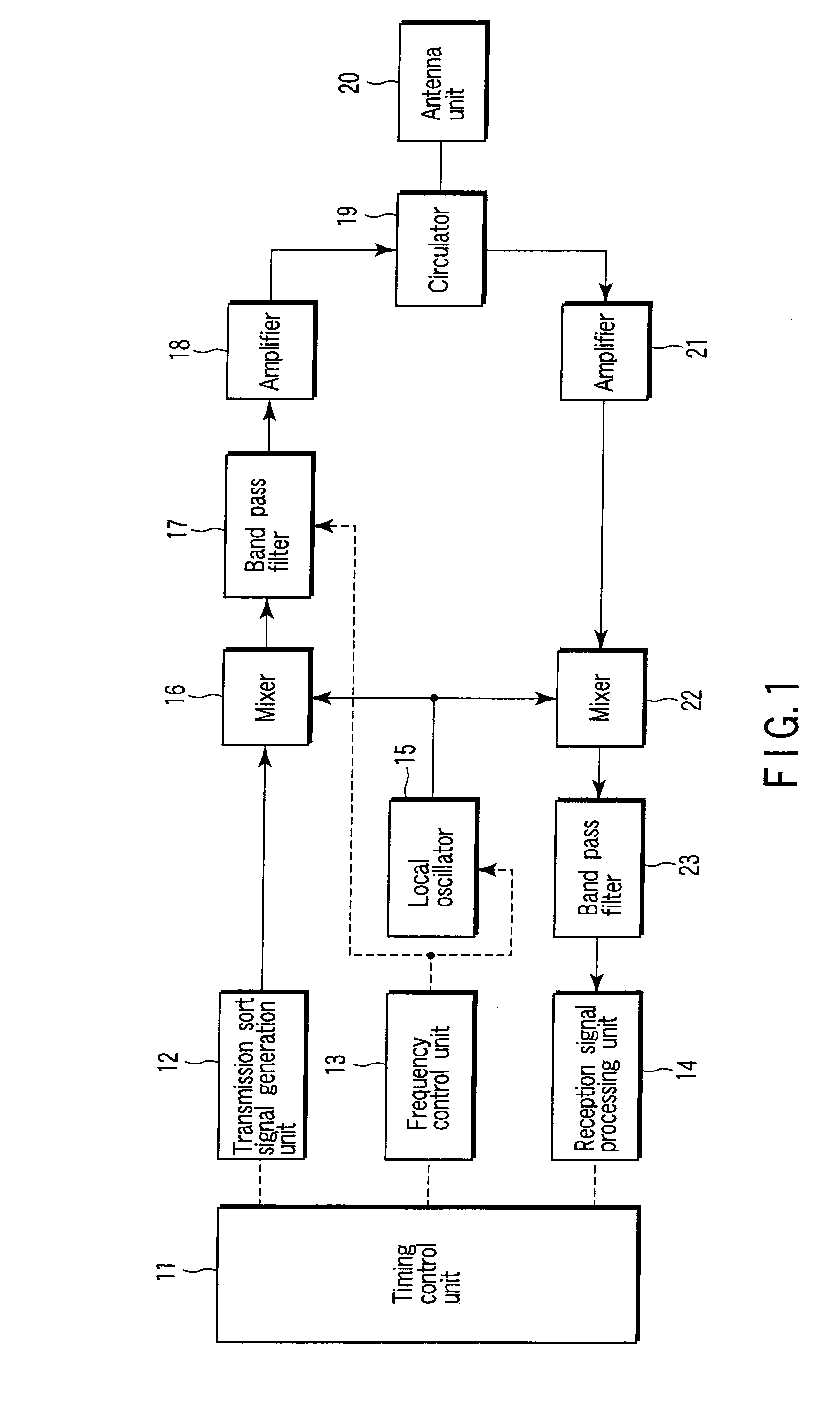

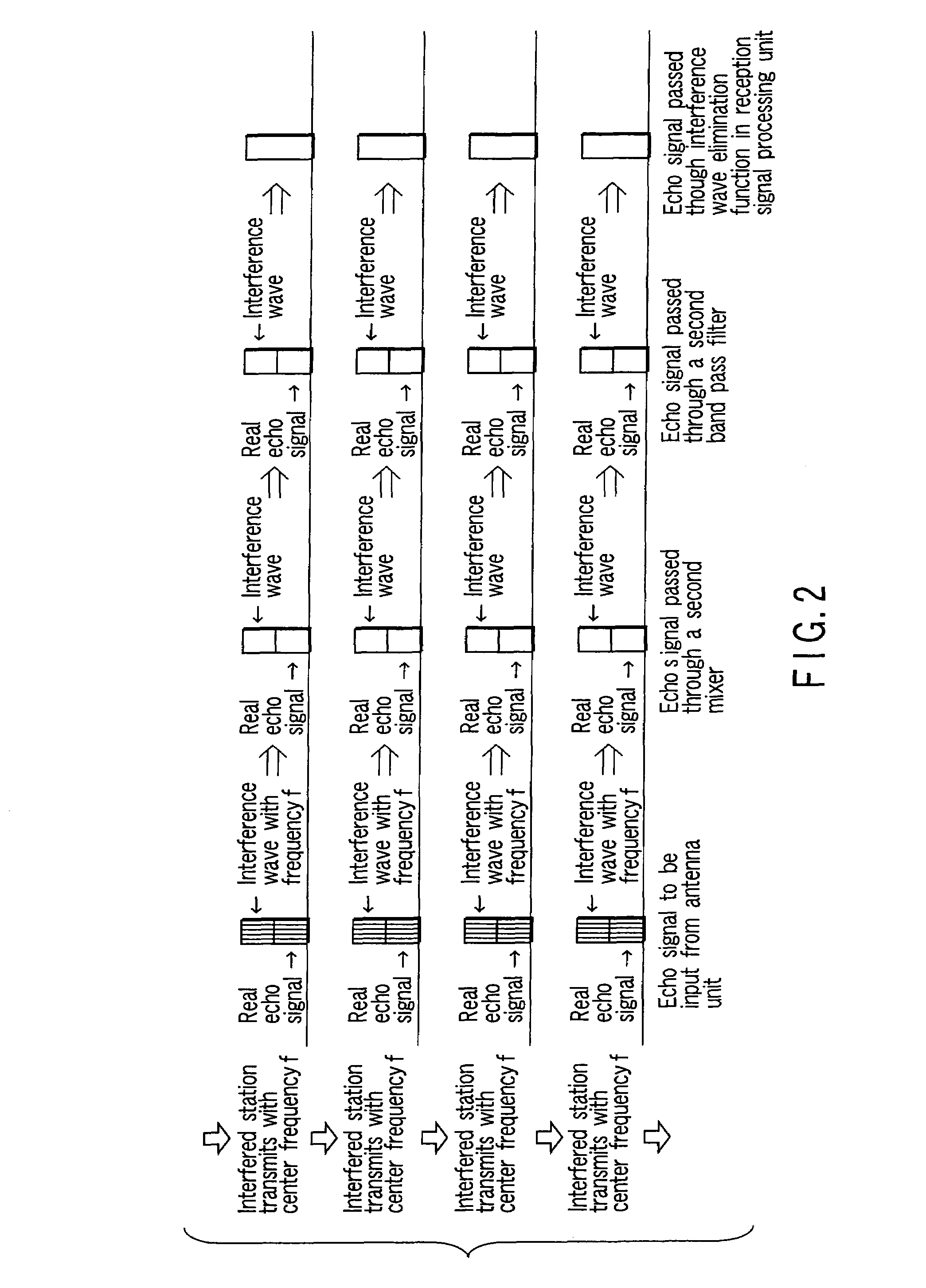

Radar device and method for adjusting among radar sites

InactiveUS20070229349A1Detection precision is loweredAffect precisionRadio wave reradiation/reflectionICT adaptationFrequency bandRadar

A radar device includes a generation unit, a transmission unit, and a control unit. The generation unit selectively generates a set of a plurality of transmission signals whose center frequencies are different from one another within an assigned frequency band. The transmission unit emits the transmission signals. The control unit controls the generation unit so as to vary the center frequencies for each emission of the transmission signals.

Owner:KK TOSHIBA

Locating of pressure taps on face of orifice plate device

ActiveUS9062994B2Accurate measurementHigh speedVolume/mass flow by dynamic fluid flow effectVolume/mass flow by differential pressureVena contracta diameterDifferential pressure

A process flow device that includes a self-averaging orifice plate type of primary flow element with a high pressure tap located on or incorporated into its upstream surface, and a low pressure tap located on or incorporated into its downstream surface, for measuring, by a differential pressure process, the volumetric rate of fluid flow at a point in a fluid carrying conduit where the velocity profile of the fluid is asymmetric with respect to the longitudinal axis of the conduit. The improved pressure tap configuration consists of two fluid conduits, one carried by each of the downstream and upstream faces of the orifice plate, establishing fluid communication between openings in the downstream and upstream faces of the orifice plate and their respective terminal pressure ports. Location of the pressure taps on the faces of the orifice plate in this manner allows for increased resolution of the pressure signals by minimizing the effects of upstream pipe flow disturbances on pressure taps used in conjunction with conditioning orifice plate primary flow elements, especially those with higher beta ratios.

Owner:DIETERICH STANDARD

Radar device and method for adjusting among radar sites

InactiveUS20080284638A1Detection precision is loweredAffect precisionICT adaptationRadio wave reradiation/reflectionRadarEngineering

Owner:KK TOSHIBA

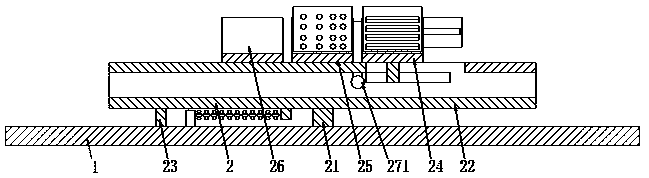

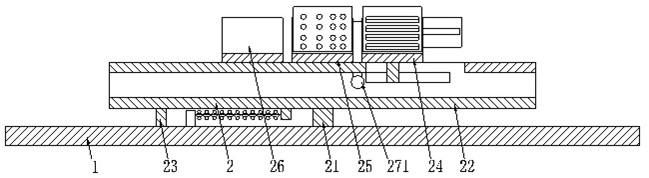

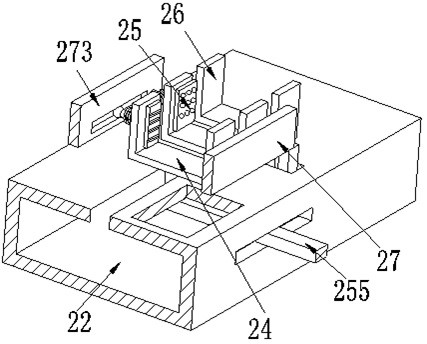

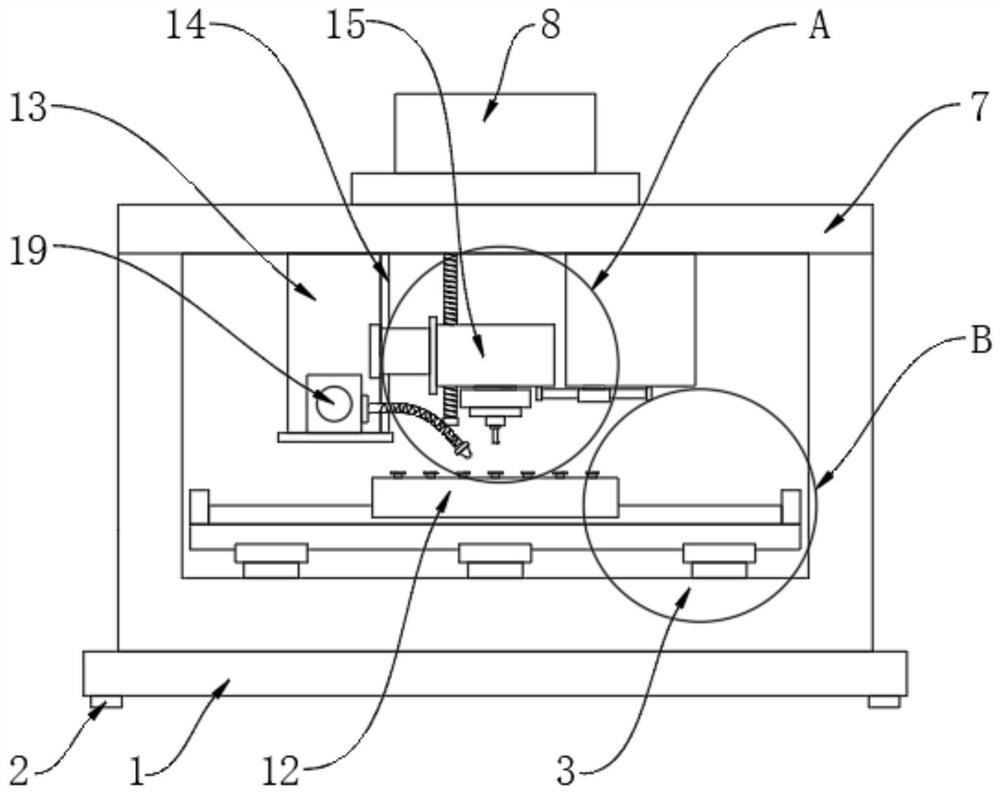

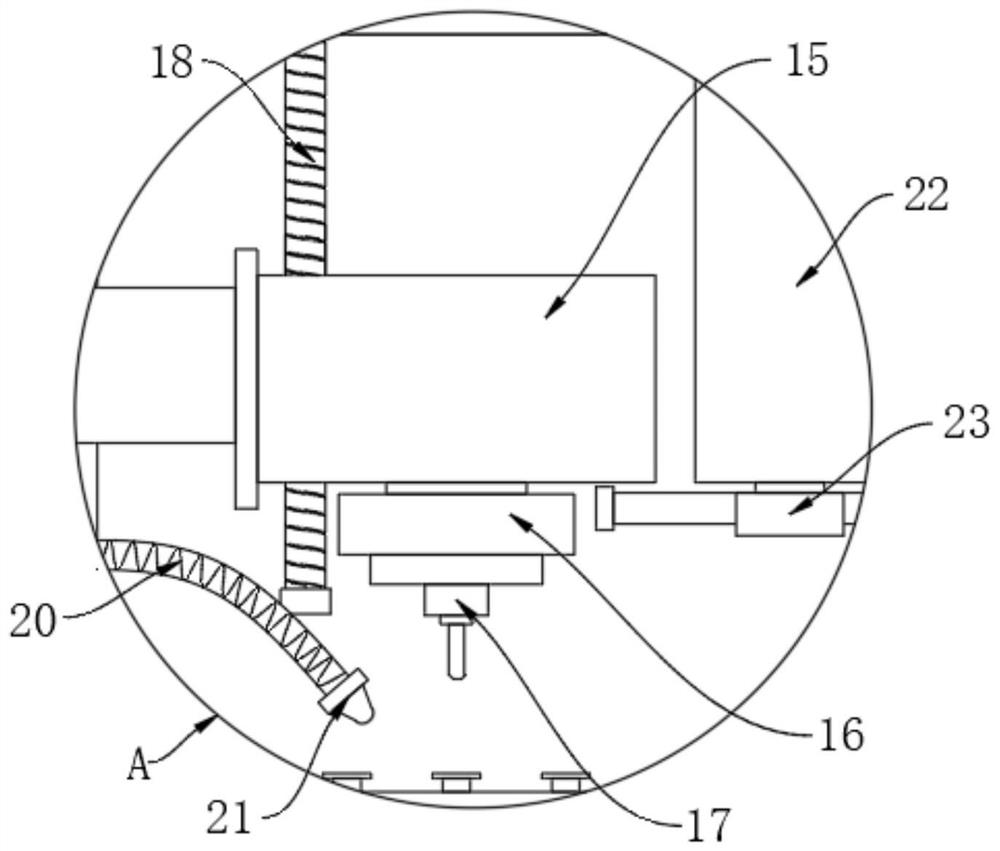

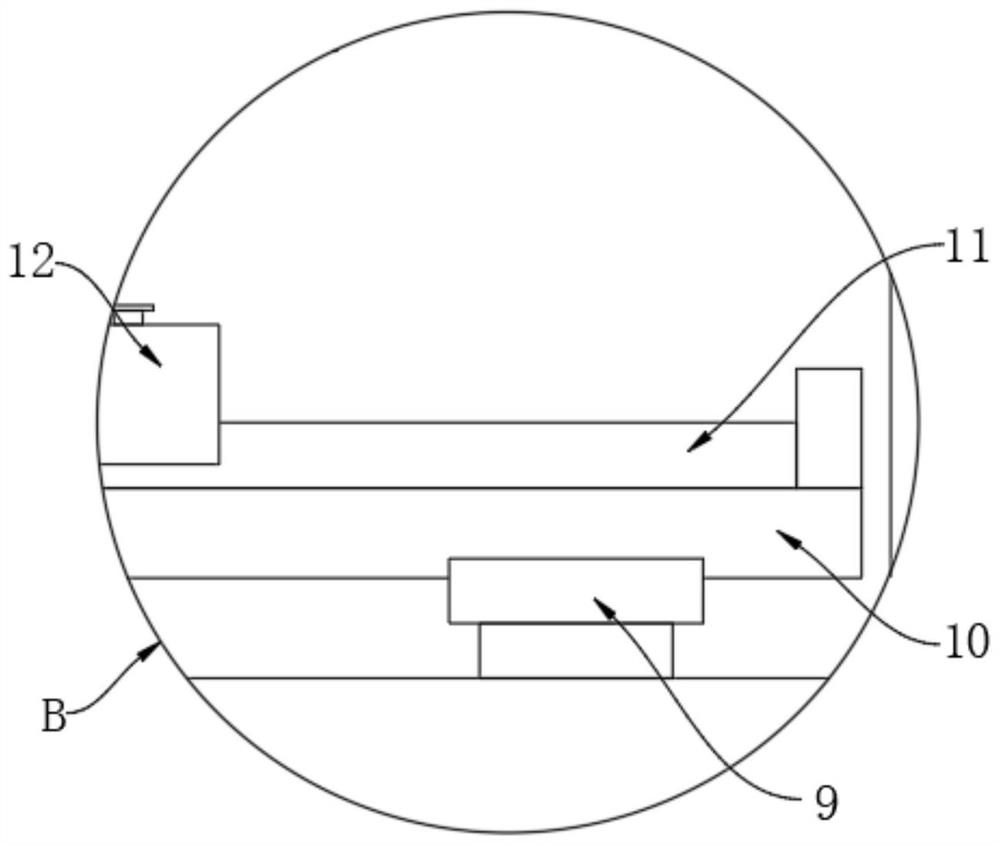

Fault detectable sheet body fixed distance conveying and punching assembly

ActiveUS20190389022A1Increase productivityLow efficiencyEdge grinding machinesGrinding carriagesPunchingAcoustic wave

The present invention relates to a fault detectable sheet body fixed distance conveying and punching assembly, which may include a rack, a conveying trough seat, a feeding trough, a processing rack and a punching device. On the rack is provided a feed motor and a feed screw. The movable feeding block is sleeved on the feed screw and the movable feeding seat is fixedly connected to the movable feeding seat. On the movable feeding seat is provided a feed lifting cylinder and on the feed lifting cylinder is provided a feed lifting block. On the feed lifting cylinder are equally provided feed blocks which may go through the feeding trough. On the processing rack is also provided a position detecting device which may include a detecting lifting cylinder provided on the processing rack. Under the detecting lifting cylinder is connected the detecting block. On the both sides of the detecting block is provided an acoustic wave range finder. The present invention includes a position detecting device, which may measure the position of the feeding block on the processing station by lifting the acoustic wave range finders on the position detecting device, and conduct integrity check to the fixed distance feeding part and maintain the entire assembly.

