Nuclear pore membrane small sample etching apparatus

An etching device and technology of nuclear pore membrane, which is applied in the field of small sample etching device of nuclear pore membrane, can solve the problem of the accuracy of heating temperature, the uniformity of etching temperature, the convenience of sealing sampling and the difficulty in meeting the requirements, the resistance of sealing materials Corrosion, sampling convenience is difficult to meet the requirements, etc., to achieve the effect of easy cleaning and drying, convenient sampling, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

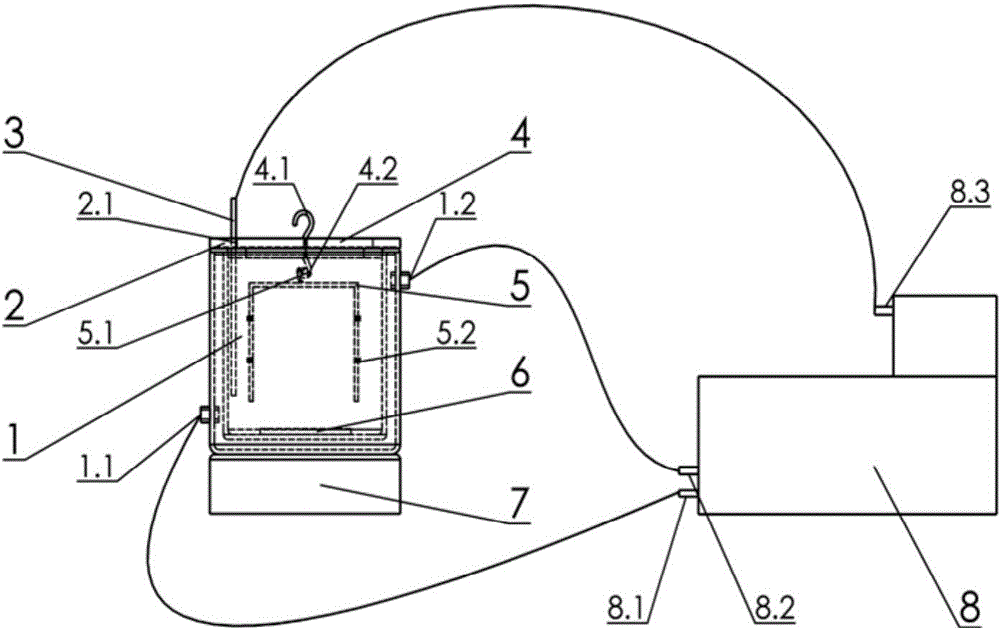

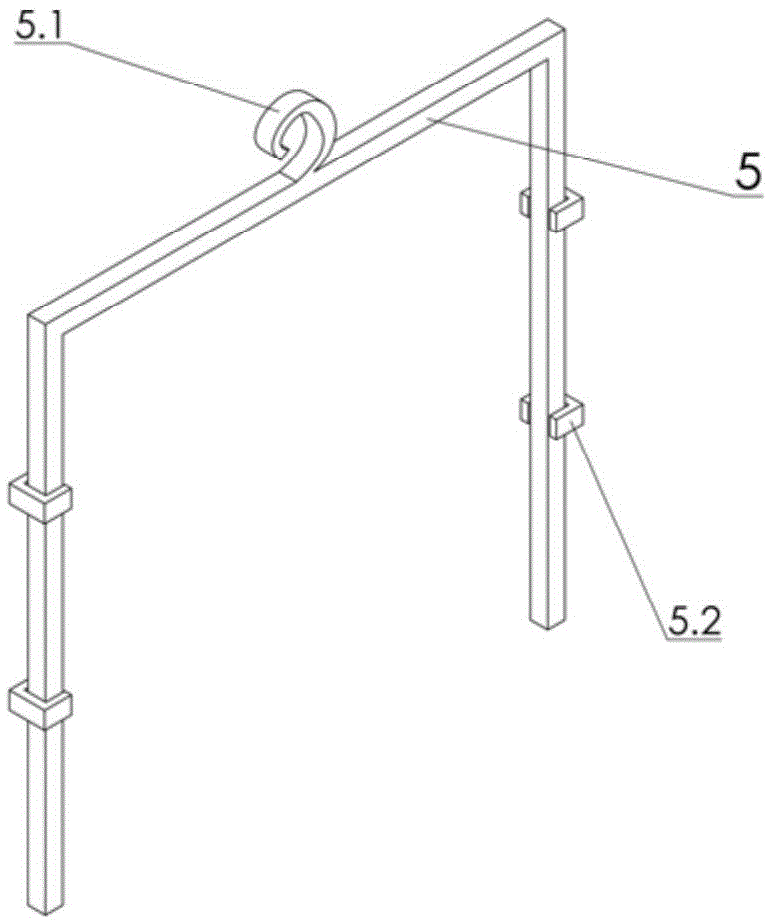

[0030] Example 1: see figure 1 , a small sample etching device for nuclear pore membranes, comprising an etching cup 1, a sealed upper cup cover 2 is arranged above the etching cup 1, and an inner part sealed with the etching cup 1 is provided below the upper cup cover 2 Cover 4, a film support 5 is provided under the inner cover 4, and a thermal probe 3 is provided in the etching cup 1; the cup wall of the etching cup 1 is double-layered, and the upper and lower sides are respectively provided with water inlets 1-1 and the water outlet 1-2, the water inlet 1-1 and the water outlet 1-2 communicate with the water outlet 8-1 and the water inlet 8-2 of the constant temperature circulation system 8 respectively; There are magnets 6 and magnetic stirrer 7 to form magnetic transmission stirring.

