Method for measuring content of free magnesium oxide in steel slag

A free magnesia and determination method technology, applied in the field of comprehensive utilization of steel slag, can solve the problems of low activity of free magnesia, concrete stability, cracking of steel slag concrete, etc., and achieve the effect of easy color and observation at the end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

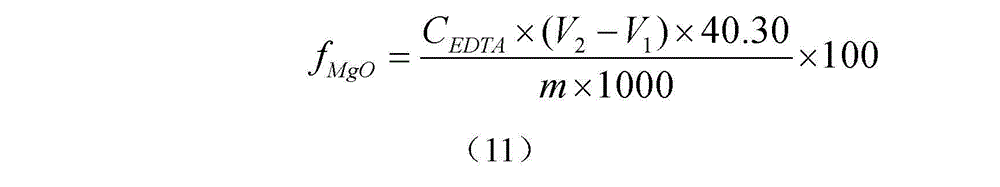

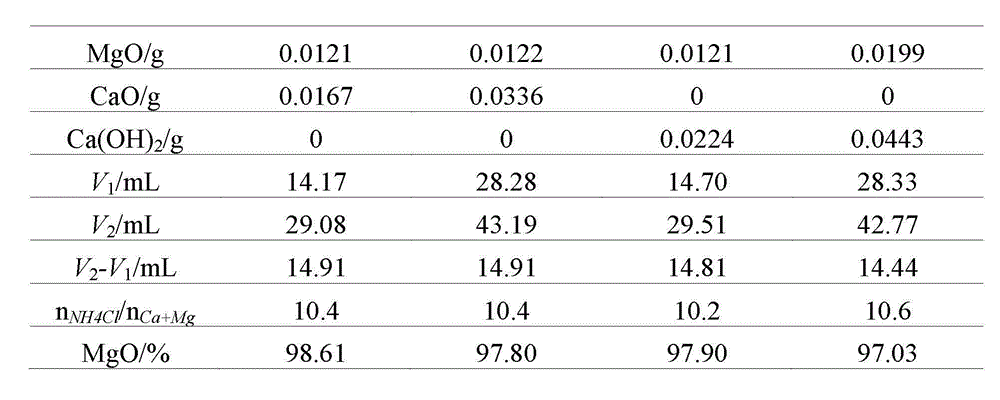

[0053] At the same time, weigh two parts of the mixed sample of analytical pure magnesium oxide and calcium oxide and the mixed sample of analytical pure magnesium oxide and calcium hydroxide. Calcium 0.0336 g, 3# is magnesium oxide 0.0121 g, calcium hydroxide 0.0224 g, 4# is magnesium oxide 0.0119 g, calcium hydroxide 0.0443 g. Place them in dry ground-mouthed Erlenmeyer flasks, add 30 mL of ethylene glycol-ethanol solution and catalyst ammonium chloride, connect the Erlenmeyer flasks to a condenser, then magnetically heat and stir, and heat the solution for 20 min after slightly boiling and refluxing. Stop heating, wait until all the liquid in the condenser pipe flows into the conical flask, transfer the liquid in the conical flask to a dry centrifuge tube, wash the conical flask with ethanol for 3 times, pour the washing solution into the centrifuge tube, and place the liquid in the centrifuge at 3500 r Centrifuge at a speed of 15 min, discard the precipitate after centrifu...

Embodiment 2

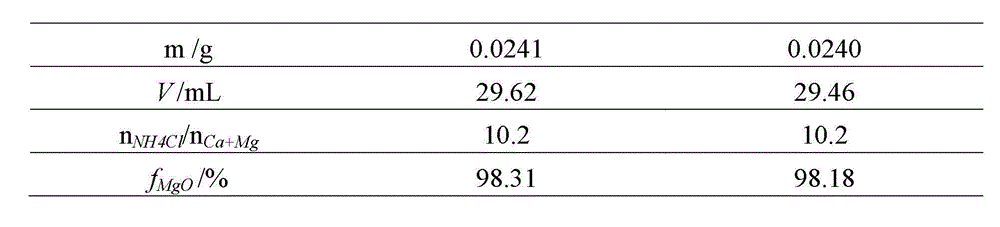

[0062] At the same time, weigh two samples of free magnesia obtained from analytically pure magnesia by calcination at 1600 °C and heat preservation for 50 minutes. Place them in dry ground-mouth Erlenmeyer flasks, add 30 mL of ethylene glycol-ethanol solution and 0.3220 g of ammonium chloride, connect the Erlenmeyer flasks to a condenser, then magnetically heat and stir, and heat the solution for 20 min after slightly boiling and refluxing. Stop heating, wait until all the liquid in the condenser pipe flows into the conical flask, transfer the liquid in the conical flask to a dry centrifuge tube, wash the conical flask with ethanol for 3 times, pour the washing solution into the centrifuge tube, and place the liquid in the centrifuge at 3500 r Centrifuge at a speed of 15 min, discard the precipitate after centrifugation, pour the upper layer liquid into a dry Erlenmeyer flask, then transfer the upper layer liquid into a 100 mL volumetric flask and dilute to the mark, and final...

Embodiment 3

[0069] At the same time, weigh four samples of 0.4000 g Xinyu steel slag, add different amounts of ammonium chloride, 0.8663 g for 1#, 1.0002 g for 2#, 1.5559 g for 3#, and 2.0000 g for 4#, and place them in the dry grinding port respectively Add 30 mL of ethylene glycol-ethanol solution to the Erlenmeyer flask, connect the Erlenmeyer flask to the condenser, then magnetically heat and stir, and heat the solution for 20 min after slightly boiling and refluxing. Stop heating, wait until all the liquid in the condenser pipe flows into the conical flask, transfer the liquid in the conical flask to a dry centrifuge tube, wash the conical flask with ethanol for 3 times, pour the washing solution into the centrifuge tube, and place the liquid in the centrifuge at 3500 r Centrifuge at a speed of 15 min, discard the precipitate after centrifugation, pour the upper layer liquid into a dry Erlenmeyer flask, then transfer the upper layer liquid into a 100 mL volumetric flask and dilute to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com