Owner:DONGGUAN UNIV OF TECH

Temperature-compensated in-vivo sensor

InactiveUS20100010323A1Accurate measurementBody temperature can fluctuateCatheterDiagnostic recording/measuringAnalyteMicrosphere

Owner:SANVITA MEDICAL CORPORATION

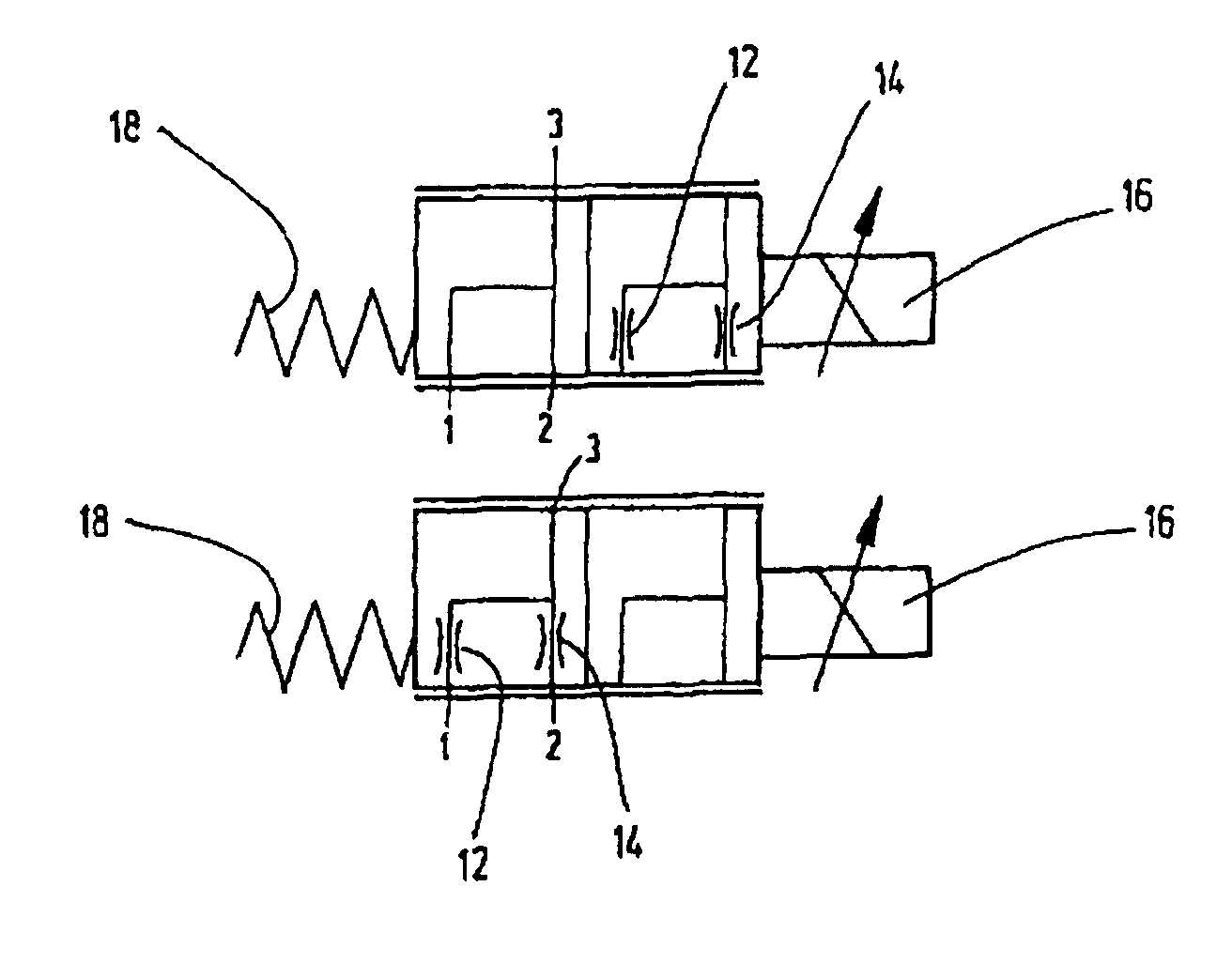

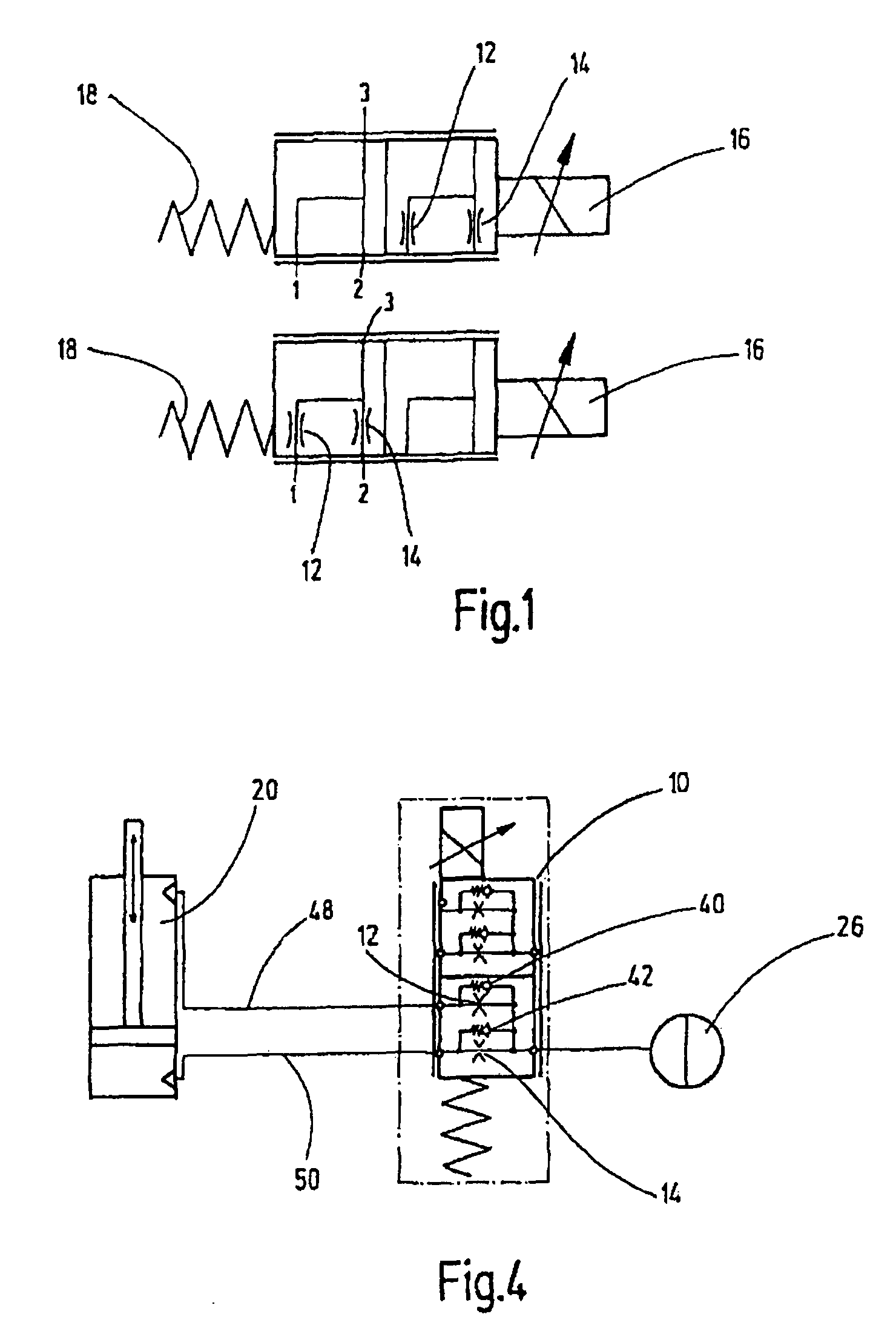

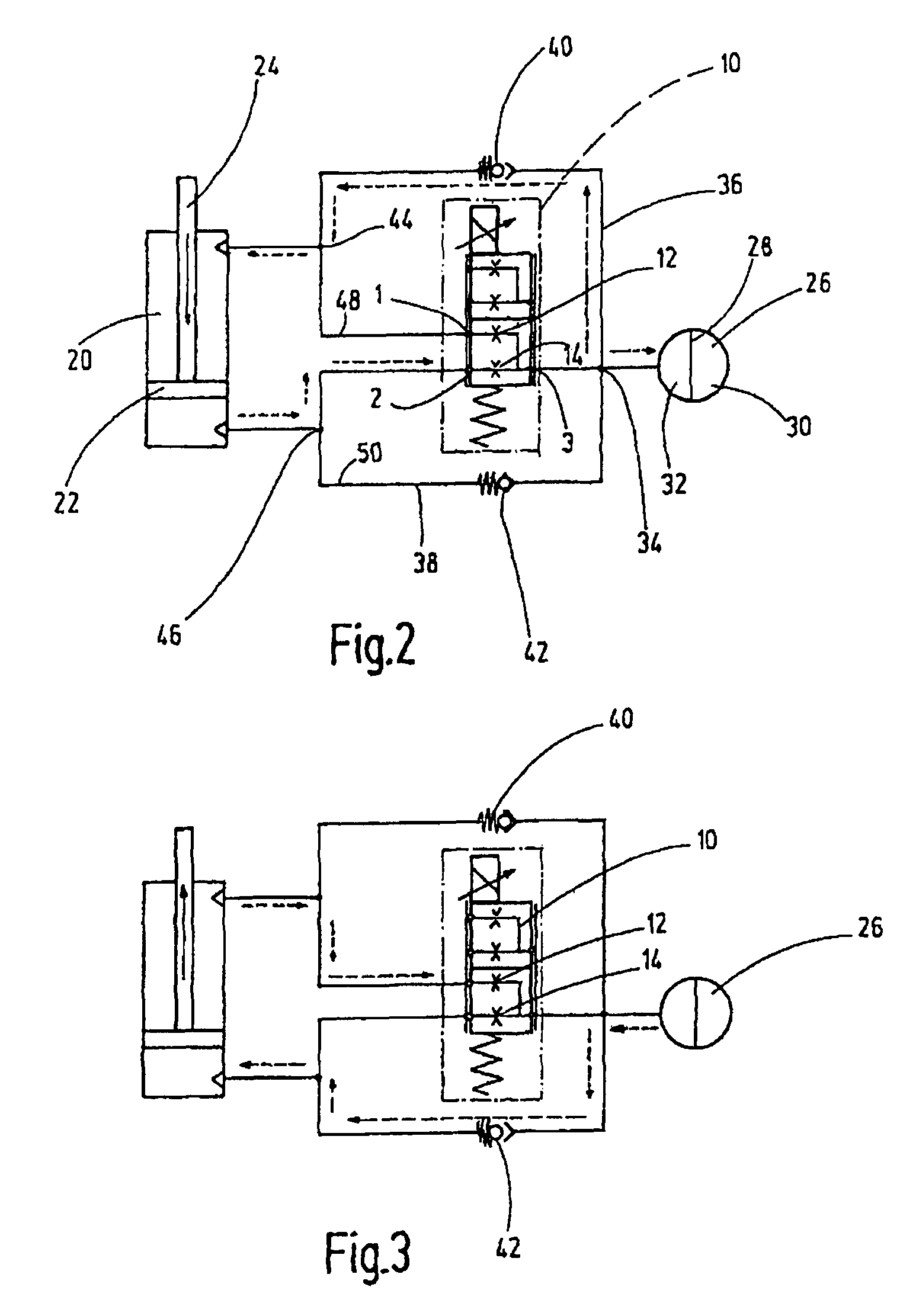

Damping system

ActiveUS8240646B2Simplified dampingConstant damping ratiosTorsion springsResilient suspensionsControl theorySpring system

A damping system, in particular in the form of a hydraulic cabin spring system, has at least one hydraulically triggerable actuating part (20) and has at least one hydraulic accumulator (26) connected to the actuating part (20). By a proportional throttle valve (10), proportional damping for the actuating part (20) is achieved. Variable proportional damping which can react to events in a manner specific to the user can be implemented.

