Automatic mixing device for mixed feed additive

A technology of feed additives and mixing equipment, applied in feed, mixers, mixing methods, etc., can solve the problems of insufficient sealing, no refrigeration temperature control system, etc., and achieve the effects of improving quality, reducing dust leakage, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

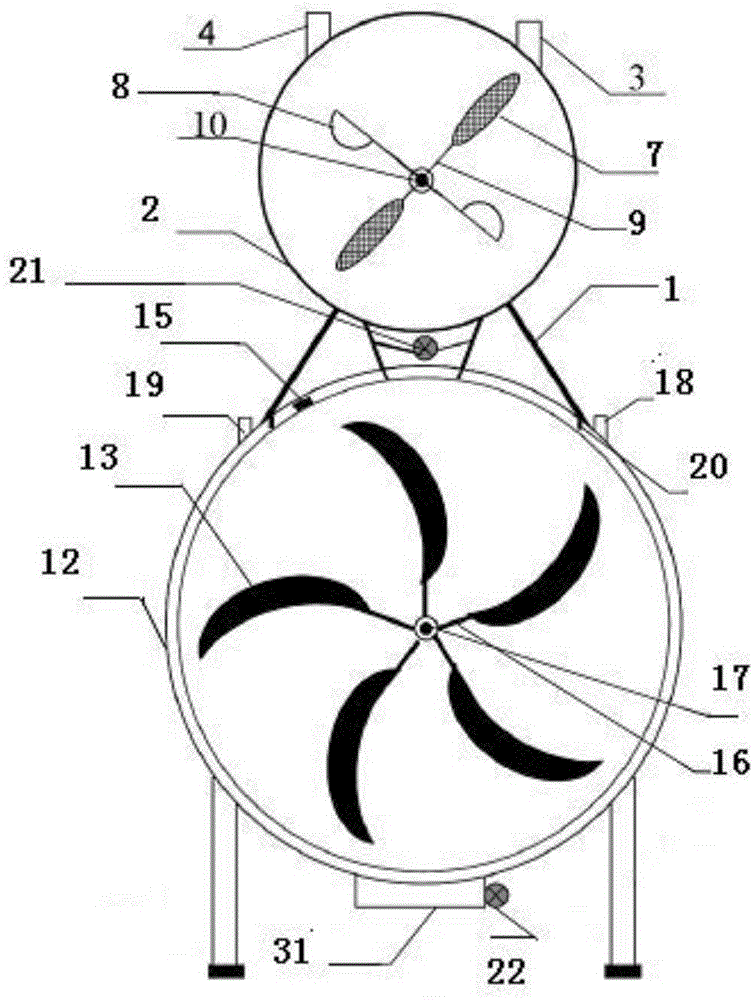

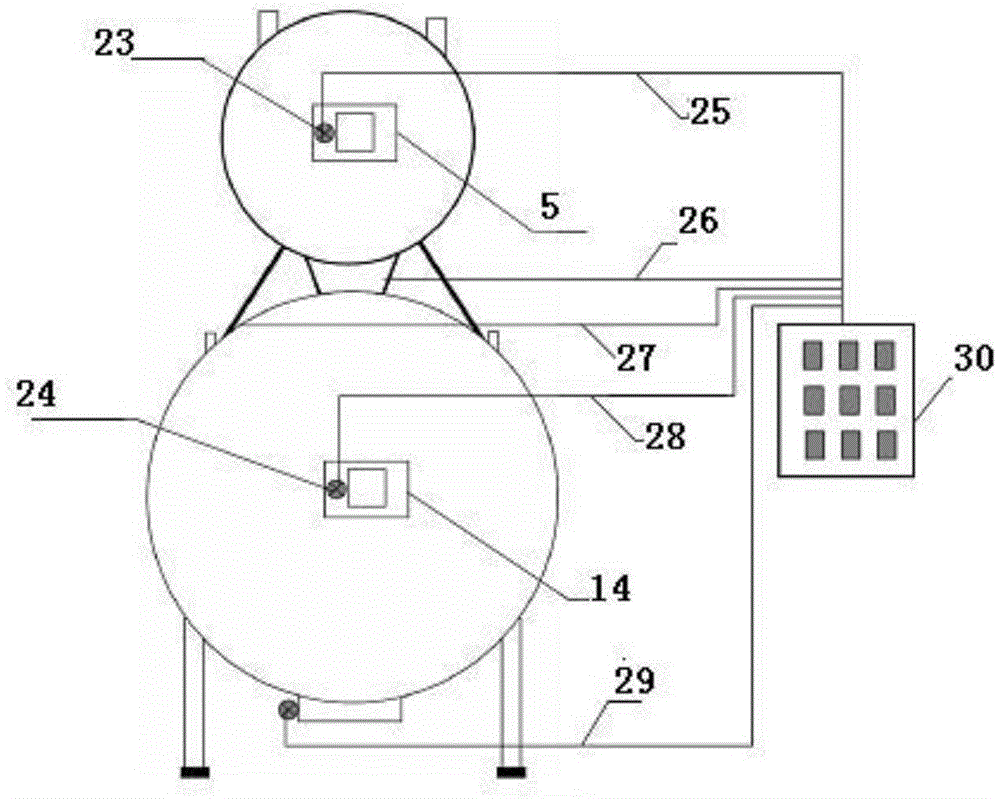

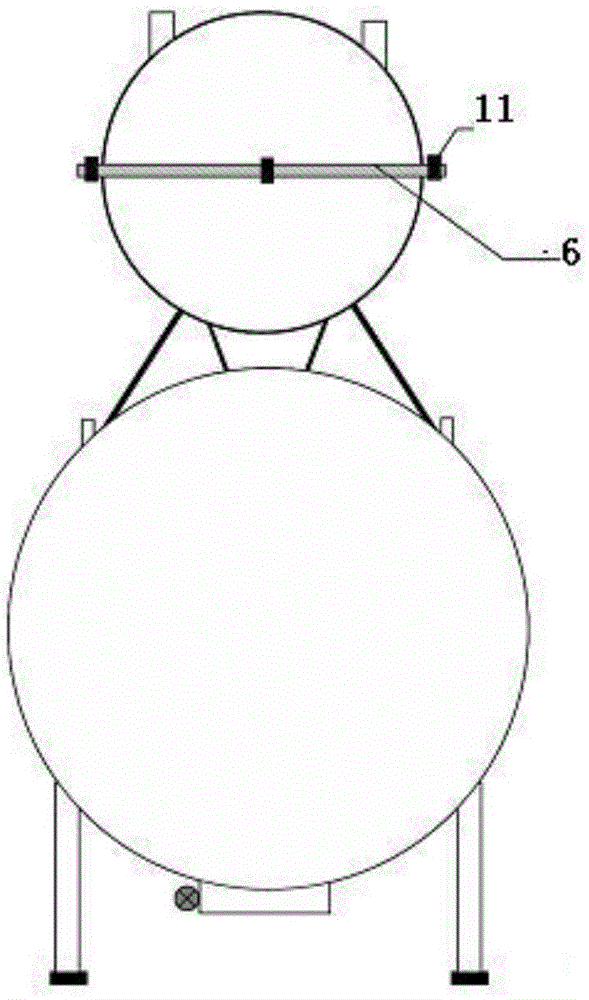

[0026] The basic implementation principle of the mixed feed additive automatic mixing equipment provided by the present invention is: after the mixed feed additive production order is issued, first set the relevant programs on the automation control board, including the program for operating the relay switch Setting button, program setting button of vibrator, interlayer inlet and outlet flow control button. Then, according to the production requirements on the production order sheet, the corresponding main materials and auxiliary materials are respectively entered into the pre-mixing bin from the main material inlet and auxiliary material inlet, and then the operator can leave the site, and the equipment performs the mixing operation according to the set procedure. job production. The specific program settings can be summarized as follows: firstly, the adjustable motor of the pre-mixing bin is controlled by the relay switch to open and run, so that it drives the stirring blade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com