High-intensity and high-plasticity magnesium alloy composite plate and preparation method thereof

A composite plate and magnesium alloy technology, applied in the field of materials, can solve the problems of reduced strength and weakened magnesium alloy texture, and achieve the effects of increased plasticity and strength, improved grain refinement, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

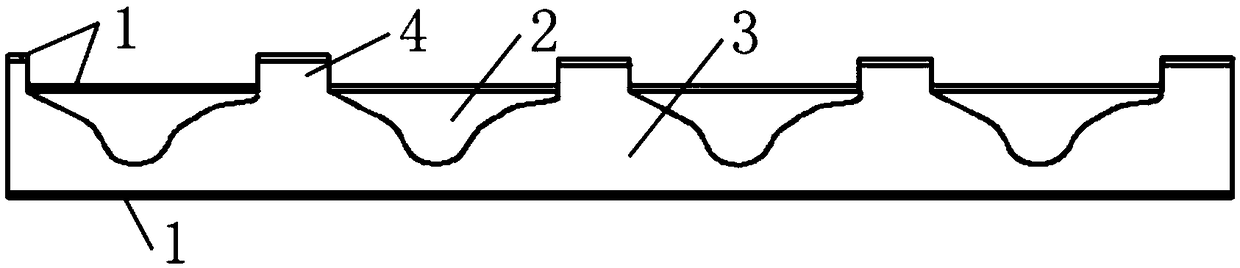

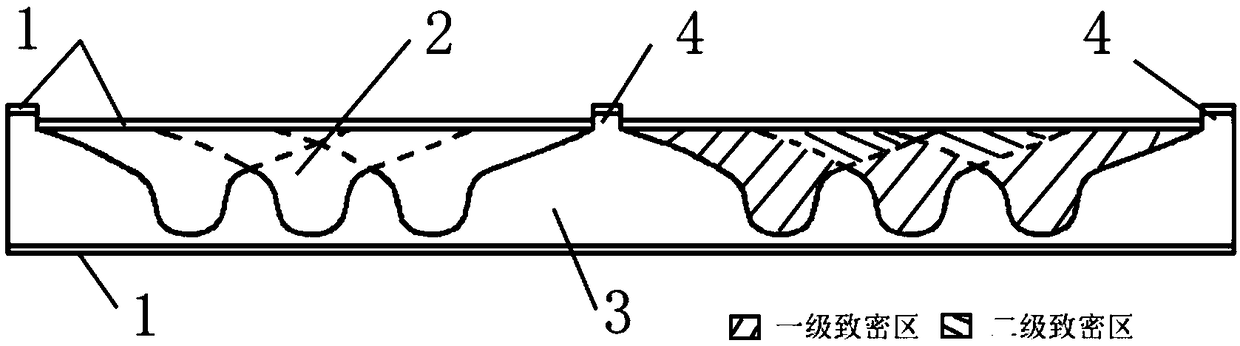

Method used

Image

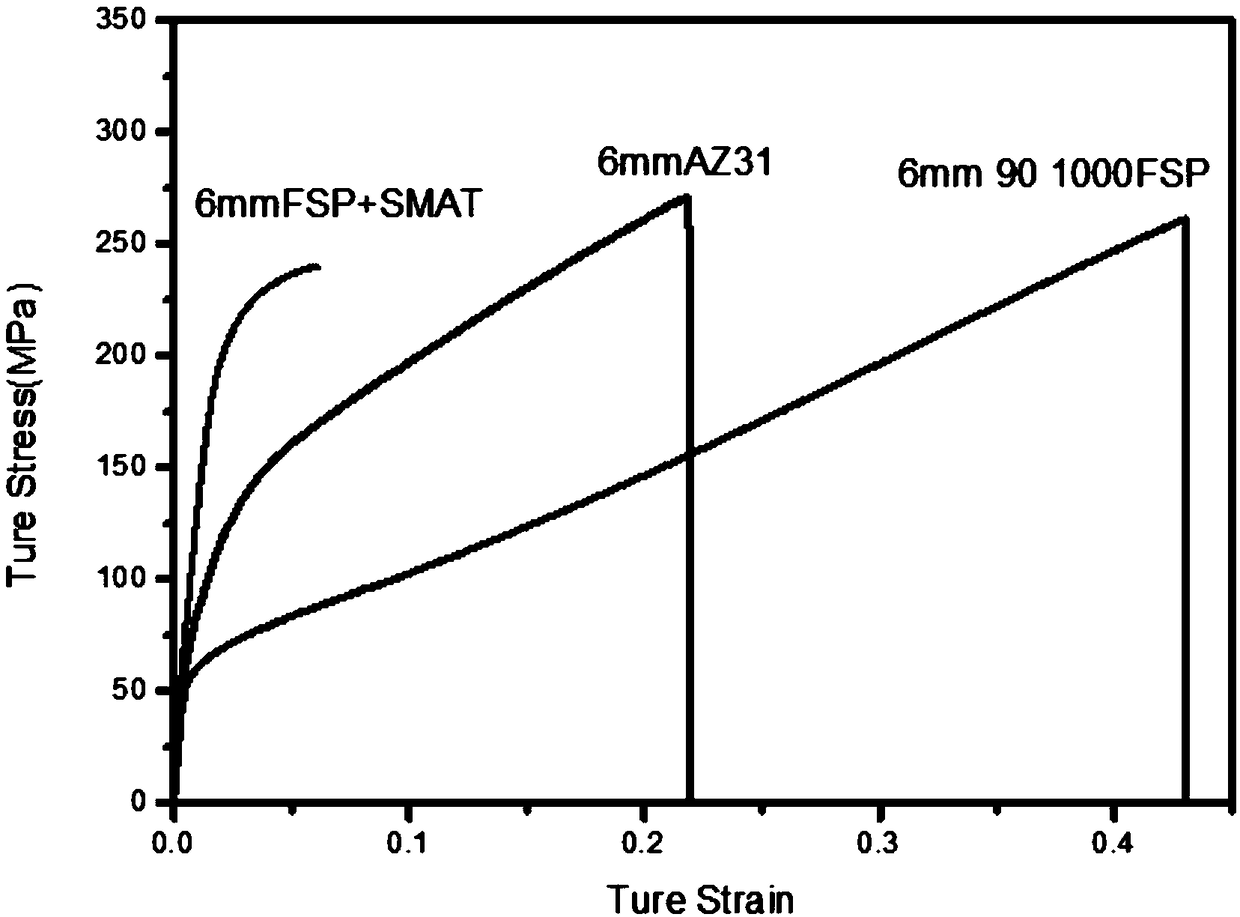

Examples

Embodiment 1

[0057] Step 1: Fix the 6mm thick magnesium alloy plate on the friction stir machine tool.

[0058] Step 2: Spray water on the magnesium alloy, so that the overall friction stir processing is placed under water cooling conditions.

[0059] Step 3: The stirring head slowly presses down on the magnesium plate at a speed of 1000r / min until the shaft shoulder contacts the magnesium plate and still presses down 1mm. After staying for 3-5s, the stirring head moves forward at a feed speed of 90mm / min , until the magnesium alloy sheet is finished.

[0060] Step 4: Complete the first friction stir processing, return the stirring head to the initial position of the first processing, and process the subsequent passes at a position offset by 25mm on the backward side in the vertical direction of the processing direction in the second pass.

[0061] Step 5: Complete subsequent passes according to step 4.

[0062] Step 6: Shot peening treatment on the front and back of the magnesium alloy,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com