Owner:HYDAC SYST

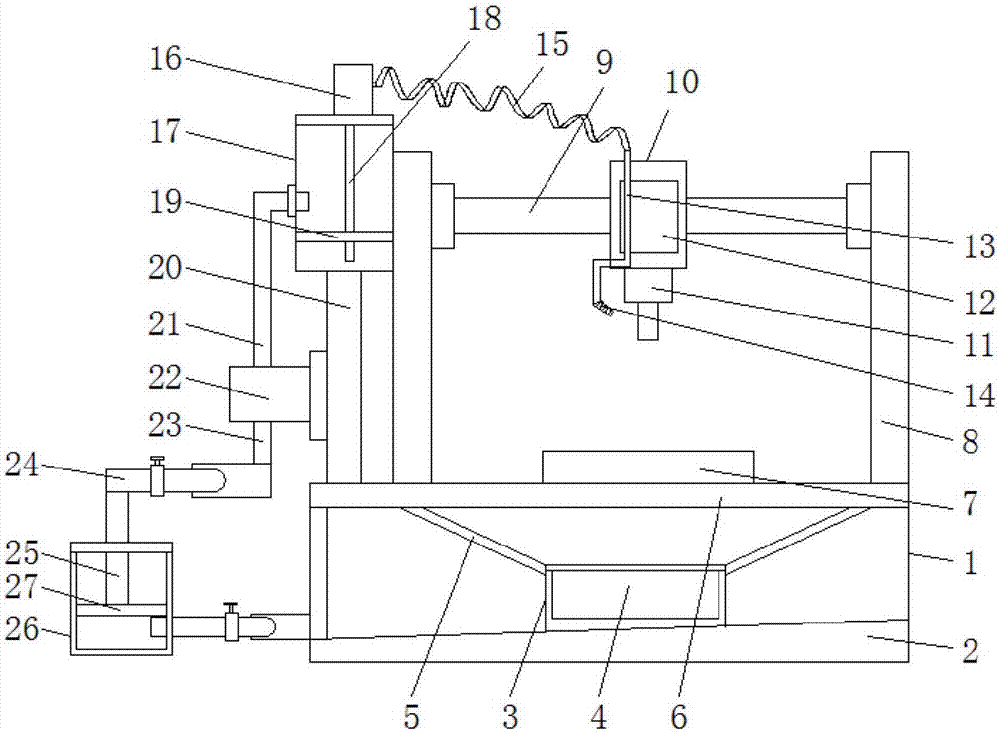

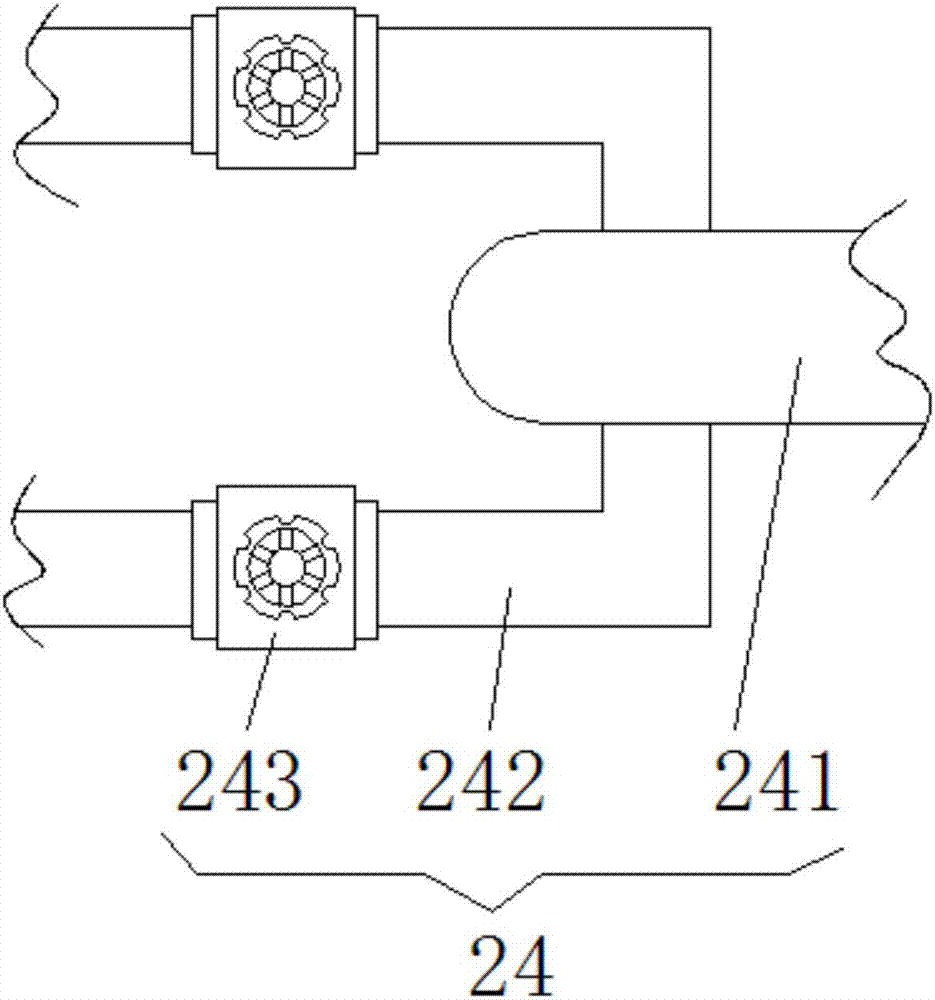

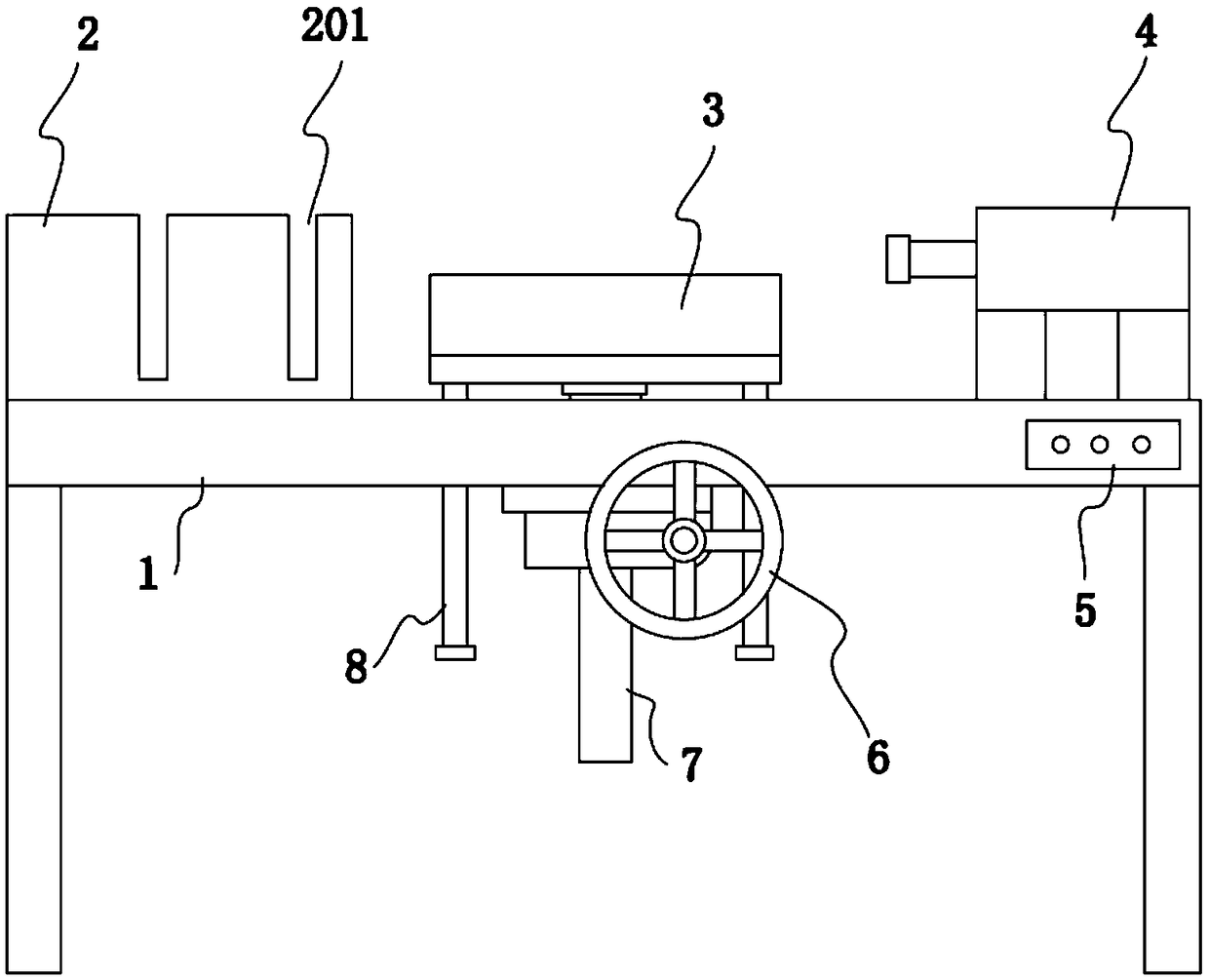

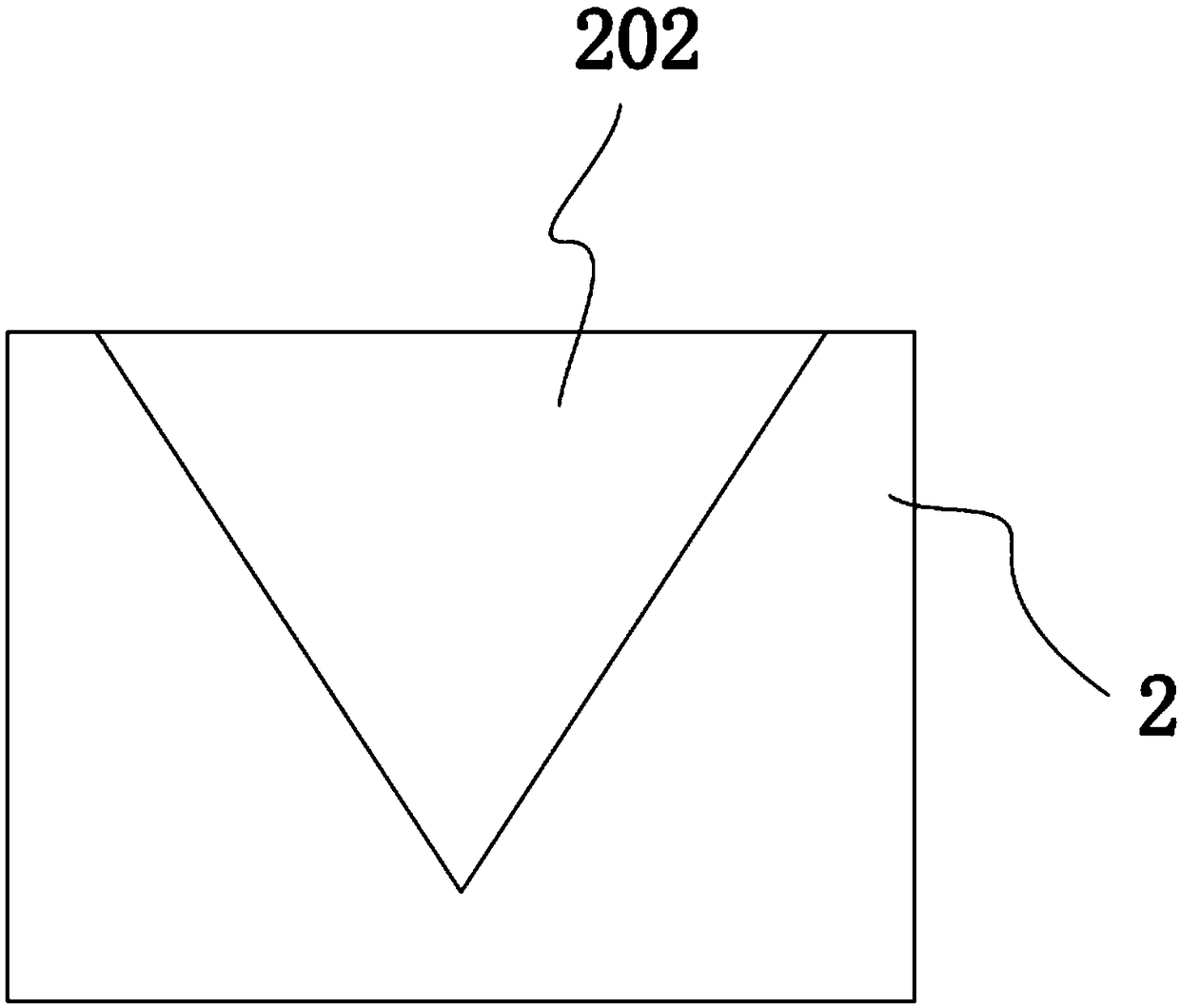

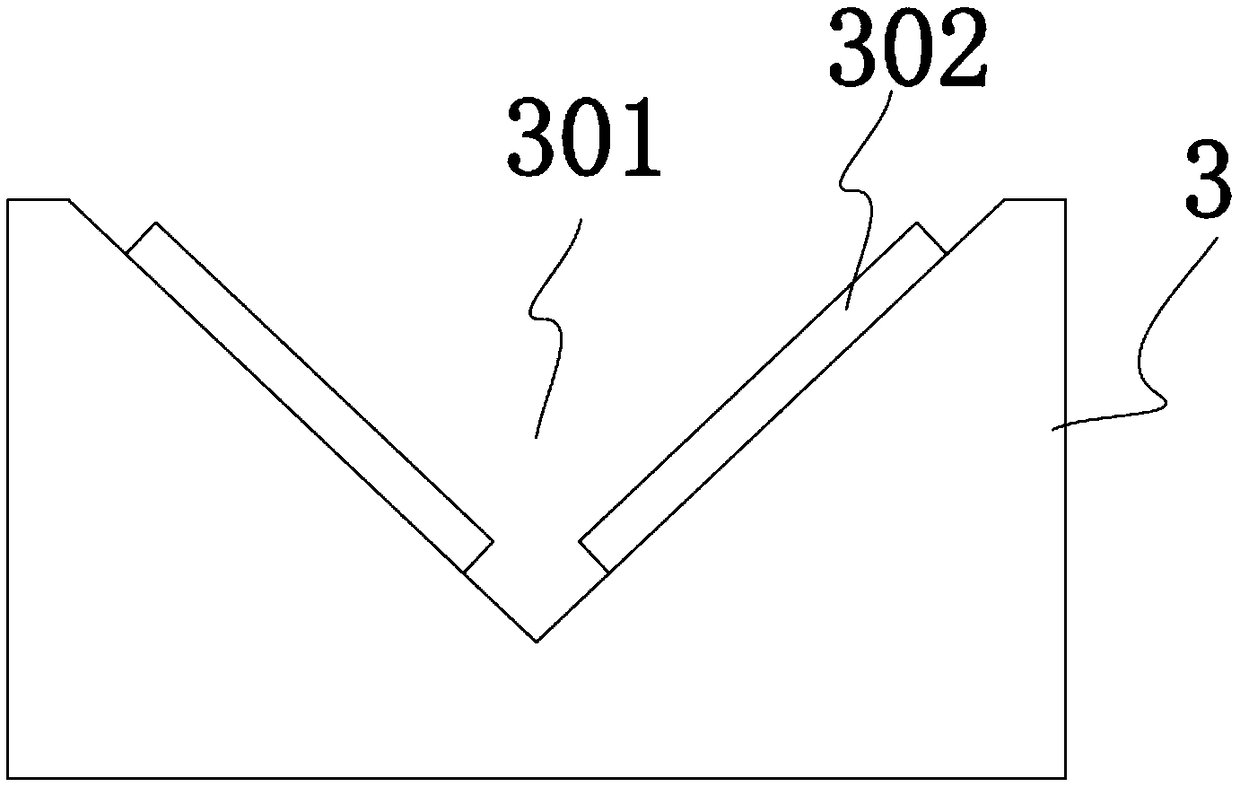

Lubricating device for lathe machining

InactiveCN107414589AValid importAffect precisionMaintainance and safety accessoriesEngineeringMachining

The invention discloses a lubricating device for lathe machining. The lubricating device for lathe machining comprises a machine table, wherein an internal plate is fixedly mounted at the bottom end of a cavity of the machine table; a fixed rack is fixedly mounted in the middle of the top end of the internal plate; an impurity collecting barrel is movably inserted in the fixed rack; side surfaces of the fixed rack are fixedly connected with sloping plates; the top ends of the sloping plates are fixedly connected with the bottom end of a supporting table; the supporting table is fixedly mounted at the top end of the machine table; and a machining table is fixedly mounted in the middle of the top end of the supporting table. According to the lubricating device for lathe machining, two precipitating tanks are matched with two flow distributing devices, collected lubricating oil is precipitated, tiny impurities which are doped in the lubricating oil are precipitated, by independent control of the other flow distributing device, the precipitated lubricating oil is guided out and used, precipitation is implemented by the two precipitating tanks alternately, therefore, the content of the impurities in the lubricating oil is greatly reduced, the purity of reused lubricating oil is improved, and the lubricating effect and long-time supply efficiency and effect are ensured.

Owner:周晓红

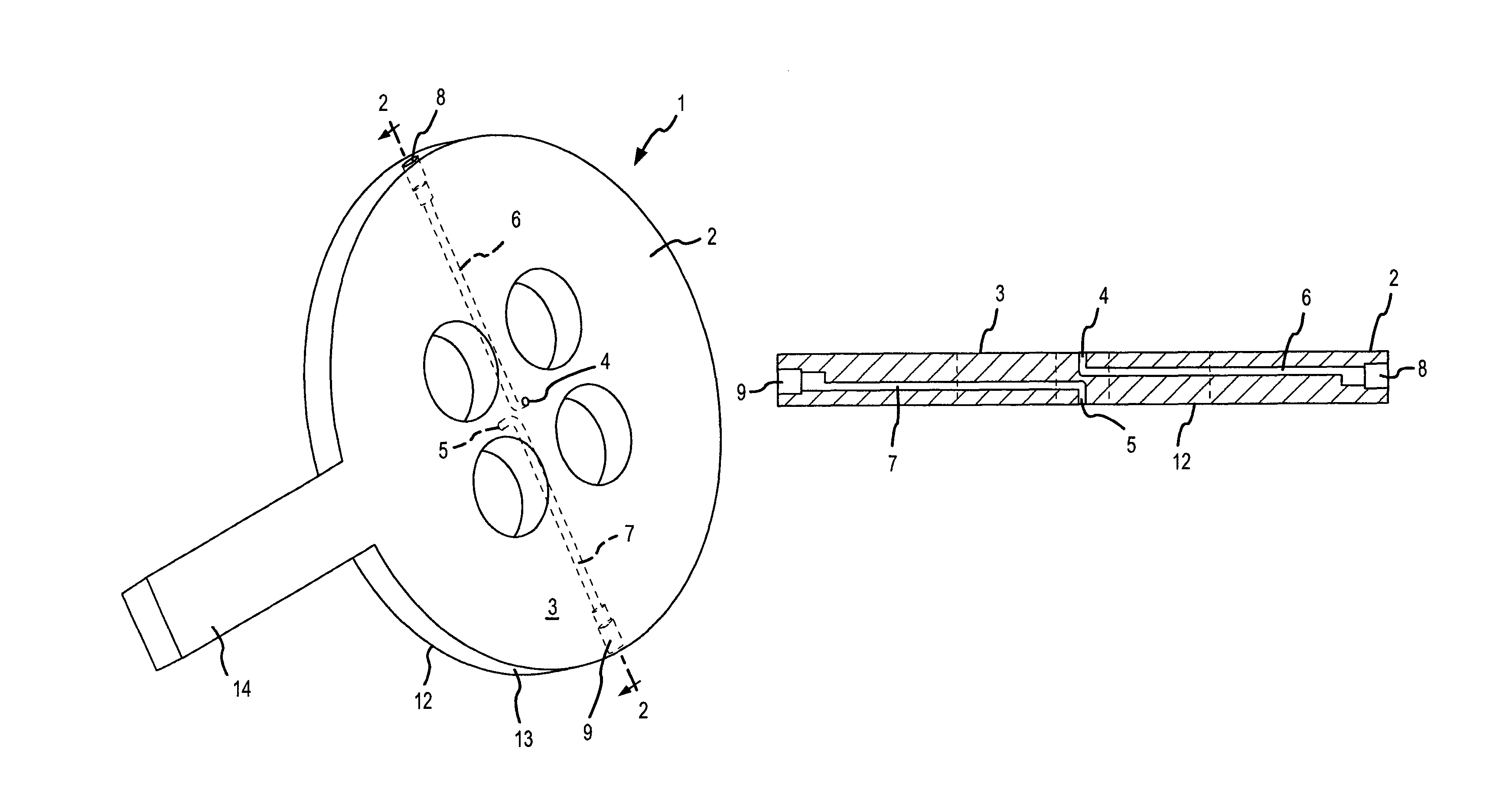

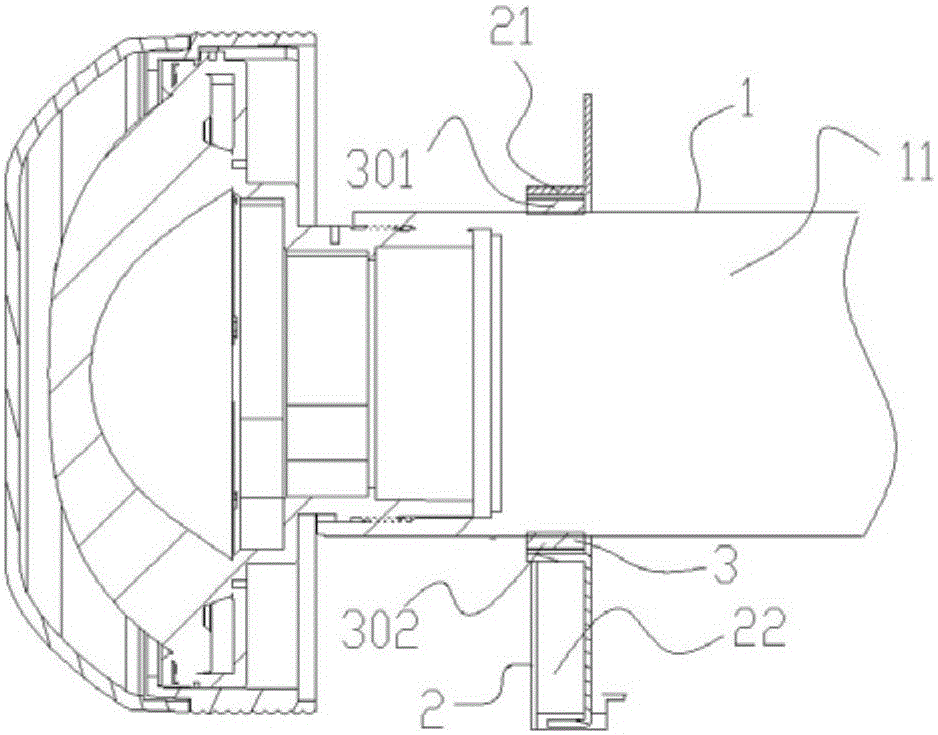

Lens module and projection device

The invention discloses a lens module and a projection device. The lens module comprises a lens cone, a supporting part and a buffering part, wherein the supporting part is arranged on the lens cone in a sleeving mode and supports the lens cone, the buffering part is arranged between the lens cone and the supporting part, and the buffering part is provided with a main portion and multiple buffering portions. Each buffering portion is provided with a boss and a connecting portion, wherein the boss abuts against the lens cone, the connecting portion is connected with the main portion and the boss, and the connecting portion can deform. Hollow areas are form in the buffering part and correspond to the bosses, a gap is formed between the buffering part and the lens cone, and the gap and the hollow areas are used for providing a space for deformation of the buffering portions so that external impact can be buffered effectively, the situation that poor images are generated due to deviation of the light path of a lens can be avoided, and imaging quality can be guaranteed. Meanwhile, the buffering part abuts against the lens cone and deforms to counteract assembly tolerance, and the situation that the precision of the light path is affected due to deviation of the light path when local stress is too large is avoided.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD

