Device and method used for removing hypophosphites and phosphites in chemical nickel plating waste water

A technology of electroless nickel plating and hypophosphite, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of low removal efficiency, high treatment cost, incomplete treatment, etc., and achieve operating costs Low sludge yield, efficient and thorough reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

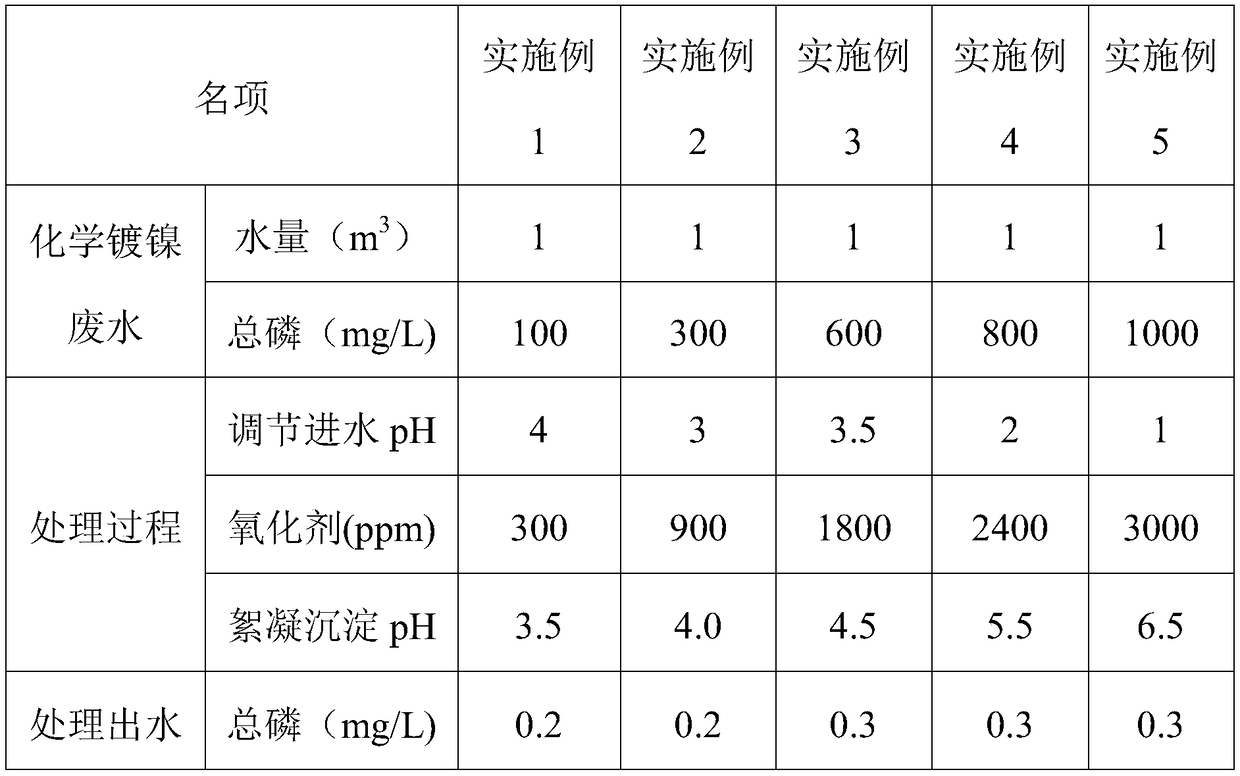

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing:

