High-entropy diboride-boron carbide composite ceramic as well as preparation method and application thereof

A technology of diboride and multiphase ceramics, applied in the field of multiphase ceramics, can solve the problems of easy introduction of oxygen pollution, large grain size, high entropy effect and limited improvement of relative material properties, and achieves wide application prospects, High hardness, remarkable effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The molar parts of raw materials are as follows: 1 part of titanium carbide, 1 part of zirconium carbide, 1 part of hafnium carbide, 1 part of niobium carbide, 1 part of tantalum carbide, and 32 parts of boron powder. The preparation process is as follows: (1) put the carbide powder and boron powder into a polyethylene bottle, add zirconia balls and absolute ethanol, and ball mill and mix for 24 hours; (2) evaporate the mixed slurry on a rotary evaporator (3) pass the dried powder through a 200-mesh standard sieve; (4) put the sieved powder into a graphite mold, and sinter In the furnace, the temperature was raised to 2000°C at a rate of 100°C / min, while the pressure was increased to 40MPa, vacuum sintered for 6 minutes, and then the temperature was lowered and the pressure reduced; (5) demoulding, and the sintered ceramic sample was taken out.

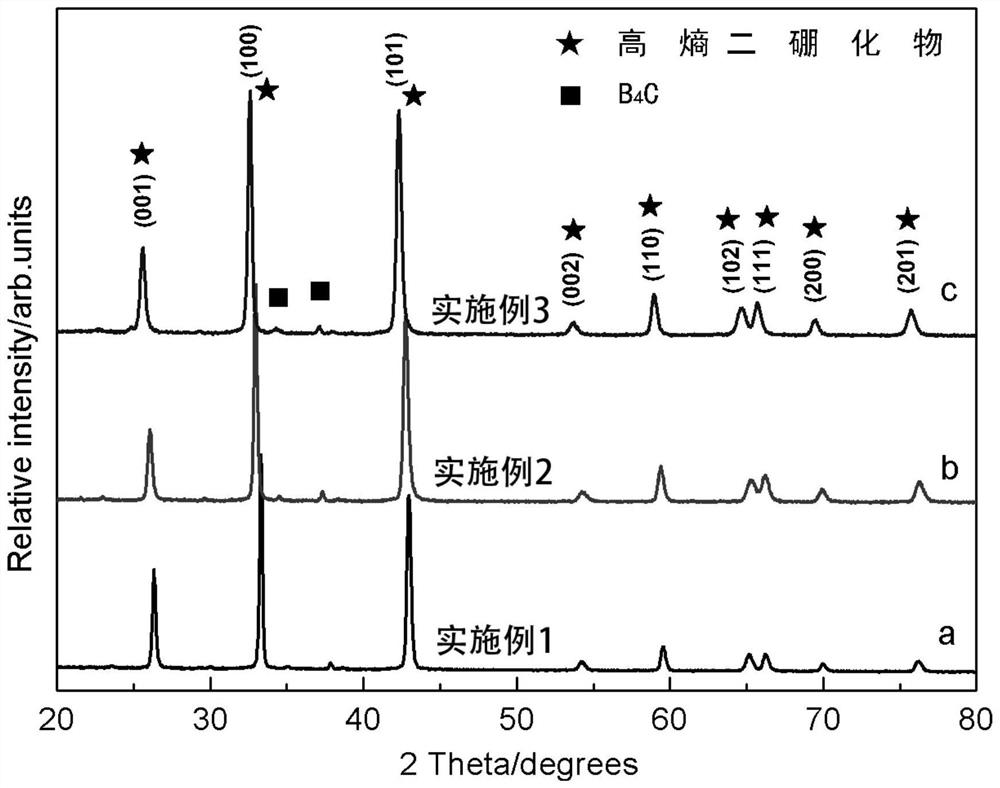

[0030] The X-ray diffraction patterns of the obtained in situ self-generated high-entropy diboride-boron carbide composite ce...

