Magnesium and magnesium alloy grain refining method

A technology of grain refinement and magnesium alloy, which is applied in the field of metal materials, can solve the problems that cannot be used as α-Mg heterogeneous nucleation core, large difference in lattice parameters, and different crystal structures, etc., to achieve the effect of grain refinement Significant, small fading effect, short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Grain refinement treatment of pure magnesium

[0030] Using amorphous alloy to refine pure Mg, the implementation process is as follows:

[0031] 1. Preparation of intermediate carrier containing zirconium-based amorphous alloy.

[0032] In order to add zirconium-based amorphous alloy into Mg melt conveniently, safely and effectively, firstly, zirconium-based amorphous alloy and magnesium chips are mixed and pressed to form an intermediate carrier containing zirconium-based amorphous alloy.

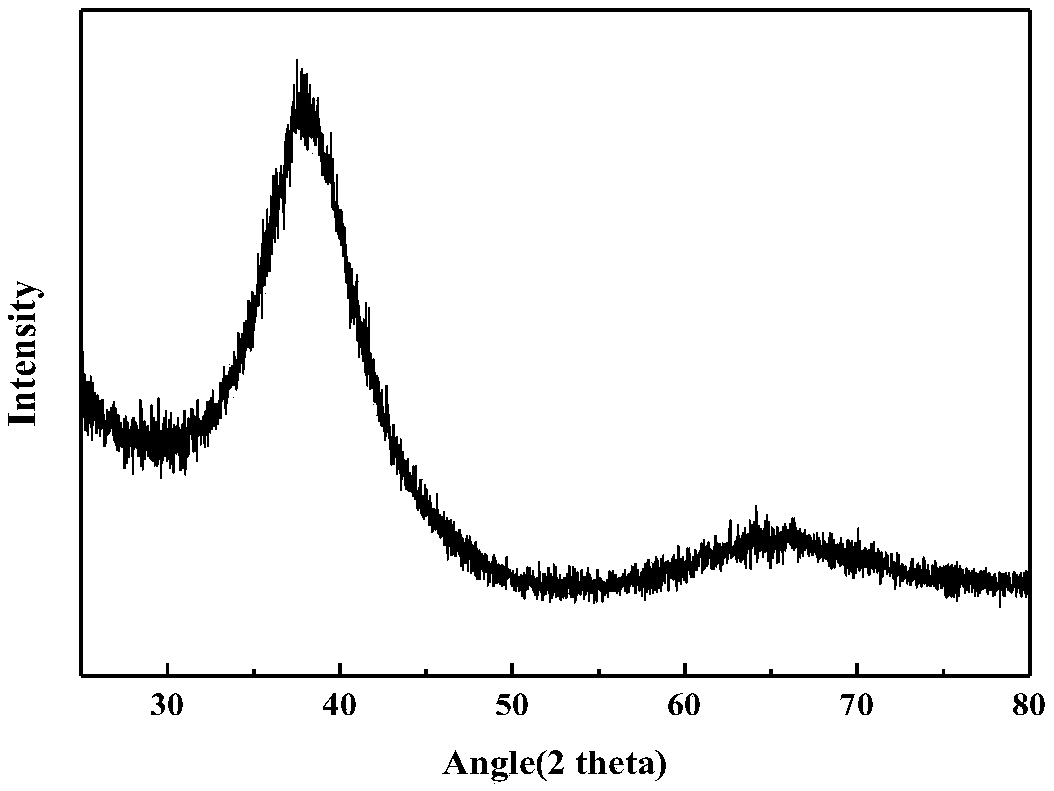

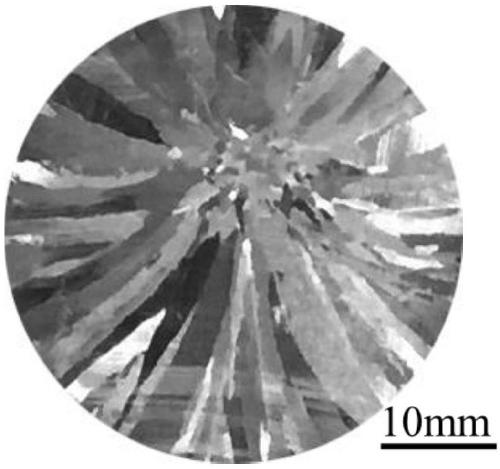

[0033] The preparation method is as follows: cutting the long zirconium-based amorphous alloy into smaller fragments. In addition, magnesium shavings obtained from cutting are collected. Mix magnesium chips and zirconium-based amorphous alloy fragments uniformly at a mass ratio of 7:3, press at room temperature under a pressure of 120MPa to form a Φ30mm round cake, and obtain a zirconium-based amorphous intermediate carrier.

[0034] 2. Alloy melting and refining t...

Embodiment 2

[0038] Embodiment 2: Grain refinement treatment method of AZ31B magnesium alloy

[0039] This embodiment 2 is used to illustrate the refinement effect of zirconium-based amorphous alloy on AZ31B magnesium alloy. The preparation process of the intermediate carrier containing zirconium-based amorphous is the same as in Example 1, wherein the magnesium chips and zirconium-based amorphous alloy fragments are pressed by 6 : 4 mass ratio, mixed evenly, pressed at room temperature under 120MPa pressure into a round cake shape of Φ30mm to obtain a zirconium-based amorphous intermediate carrier.

[0040] Melting AZ31B magnesium alloy, the melting temperature is 760°C. After melting, an intermediate carrier containing zirconium-based amorphous alloy is added, and the added amount of zirconium-based amorphous alloy is controlled to be 0.5% of the mass of the melt. Use N 2 +0.5% SF 6 The mixed gas protects the melt, and the melt is manually stirred for about 1 minute. After stirring, i...

Embodiment 3

[0042] Embodiment 3: Grain refinement treatment method of AZ31B magnesium alloy

[0043] This Example 3 is used to illustrate the refining effect of the zirconium-based amorphous on the AZ31B magnesium alloy, and the preparation process of the intermediate carrier containing the zirconium-based amorphous is the same as that in Example 1.

[0044] Melting AZ31B magnesium alloy, the melting temperature is 760°C. After melting, an intermediate carrier containing zirconium-based amorphous alloy is added, and the added amount of zirconium-based amorphous alloy is controlled to be 1.0% of the mass of the melt. Use N2 + 0.5% SF6 mixed gas to protect the melt, manually stir the melt for about 1 minute, let it stand for 10 minutes after stirring, pull the slag out of the furnace and cast it. The casting mold is made of carbon steel, and the mold preheating temperature is 500°C.

[0045] Figure 7 Shown is the microstructure photo of AZ31B magnesium alloy after refinement, and its gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com