A kind of preparation method of alumina ceramic material and alumina ceramic substrate

A technology of alumina ceramics and alumina powder, applied in the field of ceramic materials, can solve the problems of low thermal conductivity and fracture toughness, increase of substrate firing temperature, increase of thermal expansion coefficient, etc., achieve high density, reduce sintering temperature, increase Effect of Thermal Shock Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

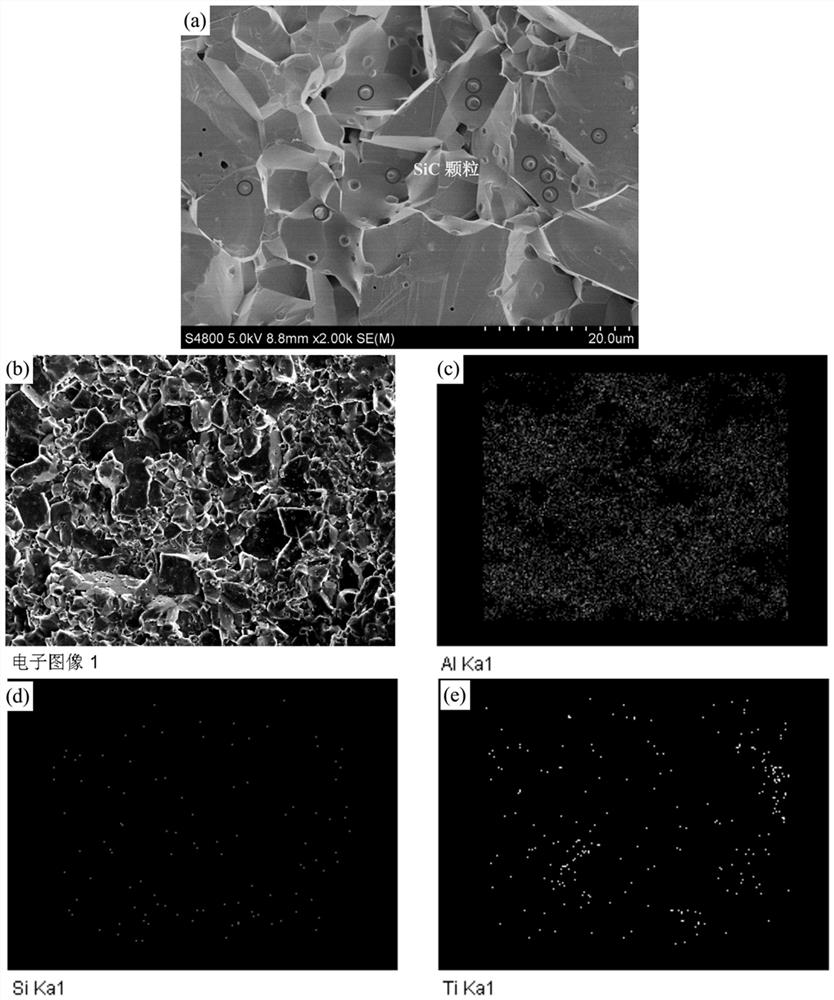

[0062] The preparation method of the alumina ceramic substrate of the present embodiment is as follows:

