Preparation method for polyvinyl butyral resin

A polyvinyl alcohol and resin technology, applied in the field of preparing polyvinyl butyral, can solve problems such as affecting product production, and achieve the effects of improving reactivity, reducing hydroxyl value, and promoting the formation of microphases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

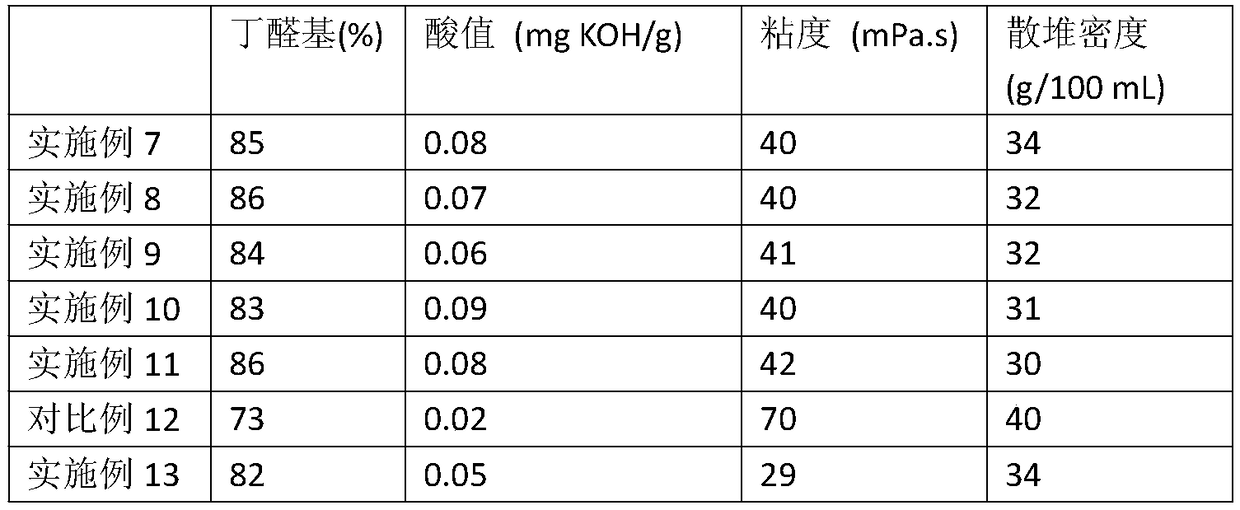

Examples

Embodiment 1

[0034] Add 800mL of deionized water to a 2000mL four-necked bottle equipped with a stirrer, a thermometer and a dropping funnel and heat it to 98°C with an electric heating mantle. Add 100g of polyvinyl alcohol in batches until the polyvinyl alcohol is completely dissolved. An aqueous solution of polyvinyl butyral was prepared.

[0035] Catalyst preparation method

[0036] A series of organic sulfonic acid compounds with C10-C30 were prepared by acidification with sodium sulfonate.

[0037] At 0-5°C, add 5-20 g of organic sulfonic acid sodium salt into 10 times the amount (mass) of 1 mol / L hydrochloric acid solution, and extract the aqueous phase with ether. The organic phase was dried, filtered and concentrated to prepare organic sulfonic acid.

Embodiment 2

[0039] At 0-5°C, add 20 g of sodium dodecylsulfonate to 10 mL of 1 mol / L hydrochloric acid solution, and extract the aqueous phase three times with 20 mL of ether. The organic phase was dried over anhydrous sodium sulfate for 1-2 hours, the organic phase was dried, filtered and concentrated, concentrated under low temperature and reduced pressure to obtain 10.2 g of dodecylsulfonic acid light yellow oil.

Embodiment 3-6

[0041] Using the same method as in Example 2, different sodium salts were selected, and a series of sulfonic acid catalysts were prepared under low-temperature acidification conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com