Patents

Literature

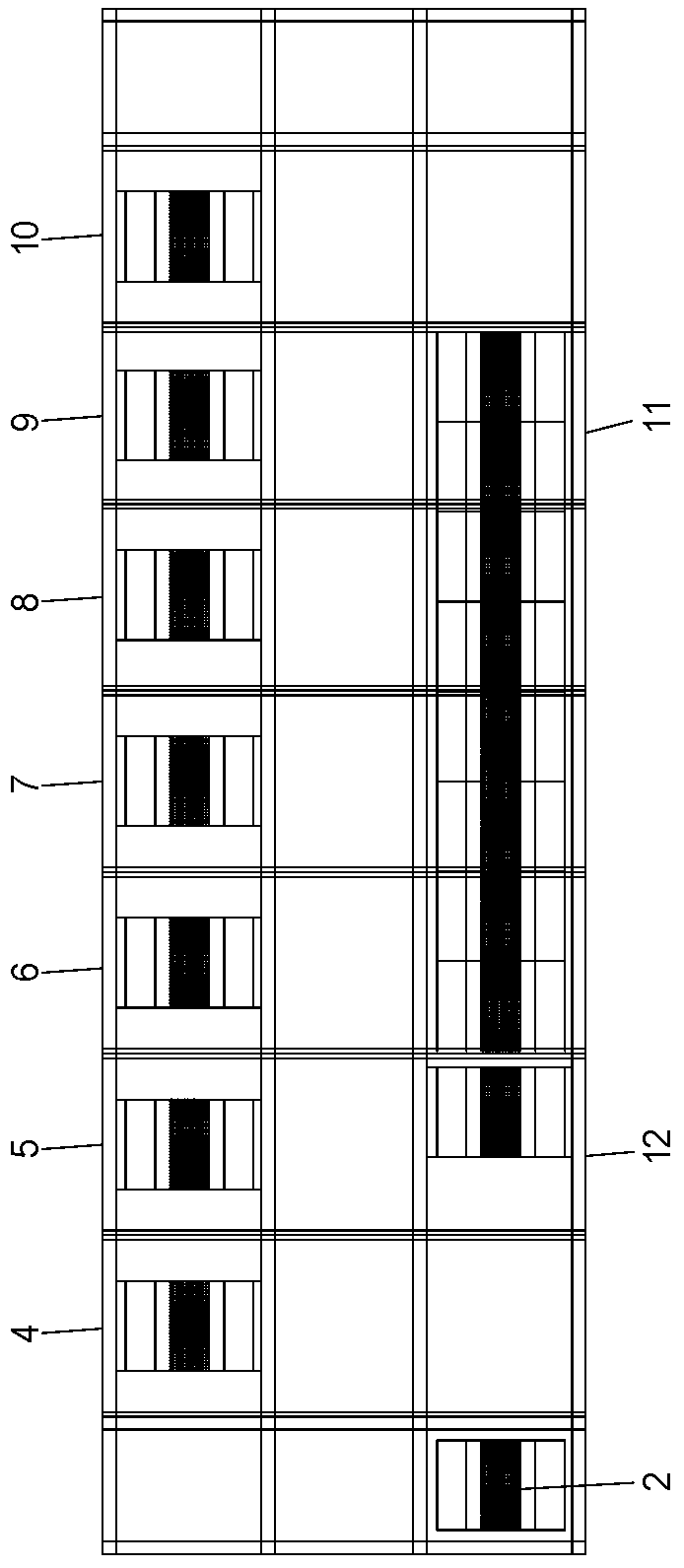

52 results about "Job production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Job production, sometimes called jobbing or one-off production, involves producing custom work, such as a one-off product for a specific customer or a small batch of work in quantities usually less than those of mass-market products. Job production consists of an operator or group of operators to work on a single job and complete it before proceeding to the next similar or different job. Together with batch production and mass production (flow production) it is one of the three main production methods.

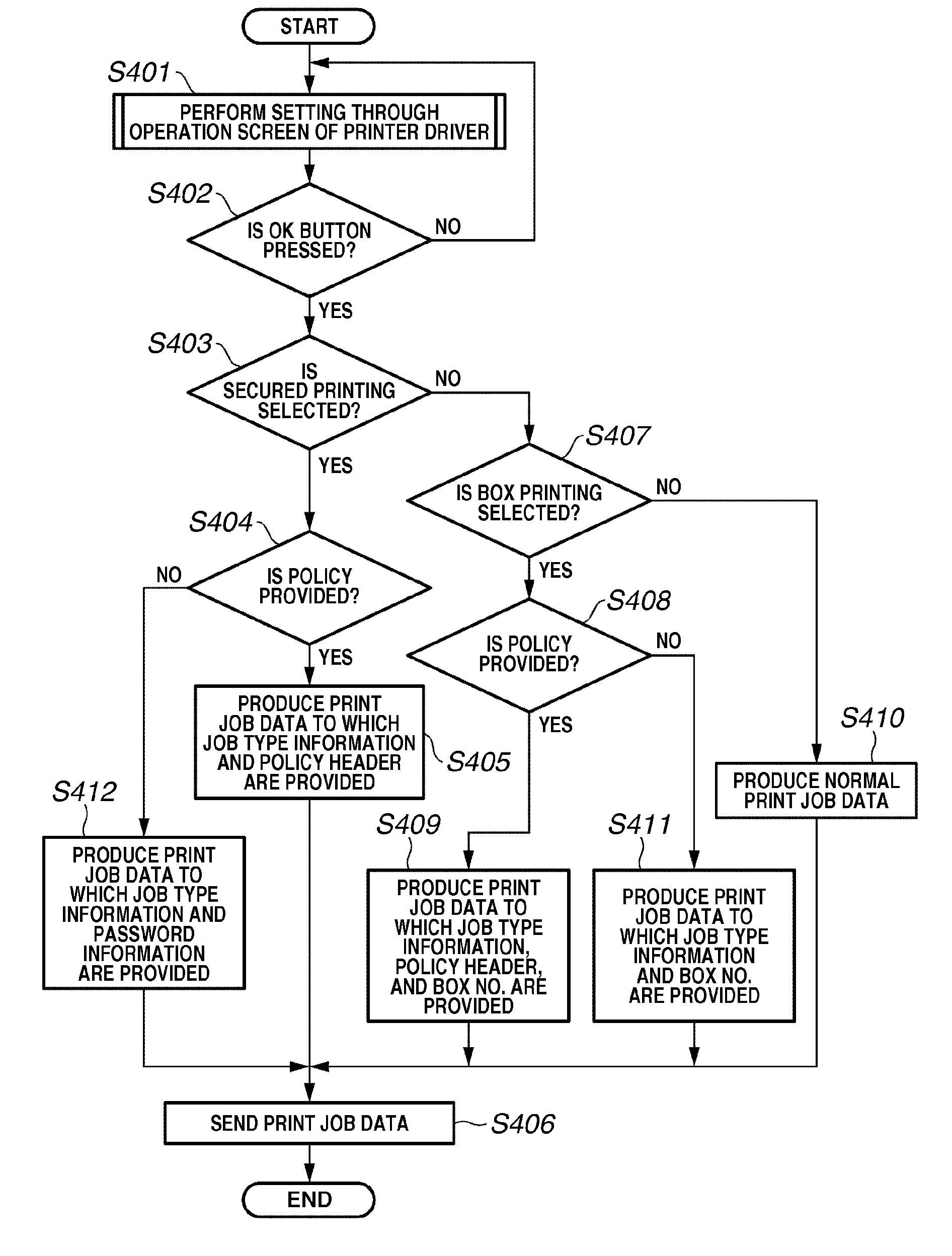

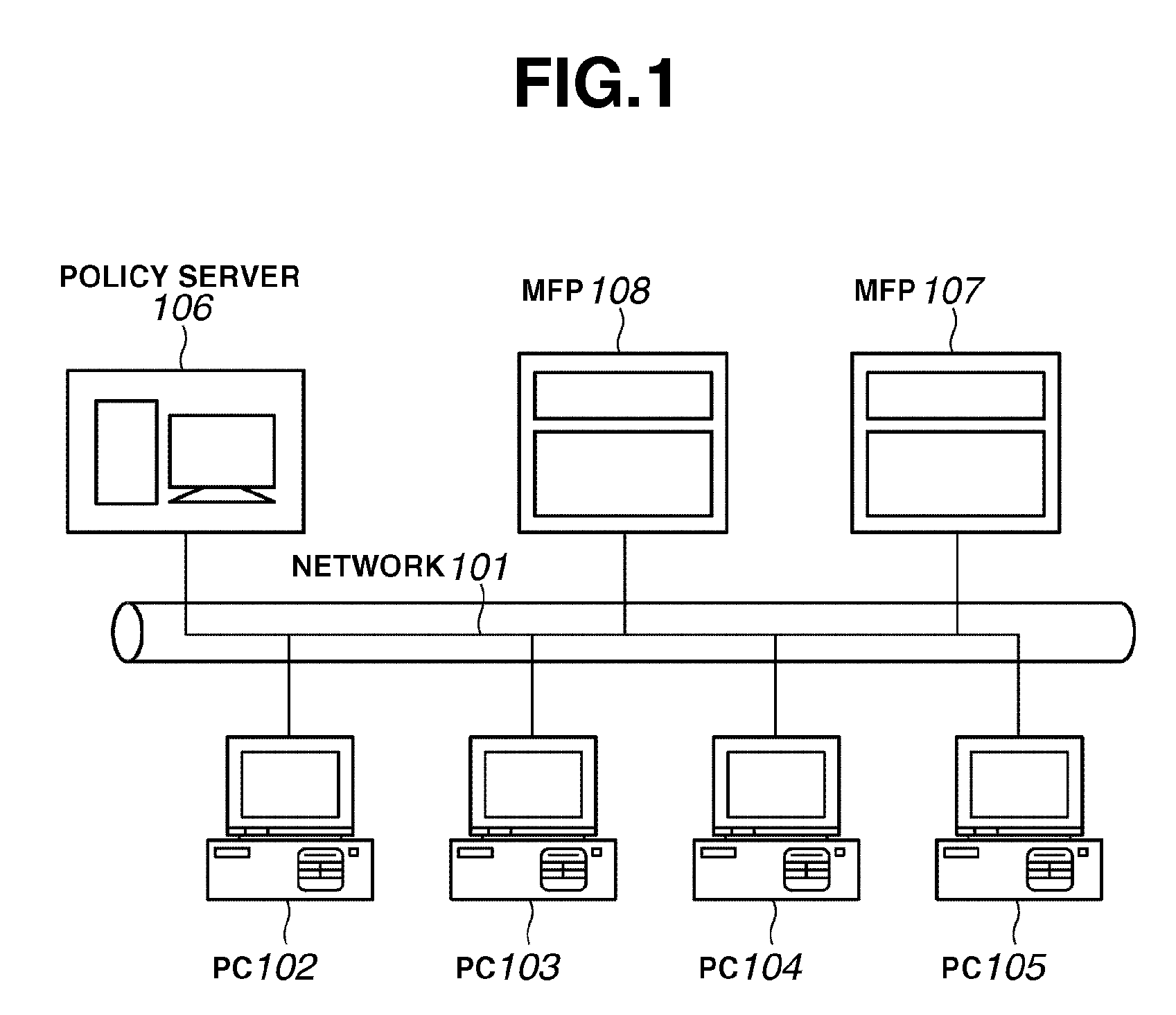

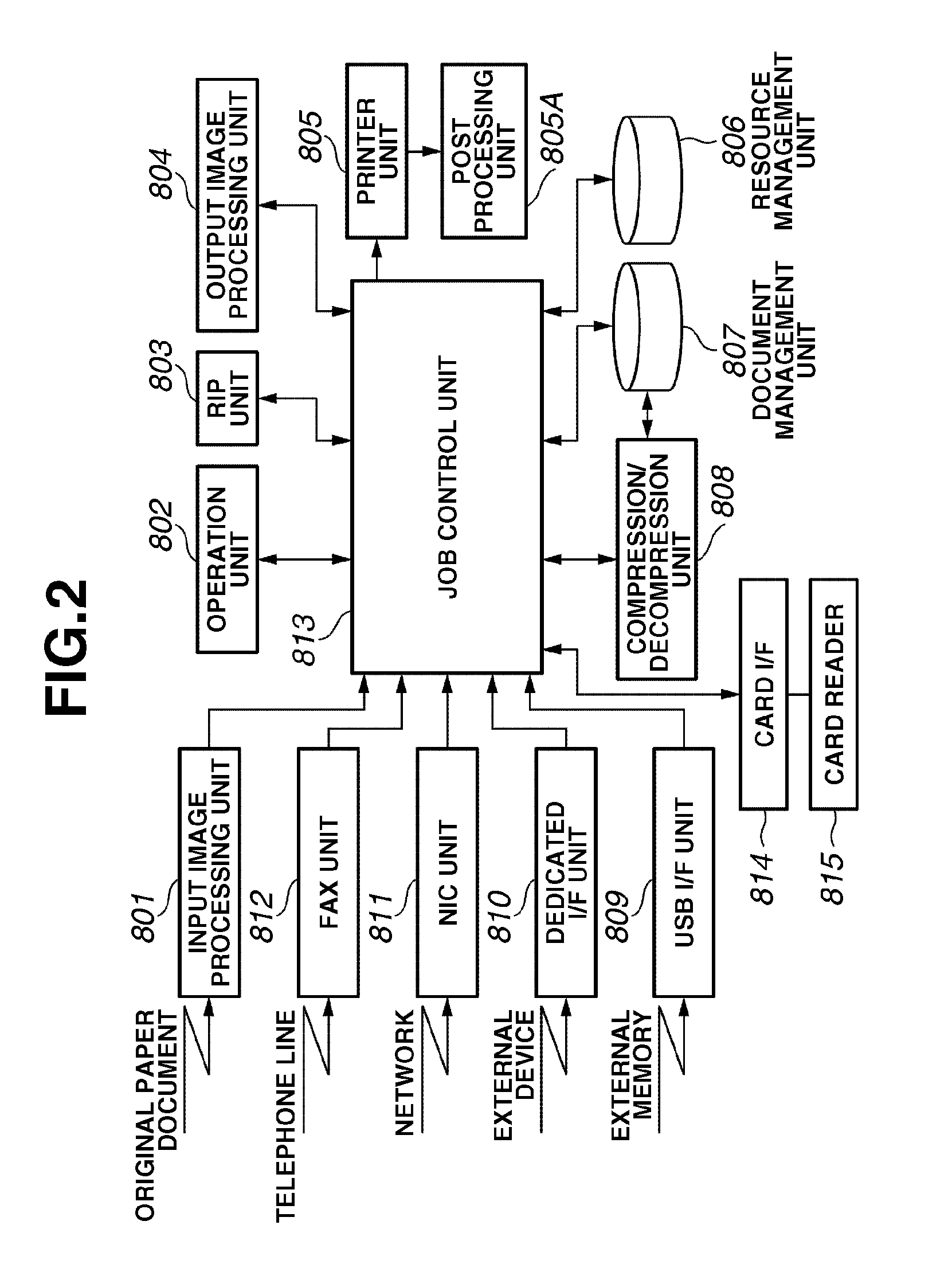

Data processing apparatus, image processing apparatus, print job production method, and print job output method