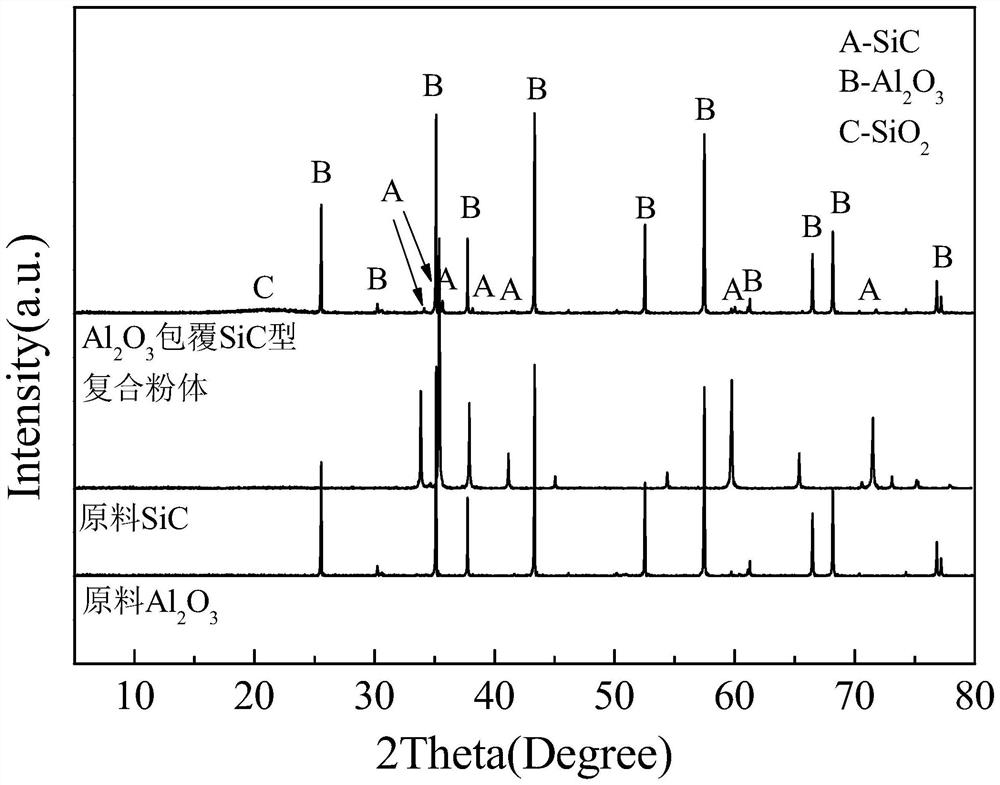

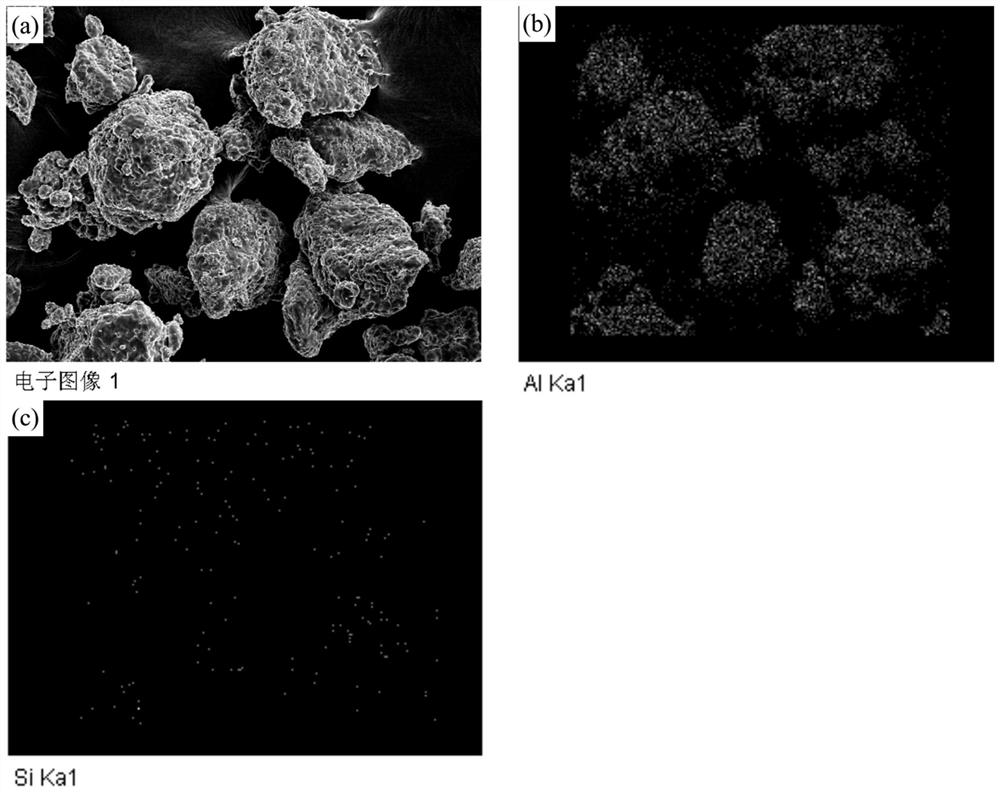

[0063] (1) will D 50 2.5μm silicon carbide powder (μm-SiC), 1.0μm alumina powder (μm-Al 2 o 3 ), 50nm alumina powder (nm-Al 2 o 3 ) powder, and 1.0μm sintering aid powder TiO 2 All were dried at 80°C for 24 hours, and then pressed as μm-SiC powder 4%, μm-Al2 o 3 Powder 89.8%, nm-Al 2 o 3 Powder 5%, sintering aid powder TiO 2 1.2% (mass percentage) was weighed separately for subsequent use;

[0064] (2) The weighed μm-SiC and μm-Al 2 o 3 Put the powder into the ball mill, use water as the medium, and the corundum ball as the grinding ball (the mass ratio of powder: grinding ball: water is 1:2:1.5), first ball mill for 4 hours, and the speed of the ball mill is 300 rpm. -1 , and then add powder (μm-SiC and μm-Al 2 o 3 ) quality 10% PVA solution (concentration of PVA is 4wt%), ball milling 0.5h again, ball mill speed is 200 rev min -1 ;

[0065] (3) Spray gran...

Embodiment 2

[0069] The preparation method of the alumina ceramic substrate of the present embodiment is as follows:

[0070] (1) will D 50 2.5μm silicon carbide powder (μm-SiC), 1.0μm alumina powder (μm-Al 2 o 3 ), 50nm alumina powder (nm-Al 2 o 3 ) powder, and 1.0μm sintering aid powder (made of MgO, TiO 2 According to the mass ratio of 2:3), all were dried at 80°C for 24h, and then 8% of μm-SiC powder, μm-Al 2 o 3 Powder 81%, nm-Al 2 o 3 10% of the powder and 1% (mass fraction) of the sintering aid powder are weighed separately for later use;

