A kind of heavy-duty engine powder metallurgy valve seat material and preparation method thereof

A powder metallurgy and engine technology, applied in the field of powder metallurgy valve seat materials for heavy-duty engines and their preparation, can solve problems such as poor wear resistance, and achieve the effects of improving wear resistance, avoiding spalling, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

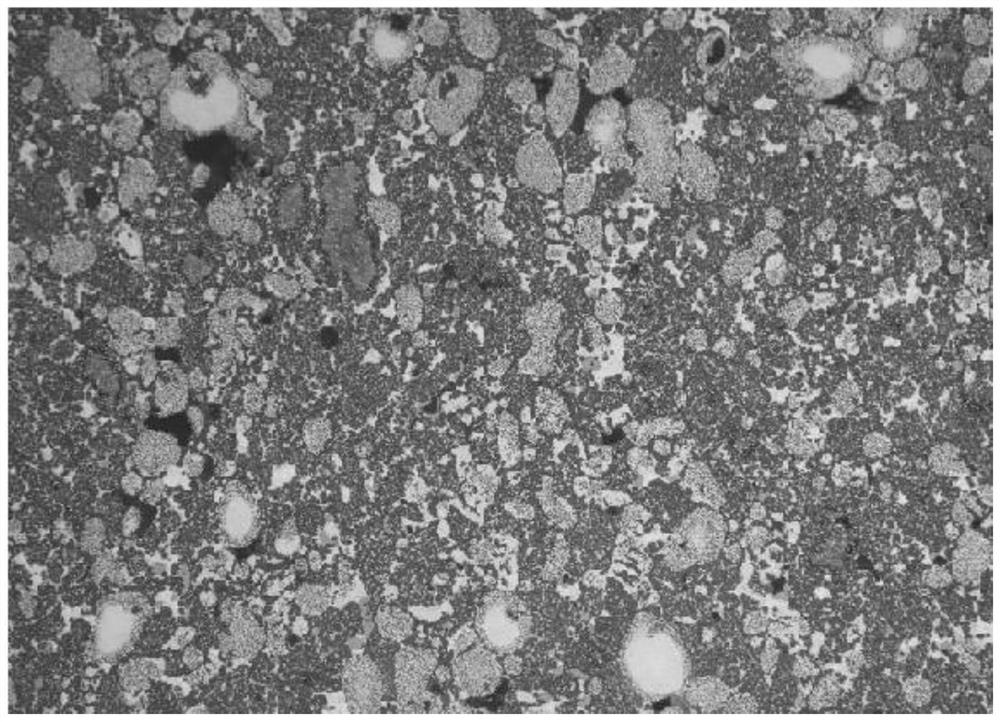

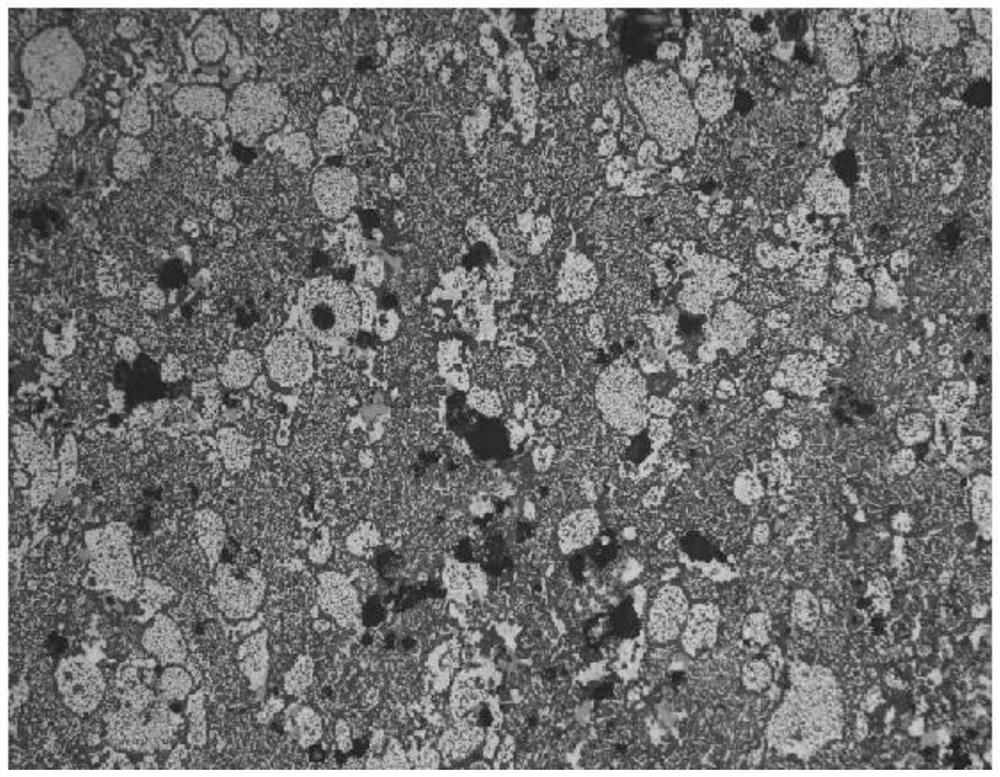

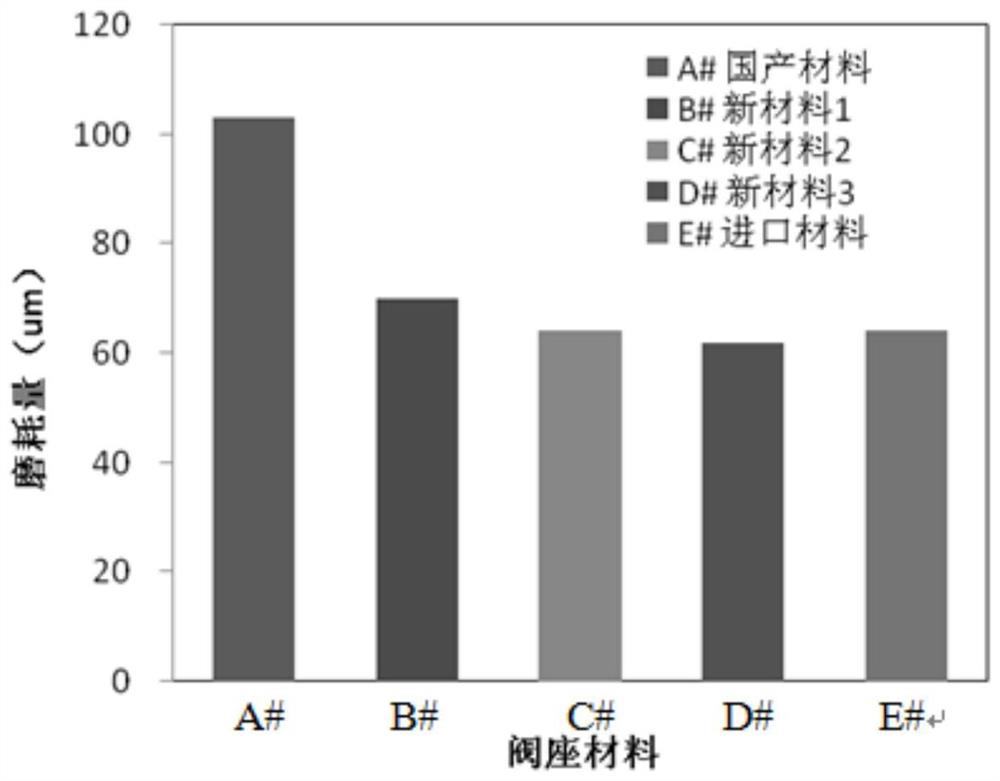

Image

Examples

preparation example Construction

[0039] A method for preparing a powder metallurgy valve seat material for a heavy-duty engine comprises the following steps in sequence:

[0040] 1. First mix the FeMoSiMn metal alloy powder, solid lubricant and matrix forming powder in proportion, and then press the mixed powder into a green body;

[0041] 2. First sinter the green body and carry out infiltration copper treatment in the form of a copper billet, and then perform tempering treatment and cryogenic treatment in sequence.

[0042] In step 1, the mixing time is 1-2 hours, and the density of the green body is 6.6-7.0 g / cm 3 ;

[0043] In step 2, the sintering temperature is 1100-1200°C, and the tempering temperature is 400-600°C.

[0044] Composition and effect of material of the present invention are as follows:

[0045] In the present invention, a large amount of FeMoSiMn metal alloy powder is added to the powder formed by the iron matrix, and the fine powder and coarse powder are added in a certain proportion,...

Embodiment 1

