a cleaning component

A technology for cleaning components and components, used in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of large mopping area, reduced service life, inconvenient cleaning, etc., to reduce work intensity, improve service life, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

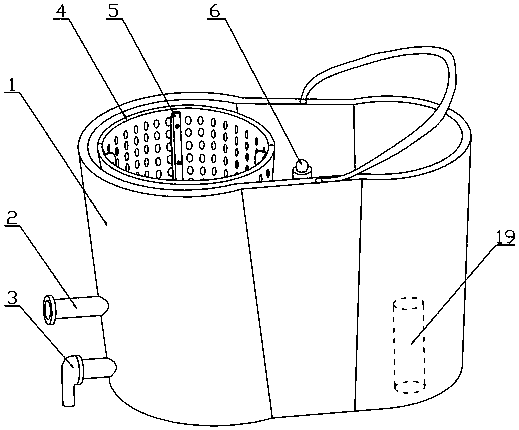

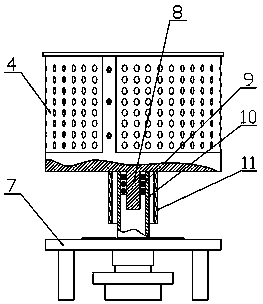

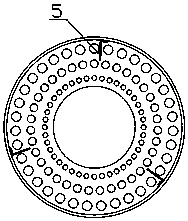

[0031] Embodiment 1 of the present invention: directly place the disc-fixed mop head in the cleaning bucket for cleaning, and then clamp the disc in the middle of the circularly arranged limiting plate for spin-drying before use.

Embodiment approach 2

[0032] Embodiment 2 of the present invention: when mopping the floor with bulk mop heads for cleaning, since the bulk mop heads are relatively bulky, first place a centering chuck on the end of the telescopic rotating handle, and then turn the loose-leaf lock plate down and lock it. Then place the centering chuck in the limit plate arranged in a ring and rotate for dehydration (the centering chuck can effectively prevent the mop head from deviating from its position during dehydration). In this case, the big mop head can still be cleaned conveniently and quickly Shake dry.

[0033] The present invention has the following beneficial effects:

[0034] 1. It can realize the cleaning and drying of the disc fixed mop head (the set limit plate realizes the clamping of the disc fixed mop head) and the bulk mop head at the same time, overcoming the traditional cleaning equipment that can only clean and dry the disc fixed mop The disadvantages of the mop head; and because the bulk mop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com