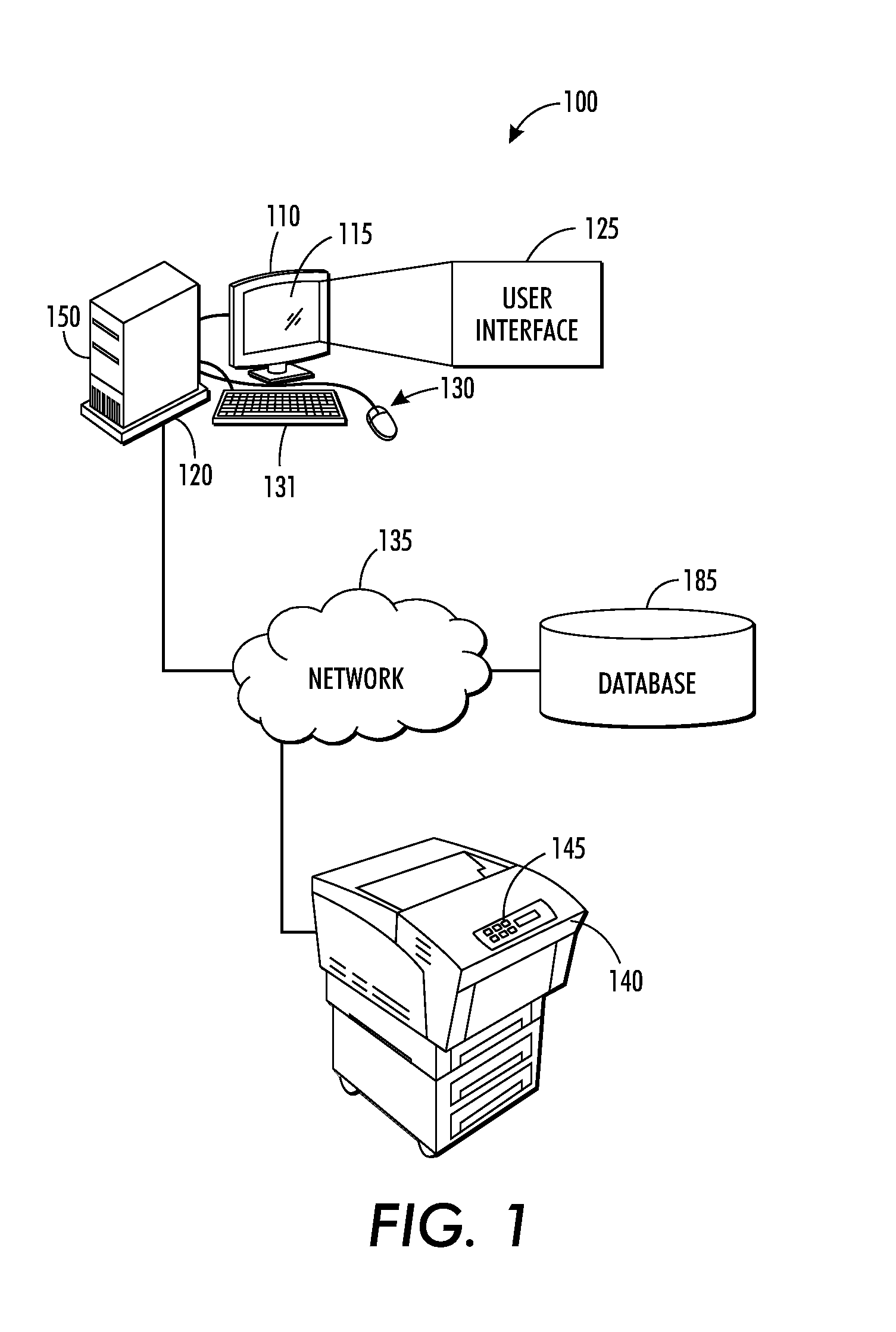

InactiveUS20070133044A1Computer security arrangementsVisual presentationImaging processingElectronic data

A data processing apparatus includes a storage unit configured to store electronic data including first data for identifying policy data that is information indicating an authority for handling the electronic data and is managed by a server apparatus. The data processing apparatus includes a print job data production unit configured to produce print job data based on electronic data to be printed, an acquisition unit configured to acquire the first data included in the electronic data, an adding unit configured to add the first data acquired by the acquisition unit to the print job data, and a sending unit configured to send the print job data having the first data added thereto to an image processing apparatus.

Owner:CANON KK

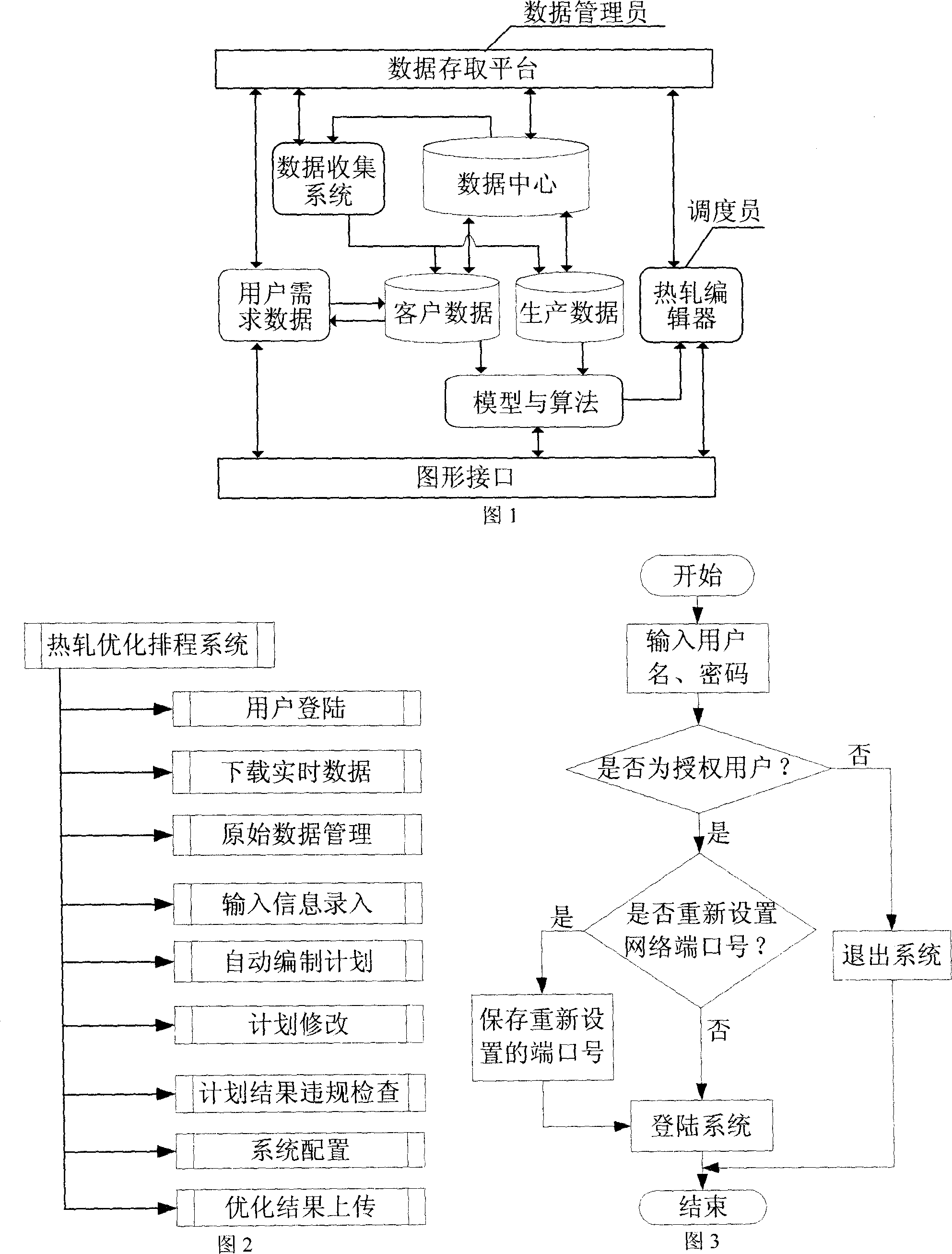

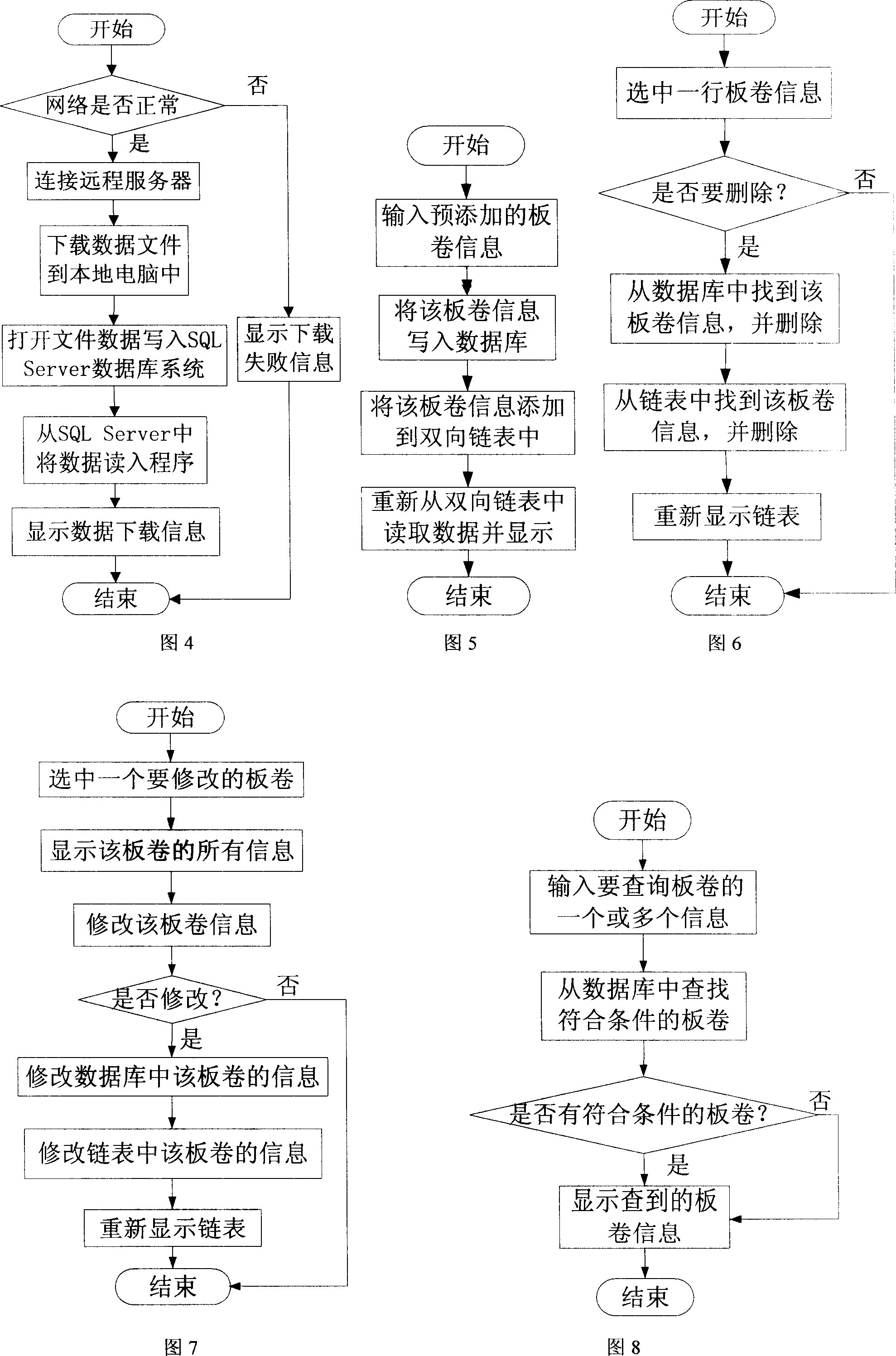

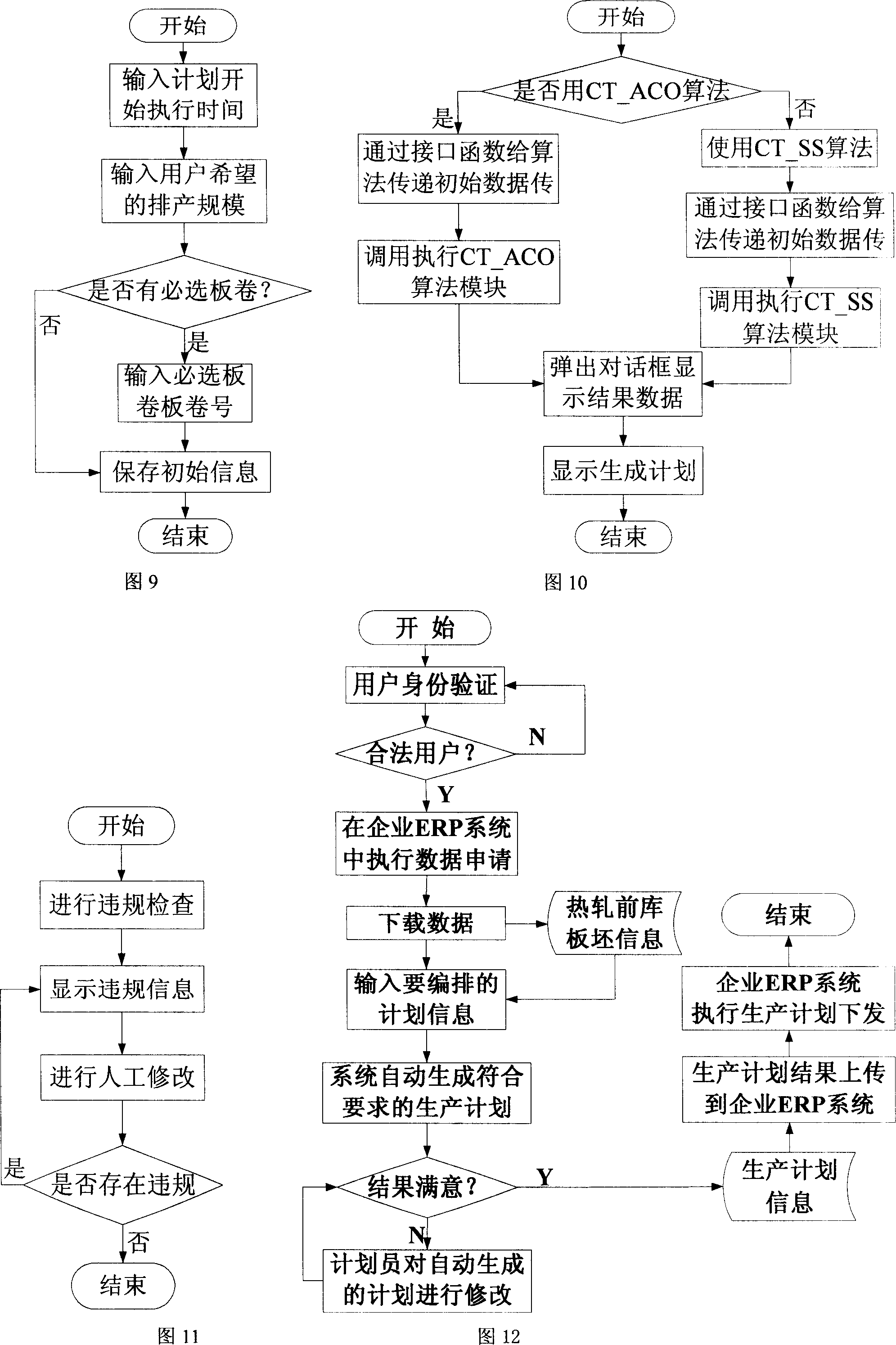

Metal hot rolling optimizing scheduling method and system thereof

InactiveCN101097617AIncrease reflectionRealize economic schedulingForecastingSpecial data processing applicationsData centerMathematical model

A kind of optimized dispatching method for hot-rolled metal, which includes that it extracts the customer data and production data from data collection system and data center, and makes the hot-rolled production plan according to the built mathematical model of optimized production, and the characteristics are: the model is built according to the craft constraints and the hot-rolled cost, and the aims for undetermined plans and parallel hot-rolled plan is to minimize the production cost; (2)the solution of model adopts two kinds of hybrid algorism containing loop exchange algorism. It provides the hot-rolled dispatching optimized system and device based on said method, and the system is formed by combination of model design idea and graph interface, and the model construction module and model solution module are embedded in the auto production module for production plan; and the devices include PC, interface, router or switcher, and the complete software which consists of said functional module is mounted on the PC, and which is connected with the front end of hot-rolled control system by network or inner sever.