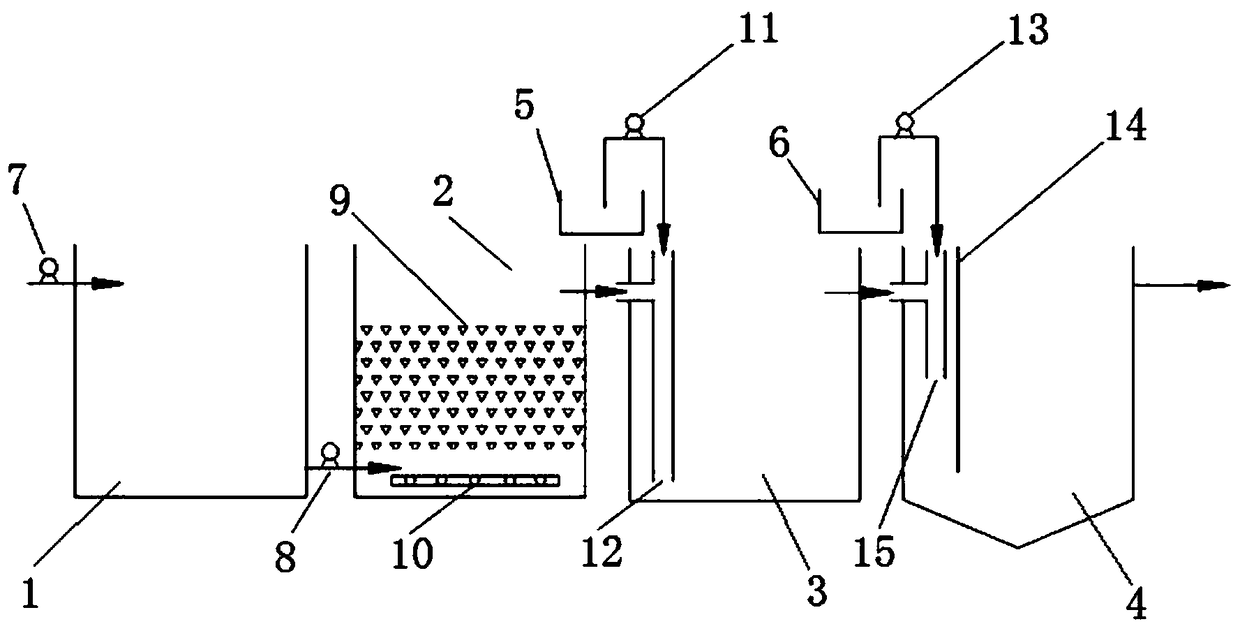

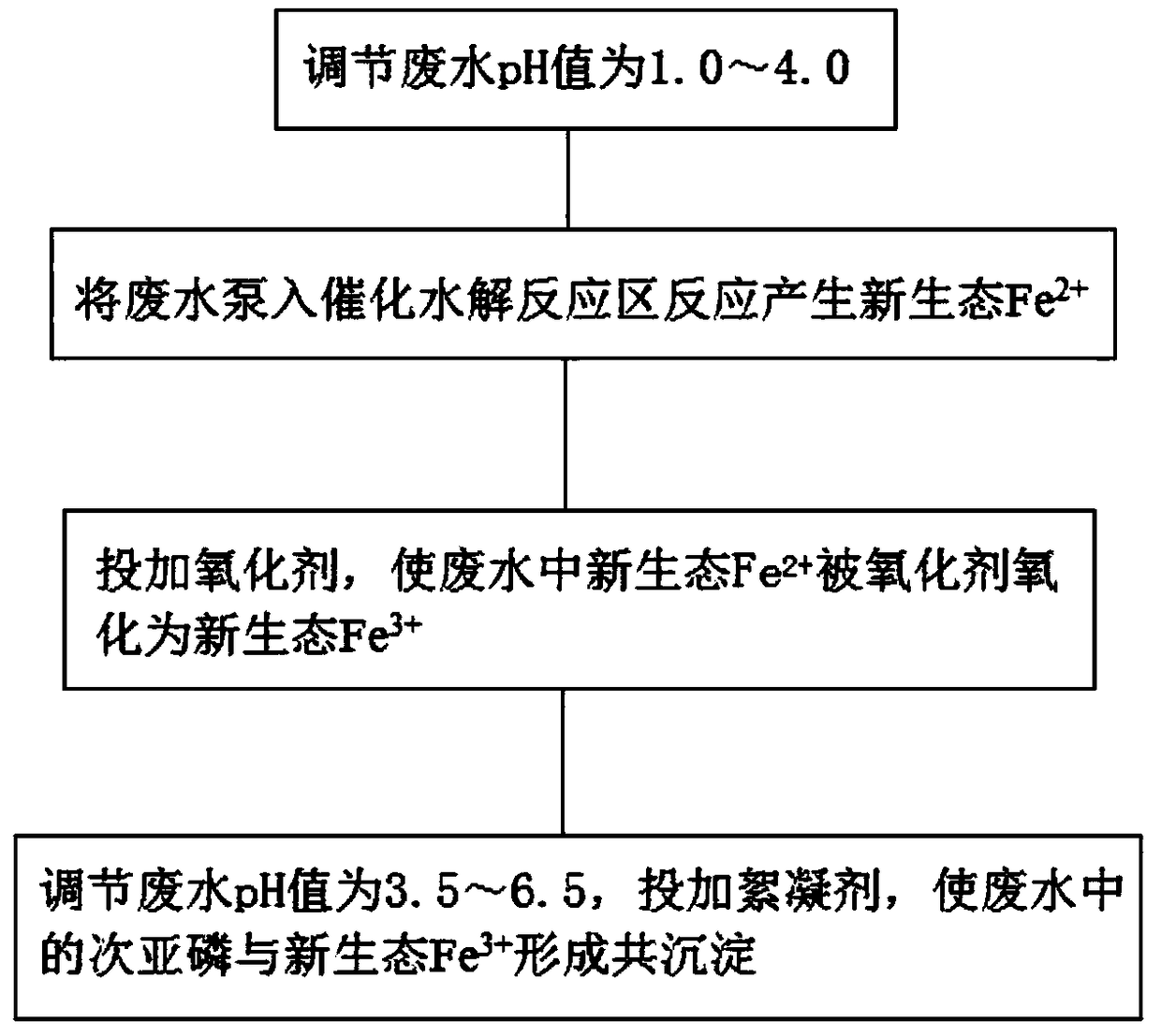

[0033] see figure 1 As shown, a device for removing hypophosphorous in electroless nickel-plating wastewater is provided, including a regulating tank 1, a catalytic hydrolysis reaction tank 2, an oxidation tank 3, a flocculation sedimentation tank 4 connected in sequence by pipelines, and also includes an oxidant storage tank 5 and A flocculant storage tank 6, the oxidant storage tank 5 is connected to the oxidation tank 3, the flocculant storage tank 6 is connected to the flocculation sedimentation tank 4, and the water inlet of the adjustment tank 1 is provided with a first lift pump 7 A second lift pump 8 is provided on the pipeline connected between the regulating tank 1 and the catalytic hydrolysis reaction tank 2, and a first metering pump 11 is provided on the pipeline connected between the oxidant storage tank 5 and the oxidation tank 3, A second metering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com