Forage treatment device for livestock breeding

A technology for processing device and forage, applied in the field of animal husbandry, can solve the problems of inclusions, multiple harmful impurities, and high input cost, and achieve the effects of reducing harmful impurities, improving growth quality, and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

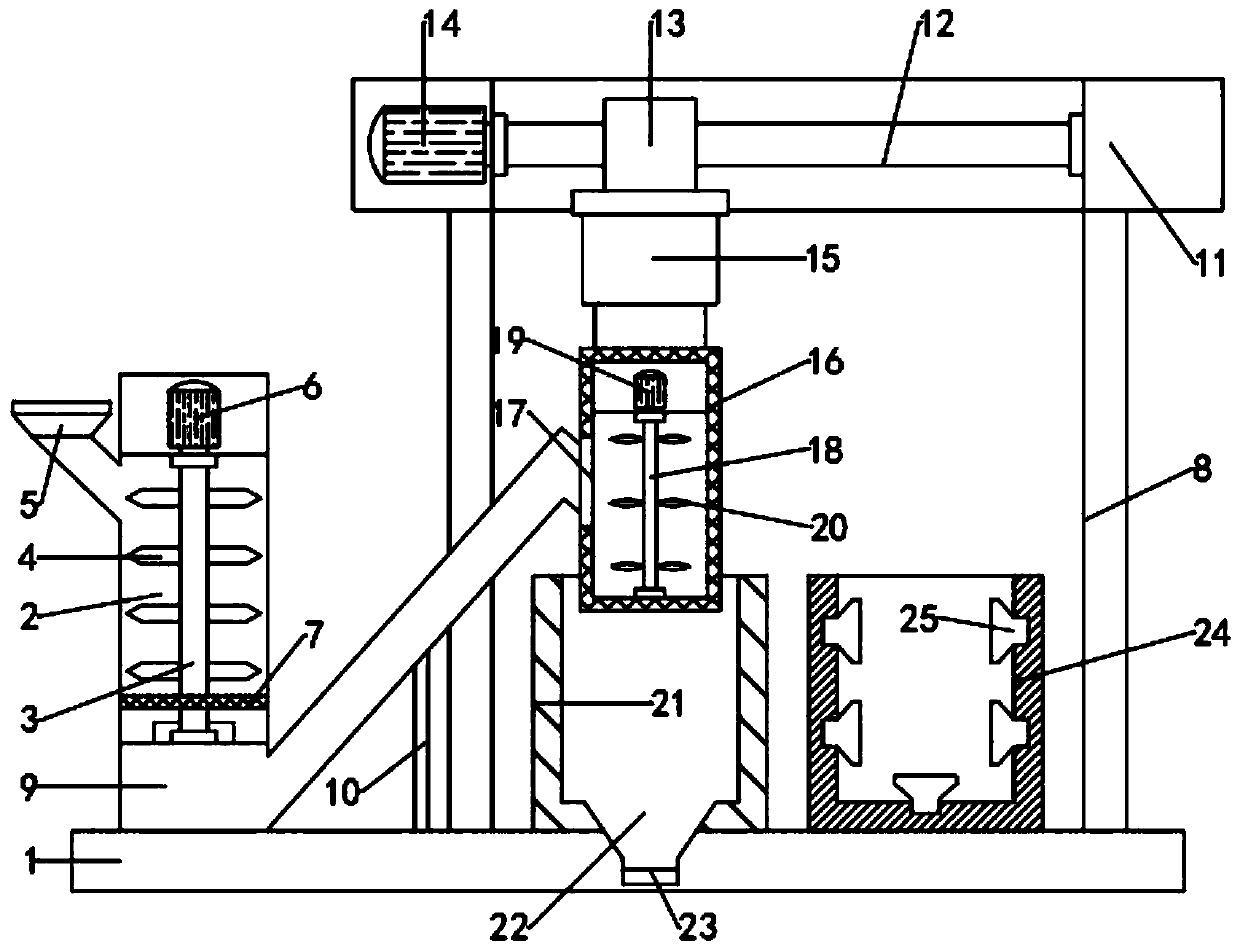

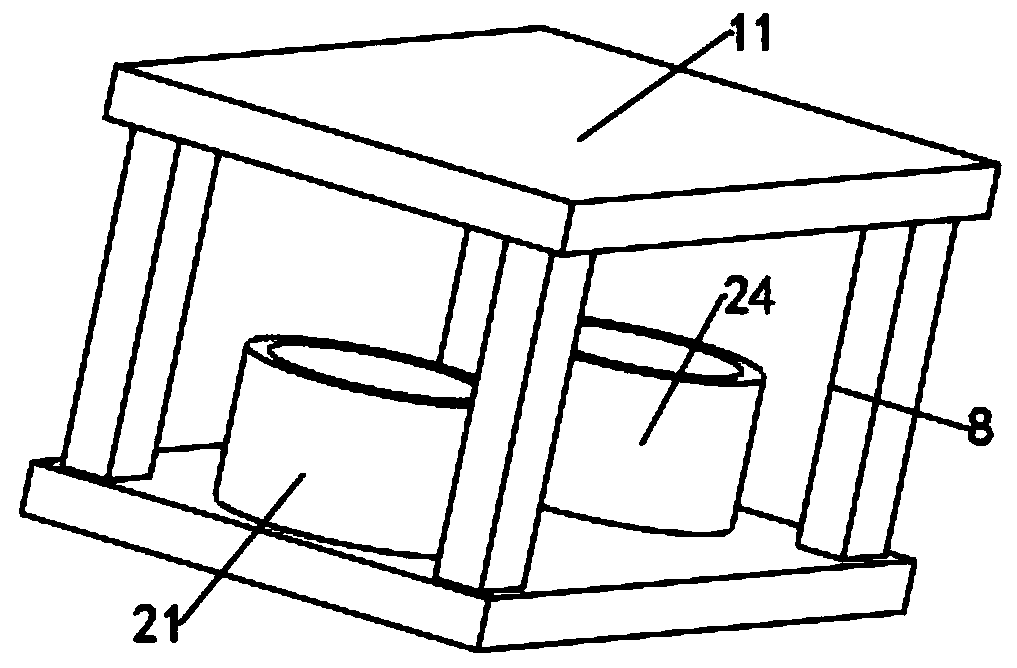

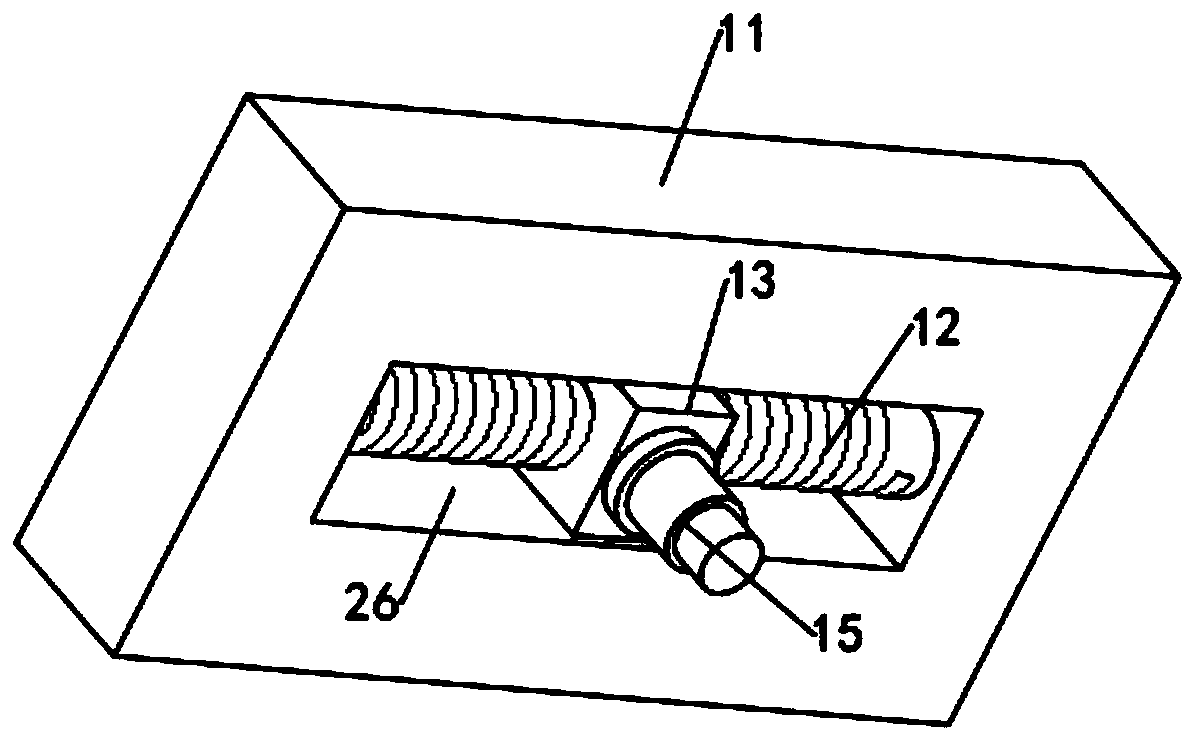

[0021] see Figure 1-4 , a forage processing device for animal husbandry, comprising a base 1, the upper end surface of the base 1 is sequentially provided with a crushing mechanism, a cleaning mechanism and a drying mechanism; the crushing mechanism includes a crushing chamber 2, the crushing chamber 2 The inside is equipped with a vertical crushing shaft 3, and a plurality of crushing blades 4 are uniformly arranged on the crushing shaft 3, and one end of the crushing shaft 3 extends to the inner upper part of the crushing chamber 2 and is connected with a crushing motor 6; The upper part of one side is obliquely connected with a hopper 5, and the inner lower part of the crushing chamber 2 is equipped with a screen 7, and the lower part of one side of the crushing chamber 2 is movably connected with the storage chamber 6 through a screw conveyor 9, and the screw conveyor 9 passes through a fixed frame 10 Tilted on the base 1.

[0022] The upper end surface of the base 1 is ...

Embodiment 2

[0031] After cleaning the fodder, there is still a lot of dirt in the cleaning chamber 21, and the cleaning chamber 21 needs to be rinsed. In order to facilitate the cleaning of the cleaning chamber 21, this embodiment is improved on the basis of Embodiment 1. The place is: the inner bottom of the cleaning chamber 21 is provided with a funnel-shaped deflector 22, and the deflector 22 is connected with the outlet pipe 23, so as to completely clean and discharge the dirt in the cleaning chamber 21, which is convenient for subsequent use .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com