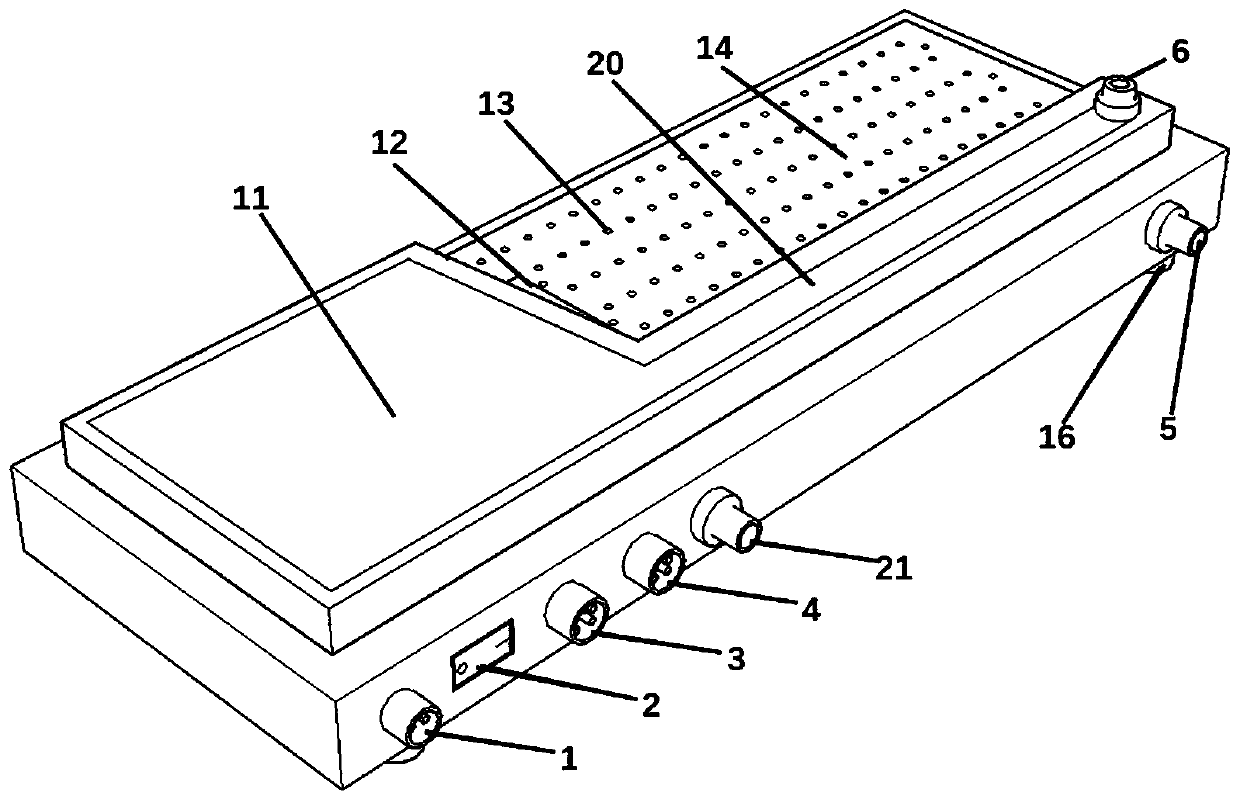

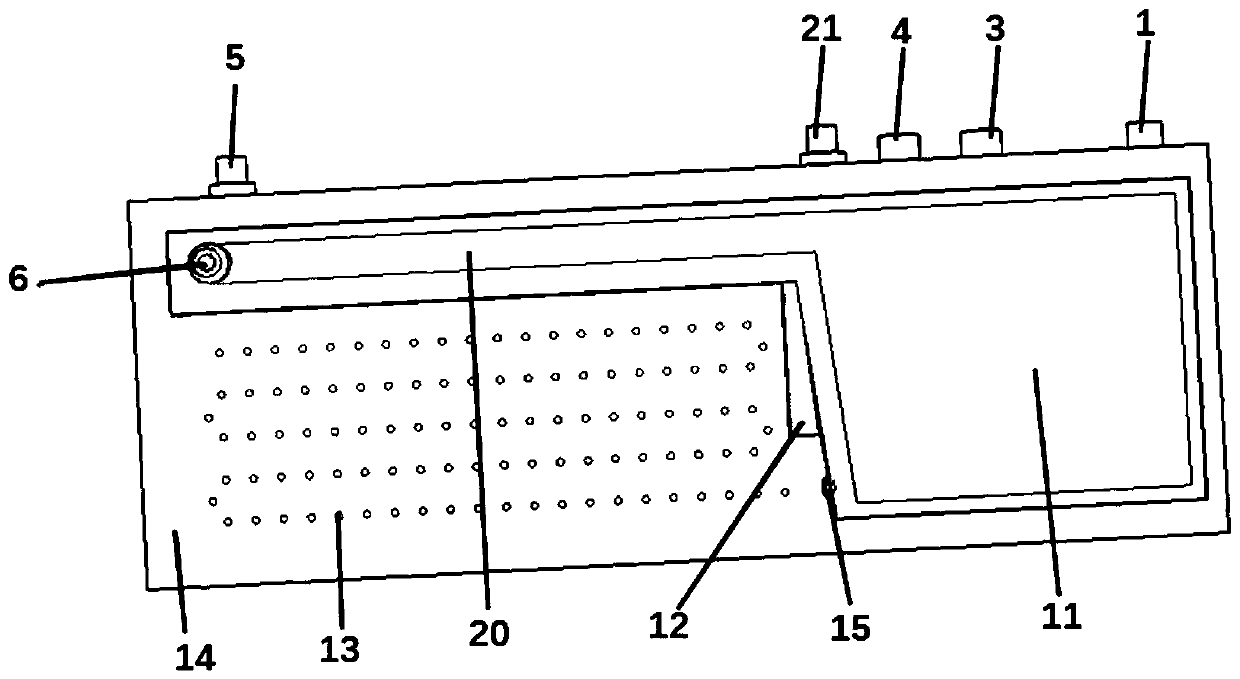

Surface flatness testing device and method thereof

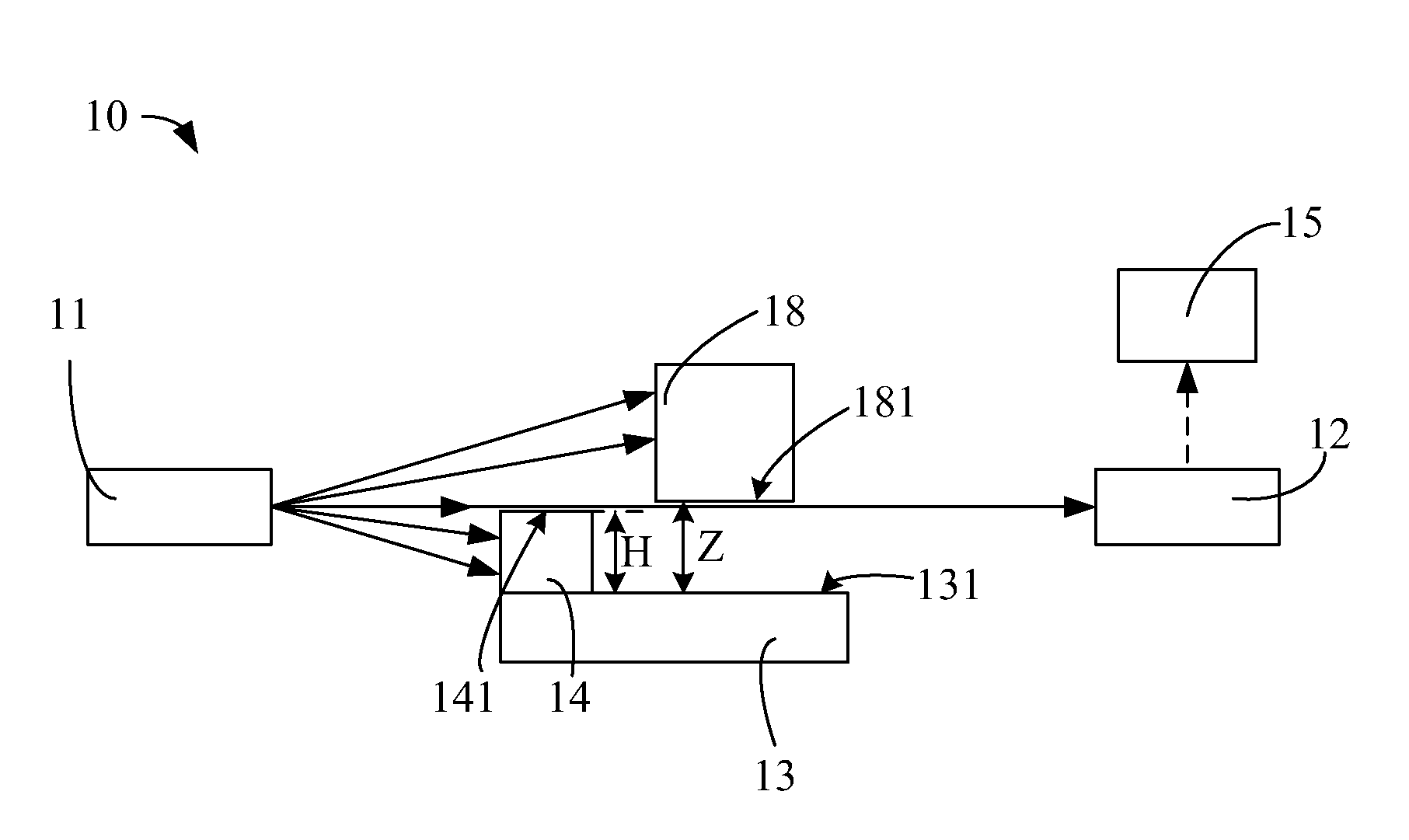

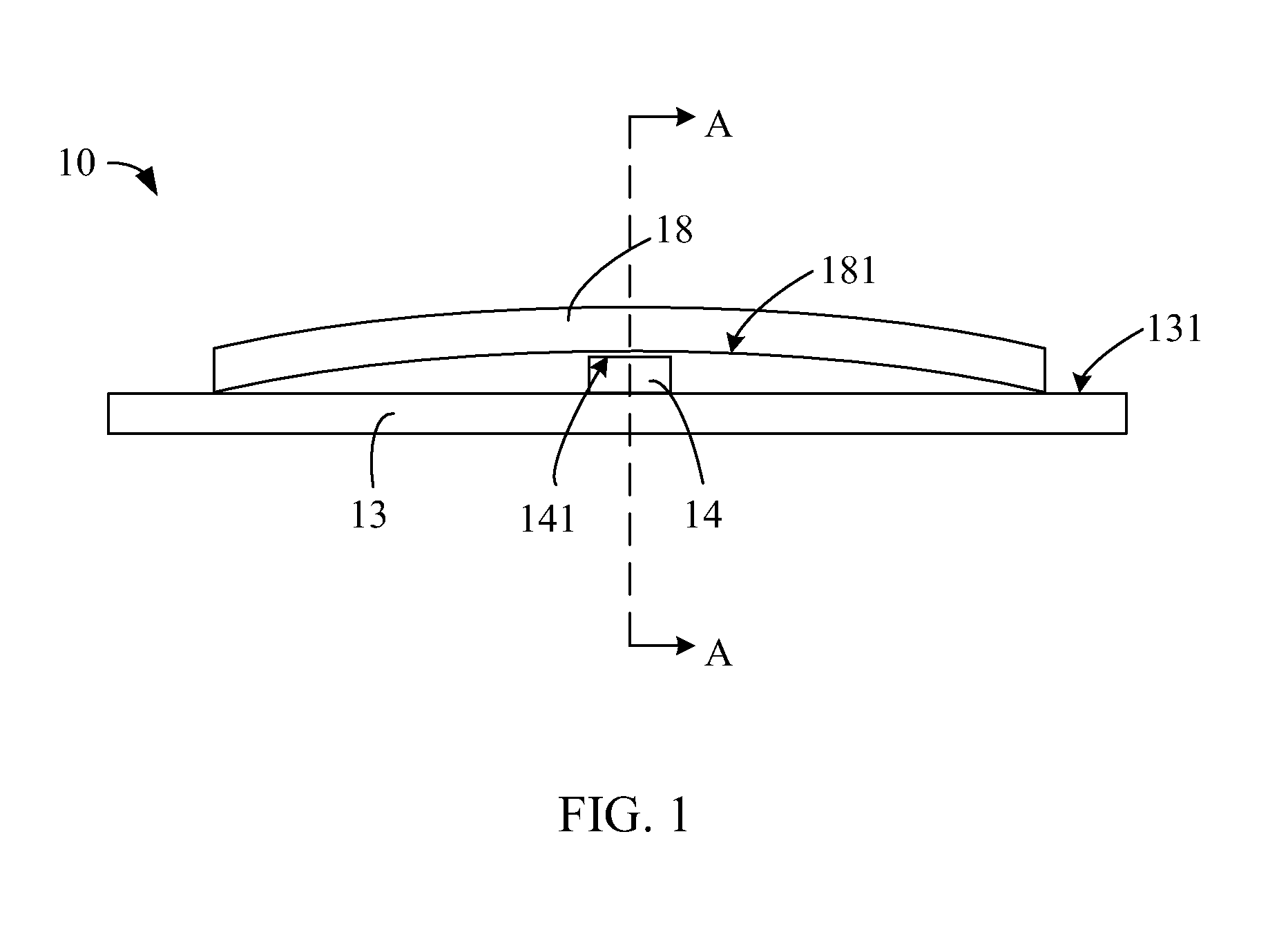

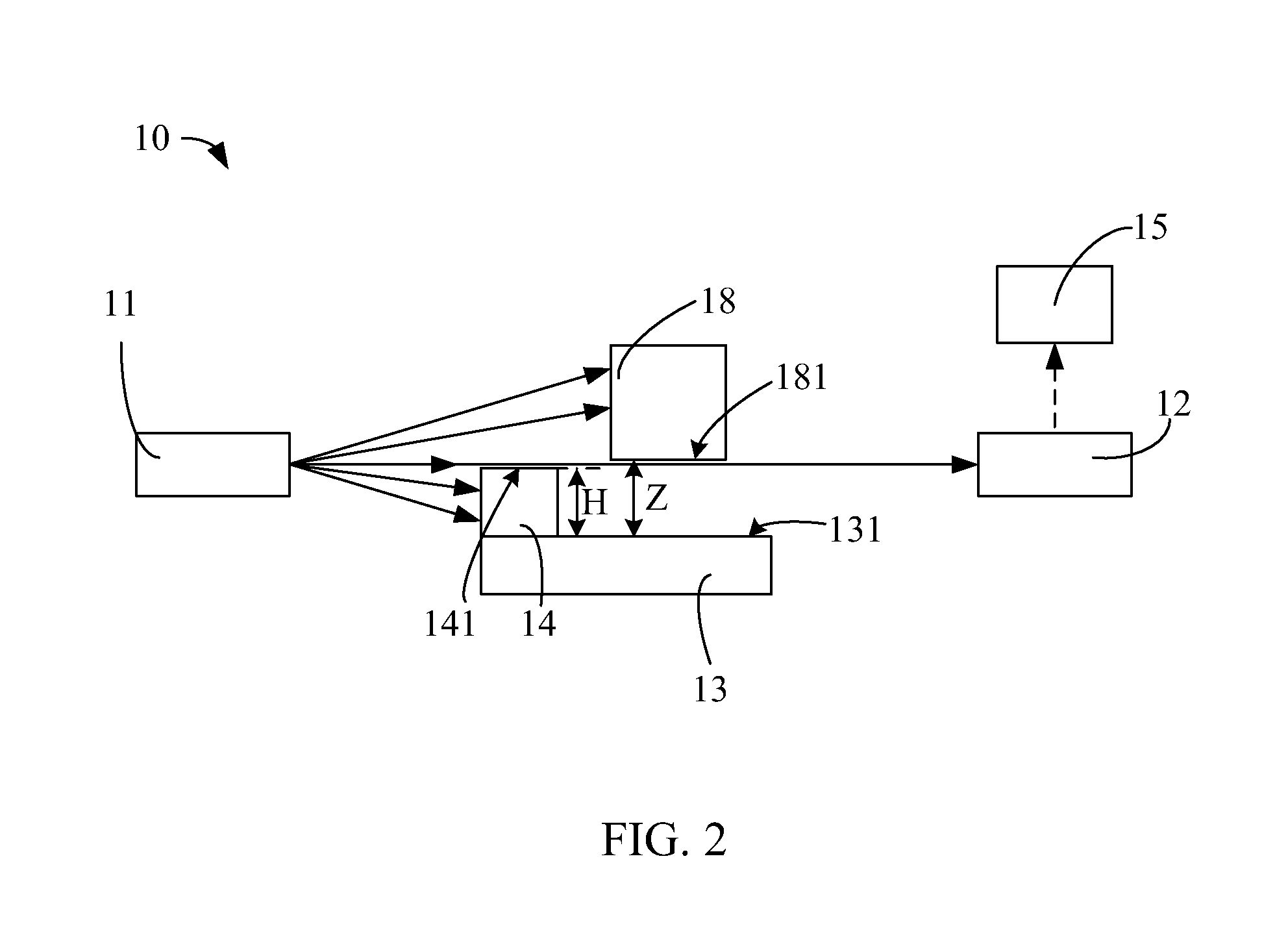

InactiveUS20080225280A1Method is lowImprove errorOptically investigating flaws/contaminationUsing optical meansEngineeringSurface flatness

An exemplary surface flatness testing device (10) includes a light emitting unit (11), a light receiving unit (12), a platform (13), an adjusting unit (14) and a processing unit (15). The light receiving unit faces the light emitting unit. The platform is located between the light emitting unit and the light receiving unit, which is configured for holding a workpiece (18) having a testing surface (181). The adjusting unit is disposed between the light emitting unit and the light receiving unit. The adjusting unit and the testing surface of the workpiece are controlling light from the light emitting unit to the light receiving unit. The processing unit is configured for processing signals from the light receiving unit. The present invention also provides a surface flatness testing method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Metal pipe fitting machining method

The invention provides a metal pipe fitting machining method, and relates to the technical field of mechanical manufacturing and machining. A plurality of steps of pipe fitting cutting, pipe fitting notch processing, pipe fitting positioning and clamping, welding operation, weld joint processing, storage and the like need to be performed on metal pipe fittings during operation. By means of the method, the problems that in the angle butt joint welding process of existing metal pipe fittings, the existing pipe fittings need to be manually controlled for angle adjustment according to angles of the welded pipe fittings when being connected in a welding mode, a clamp needs to be manually controlled for fixing the pipe fittings during operation, the welding angle precision of the manually-adjusted pipe fittings is poor, the connection angle precision of the pipe fittings is affected, the angles of the pipe fittings are manually adjusted for welding operation, the pipe fittings need to be manually adjusted accordingly for different welding angles, the angle adjusting precision is low, and work efficiency and pipe fitting welding quality are affected can be solved.

Owner:宁波迪亚工业设备有限公司

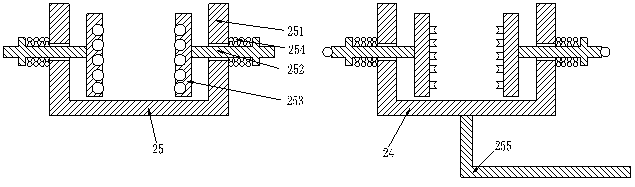

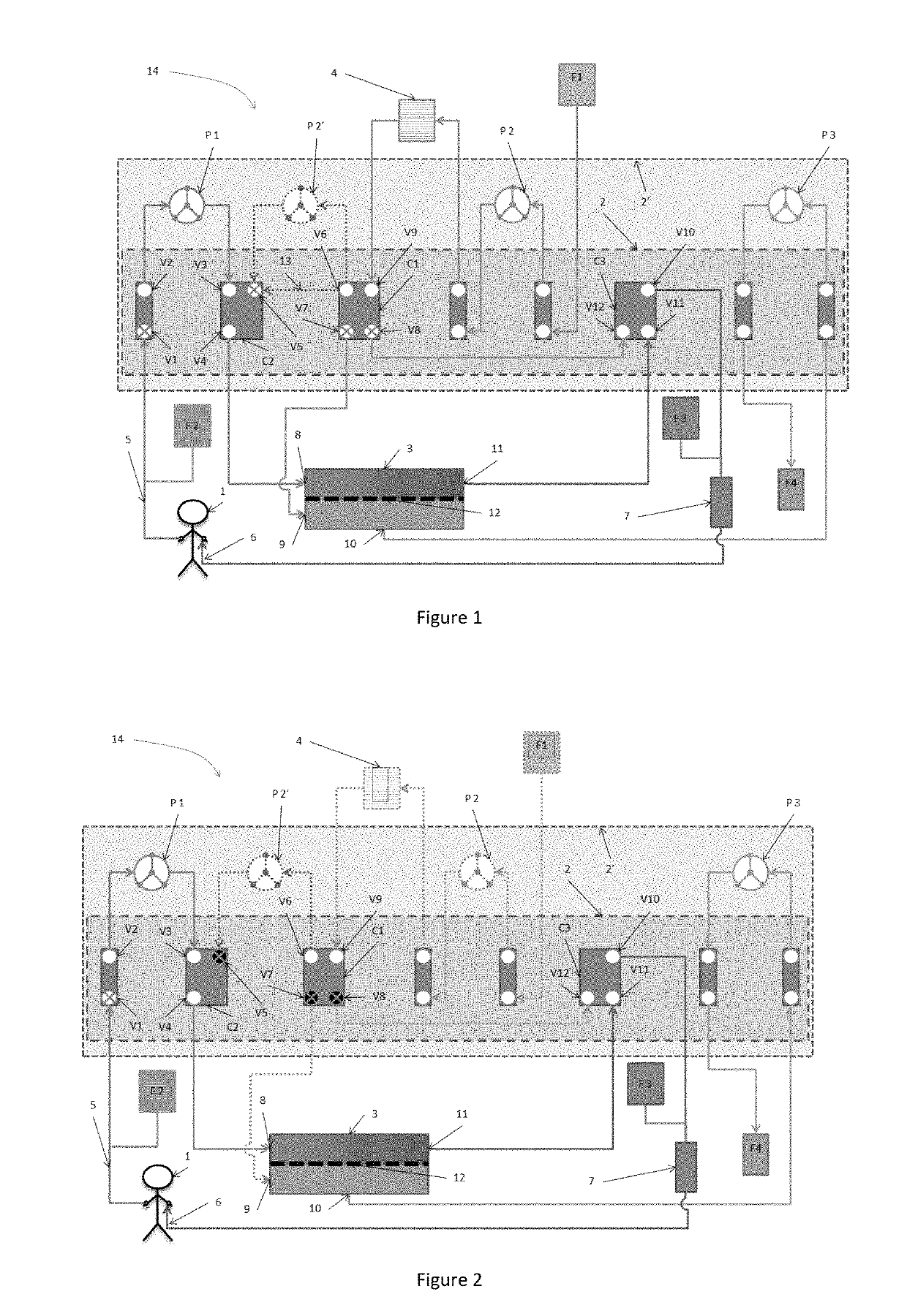

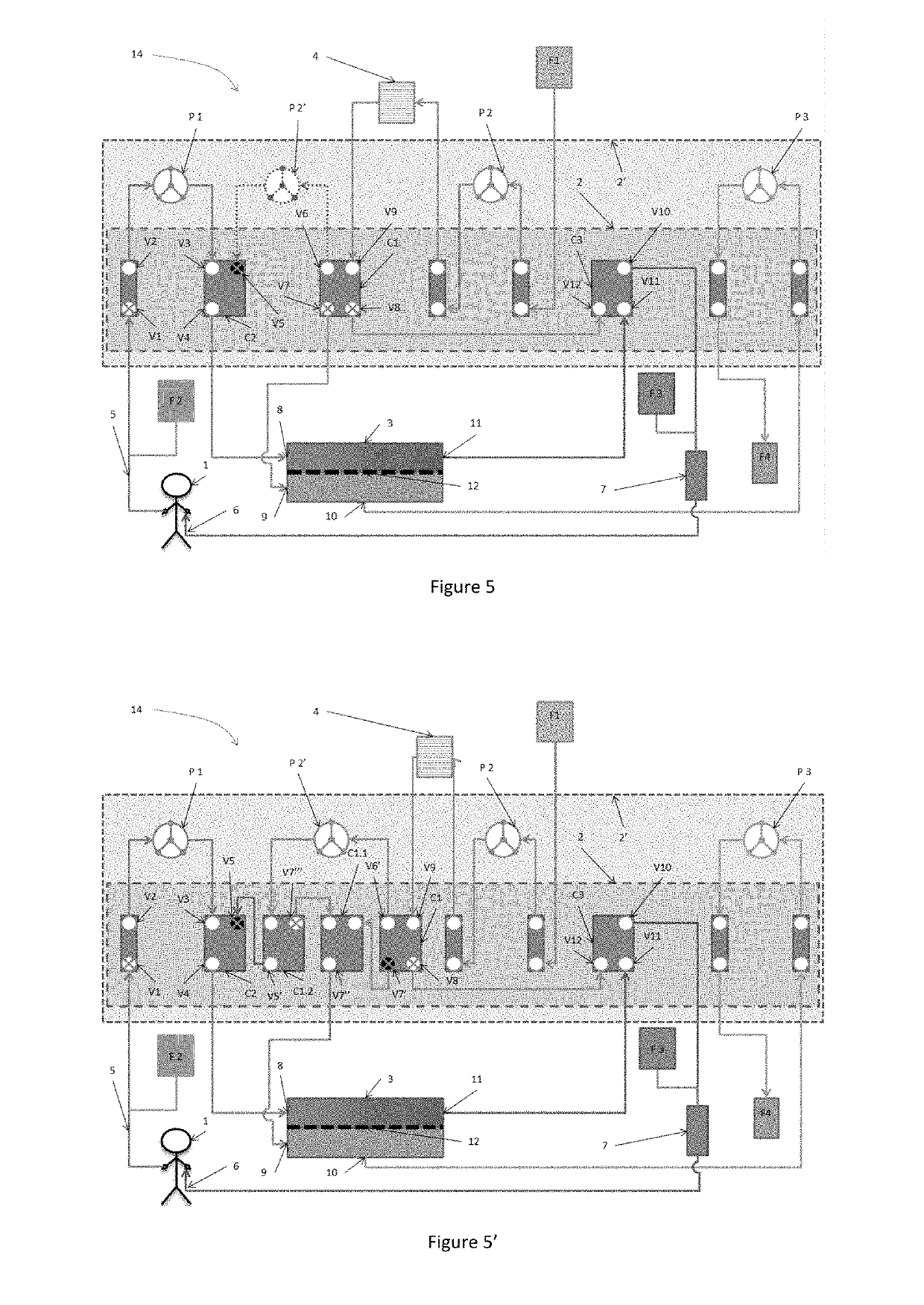

Device for extracorporeal blood treatment

ActiveUS20190120261A1Precise functionOvercome problemsEngine diaphragmsOther blood circulation devicesBlood treatmentsUrology

The invention relates to a system for treating blood, which includes a single cassette capable of carrying out the various CRRT treatments.

Owner:DEBIOTECH SA

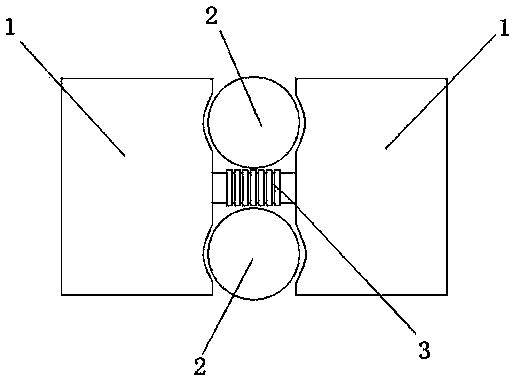

Rolling needle and rolling ball combined rolling body for bearing

InactiveCN103883617AAvoid damageStable supportBall and roller bearingsBearing componentsStress pointBall type

The invention discloses a rolling needle and rolling ball combined rolling body for a bearing. The rolling body comprises two same rolling needle bodies and multiple rolling ball bodies, wherein the two rolling needle bodies are connected and the rolling ball bodies are arranged between the two rolling needle bodies. Compared with the prior art, the rolling needle type rolling bodies and rolling ball type rolling bodies of the bearing are combined and three stress points contact an outer ring and an inner ring of the bearing simultaneously, so that the bearing has strong wear resistance and can still rotate when the rolling needle bodies or the rolling ball bodies are damaged.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

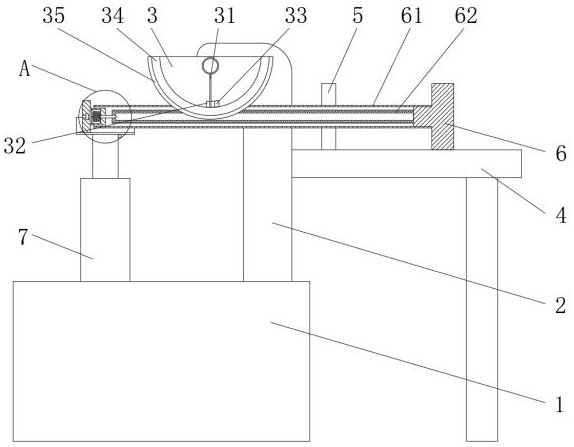

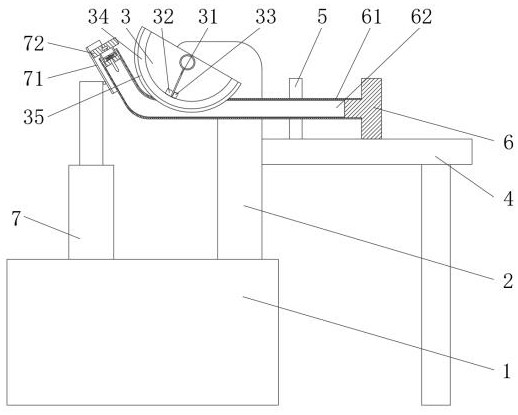

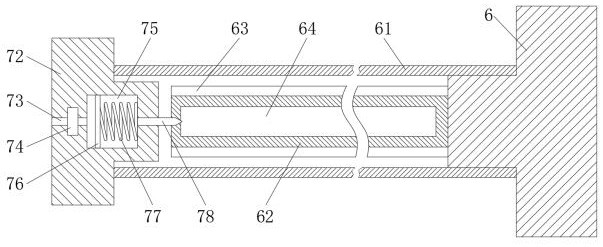

Hydraulic jack assembly equipment

PendingCN108817897AAffect precisionReduce frictionMetal working apparatusHydraulic cylinderJackscrew

The invention discloses hydraulic jack assembly equipment. The hydraulic jack assembly equipment comprises a machine frame, a cylinder block positioning seat, a piston positioning seat and a horizontal pushing hydraulic cylinder. The cylinder block positioning seat and the horizontal pushing hydraulic cylinder are separately installed and fixed to the two ends of the machine frame. The piston positioning seat is fixed to a top plate by bolts, and a connecting sleeve is fixed to the center position of the lower surface of the top plate. The connecting sleeve is rotatably connected to the top end of a stud, and a fixing seat is fixed to the bottom of the machine frame by bolts. A worm wheel is rotatably disposed in the fixing seat, and the worm wheel and the stud are connected through threads. The fixing seat is further rotatably connected with a rotating shaft, and the rotating shaft is integrally provided with a worm. By rotating an adjusting wheel, the worm on the rotating shaft is used for driving the worm wheel to rotate, and then the worm wheel drives the stud to drive the top plate to push a piston rod positioning seat to move up and down, so that the height of a piston rod isadjusted, the shaft axes of the piston rod and a cylinder block are coincident, and the hydraulic jack assembly equipment can be used for assembly of jacks of different specifications to improve theassembly speed.