Owner:NORTHEASTERN UNIV

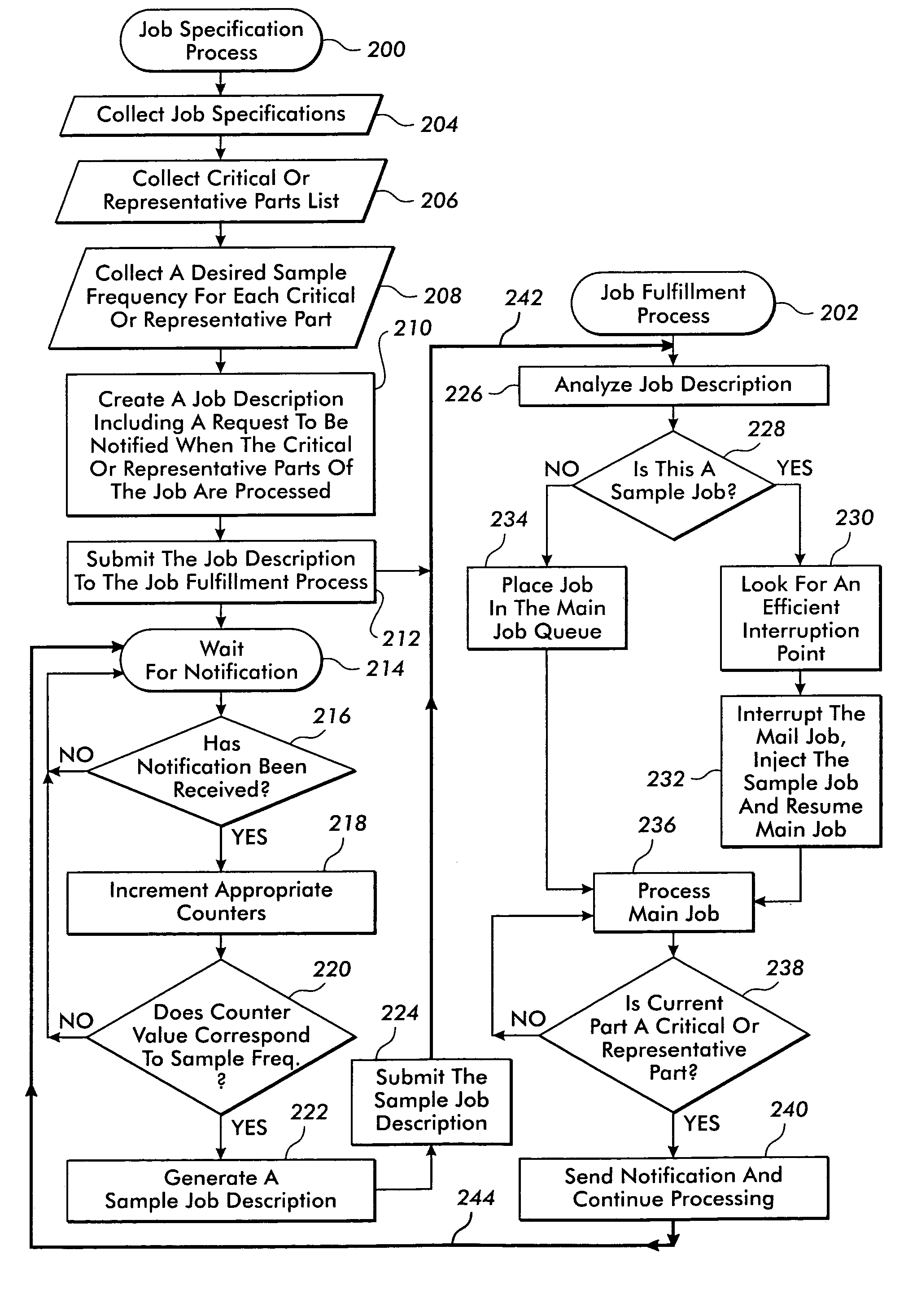

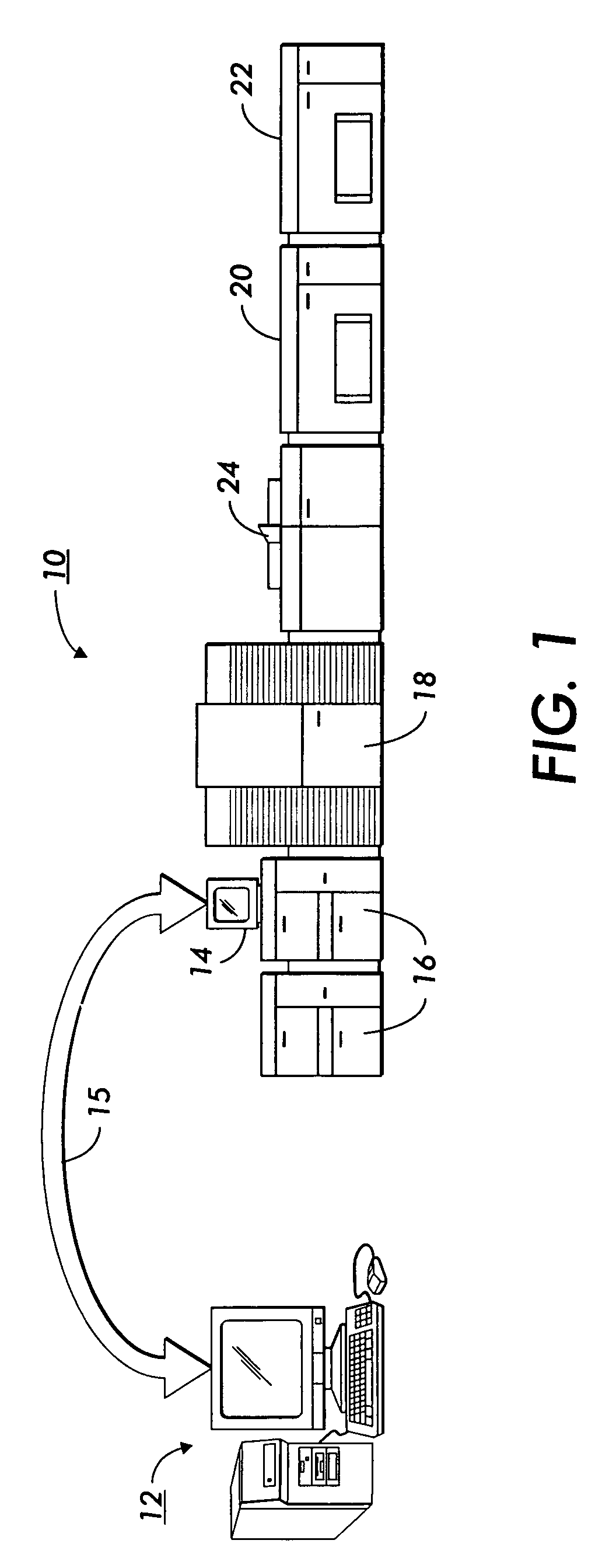

Use of job interrupt functionality for the production of interrupting and sample job output in digital printing systems

InactiveUS7075667B1Minimal costLarge amount of materialVisual presentationInput/output processes for data processingDigital printingIndustrial engineering

Main job production progress is monitored so that sample copies of parts of the main job that are designated critical or representative of the job as a whole can be produced on a regular interrupting basis. The samples are used to monitor production quality. Digital printing system modules are arranged and configured to provide a sample job destination separate from the main job destination.