[0071] (2) The weighed μm-SiC and μm-Al 2 o 3 Put it into a ball mill, use water as the medium, and corundum balls as grinding balls (the mass ratio of powder: grinding balls: water is 1:2:1.5), first ball mill for 6 hours, and the speed of the ball mill is 400 rpm. -1 , and then add powder mass (μm-SiC and μm-Al 2 o 3 quality) 10% PVA solution, then ball milled for 0.5h, and the ball mill speed was 200 rpm. -1 ;

[0072] (3) Spray...

Embodiment 3

[0076] The preparation method of the alumina ceramic substrate of the present embodiment is as follows:

[0077] (1) will D 50 2.5μm silicon carbide powder (μm-SiC), 1.0μm alumina powder (μm-Al 2 o 3 ), 50nm alumina powder (nm-Al 2 o 3 ) powder, and 1.0 μm sintering aid powder (composed of MgO, CaO in a mass ratio of 5:3) were dried at 80°C for 24 hours, and then pressed as μm-SiC powder 12%, μm-Al 2 o 3 Powder 71.4%, nm-Al 2 o 3 15% of the powder and 1.6% (mass percentage) of the sintering aid powder are weighed separately for later use;

[0078] (2) The weighed μm-SiC and μm-Al 2 o 3 Put the powder into the ball mill, use water as the medium, and the corundum ball as the grinding ball (the mass ratio of powder: grinding ball: water is 1:2:1.5), first ball mill for 8 hours, and the speed of the ball mill is 450 rpm. -1 , and then add the powder mass (μm-SiC and μm-Al 2 o 3 total mass) of 10% PVA solution, then ball milled for 0.5h, and the ball mill speed was 200 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com