Owner:安徽南方煤矿机械有限公司

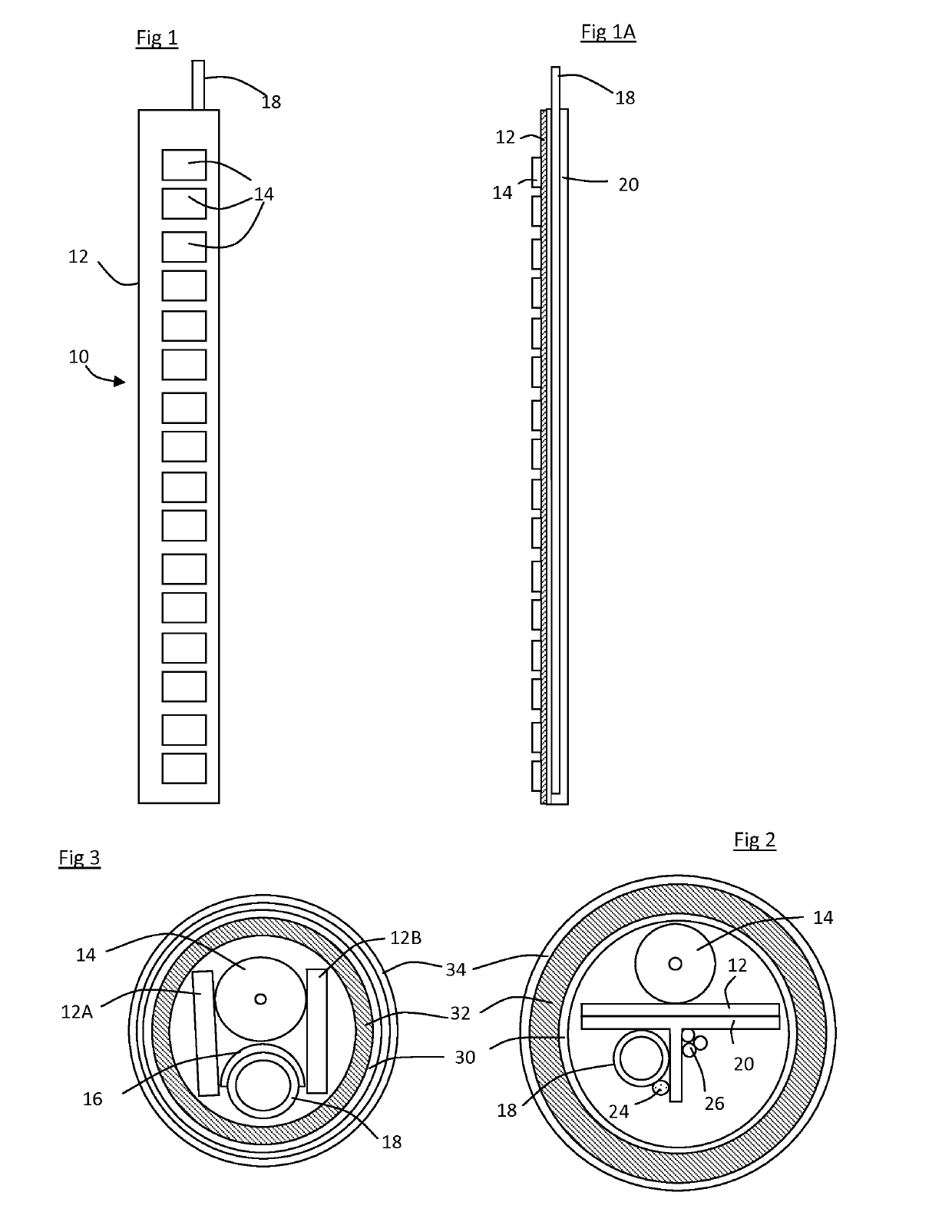

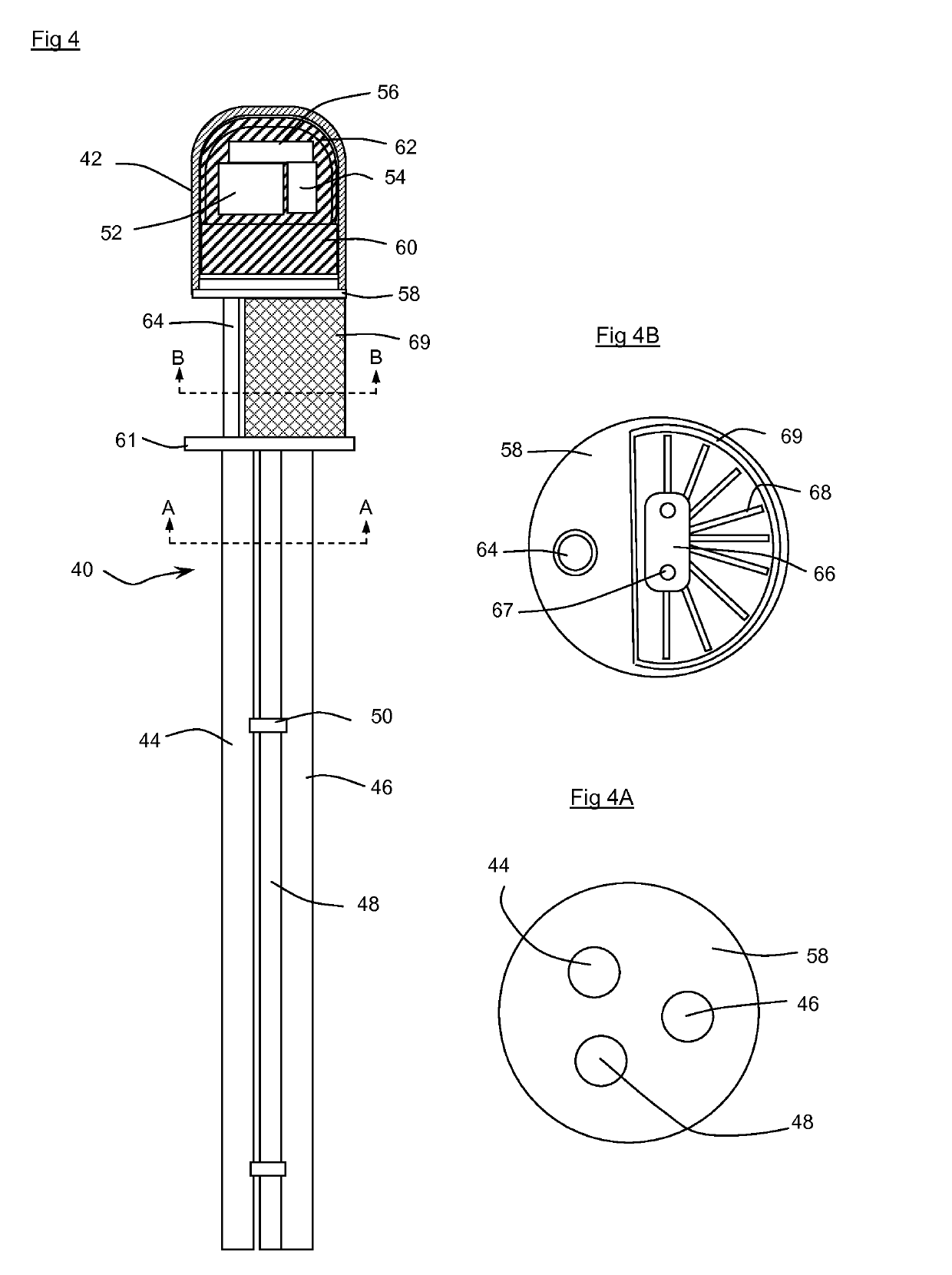

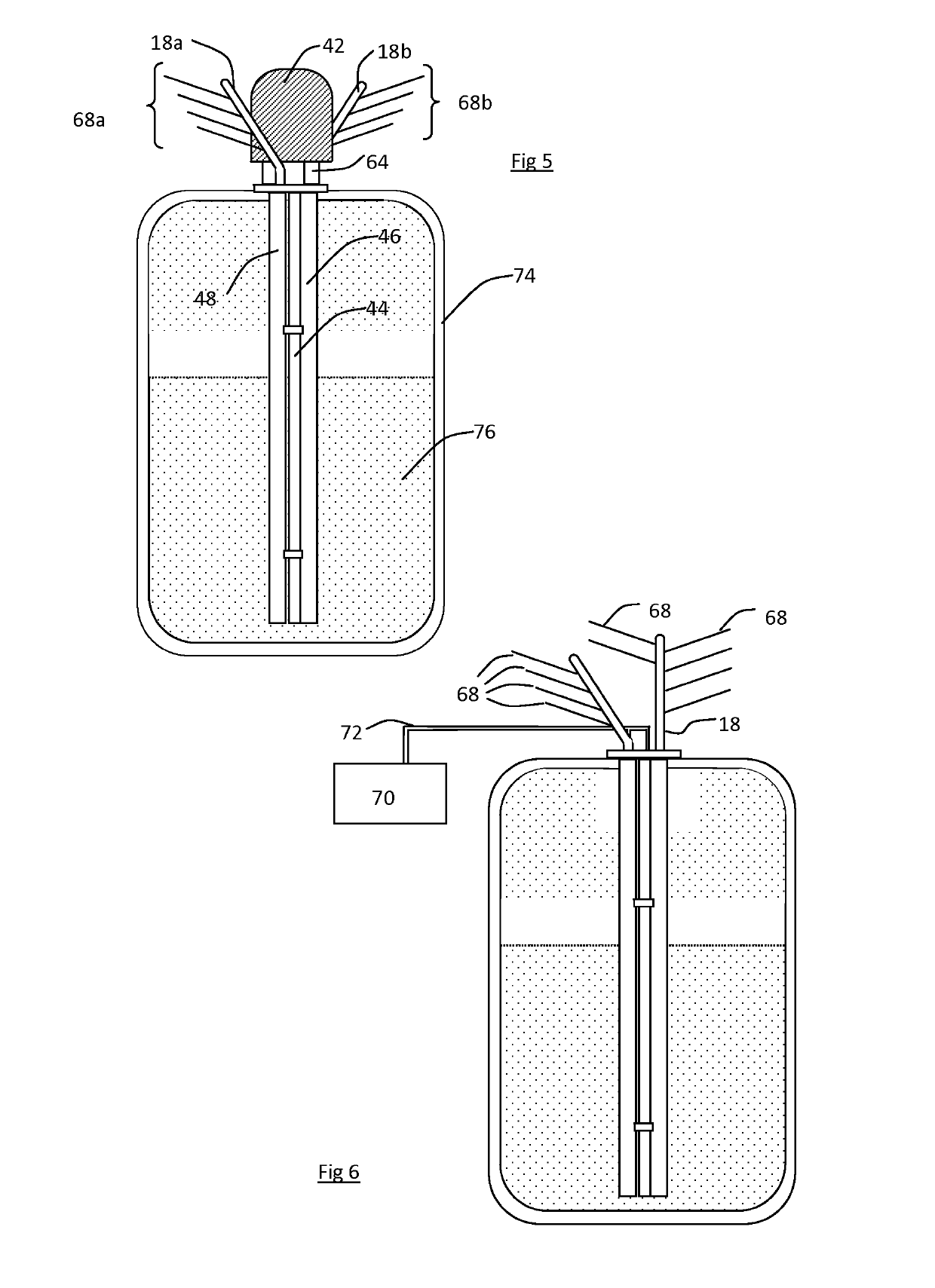

Radiation detector

ActiveUS10458834B2Easy to useEfficient removalElectric discharge tubesMachines/enginesHeat pipeInstrumentation

A detector probe, for detecting ionizing radiation and which is suitable for use in a nucleonic instrument usable in locations having a high ambient temperature, includes an array of radiation detectors mounted on a support and a heat pipe for cooling the detector probe. The nucleonic instrument incorporating such a detector probe is also described.

Owner:JOHNSON MATTHEY PLC

A split-type respiratory oxygen consumption real-time monitoring device

ActiveCN110623670BHigh measurement accuracyReduce labor intensityAnimal housingRespiratory organ evaluationWater storageHydrology