[0059] A heavy-duty engine powder metallurgy valve seat material, its raw material composition and mass percentage content are: FeMoSiMn metal alloy powder 30, CaF 2 0.8, MoS 2 0.6, MnS 0.4, micro-wax powder 0.6, and the rest are high-speed steel powder. Wherein, the FeMoSiMn metal alloy powder is composed of fine powder particles with a particle size of 20-50um and coarse powder particles with a particle size of 50-100um, and the mass percentage of the fine powder particles is 40, and the iron matrix forming powder is composed of The fine powder particles with a particle size of 20-50um and the coarse powder particles with a particle size of 50-80um are composed, and the mass percentage content of the fine powder particles is 60, and the raw material composition and weight percentage content of the FeMoSiMn metal alloy powder are Si 10 , Mo 50, Mn 4, V 1, W 2, Ni0.5, Cu 1, and the rest are Fe and unavoidable impurities.

[0060] A method for preparing a heavy-duty engine ...

Embodiment 2

[0065] The difference with Example 1 is:

[0066] The raw material composition and mass percentage content of the material are: FeMoSiMn metal alloy powder 40, MoS 2 1. MnS0.4, graphite powder 0.8, microwax powder 0.6, chromium-containing steel powder 6, and the rest are high-speed steel powder. The raw material composition and weight percent content of the FeMoSiMn metal alloy powder are Si 6, Mo 35, Mn 2, V 0.2, W 1.3, Ni 0.2, Cu 2.0, and the rest are Fe and unavoidable impurities.

[0067] In step 1, the mixing time is 2h;

[0068] In step 2, the sintering temperature is 1200°C, and the tempering temperature is 600°C.

[0069] The chemical composition and mass percentage content of the material prepared by this method are: Mo 12.84, Mn0.8, Co 0.07, W 2.8, V 0.8, Cr 1.9, Ni 0.1, Cu 18, Si 1.9, C 0.95, and the rest are Fe and unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com