Clean container latching structure

A technology for clean containers and fastening parts, which is applied in semiconductor/solid-state device manufacturing, clamping devices, closing, etc. It can solve the problem of easy accumulation of fine dust on fastening parts and metal cover plates, which is not conducive to the cleaning and drying of photomask boxes, Increase parts and other problems to achieve the effect of improving fastening reliability and cleanliness, avoiding elastic fatigue and no metal components, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The preferred embodiments of the present invention are described in detail below with reference to the drawings.

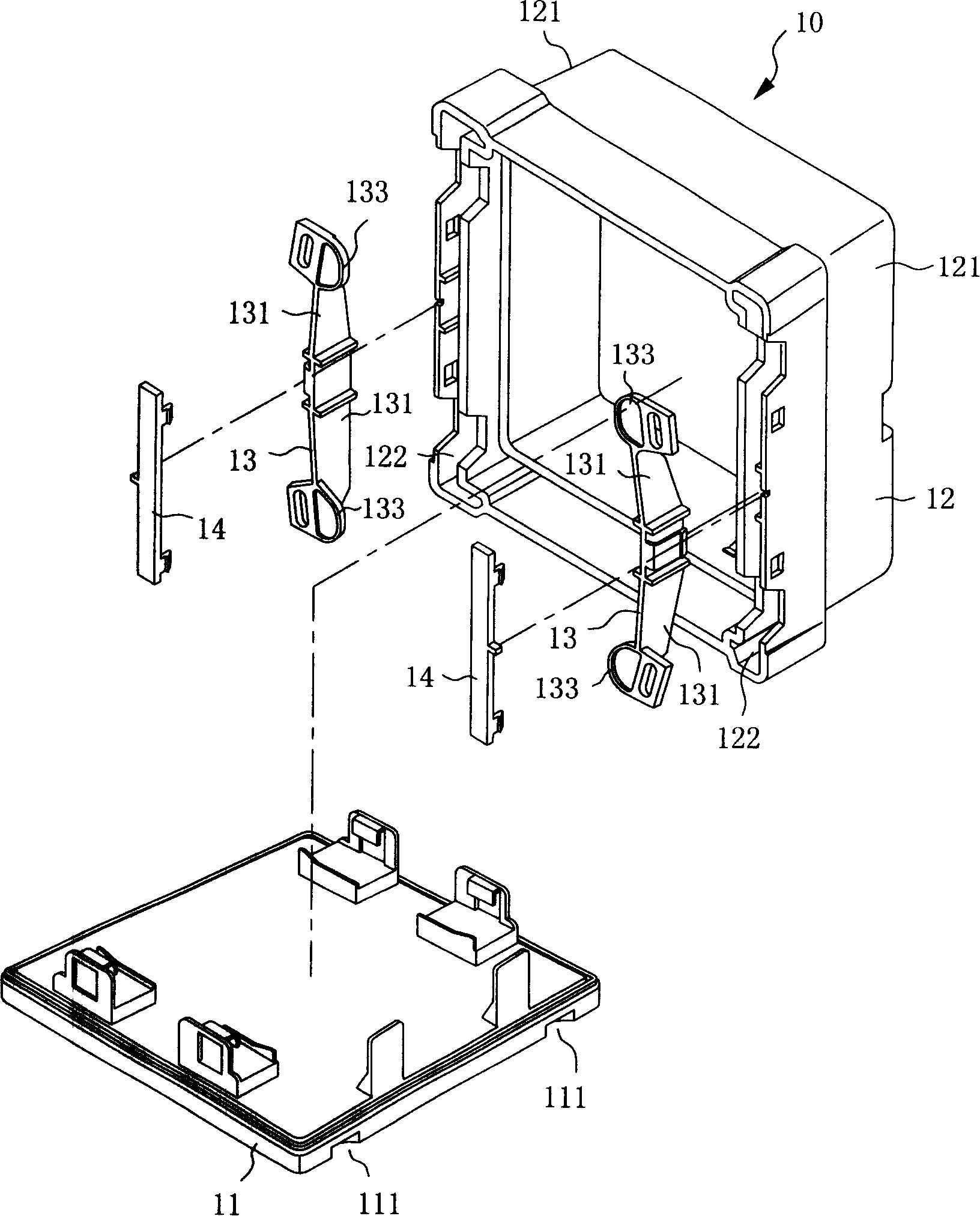

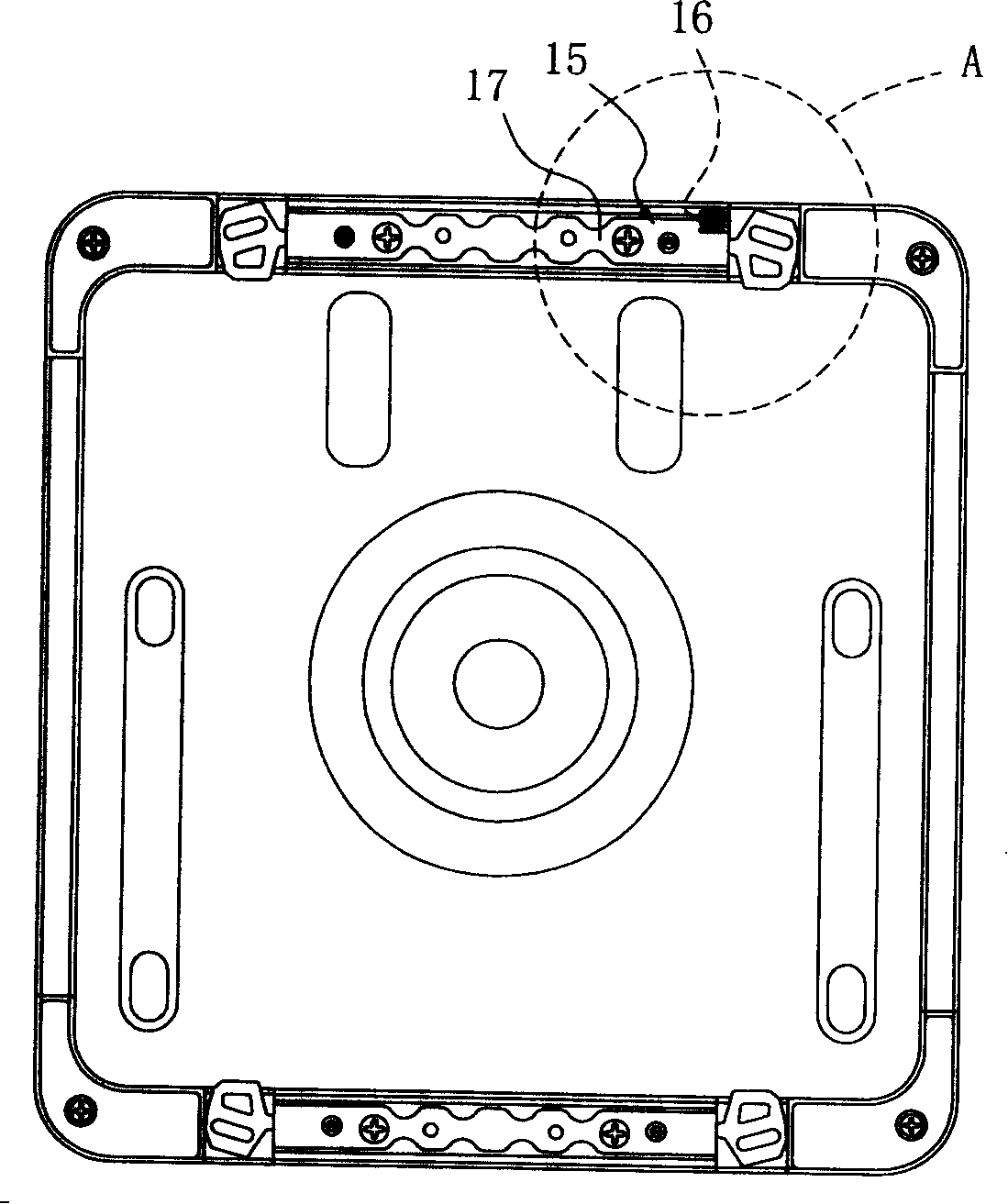

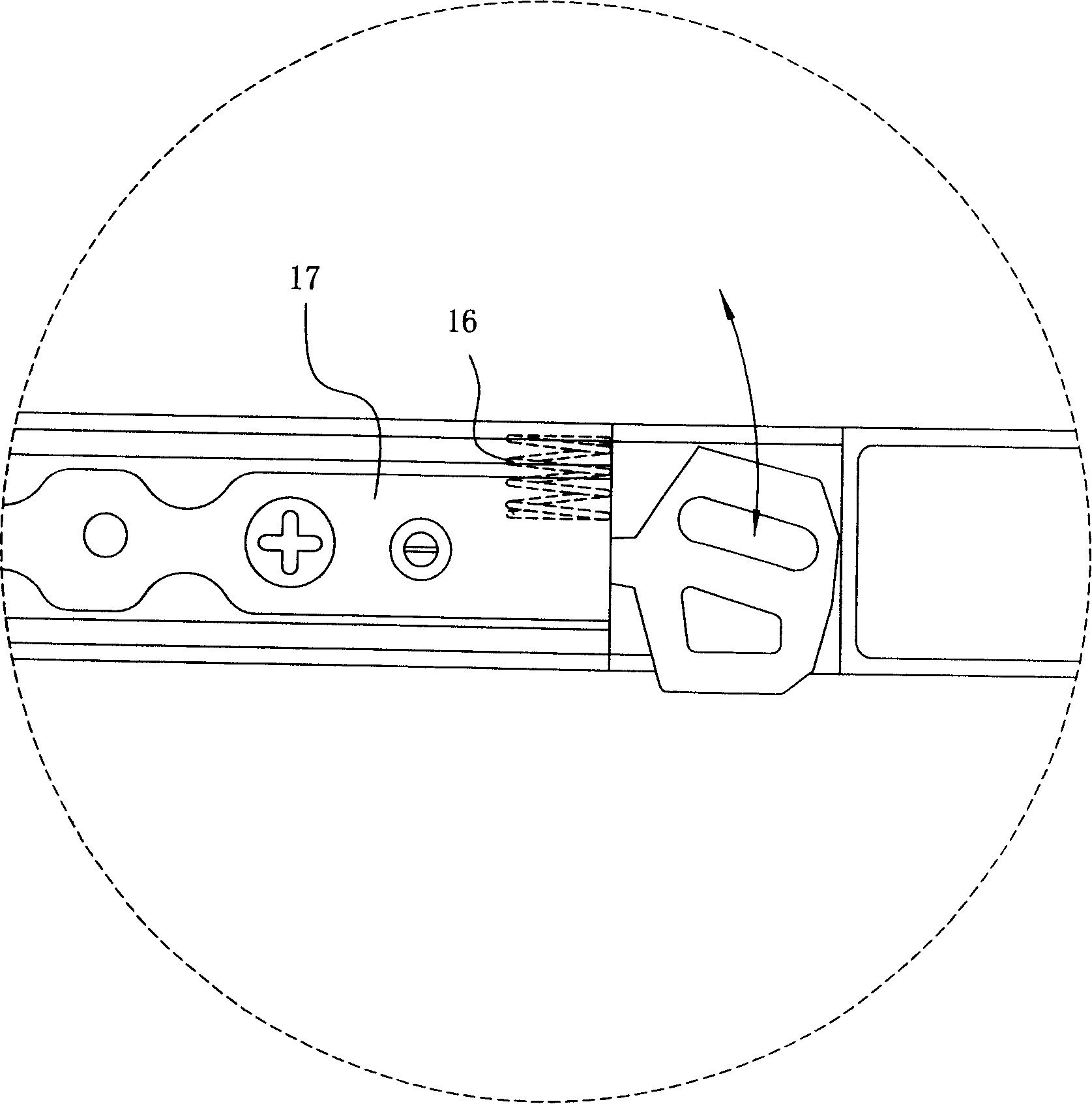

[0062] First please refer to figure 2 The three-dimensional exploded view of the illustrated embodiment of the fastening structure of the clean container of the present invention, image 3 depicted figure 2 The three-dimensional exploded view of the fastening piece and the housing groove of the cover, Figure 4 A perspective view of the first embodiment of the fastening member and the elastic auxiliary arm of the clean container fastening structure of the present invention is shown. Among them, the fastening structure of the clean container 20 in the embodiment of the present invention mainly utilizes one or more fastening parts 50, which are detachably combined with the cover 40 of the clean container in an embedded manner, so that the cover 40 can be connected with the clean The seat body 30 of the container performs the operation of fastening or ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com