Owner:ZHEJIANG UNIV

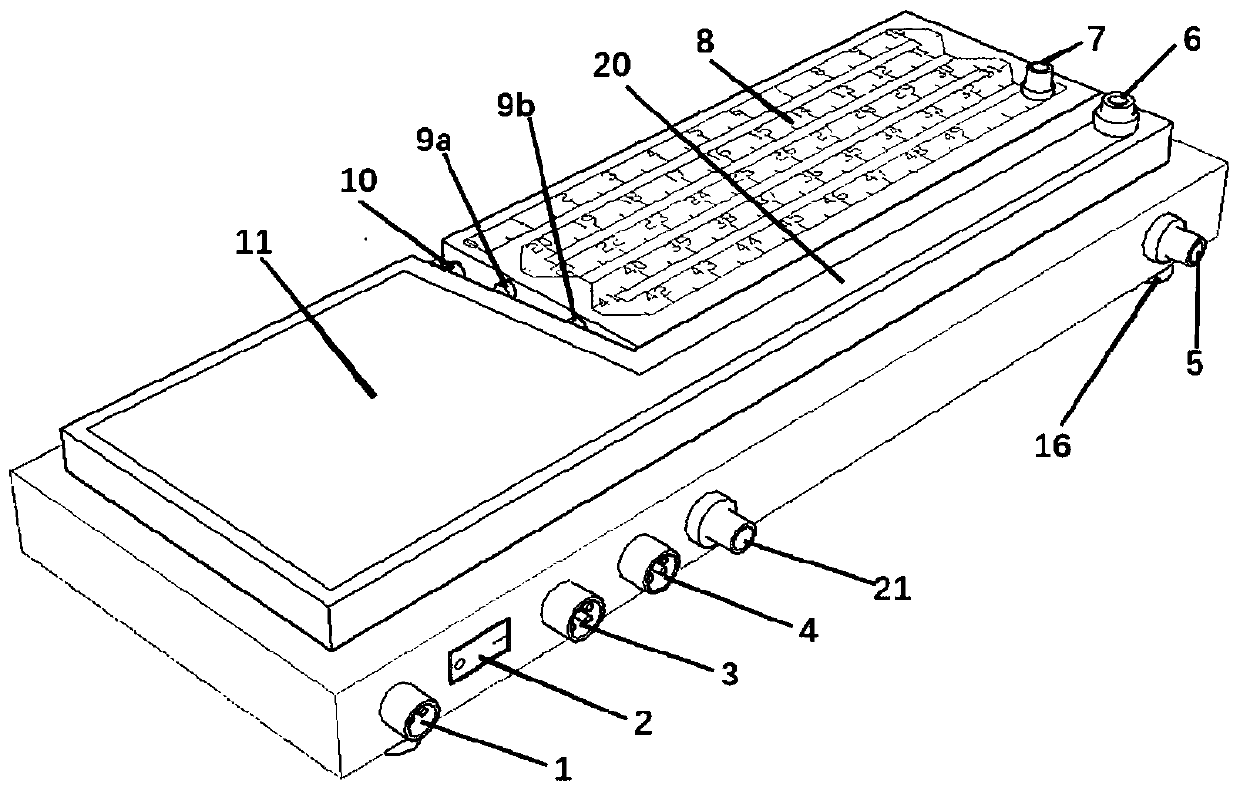

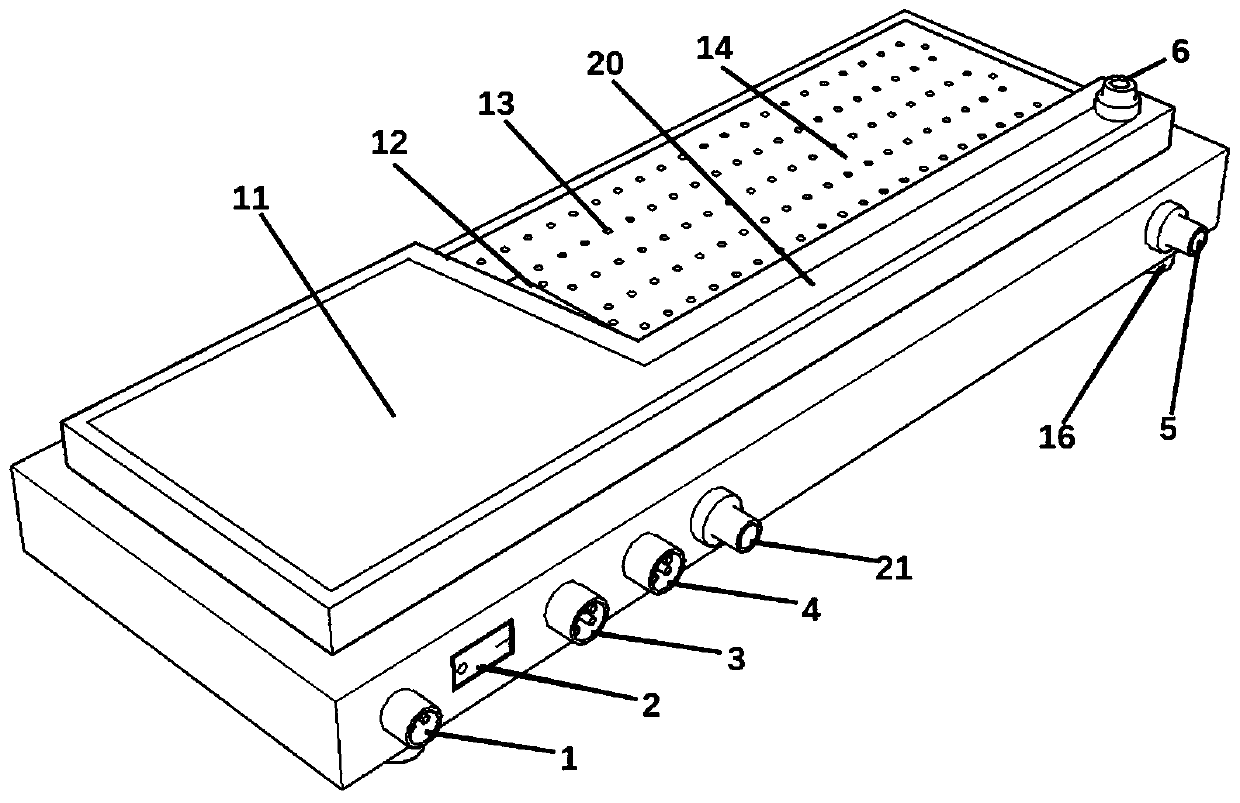

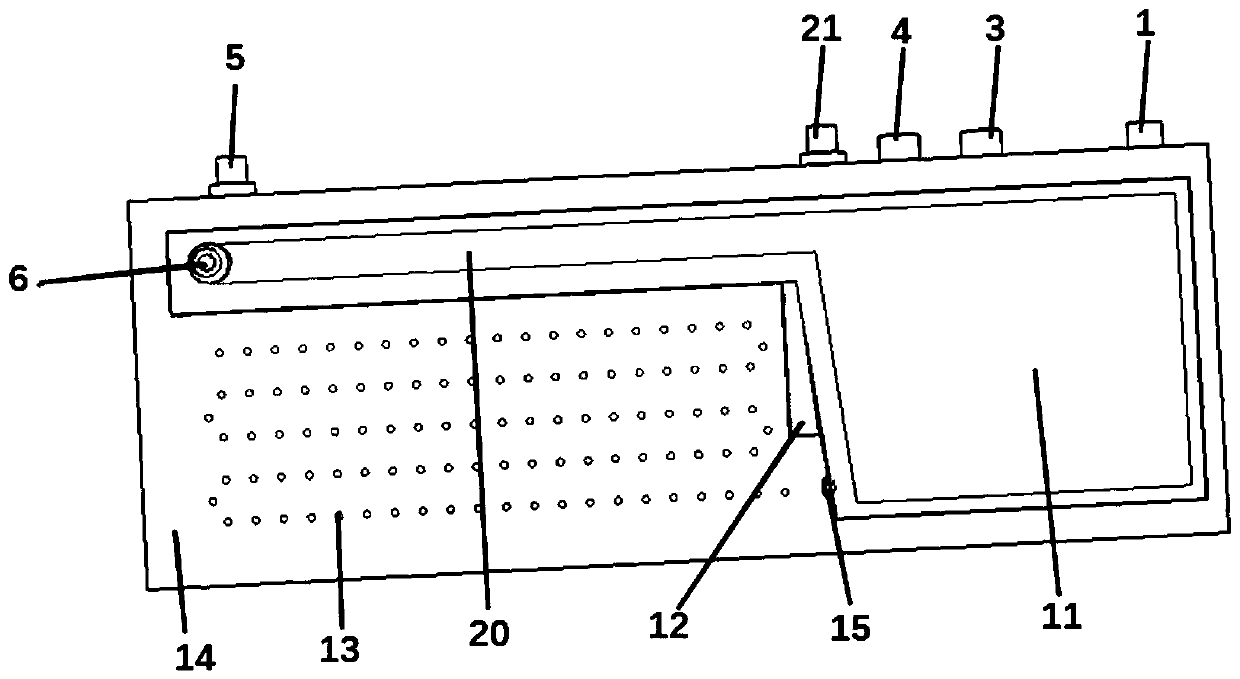

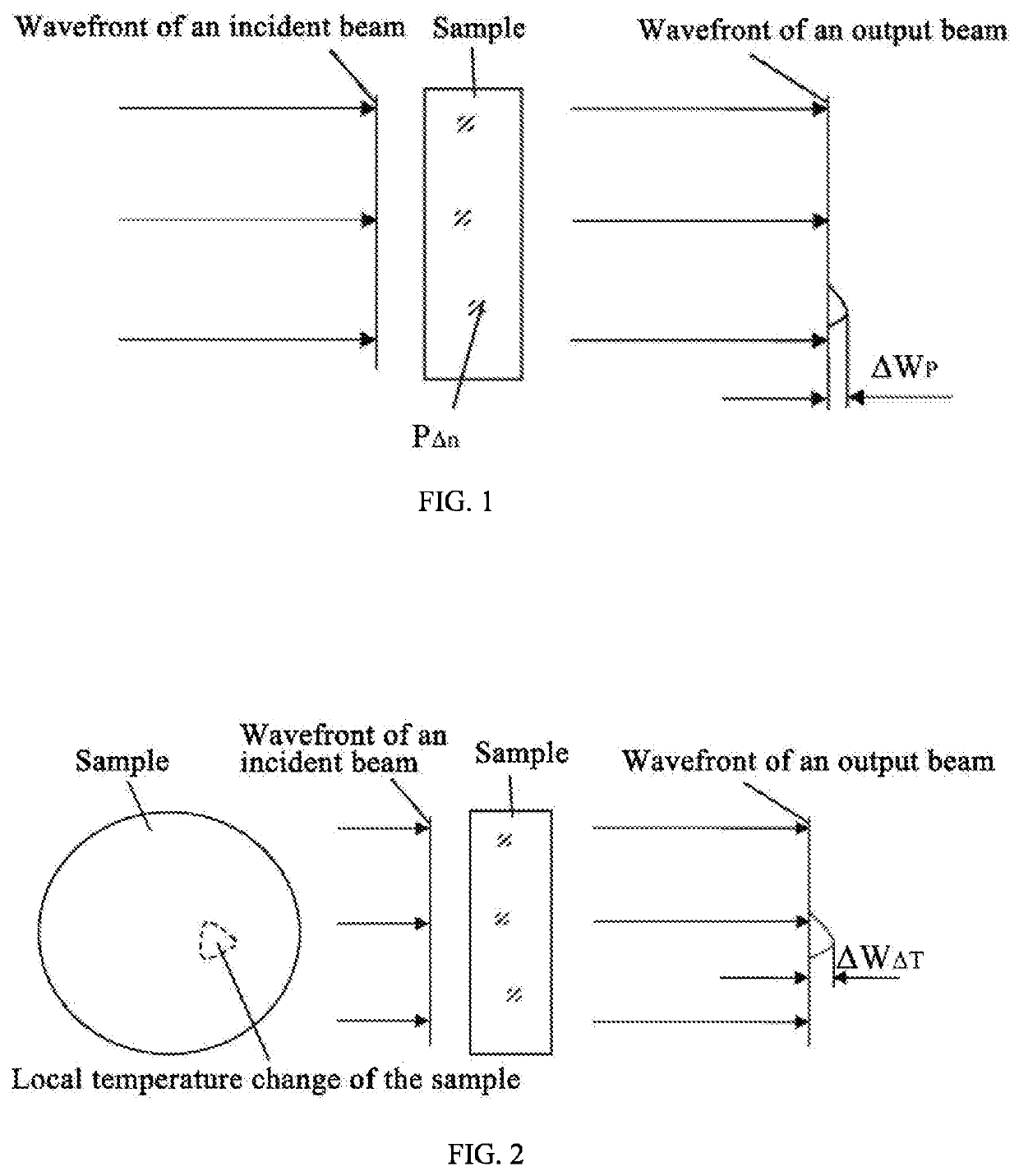

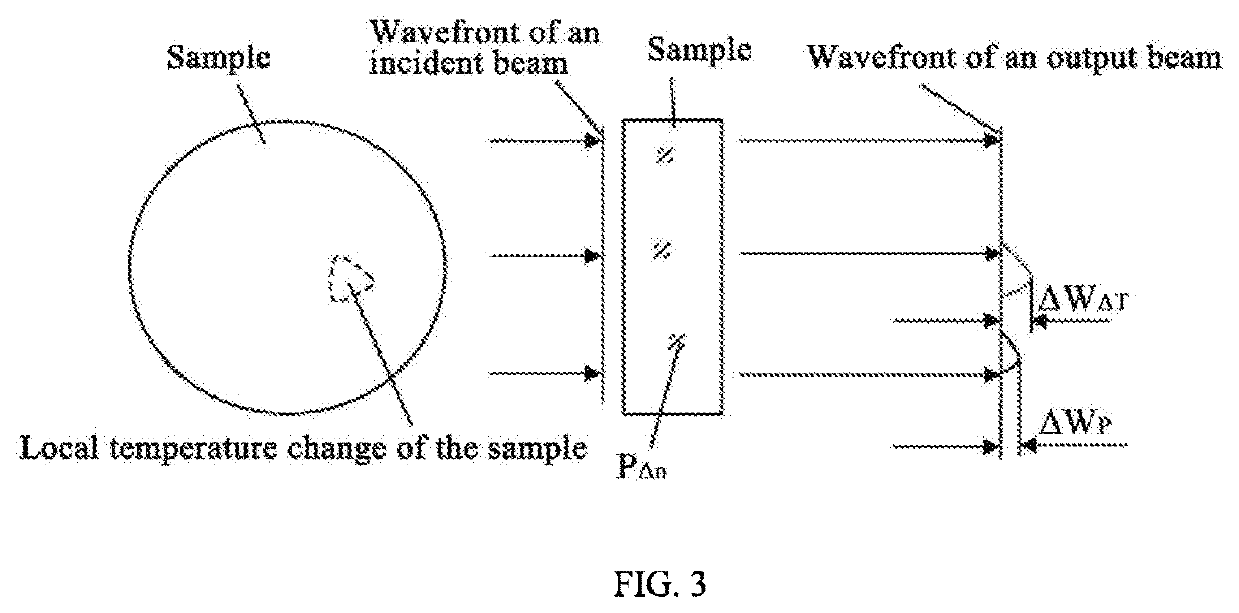

Method for evaluating and controlling temperature influence on a homogeneity test for infrared optical materials

ActiveUS20200355607A1Affect precisionAccurate guidePhase-affecting property measurementsRefractive power measurementTemperature controlRefractive index

Owner:CHINA NORTH STANDARDIZATION CENT

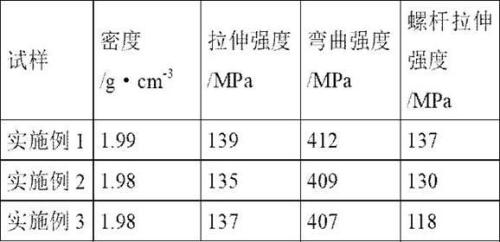

A kind of ceramic matrix composite heat-resistant plate and preparation method thereof

The invention relates to a ceramic matrix composite heat-resistant board and a preparation method thereof. (1) Prepare a fiber preform according to design; (2) Prepare an interface layer; (3) Repeat dipping-curing-cracking 2-6 times; (4) ) Process the heat-resistant plate product through holes according to the design size, and process the head of the bolt and the external thread of the screw according to the design size; (5) Apply the ceramic precursor slurry containing nanofibers on the surface of the bolt and the through hole, The bolts pass through the through holes of the heat-resistant plate; (6) Repeat the dipping-curing-low temperature cracking 2-4 times, and then repeat the dipping-curing-high temperature cracking 1-2 times; (7) CVI technology densifies the SiC matrix; (8) ) CVD deposition of SiC coating to obtain ceramic matrix composite heat-resistant plate. The heat-resistant plate produced by the invention is resistant to high temperature, can effectively prevent the engine tail flame from entering the back of the heat-resistant plate from the gap to ablate the metal bracket, prolong the service life of the metal bracket and reduce the use cost.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

A kind of processing method of metal pipe fittings

The invention provides a processing method for metal pipe fittings, which relates to the technical field of mechanical manufacturing and processing. During operation, metal pipe fittings need to be cut, pipe notched, positioned and clamped, welded, welded seam processed, sealed and put into storage, etc. steps of processing. The invention can solve the problems existing in the angle butt welding process of the existing metal pipe fittings. When the existing pipe fittings are connected by welding, it is necessary to manually control the angle adjustment of the pipe fittings according to the angle of the welded pipe fittings. During the operation, it is necessary to manually control the clamps to fix the pipe fittings. The accuracy of manual adjustment of the welding angle of pipe fittings is poor, which affects the precision of the connection angle of pipe fittings. Manual adjustment of pipe fitting angle welding operations requires manual adjustments for pipe fittings with different welding angles. The accuracy of angle adjustment is low, which affects work efficiency and pipe fitting welding the quality of.

Owner:宁波迪亚工业设备有限公司

Numerical control full-automatic machining center for precision hardware

InactiveCN111872708AEasy to fixEasy to transportLarge fixed membersCleaning using gasesComputer hardwareNumerical control

The invention discloses a numerical control full-automatic machining center for precision hardware. The machining center comprises a fixed base, supporting legs are fixedly connected to the lower surface of the fixed base, a machining center lathe body is fixedly connected to the upper surface of the fixed base, and a sliding protective cover door is arranged on the front face of the machining center lathe body; and a containing groove is formed in the front face of the machining center lathe body, a PLC control box is arranged on the inner wall of the containing groove, and a lathe body top plate is fixedly connected to the upper surface of the machining center lathe body. According to the numerical control full-automatic machining center for the precision hardware, through the arrangement of a metal corrugated pipe and a ventilation head, air compressed by a small air pump can be conveyed conveniently for blowing, the angle of the metal corrugated pipe can be bent, blowing can be conducted on different places, and therefore the effect that when a machining tool machines an object, metal flying chips generated by machining can be blown off from the machining tool, and the metal flying chips are prevented from influencing the machining precision of the object during tool changing is achieved.

Owner:山东硕达通机械设备有限公司

A high-precision cold-drawn seamless steel pipe bending device

The invention relates to the technical field of steel pipe bending, and discloses a high-precision cold-drawn seamless steel pipe bending device, which includes a frame, a pipe bending die, a pipe push plug and a hydraulic mechanism, and the middle part of the pipe bending die is movably connected with a For the first contact, a movable slot is provided inside the pipe bending die at the bottom end of the first contact, and a second contact is fixedly connected to the right end of the movable slot. In the present invention, by designing the first and second contacts and the electromagnetic layer, and by designing the push tube plug and the stop tube plug, the push tube plug and clamped slider drive the steel pipe to move during the bending process so that the ventilation tube on the stop tube plug enters Inside the air cavity, at the same time, due to the proximity of the strong magnetic layer, the magnetic piston squeezes the compressed gas inside the gas storage tank into the inside of the air cavity, so that the soft rubber rod expands to support the inner wall of the steel pipe, avoiding the bending process. The collapse and inner wrinkling of the inner wall of the steel pipe are caused by the difference in force between the inner wall and the outer wall of the bend.

Owner:徐州市全球通精密钢管有限公司 +1

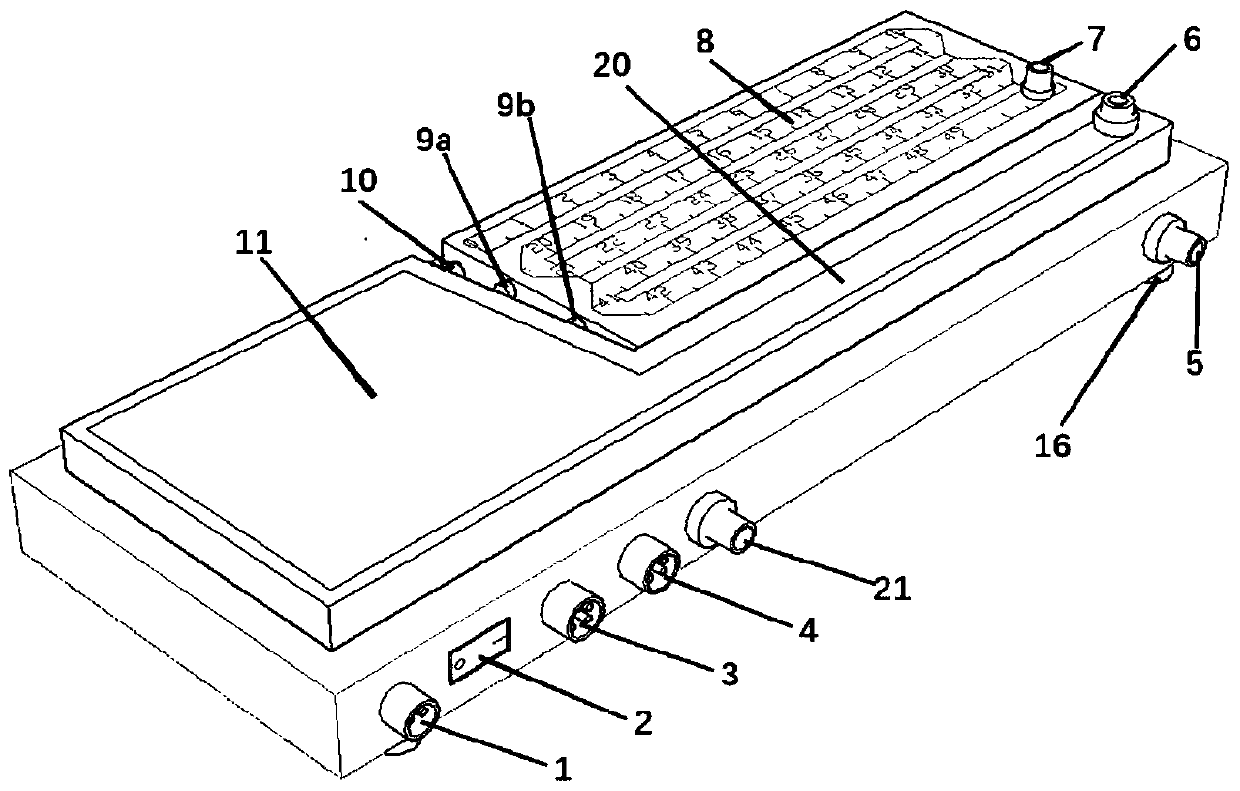

Split-type real-time monitoring device for respiratory oxygen consumption

ActiveCN110623670AHigh measurement accuracyReduce labor intensityAnimal housingRespiratory organ evaluationElectrical resistance and conductanceWater storage

The invention relates to a split-type real-time monitoring device for respiratory oxygen consumption, which comprises a split type monitoring body, the split-type monitoring body comprises a base anda monitoring plate arranged in a monitoring area of a split-type monitoring body, and the base comprises a horizontally-laid base and a light-transmitting water storage plate arranged on the surface of the base; the upper surface of the water storage plate is provided with a water storage guide groove and a water storage groove located in a first end of the base. A power interface, a breathing signal interface, an oxygen consumption interface and an air inlet are formed in the outer side surface of the base; a snake-shaped oxygen consumption monitoring groove is carved in the inner surface, facing the monitoring area, of a monitoring plate; the photoresistors are evenly laid on a shading plate in the length direction of the snake-shaped oxygen consumption monitoring groove and connected with a biological signal collecting and processing system through a resistance detection circuit, and the biological signal collecting and processing system outputs animal oxygen consumption data according to data of a sampling resistor. The device has the beneficial effects that the oxygen consumption rate in any time period in the oxygen deficit process can be collected, and the harm of limit oxygen consumption to animals is avoided; and the experimental precision is high.

Owner:ZHEJIANG UNIV

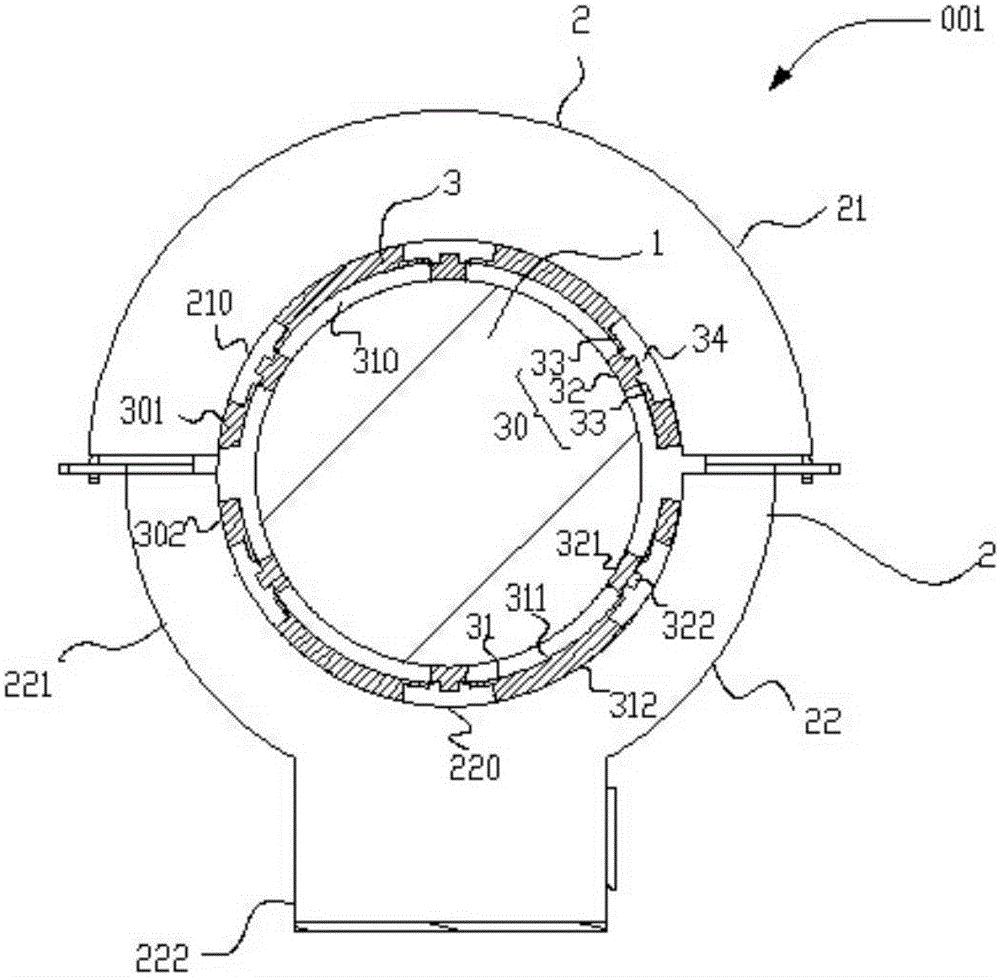

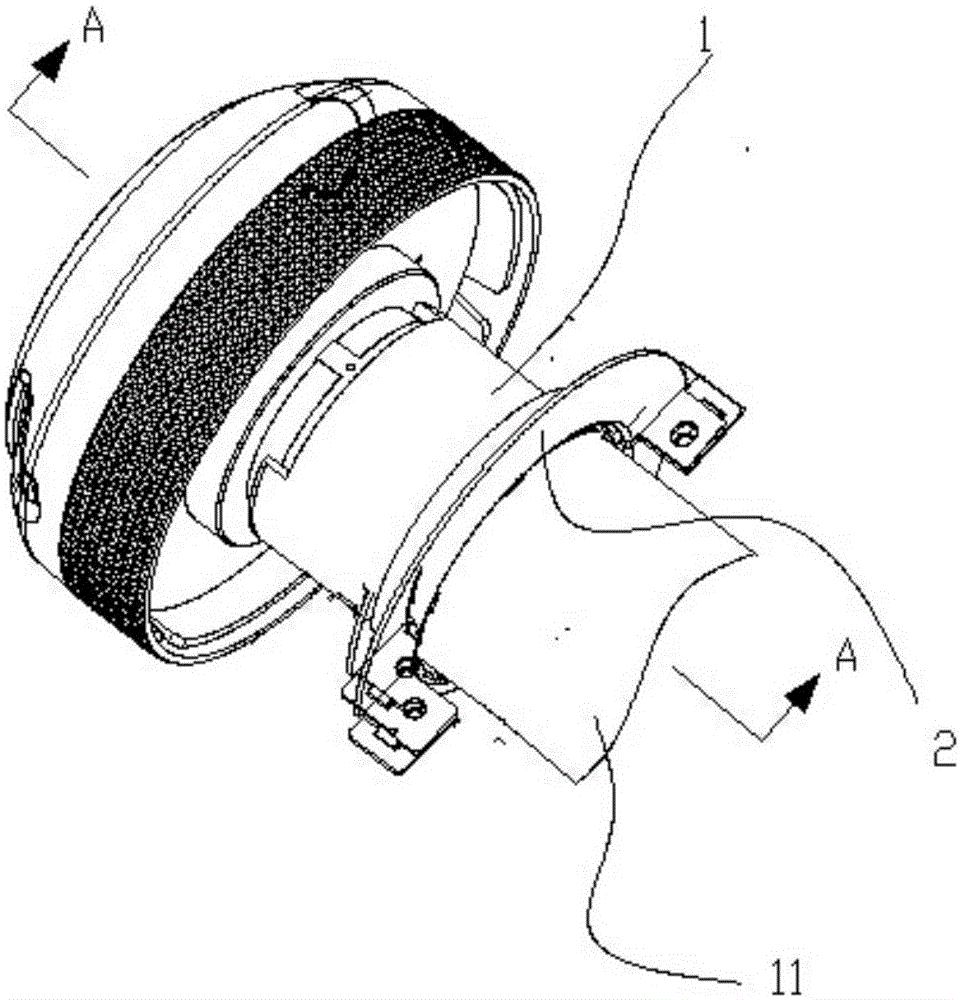

Lens module and projection device

The invention discloses a lens module and a projection device. The lens module comprises a lens cone, a supporting part and a buffering part, wherein the supporting part is arranged on the lens cone in a sleeving mode and supports the lens cone, the buffering part is arranged between the lens cone and the supporting part, and the buffering part is provided with a main portion and multiple buffering portions. Each buffering portion is provided with a boss and a connecting portion, wherein the boss abuts against the lens cone, the connecting portion is connected with the main portion and the boss, and the connecting portion can deform. Hollow areas are form in the buffering part and correspond to the bosses, a gap is formed between the buffering part and the lens cone, and the gap and the hollow areas are used for providing a space for deformation of the buffering portions so that external impact can be buffered effectively, the situation that poor images are generated due to deviation of the light path of a lens can be avoided, and imaging quality can be guaranteed. Meanwhile, the buffering part abuts against the lens cone and deforms to counteract assembly tolerance, and the situation that the precision of the light path is affected due to deviation of the light path when local stress is too large is avoided.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD

