Al-Ti-Zn intermediate alloy and preparation method thereof

An al-ta-zn, master alloy technology, applied in the field of metal alloy materials, to achieve the effect of small refinement, uniform distribution, and avoiding fluctuations in the content of zinc elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

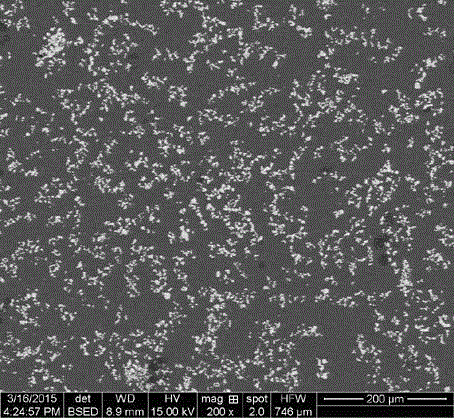

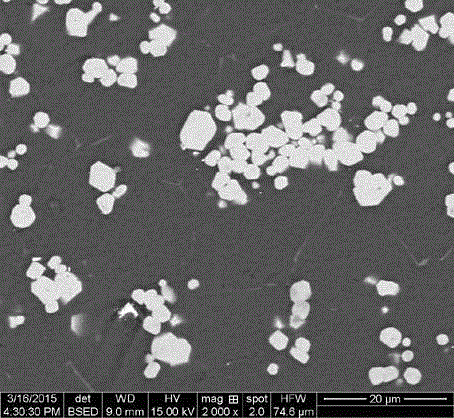

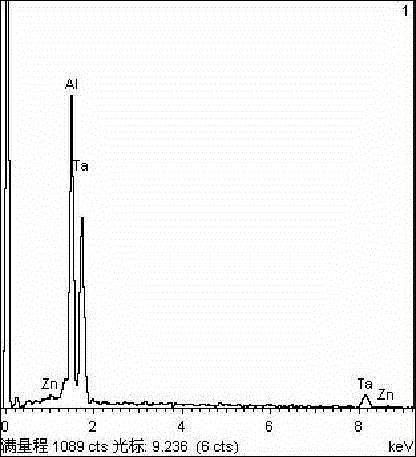

[0036] Al-15Ta-2Zn master alloy, its chemical composition is composed of the following components by mass percentage: Ta15%, Zn2%, and the rest is Al. Ta element is mainly polyhedral or spherical TaAl 3-x Zn x (03-x Zn x ( image 3 For its energy spectrum) the gray phase is the aluminum matrix.

[0037] The above Al-15Ta-2Zn master alloy has a significant grain refinement effect on industrial pure aluminum: the average grain diameter of industrial pure aluminum (purity 99.7wt.%) without any refiner is about 4mm ( Figure 4 ), the average grain diameter of industrial pure aluminum after adding the above-mentioned Al-15Ta-2Zn master alloy with an atomic ratio of 0.02% of tantalum element is about 0.4mm, and the grain size is uniform ( Figure 5 ). After adding the Al-10Ti master alloy with a Ti atomic ratio of 0.02%, the grain size of industrial pure aluminum is not uniform, and the diameter of the largest grain can reach about 0.9mm ( Image 6 ). Compared Figure 5 and ...

Embodiment 2

[0044] Al-8Ta-8Zn master alloy, its chemical composition is composed of the following components by mass percentage: Ta8%, Zn2%, and the rest is Al. This master alloy is compared with the master alloy prepared in Example 1, except TaAl 3-x Zn x (0

[0045] The process of preparing 2000 grams of the above-mentioned Al-8Ta-8Zn master alloy is as follows:

[0046] (1) Weigh 1720 grams of raw material pure aluminum, 160 grams of pure zinc and K 2 TaF 7 347 grams;

[0047] (2) Melting pure aluminum and pure zinc to the range of 690-730°C in a melting furnace to obtain an aluminum melt;

[0048] (3) The above K 2 TaF 7 Add to the above-mentioned aluminum melt in 3 batches for reaction, and add the next batch after each ba...

Embodiment 3

[0051] Al-6Ta-5Zn master alloy, its chemical composition is composed of the following components by mass percentage: Ta6%, Zn5%, and the rest is Al. This master alloy is compared with the master alloy prepared in Example 1, except TaAl 3-x Zn x (0

[0052] The process of preparing 1000 grams of the above-mentioned Al-6Ta-5Zn master alloy is as follows:

[0053] (1) Weigh 905 grams of raw material pure aluminum, 50 grams of pure zinc and K 2 TaF 7 130.2 grams;

[0054] (2) Melting pure aluminum and pure zinc in the melting furnace to the range of 680-730°C to obtain zinc-containing aluminum melt;

[0055] (3) The above K 2 TaF 7 Add to the above-mentioned pure aluminum melt in 2 batches for reaction, each batch react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com