Owner:XEROX CORP

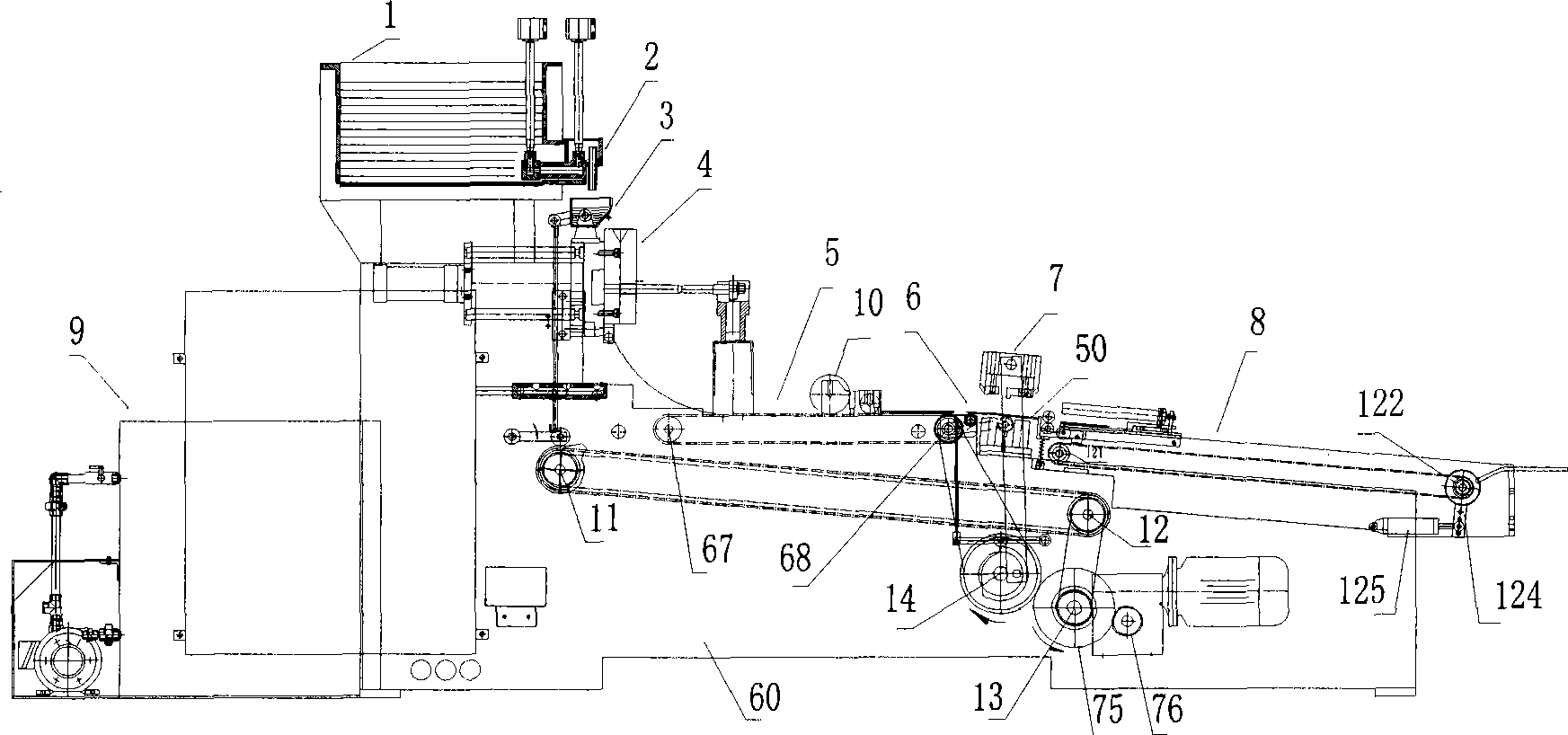

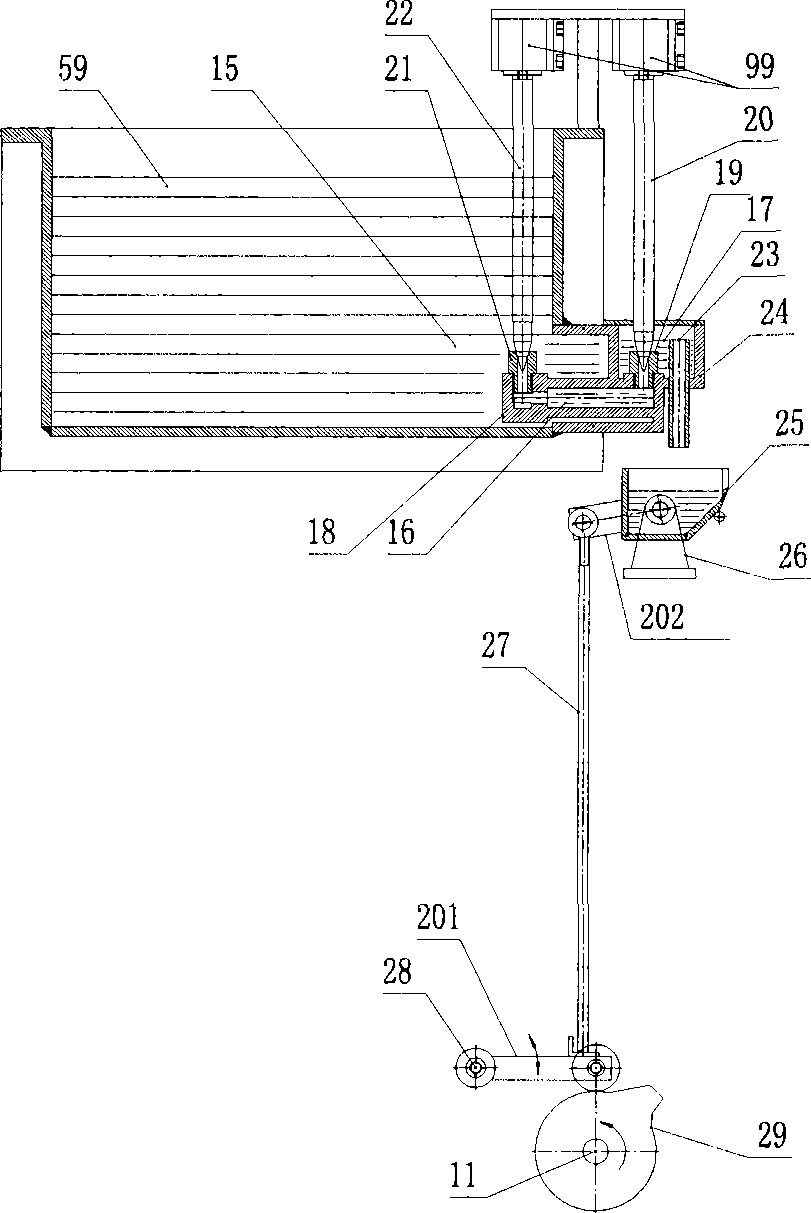

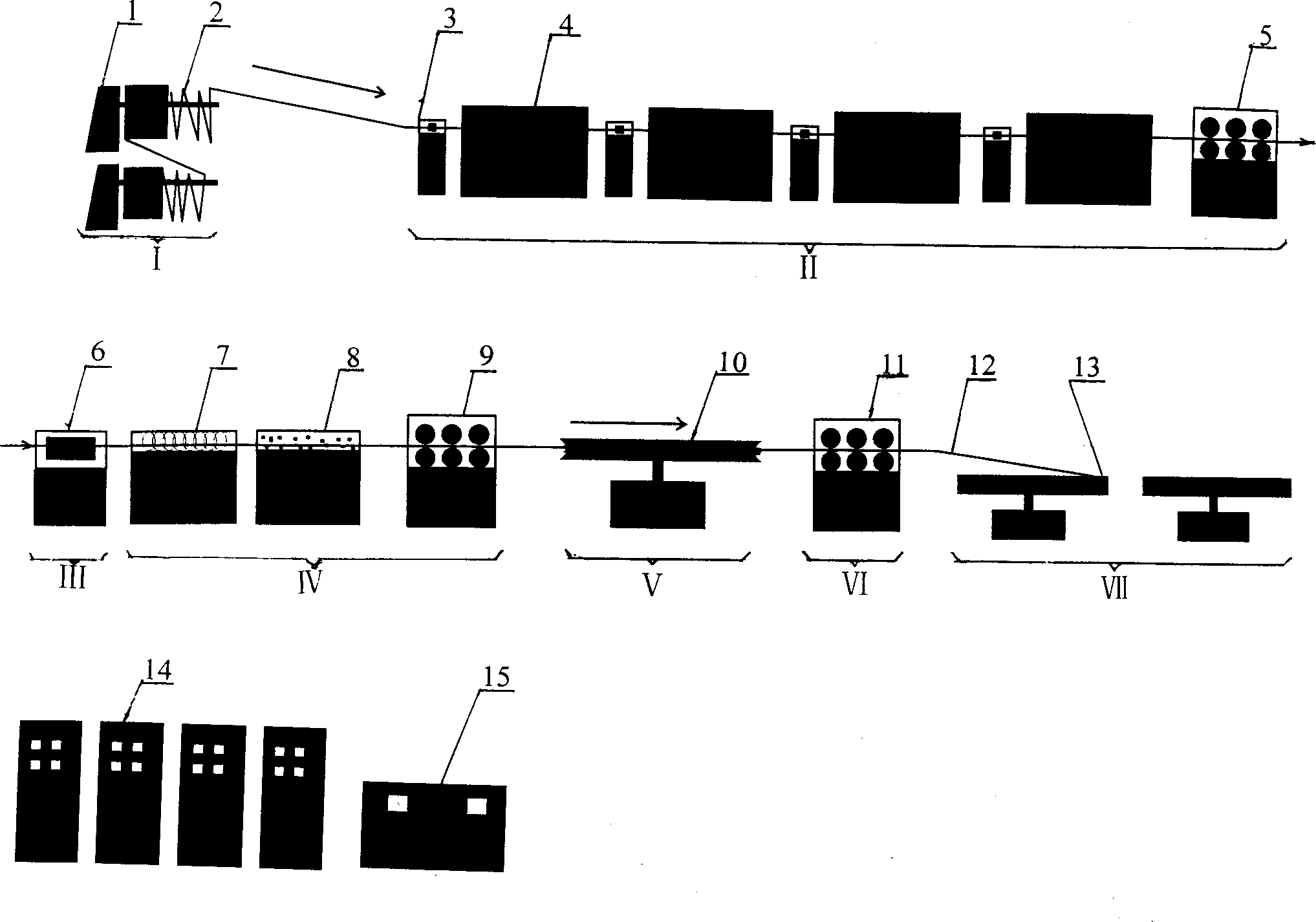

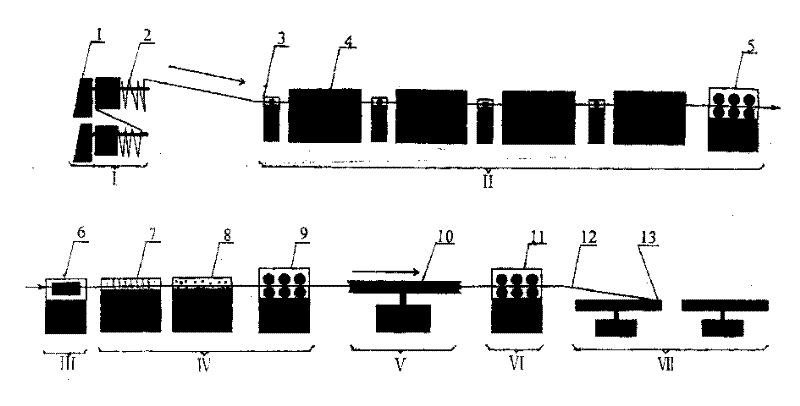

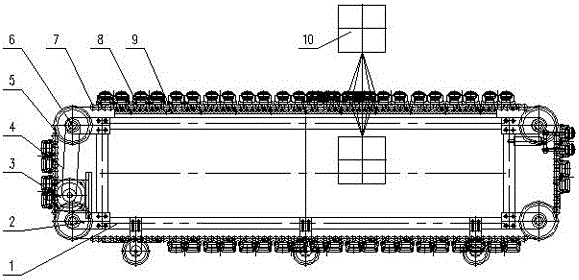

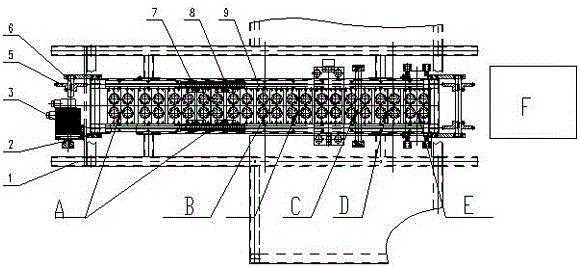

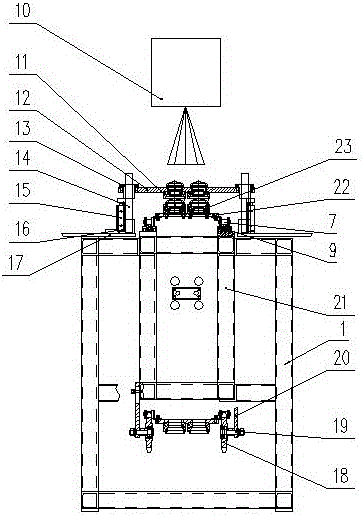

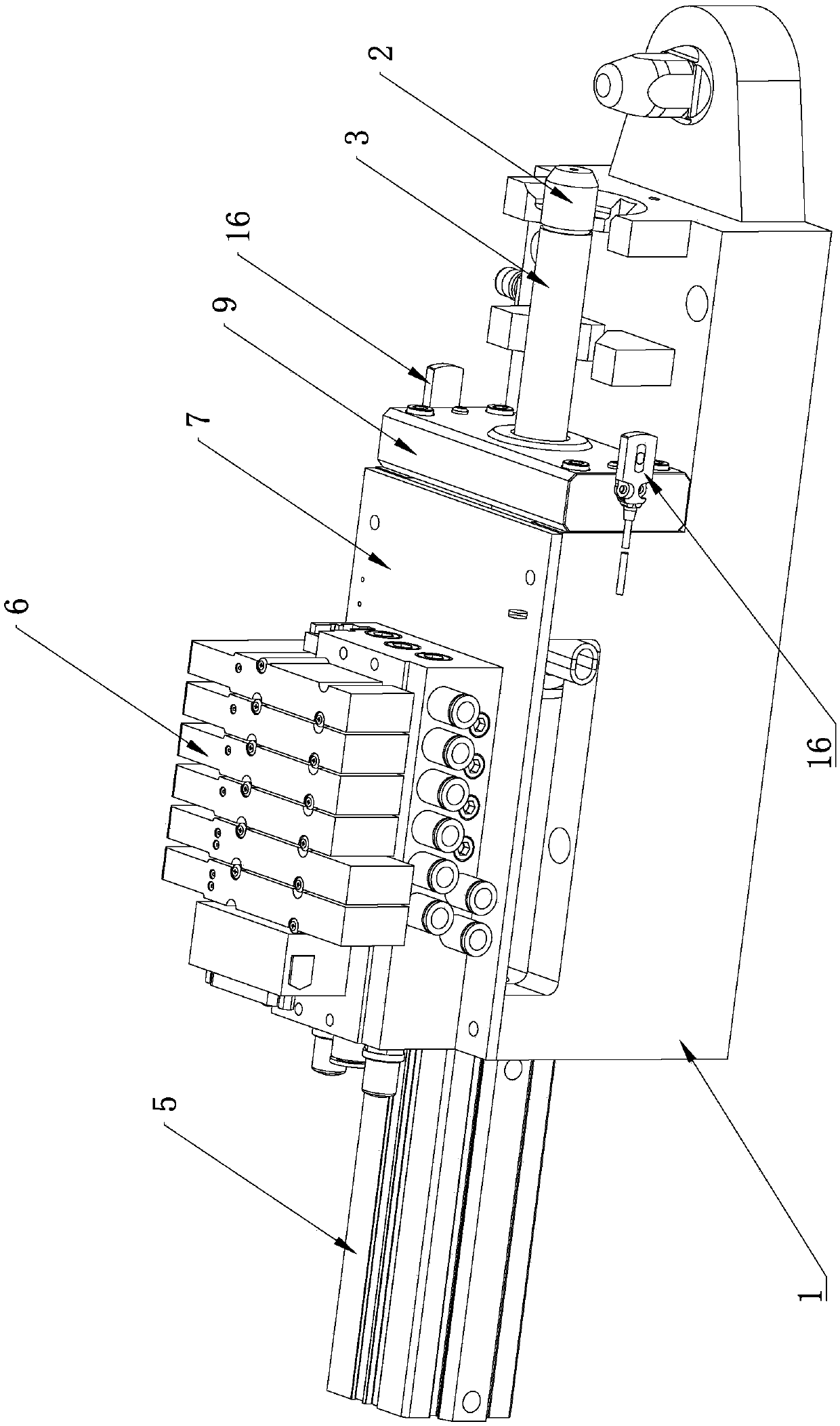

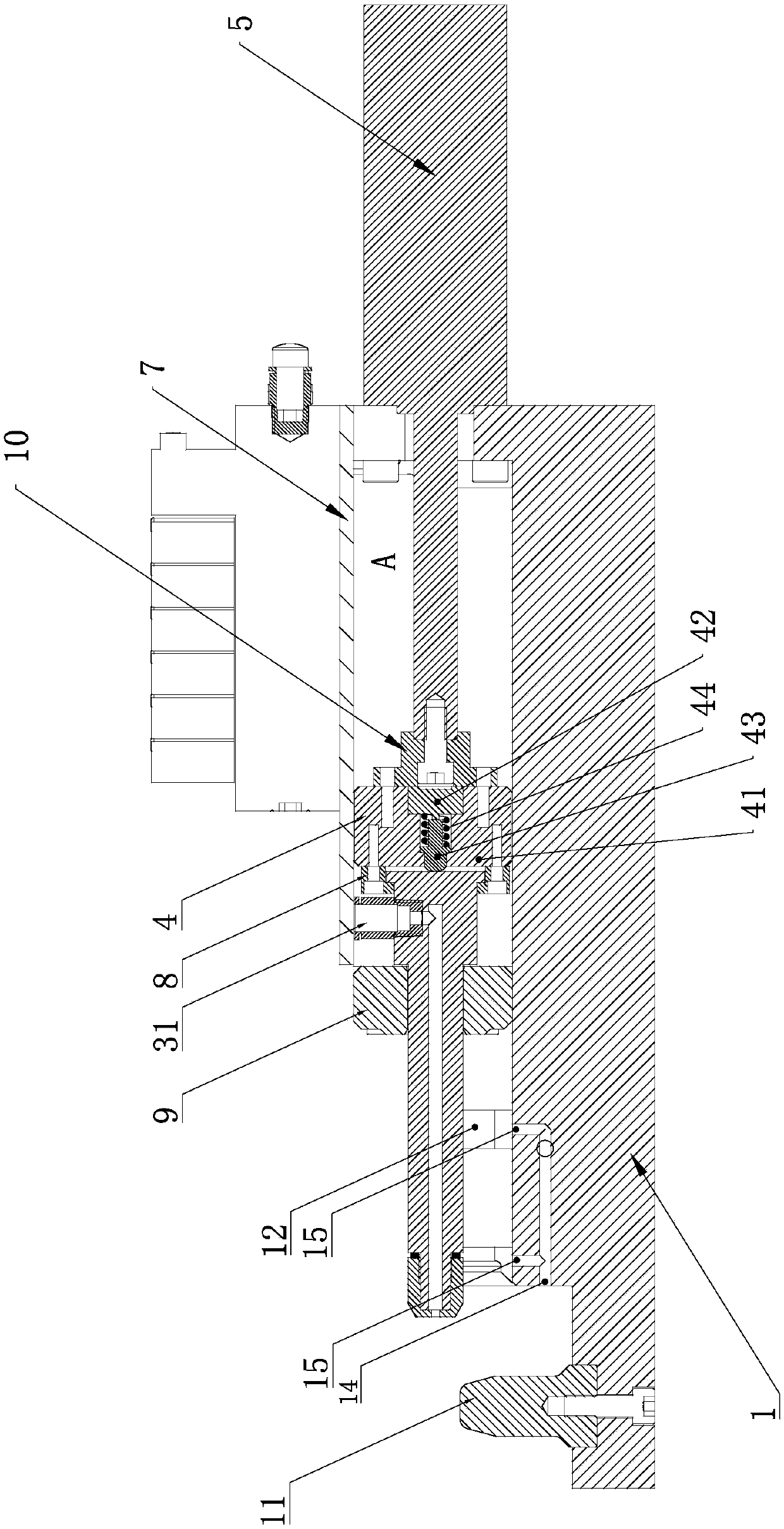

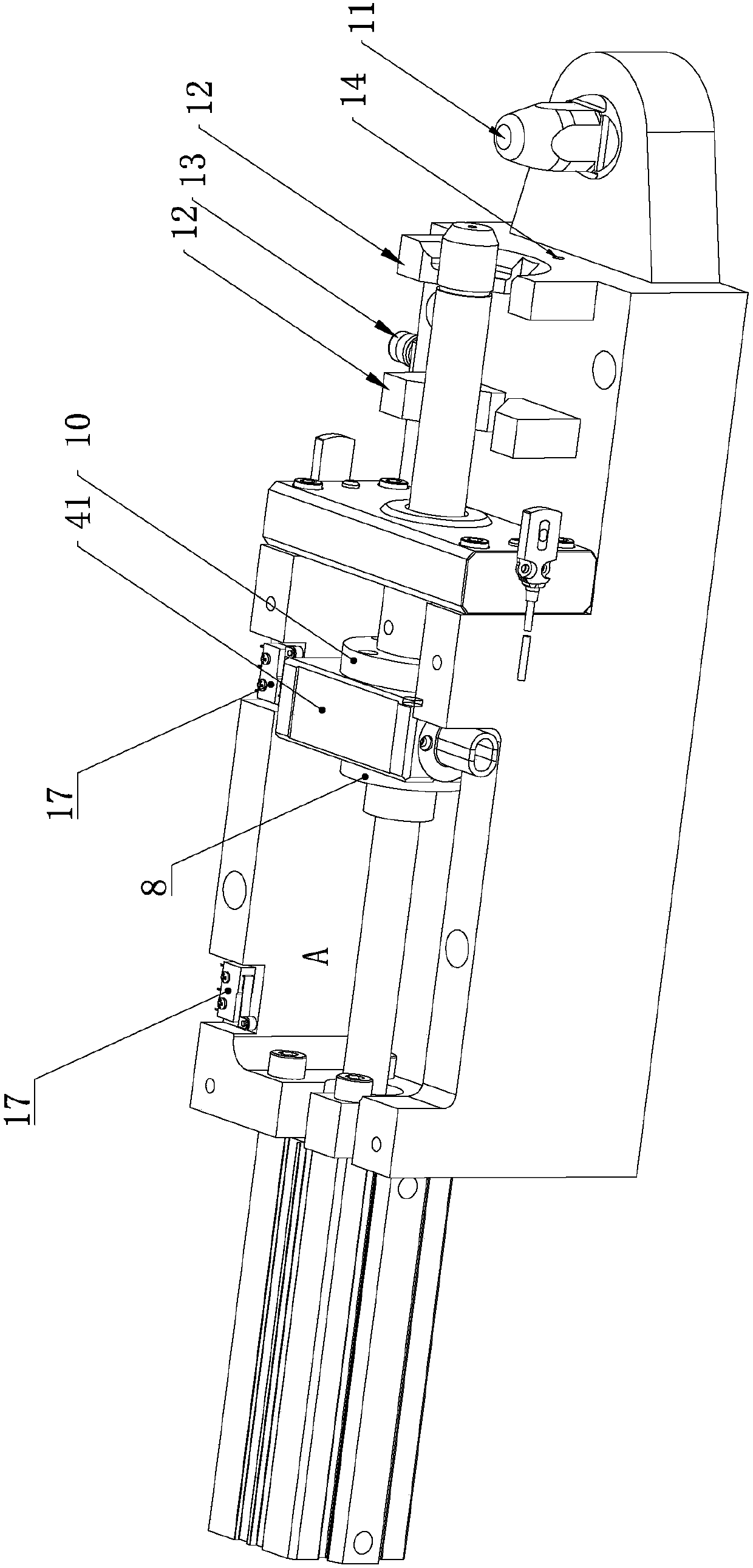

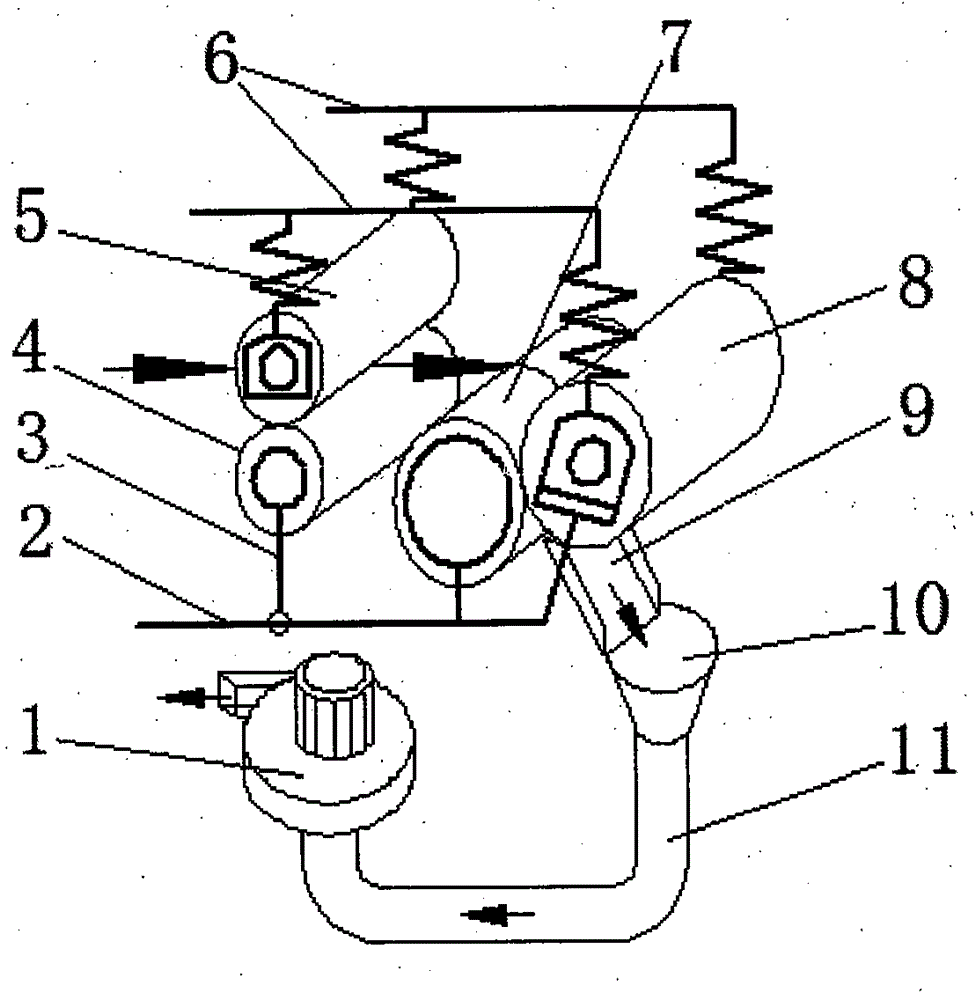

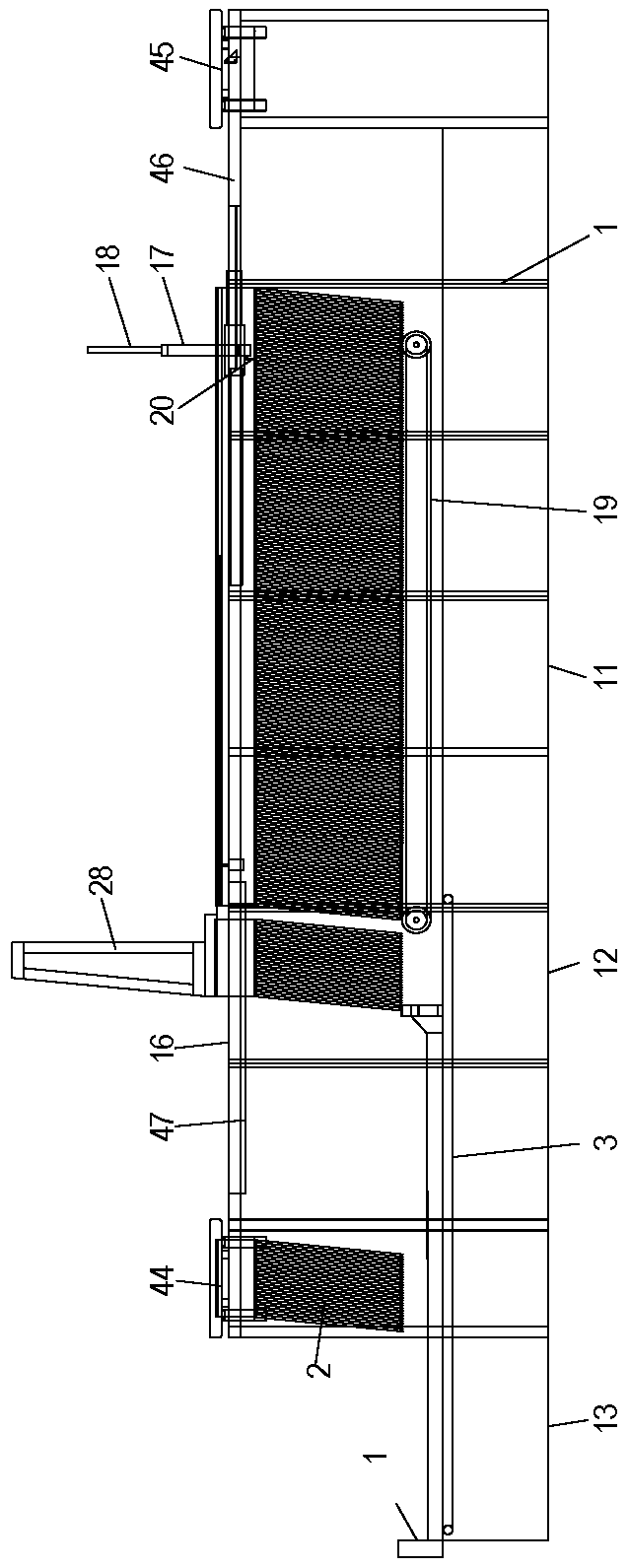

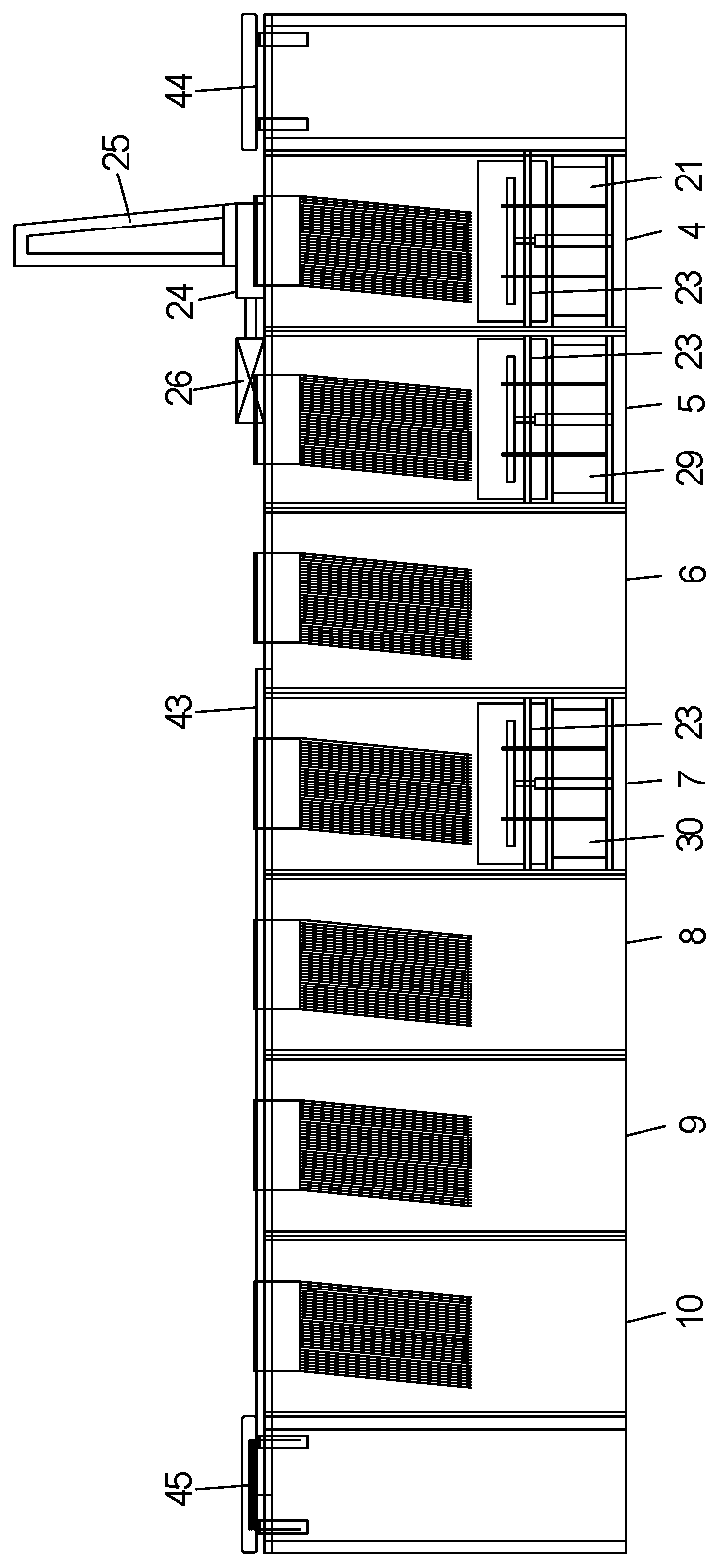

Flat cut type plate-casting machine

The invention relates to a truncated slab casting machine, in particular to a lead alloy slab lattice casting and forming device for manufacturing a lead-acid accumulator. The lead alloy slab lattice casting and forming device comprises a production line device which is formed by connecting a high-level lead smelting furnace, a tandem lead valve gear, a lead scoop lead turnover mechanism, a die switching die mechanism, a reshaping and conveying mechanism, a slab lattice horizontal positioning mechanism, a truncated cutting-knife die, a slab lattice receiving mechanism and a circulating water tank in sequence. The device is cooperatively operated under automatic electric control. The truncated slab casting machine adopts the tandem lead valve gear, the slab lattice horizontal positioning mechanism and the truncated cutting-knife die, is accurate to quantitatively supply lead and convenient to replace valve cores, makes lead alloy slab lattices horizontally positioned on a lower positioning plate at a uniform velocity to realize non-deformation of the lead alloy slab lattices, realizes automatic casting forming of the lead alloy slab lattices, completes transformation of the production flow from manual labor to automatic operation, greatly reduces the production strength and the operation cost of manual operation, guarantees the casting quality of quantitative and accurate supply of the leads, convenient replacement of the valve cores and non-deformation of the lead alloy slab lattices, and improves the labor productivity.