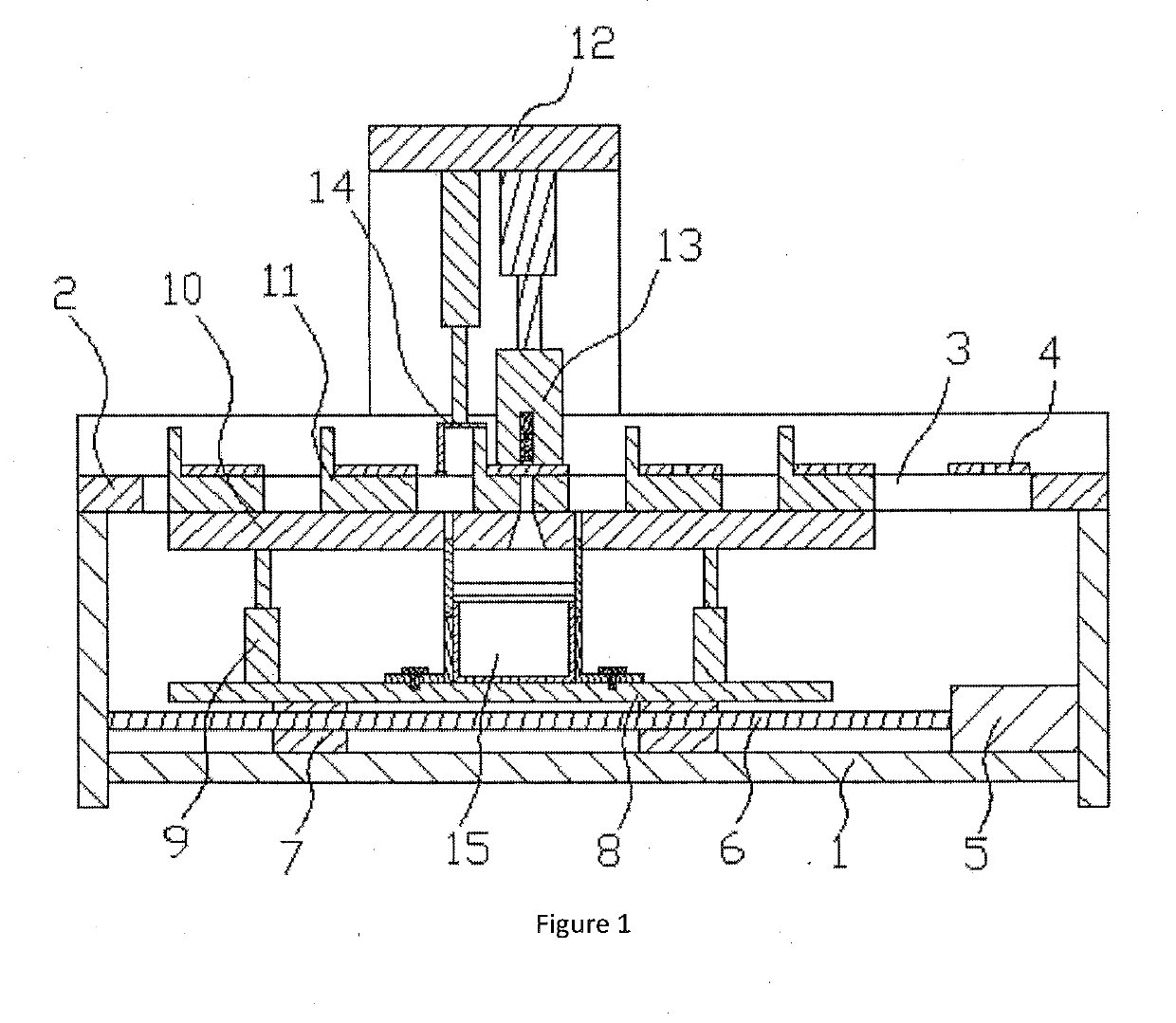

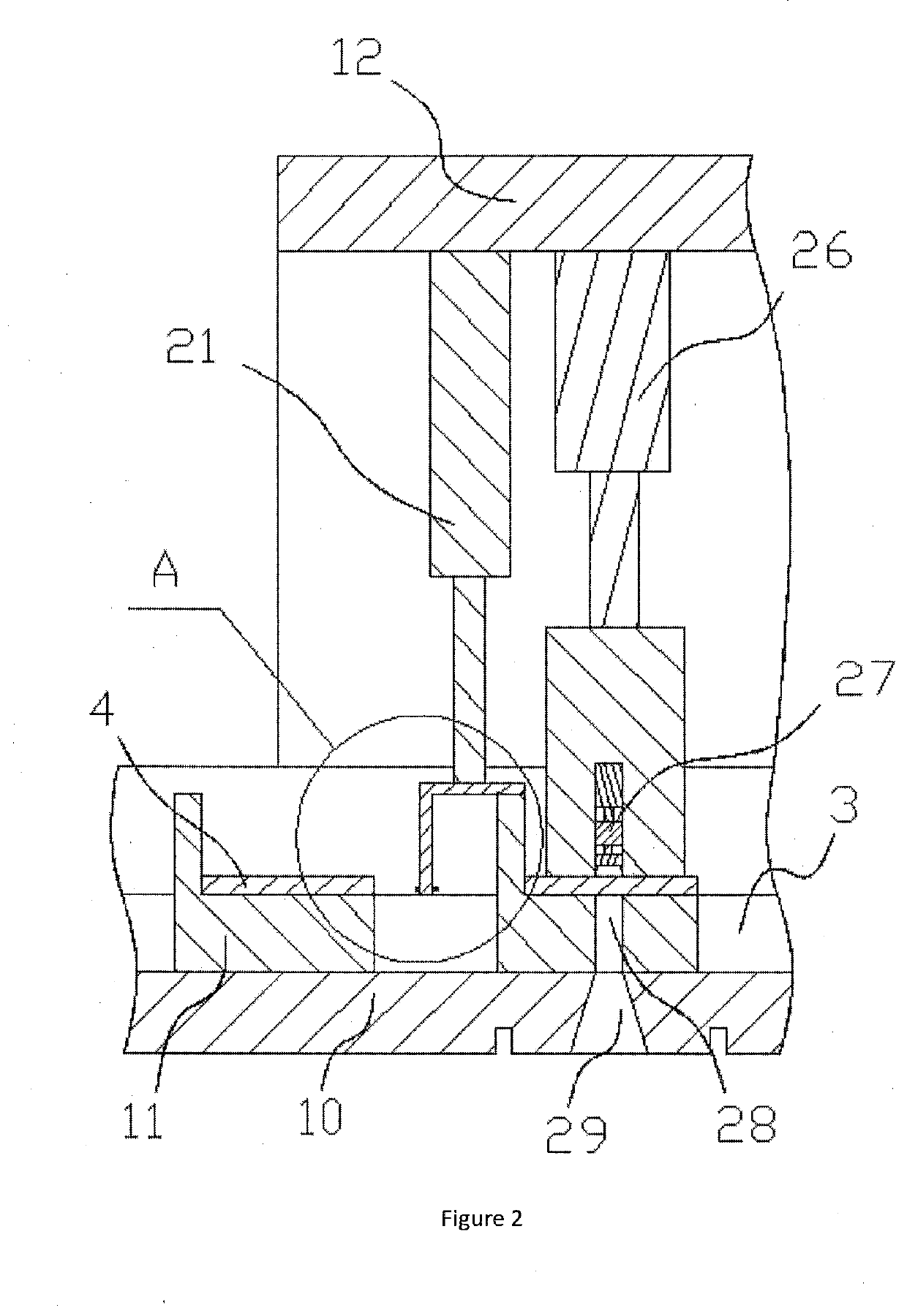

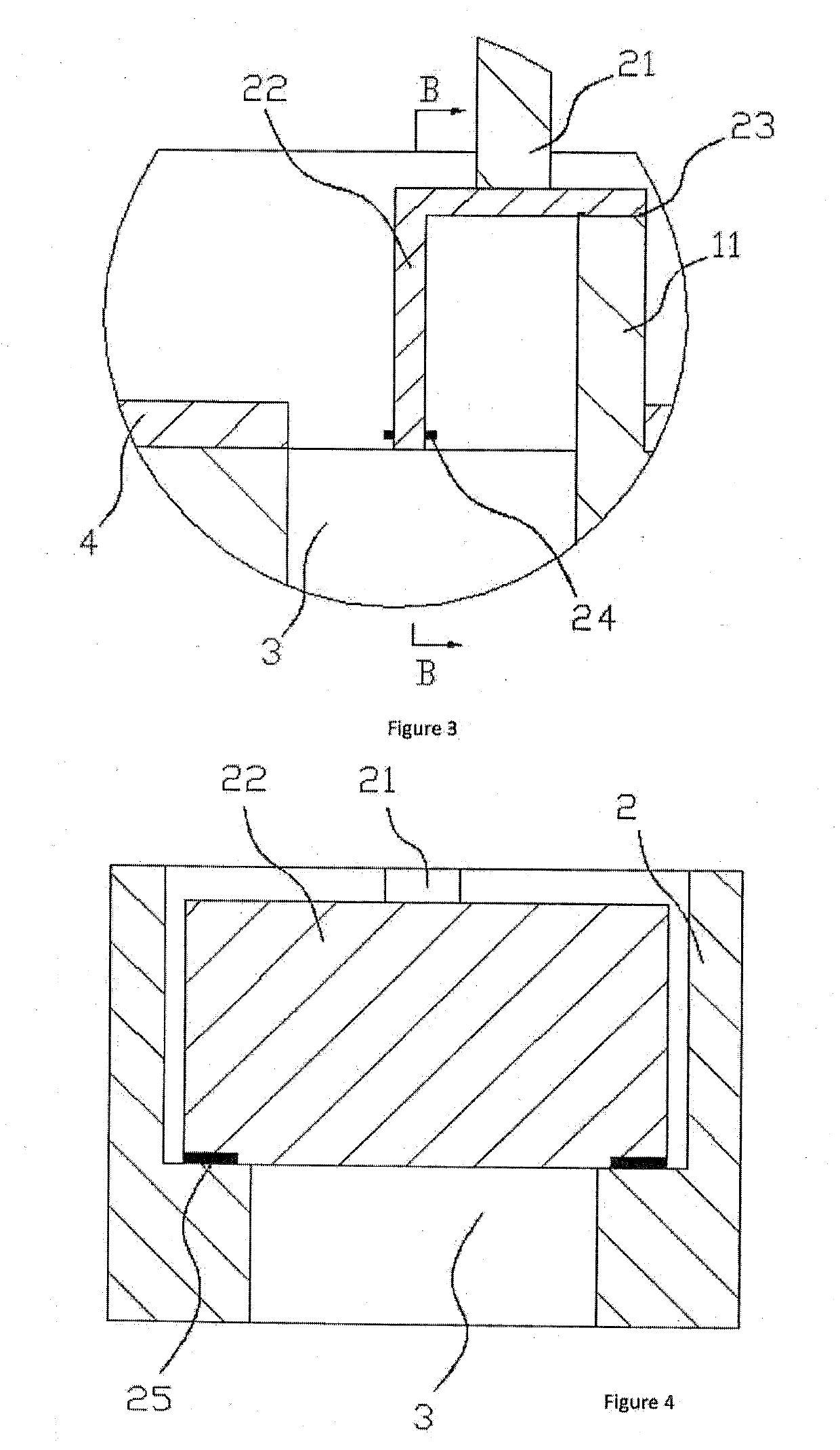

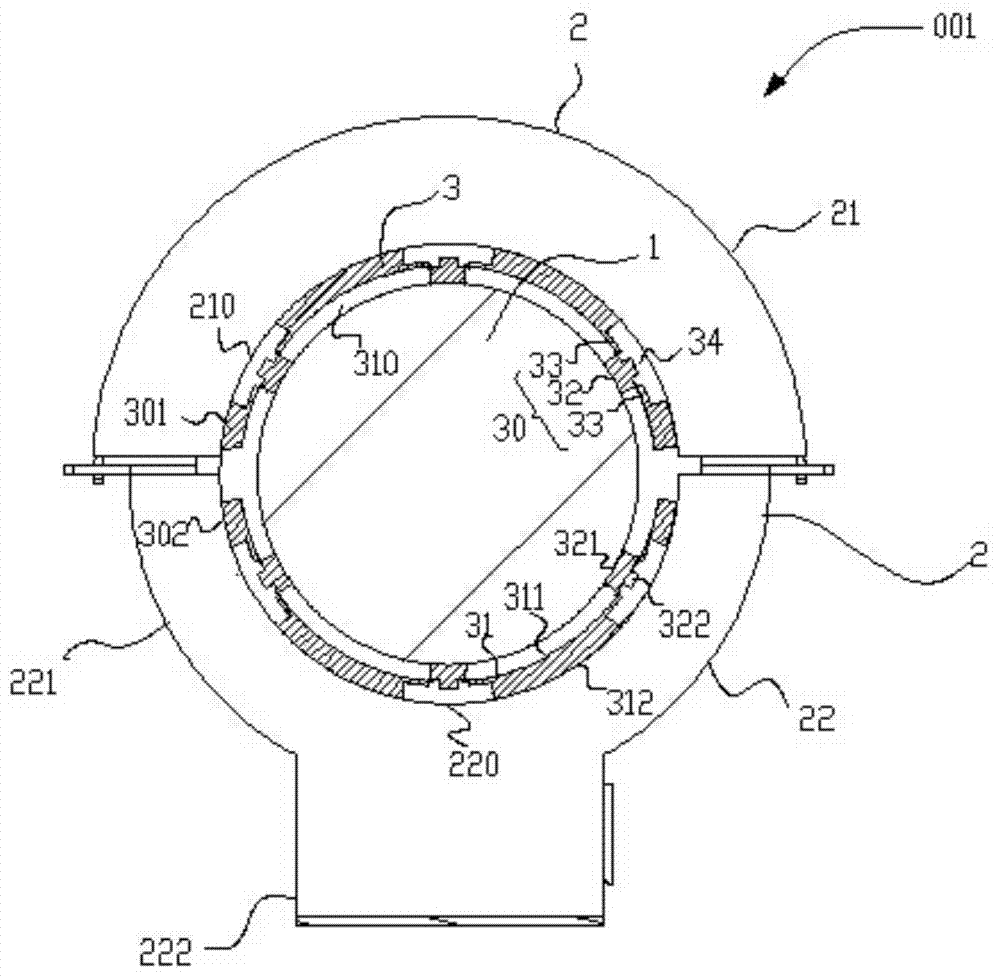

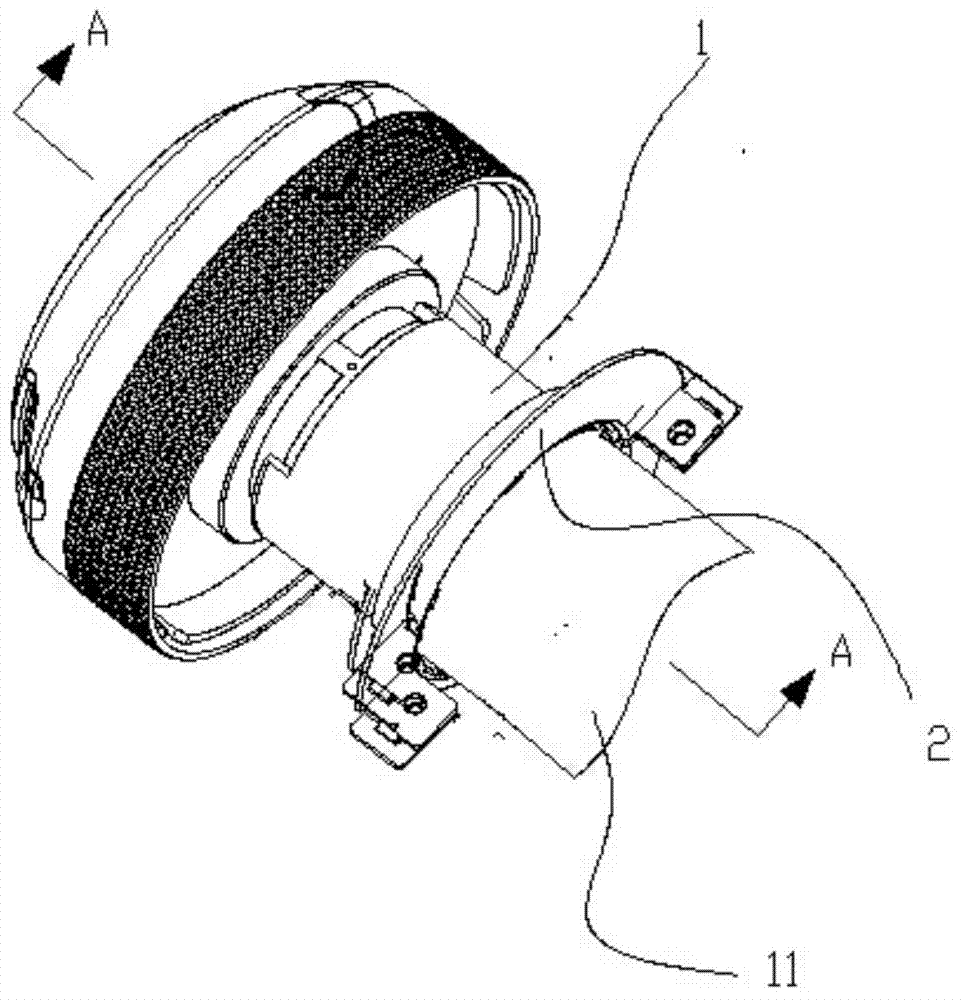

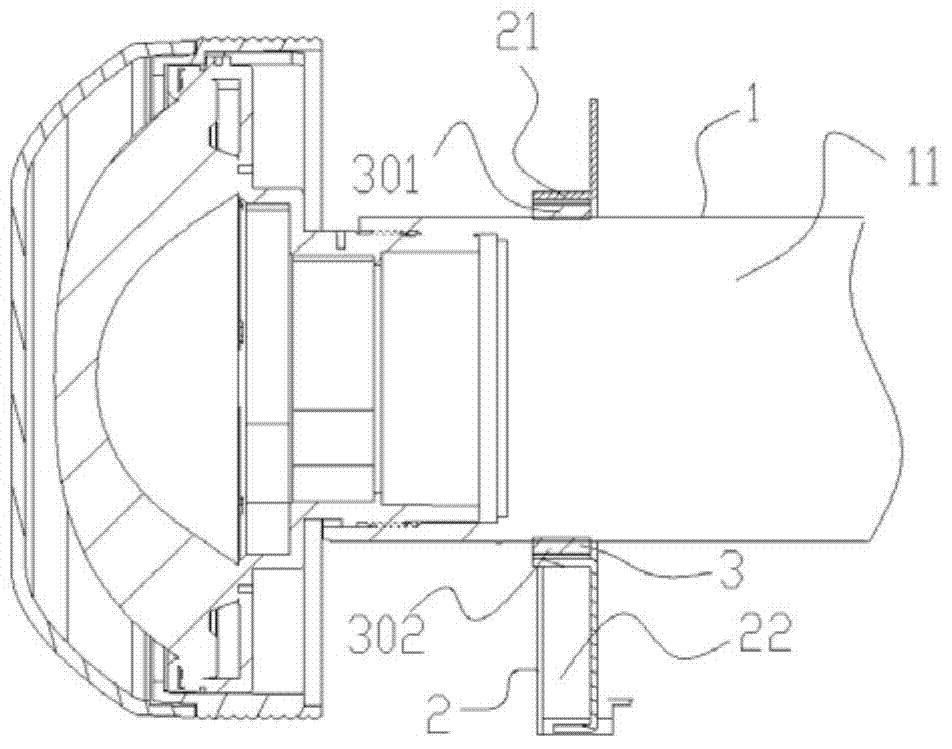

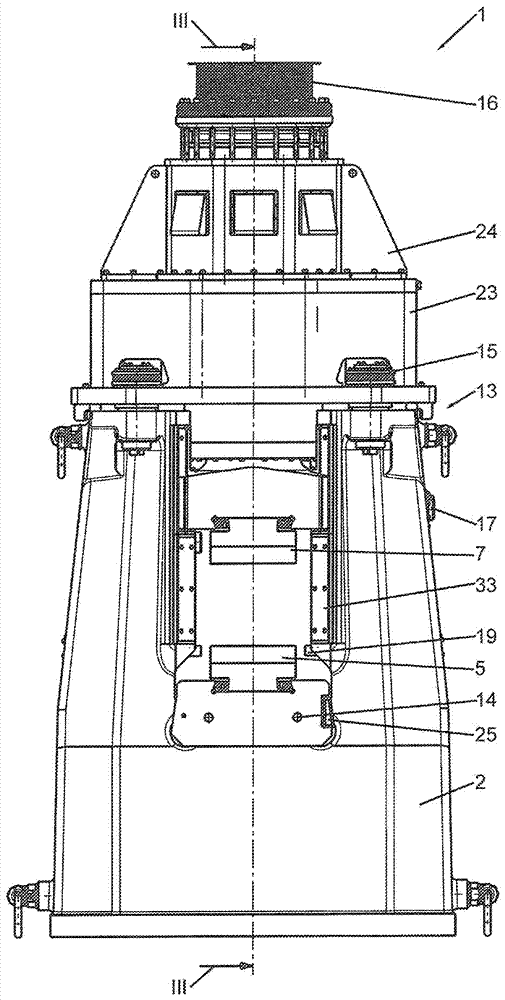

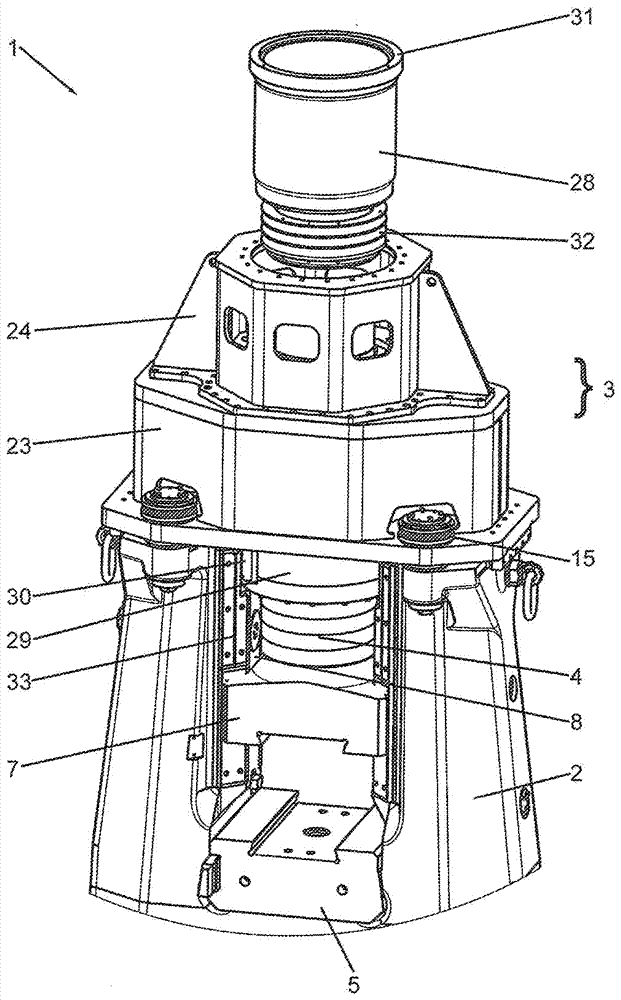

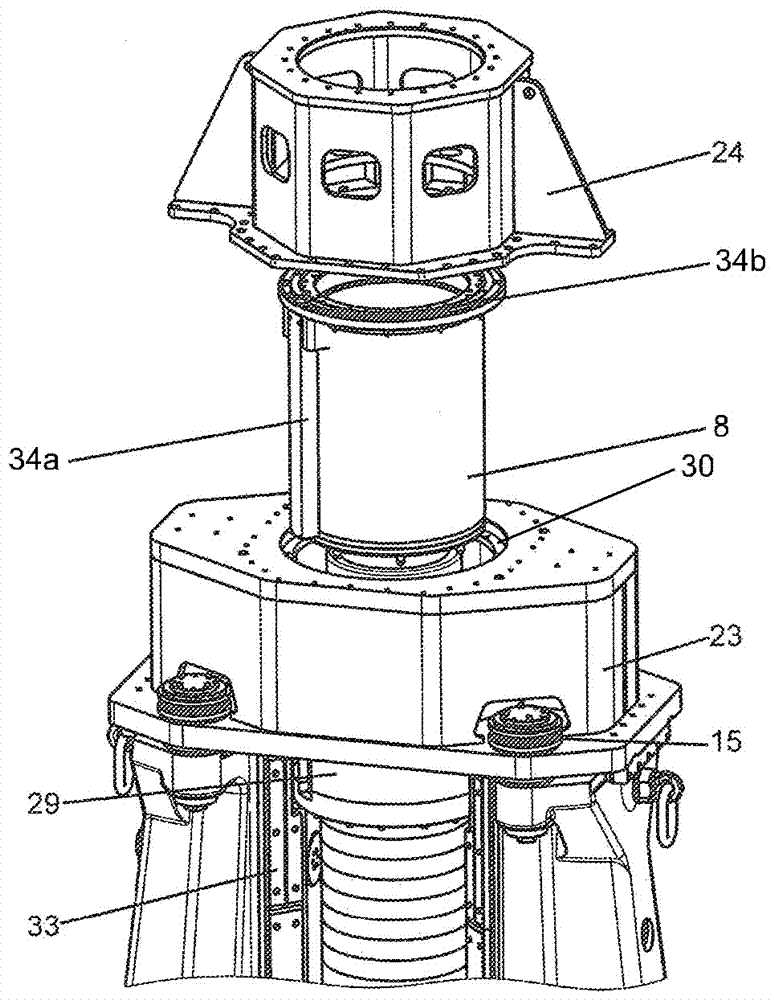

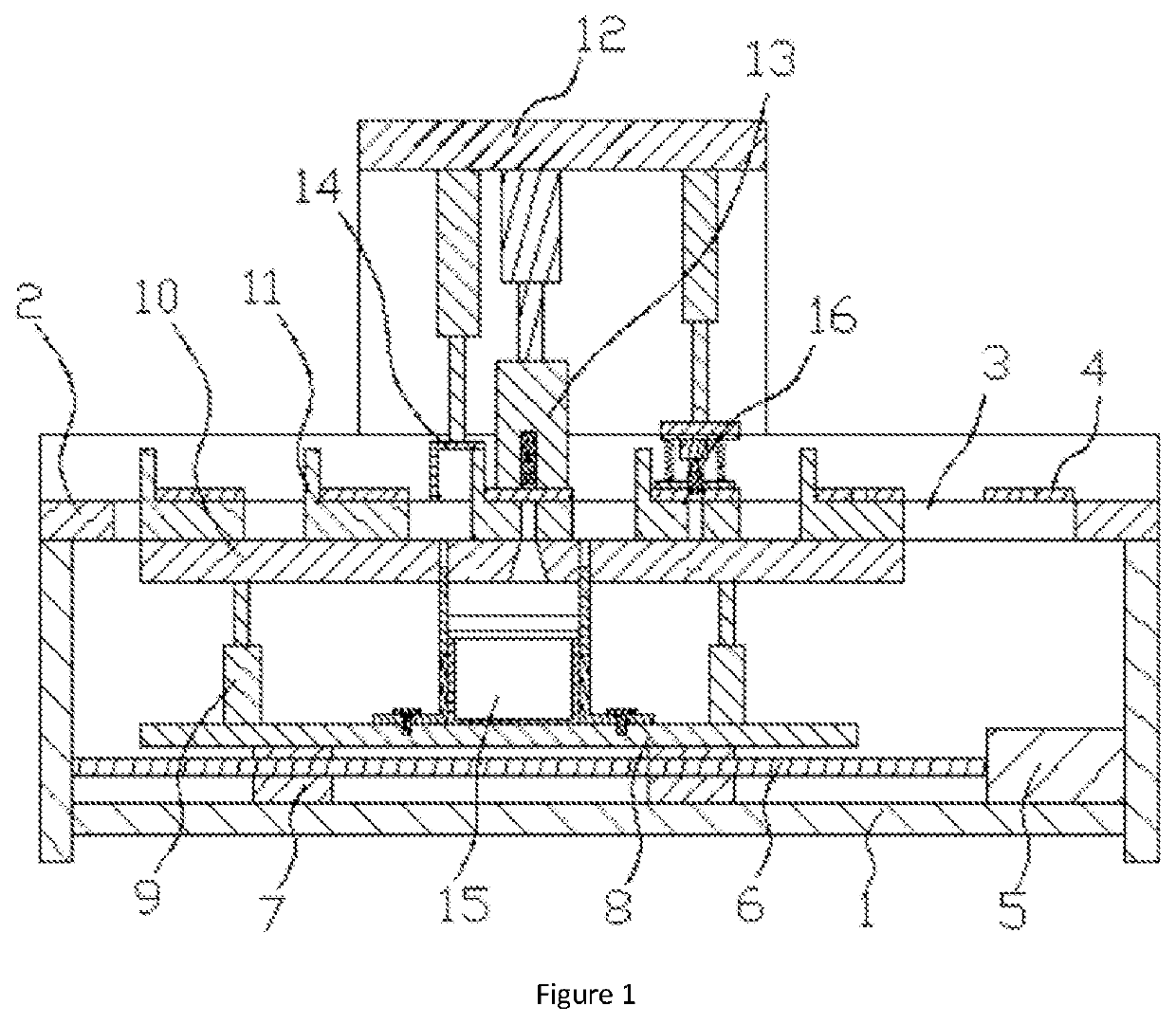

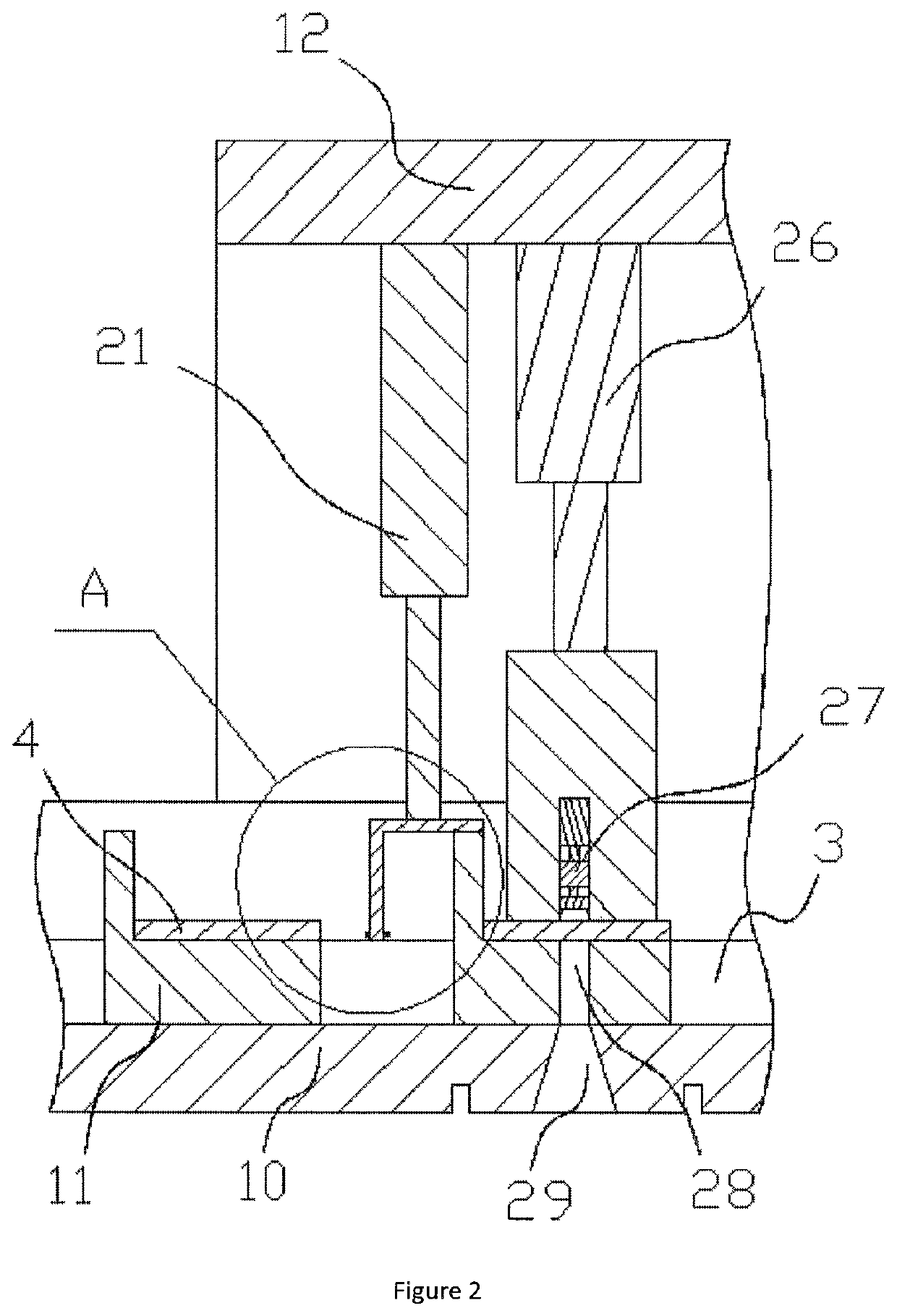

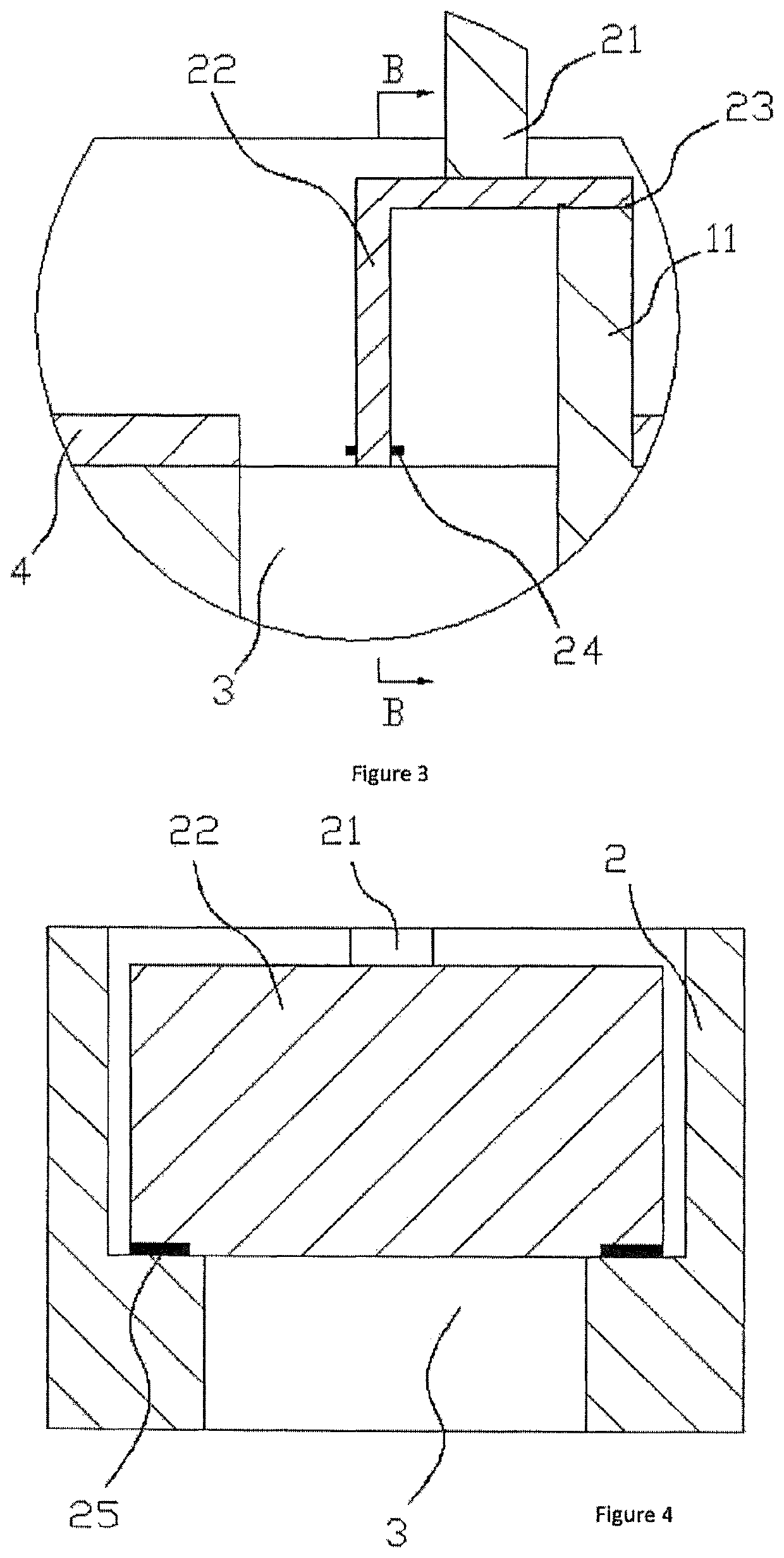

A forging hammer

ActiveCN106984753AReduce maintenanceReduce maintenance consumptionPower hammersHammer drivesStructural engineeringEngineering

The invention relates to a forging hammer (1) including an anvil (2), a head segment (3) and a hammer head (4). The head segment (3) and the anvil (2) are connected to each other by virtue of at least one connecting device (2401). The head segment (3) and the anvil (2) can be adjusted relative to each other.

Owner:SCHULER PRESSEN GMBH & CO KG

Box lock mechanism

ActiveCN101974997BExtended service lifeImprove securityComplete banking machinesBuilding locksLocking mechanismEngineering

Owner:GRG BAKING EQUIP CO LTD

Fault detectable sheet body fixed distance conveying and punching assembly

ActiveUS11235434B2Increase productivityLow efficiencyEdge grinding machinesGrinding carriagesPunchingClassical mechanics

The present invention relates to a fault detectable sheet body fixed distance conveying and punching assembly, which may include a rack, a conveying trough seat, a feeding trough, a processing rack and a punching device. On the rack is provided a feed motor and a feed screw. The movable feeding block is sleeved on the feed screw and the movable feeding seat is fixedly connected to the movable feeding seat. On the movable feeding seat is provided a feed lifting cylinder and on the feed lifting cylinder is provided a feed lifting block. On the feed lifting cylinder are equally provided feed blocks which may go through the feeding trough. On the processing rack is also provided a position detecting device which may include a detecting lifting cylinder provided on the processing rack. Under the detecting