Embodiment 2

[0032] The molar parts of raw materials are as follows: 1 part of titanium carbide, 1 part of zirconium carbide, 1 part of hafnium carbide, 1 part of niobium carbide, 1 part of tantalum carbide, 1 part of vanadium carbide, and 38.5 parts of boron powder. The preparation process is the same as in Example 1, and will not be repeated here.

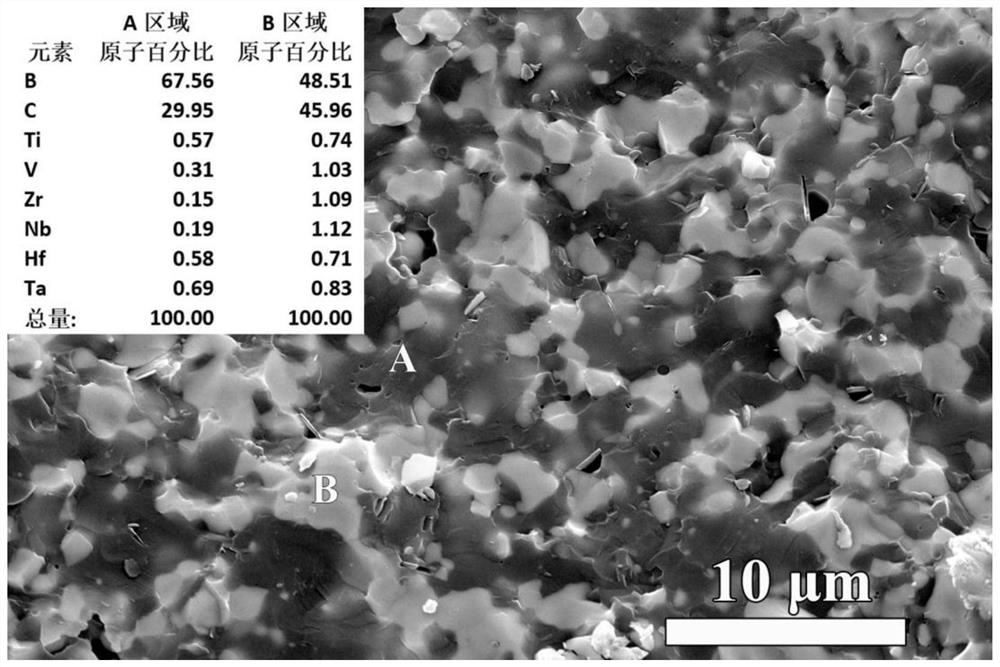

[0033] The X-ray diffraction patterns of the obtained in situ self-generated high-entropy diboride-boron carbide composite ceramics are as attached figure 1 As shown in b, the main phases include high-entropy diboride and boron carbide. The grain size of high-entropy diboride and boron carbide in composite ceramics is about 1 μm, and the metal elements in the high-entropy phase are evenly distributed (attached figure 2 ). The Vickers hardness (Hv5) of the composite ceramics is 21.3±0.8GPa, the flexural strength is 478±49MPa, and the fracture toughness is 5.80±0.55MPa m 1 / 2 .

Embodiment 3

[0035] The parts by weight of raw materials are as follows: 1 part of titanium carbide, 1 part of zirconium carbide, 1 part of hafnium carbide, 1 part of niobium carbide, 1 part of tantalum carbide, 0.25 part of tungsten carbide, and 33.6 parts of boron powder. The preparation process is the same as in Example 1, and will not be repeated here.

[0036] The X-ray diffraction pattern of the obtained in-situ self-generated high-entropy diboride-boron carbide composite ceramics is as follows: figure 1 As shown in c, the main phases include high-entropy diboride and boron carbide. The Vickers hardness (Hv5) of the composite ceramic is 20.9±0.5GPa, the flexural strength is 561±72MPa, and the fracture toughness is 4.45±0.61MPa m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com