Owner:武汉深蓝自动化设备股份有限公司

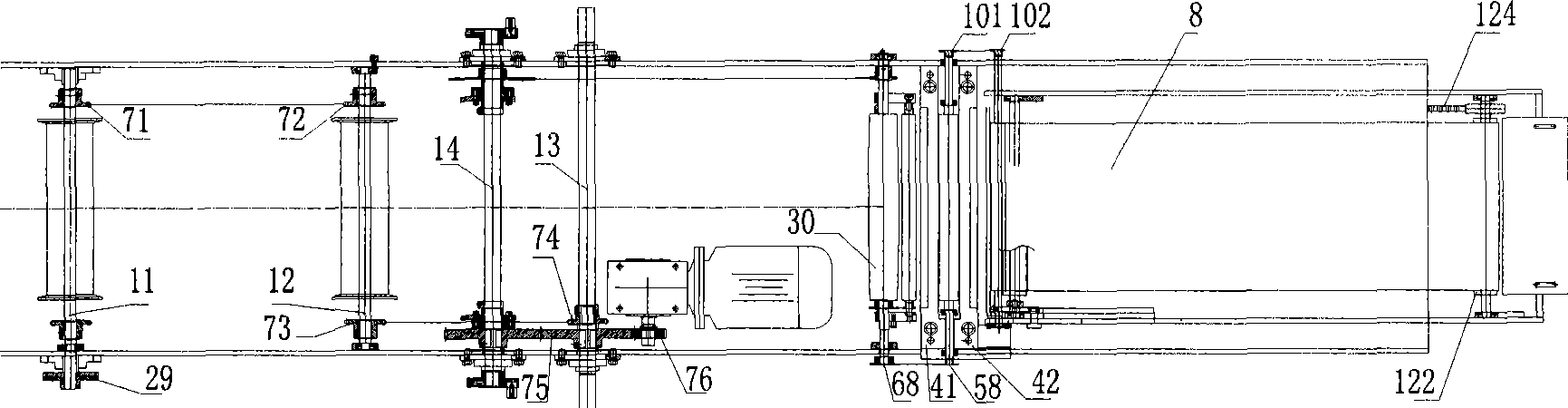

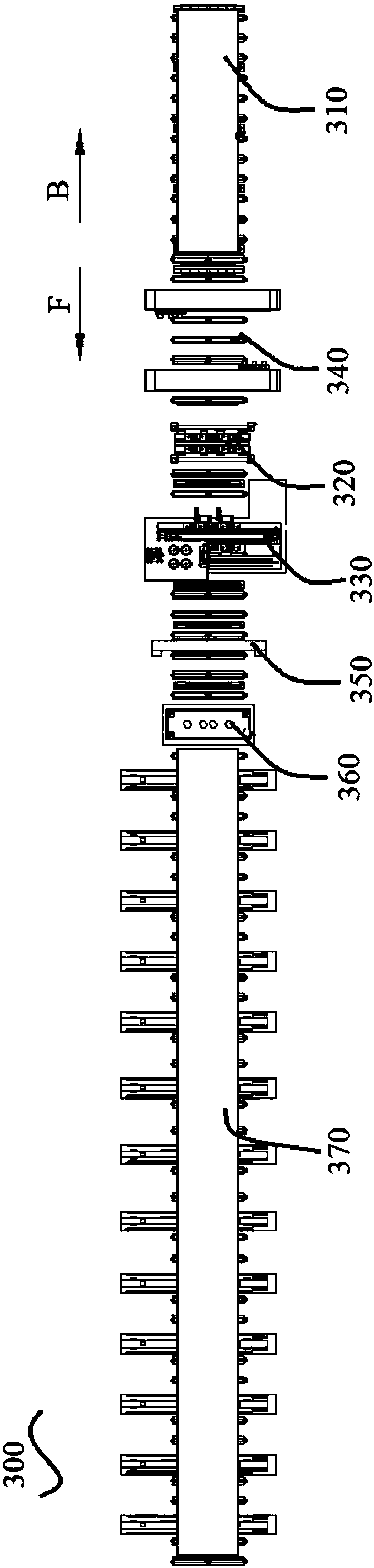

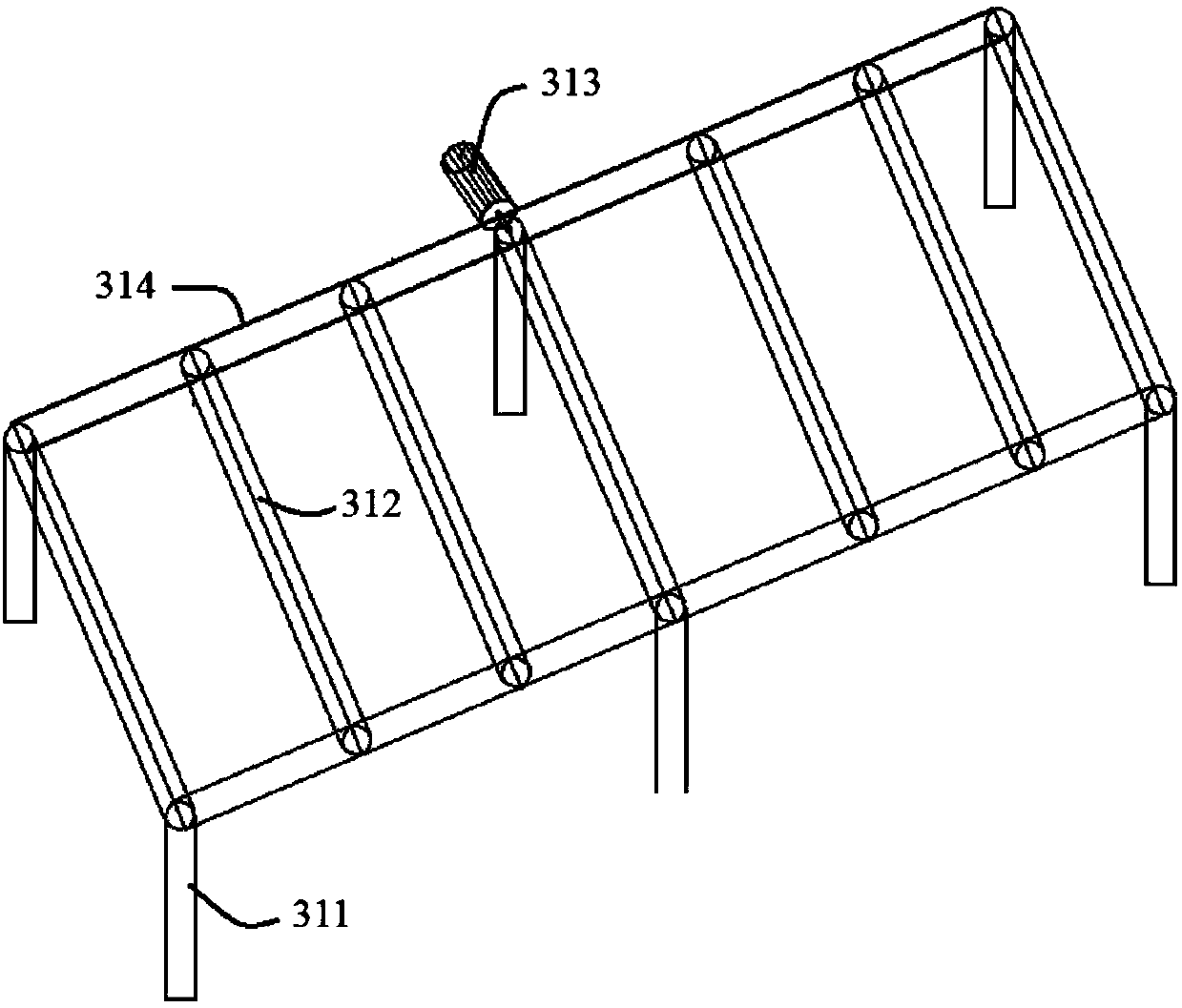

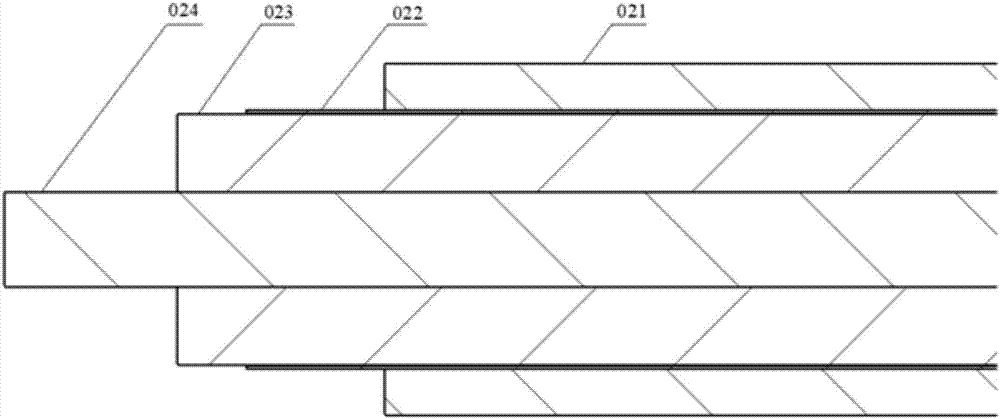

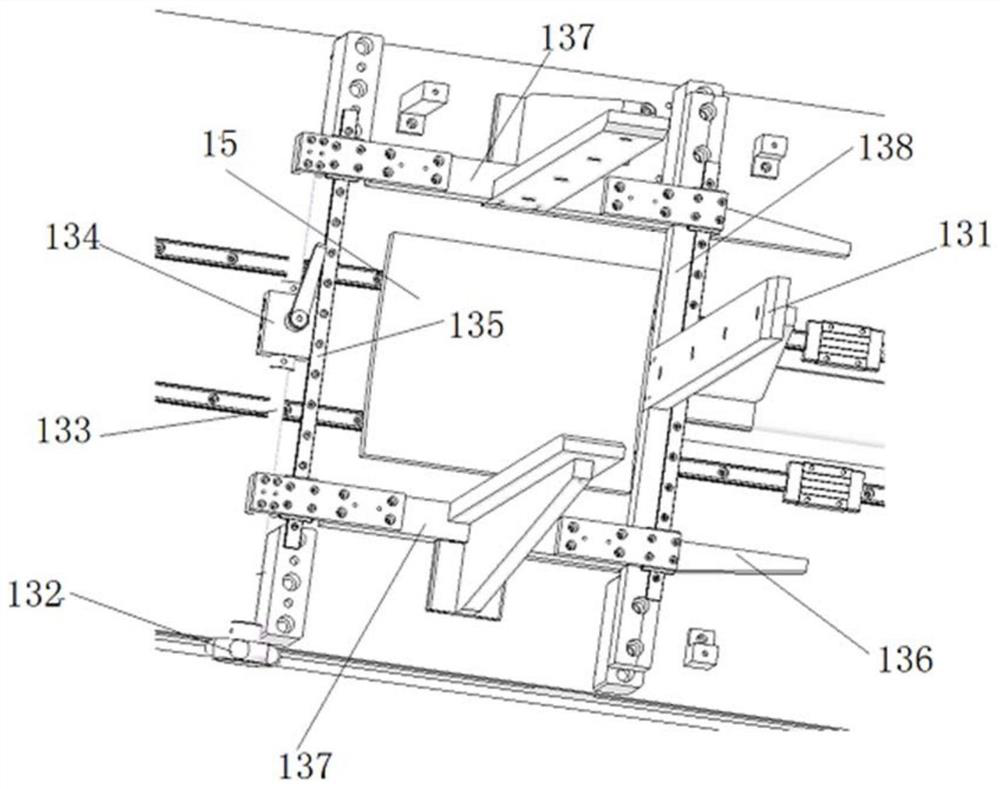

Board splicing assembly line and board splicing method

PendingCN107813146AAvoid deformationIncrease flexibilityOther manufacturing equipments/toolsAssembly lineIndustrial engineering

The invention provides a board splicing assembly line and a board splicing method. The board splicing assembly line comprises a conveying channel used for conveying boards. The assembly line sequentially comprises edge milling equipment, pre-splicing equipment, welding equipment, arc striking and extinguishing board removing equipment, rolling correction equipment and board overturning equipment in the forward direction of the boards. The degree of mechanization is high, the labor intensity is relieved obviously, the labor environment is improved and the manufacturing quality can be better guaranteed. According to the board splicing assembly line and the board splicing method, assembly-line-type operations are adopted, the production process is made more rhythmic, the technological processis more coordinated, and therefore the labor production efficiency can be greatly improved, and the stable yield, high yield, high quality and low consumption are realized.