lifting cylinder is connected the detecting block. On the both sides of the detecting block is provided an acoustic wave range finder. The present invention includes a position detecting device, which may measure the position of the feeding block on the processing station by lifting the acoustic wave range finders on the position detecting device, and conduct integrity check to the fixed distance feeding part and maintain the entire assembly.

Owner:DONGGUAN UNIV OF TECH

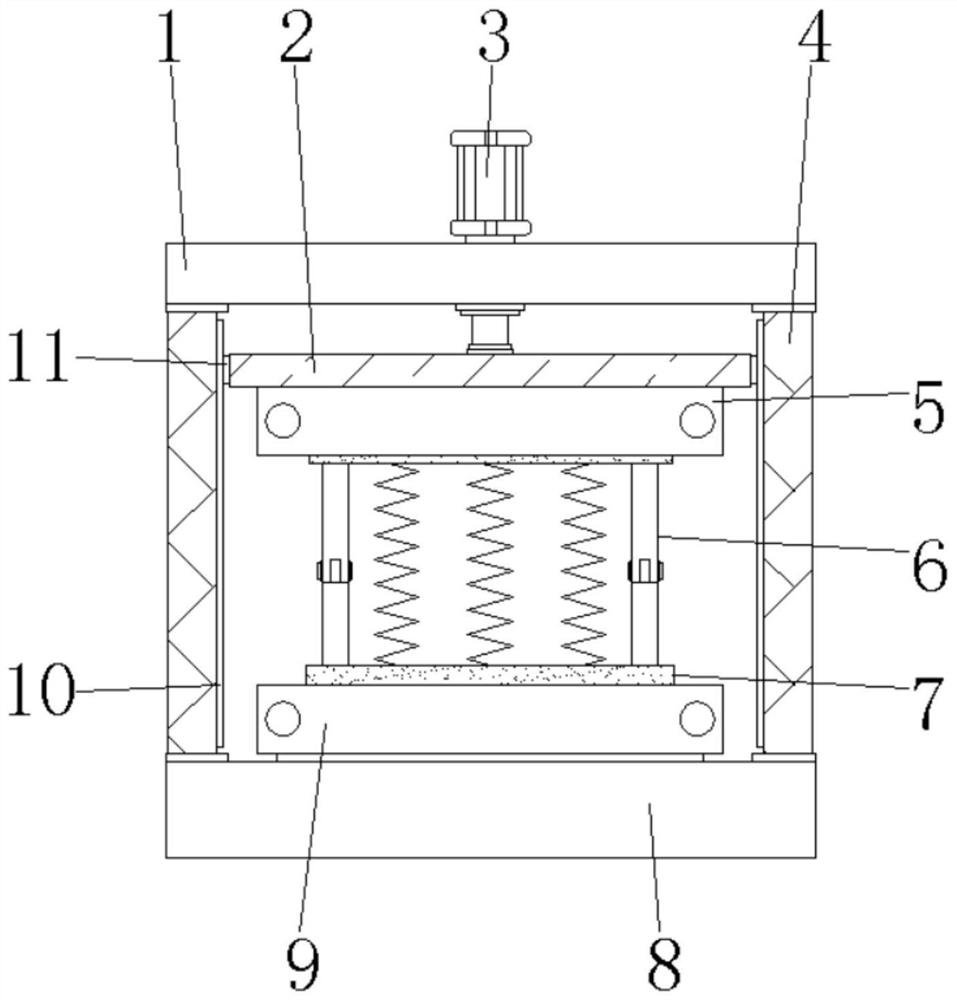

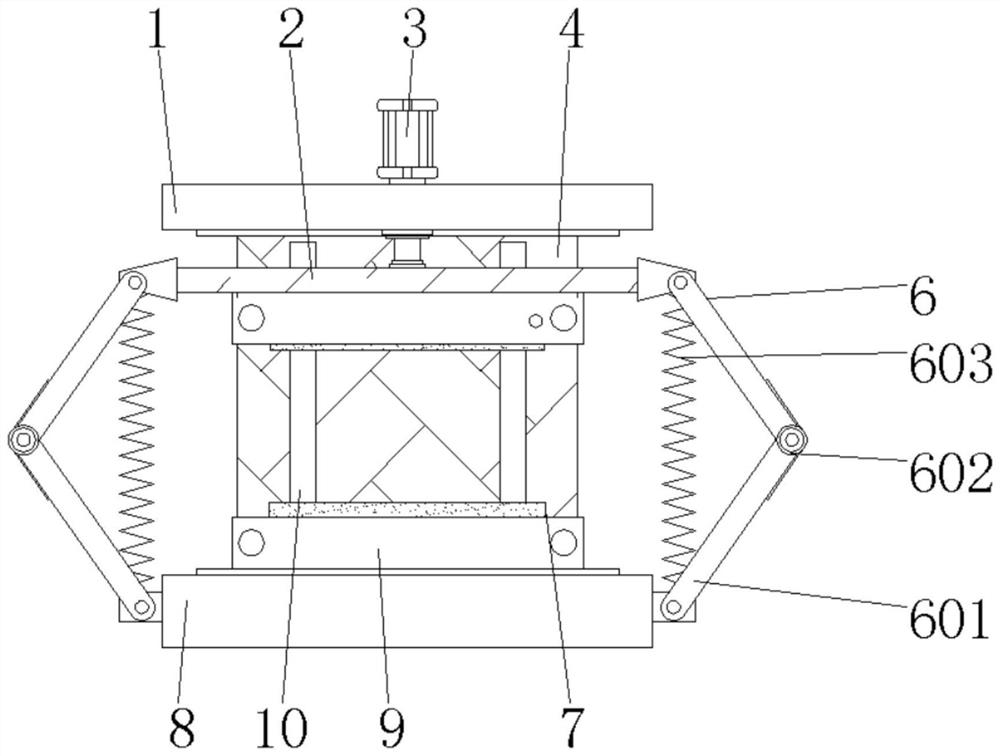

High-precision automobile part machining die

InactiveCN113385586ANot easy to shiftImprove stabilityShaping toolsShaping safety devicesStructural engineeringMechanical engineering

The invention discloses a high-precision automobile part machining die which comprises a bottom plate. A lower die frame is mounted at the top end of the bottom plate, side plates are mounted at the two sides of the top end of the bottom plate correspondingly, a sliding groove is formed in one side of each side plate, sliding blocks are mounted in the sliding grooves correspondingly, a top plate is mounted at the top ends of the side plates, a hydraulic telescopic rod is installed in the top plate, a supporting plate is installed at the bottom end of the hydraulic telescopic rod, buffering structures are arranged at the two ends of the supporting plate, an upper die frame is installed at the bottom end of the supporting plate, and dismounting structures are arranged in the upper die frame and the lower die frame correspondingly. The high-precision automobile part machining die is provided with the dismounting structure, a bolt is pulled towards one end, the bolt can be driven to be separated from the interiors of a reserved groove and a clamping groove, then the die can be dismounted from the interiors of the upper die frame and the lower die frame, the die can be replaced and overhauled, various dies can be conveniently punched, the use adaptability is better, and the function that the die is convenient to disassemble and replace is achieved.

Owner:长兴恒兴精工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com