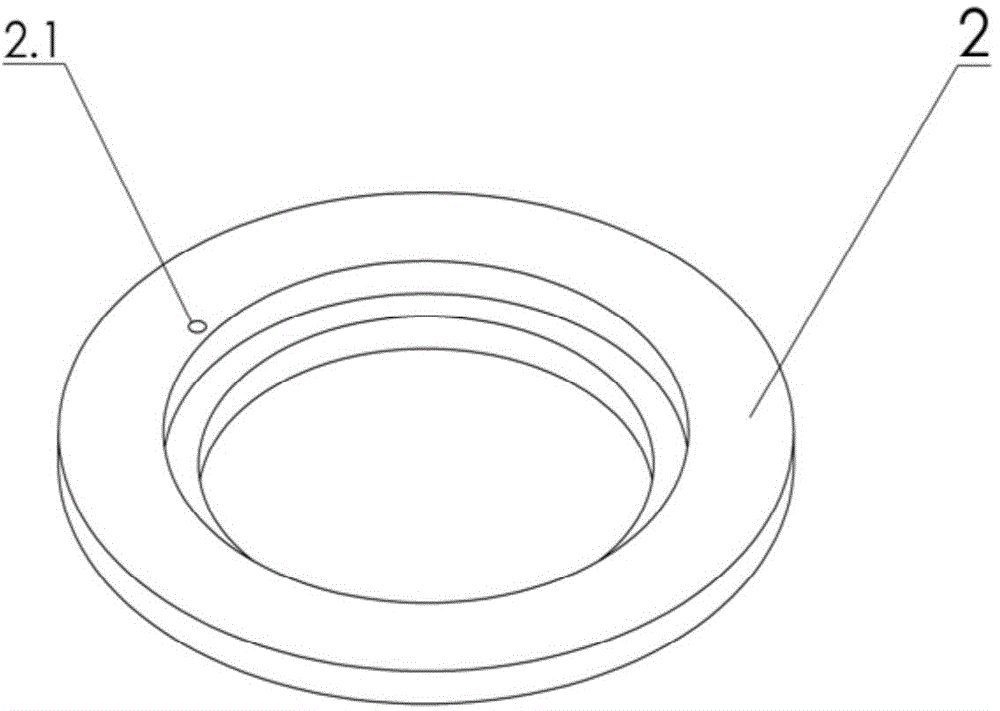

[0031] See figure 2 , the nuclear pore membrane small sample etching device, the thermal probe 3 is inserted into the etching cup 1 through the through hole 2-1 on the edge of the upper...

Embodiment 2

[0038] Embodiment 2: A device for etching small samples of nuclear pore membranes.

[0039] The cup body of described etching cup 1 is 30 centimeters in diameter, 30 centimeters in height, and material is glass.

[0040] The upper cup cover 2 has a through hole 2-1 on the edge, where a thermal probe is placed, and the material is polytetrafluoroethylene.

[0041] In the inner cover 4, the upper hook 4-1 is used to lift and hang the inner cover, and the lower hook 4-2 is connected with the hook of the membrane support, and the material is polytetrafluoroethylene.

[0042] The membrane support 5 is a frame structure with a hook 5-1 on it, and a movable fixing slider clip 5-2 on the frame. The material is polytetrafluoroethylene.

[0043] The magnetic stirrer 7 is used in groups with the etching cup.

[0044] In the constant temperature circulating water system 8, the water inlet 8-1 and the water outlet 8-2 are connected to the etching cup 1, and the temperature of the liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com