Owner:SHANGHAI ZHENHUA HEAVY IND

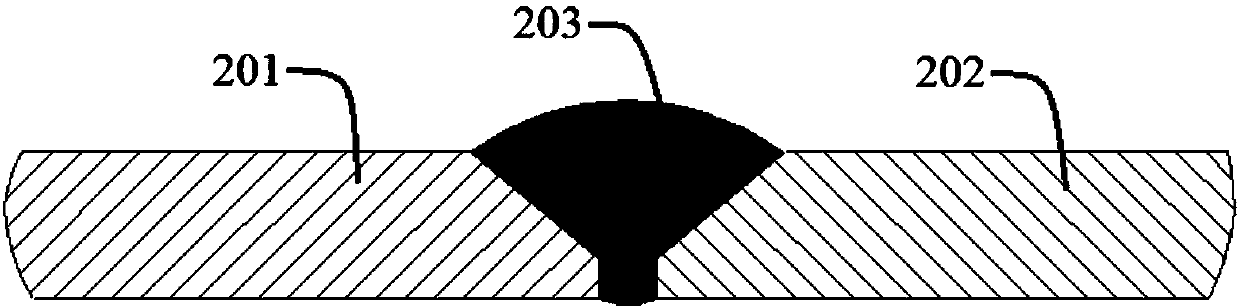

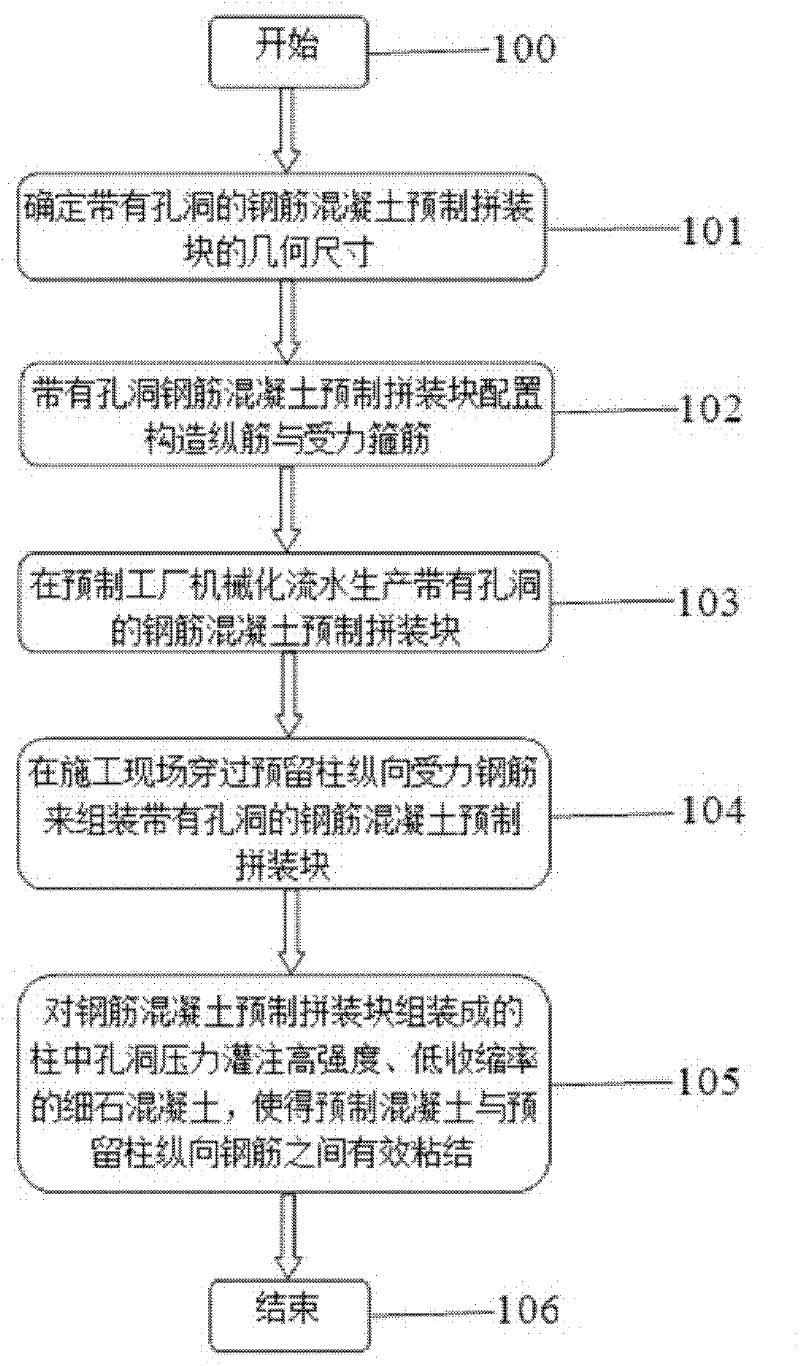

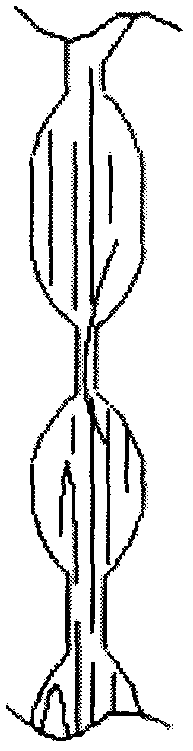

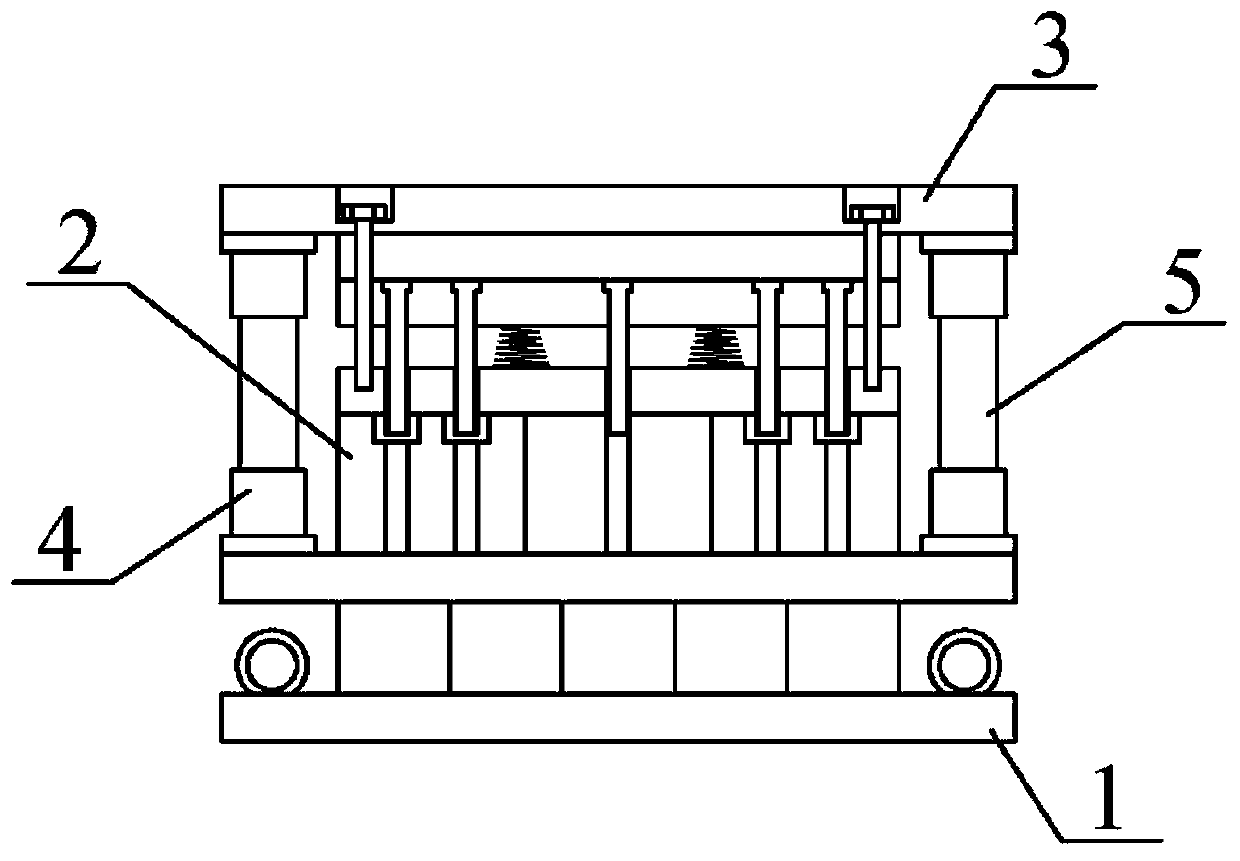

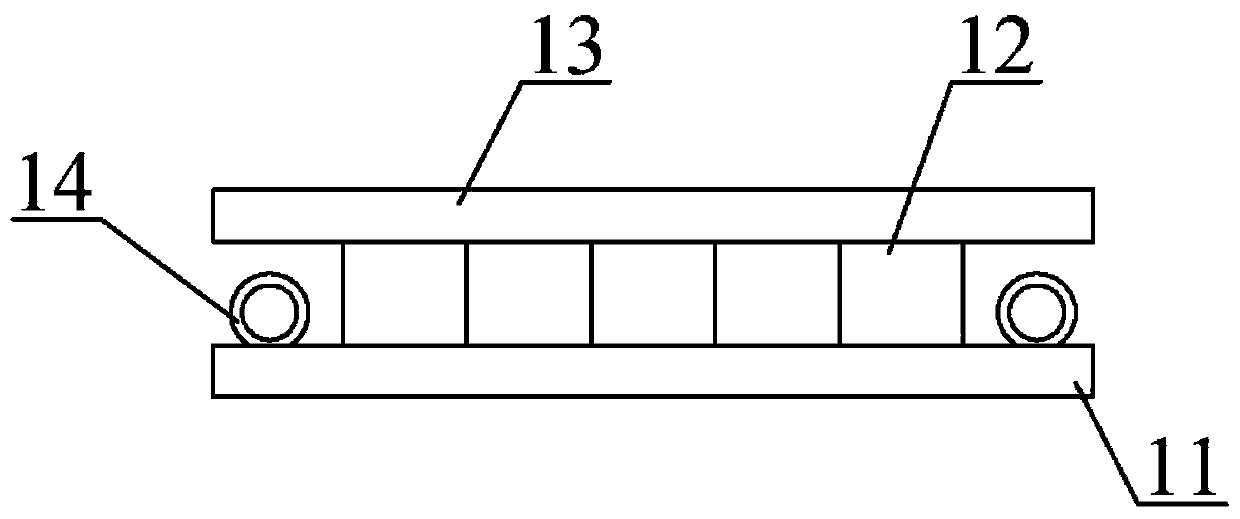

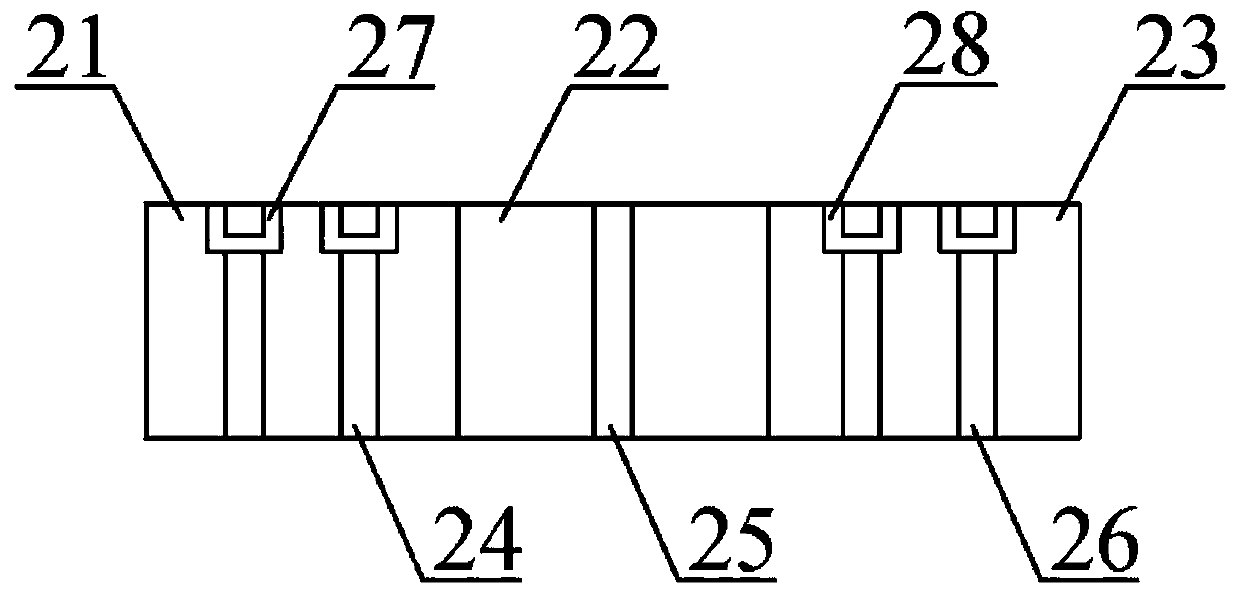

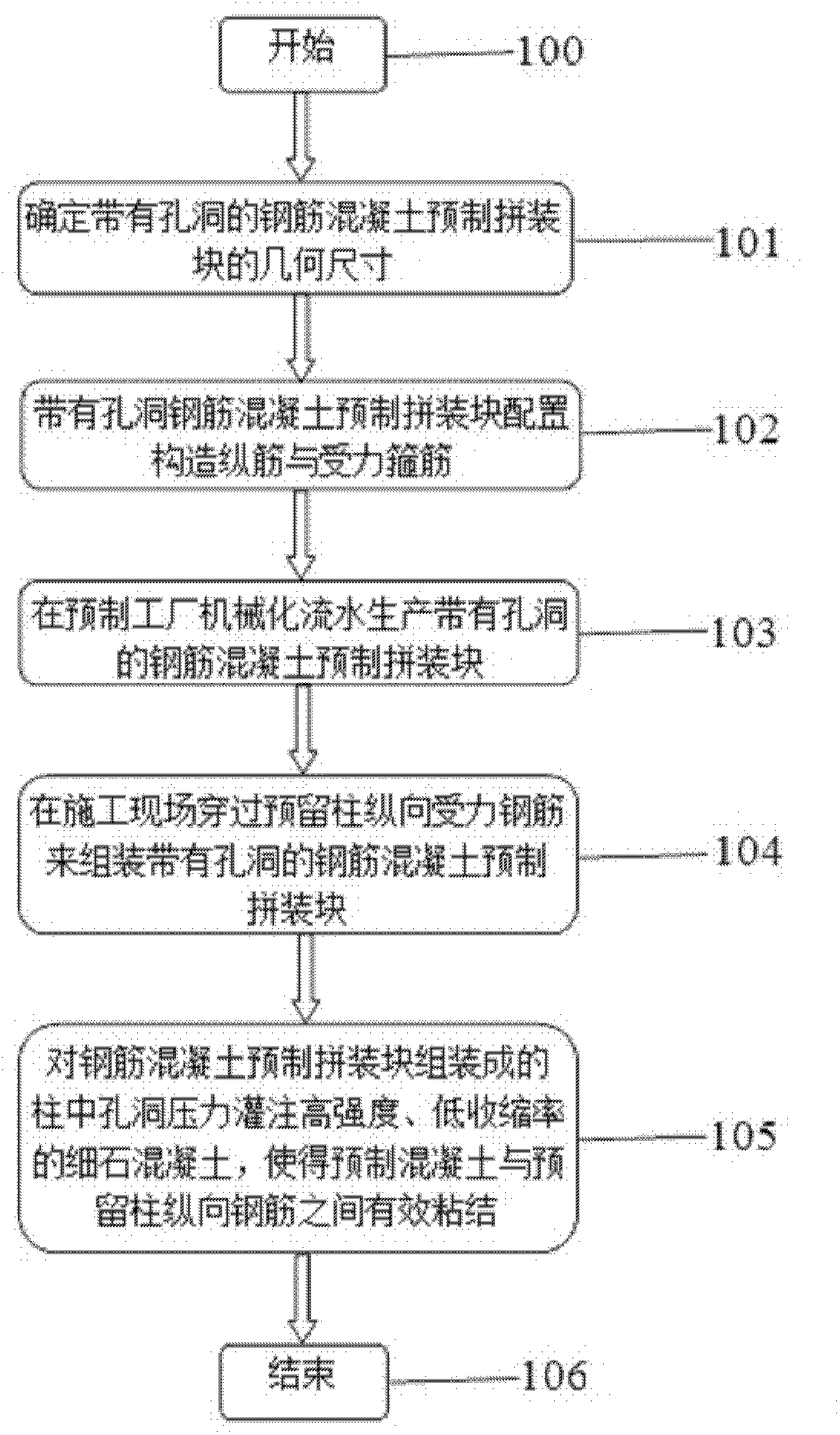

Prefabricated reinforced concrete assembled column and its manufacturing method

InactiveCN102352668AReduce in quantityReduce labor costsStrutsCeramic shaping apparatusReinforced concreteSlurry

Belonging to the technical field of structural engineering in the civil engineering industry, the invention discloses a prefabricated reinforced concrete assembled column and its manufacturing method. The prefabricated reinforced concrete assembled column comprises over two prefabricated reinforced concrete assembled blocks which are provided with vertical through holes and are in columnar stacking. And the prefabricated reinforced concrete assembled blocks are integrated through vertical stressed steel bars passing through the vertical through holes. Meanwhile, the gaps between the vertical stressed steel bars and the vertical through holes are pressure perfused slurry layers. Installation of the vertical stressed steel bars is carried out on site. Therefore, the method of the invention can realize prefabricated reinforced concrete assembled block production through mechanized flow production in prefabrication factories. Due to the employment of on-site mechanical lifting, very few people are needed for cooperation so as to produce assembled columns safely, so that the labor cost is effectively reduced and the production efficiency is improved.

Owner:SOUTHEAST UNIV

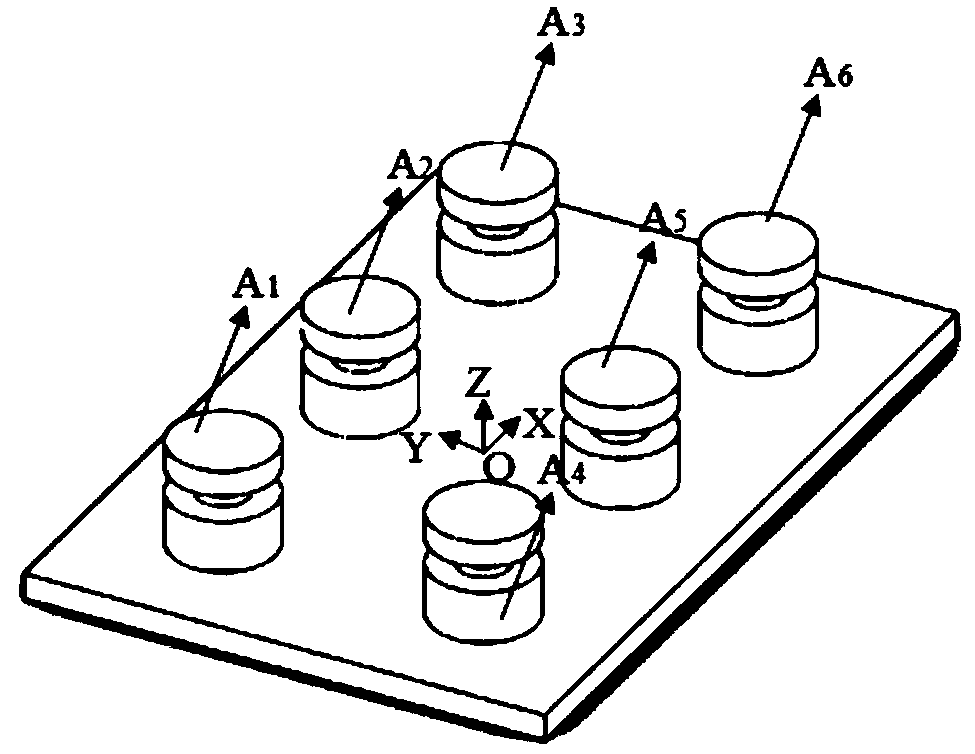

Multi-robot cooperated operation task description method

ActiveCN108527367AEasy to identifyImprove efficiencyProgramme-controlled manipulatorThree levelDecomposition

The invention discloses a multi-robot cooperated operation task description method, which is divided into three levels to describe a general objective task: (1) all product level subtasks which compose the general objective task are described; (2) the priority, change characteristic state sequences, optimization objective and reference coordinate system of each product level subtask are described;(3) the state sequence of each change characteristic of each product level subtask is described. The multi-robot cooperated operation task description method provided by the invention can express a general operation task of robot workstations which can be easily read and identified by a computer, so that subsequent intelligent decision making for the task assignment and scheduling of the robots is facilitated, the decomposition, subtask sequences, time-sequence constraint relation and the like of a robot task processed by the current artificial method are effectively solved, and the full automation and intelligence of robot operation and production are realized.

Owner:SOUTH CHINA UNIV OF TECH

Continuous torsion-less drawing process of producing steel wire with spiral rib

The continuous operation production line of spiral rib steel wire is formed by the procedures of paying-off, 1-8 multiple pass cold-drawing plastic deformation, rotating plastic deformation, medium-frequency heating stress-removing tempering, applying pretension, continuous feeding and reeling. The length of said production line is 60 m, and said production line can be controlled by microcomputer, its touch display screen and data display are clear and accurate, it adopts man-machine interface operation mode. It not only raises production efficiency, reduces production cost, but also raises quality of product, and effectively solves the difficult problem of non-uniform mechanical property of steel wire.

Owner:北京中铁建协技术开发有限公司 +1

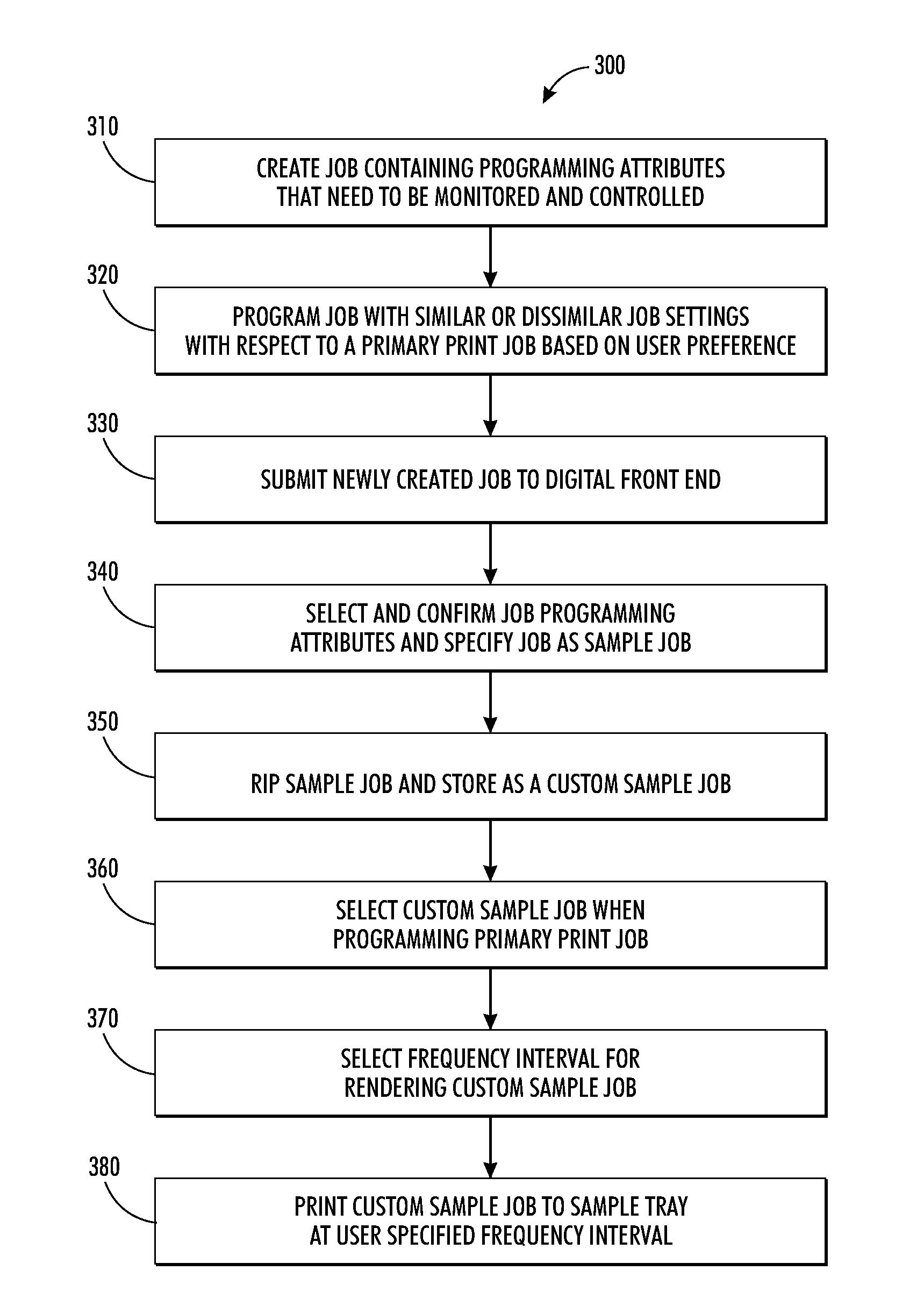

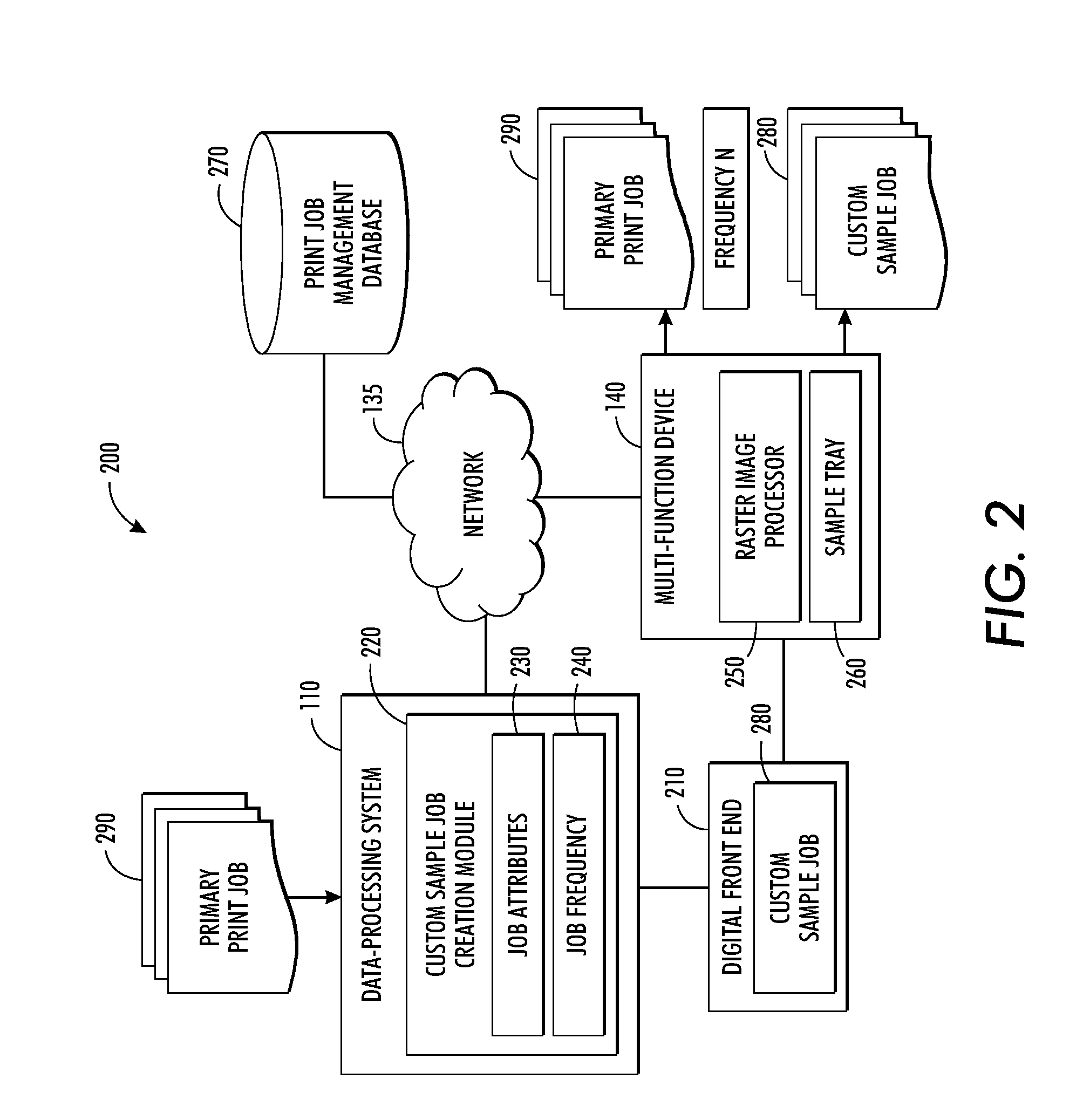

Method and system for creating and using customized sample rendering job

InactiveUS20110176151A1Prevent materialAvoid wasting timeDigitally marking record carriersVisual presentation using printersApplication softwareComputer memory

A system and method for configuring a customized sample job for monitoring print quality and increasing proofing flexibility. A sample job comprising one or more pages can be created in association with print programming attributes utilizing a document creation application. The sample job can be raster image processed with respect to a user specified job setting and stored in an electronic memory component (e.g., DFE component, computer memory, Flash memory, USB memory, etc) as a custom sample job. The custom sample job can be then selected with respect to a primary rendering job in order to render a sample page based on a predefined frequency interval (e.g., after every N sheets) to a sample tray. The frequency interval associated with the custom sample job production can be predefined on a job-by-job and / or global basis by a user.

Owner:XEROX CORP

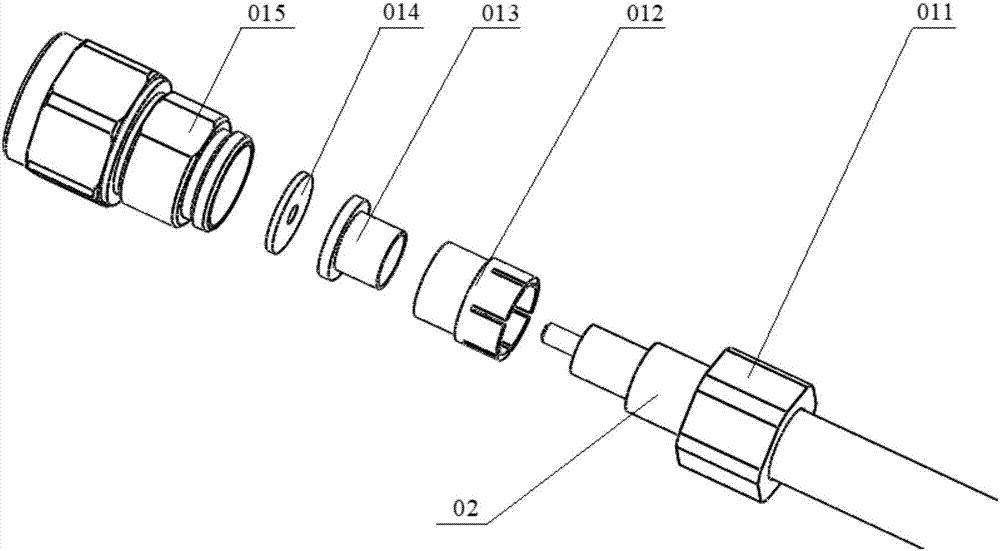

Radio frequency coaxial cable assembly assembling automatic production system

PendingCN107425389AGuaranteed uniformityGuaranteed traceabilityLine/current collector detailsCoaxial cableRadio frequency

The invention provides a radio frequency coaxial cable assembly assembling automatic production system comprising a carrier bearing a radio frequency coaxial cable, wherein the carrier passes an upper nut, a skin peeling device, an upper wire clamp, a sorting device, a cutting insulator device, an upper lining device, a wire core chamfering device, an upper insulation sheet device, an upper thread sleeve device, a nut-thread sleeve screwing device, a detector and a discharge device in sequence; the radio frequency coaxial cable assembly assembling automatic production system can realize the radio frequency coaxial cable and connector assembling automatic production process, thus ensuring uniformity and integrated quality of each assembling product, and ensuring the traceability of each assembling product; the radio frequency coaxial cable assembly assembling automatic production system can replace conventional onerous labor works, thus greatly improving production efficiency, and better ensuring the product quality and output.

Owner:CHANGSHA KINAL AUTOMATION TECH CO LTD

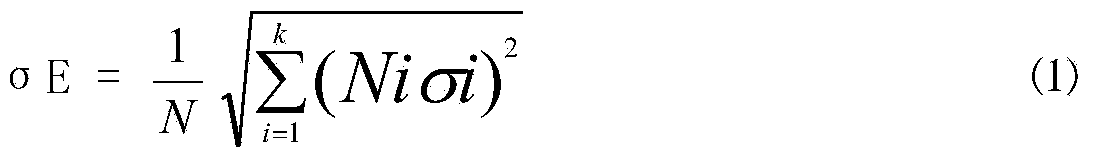

Blending effect computing method applicable to blending operation of iron ore powder

InactiveCN104008298AEasy dataImprove the mixing effectSpecial data processing applicationsAdditive ingredientCalculation methods

The invention belongs to the technical field of blast furnace ironmaking, and discloses a blending effect computing method applicable to the blending operation of iron ore powder. The blending effect computing method comprises the following steps: 1, finding iron ore content P(A) in blended material by mathematically modeling the blending operation process of the iron ore powder; 2, determining that probability of iron ore discrete type random variable X valuing around E(X) is more than or equal to Po; 3, finding the percent of pass P of continuous type random variable normal distribution of the testing ingredient in the blended material; 4, obtaining a blending efficiency computational formula applied to managing the blending operation by setting [eta] to be equal to P / Po, wherein, when [eta] is equal to 1, the blending effect is the best, when [eta] is more than 1, the more the [eta], the better the blending effect is, and when [eta] is less than 1, the less the [eta], the poor the blending effect is. According to the blending effect computing method, influence factors to the production of blending stock piles in a stock ground are comprehensively taken into consideration, thus being more accurately accordant with actual situation of the blending effect of the modern stock ground blending operation.

Owner:NANJING IRON & STEEL CO LTD

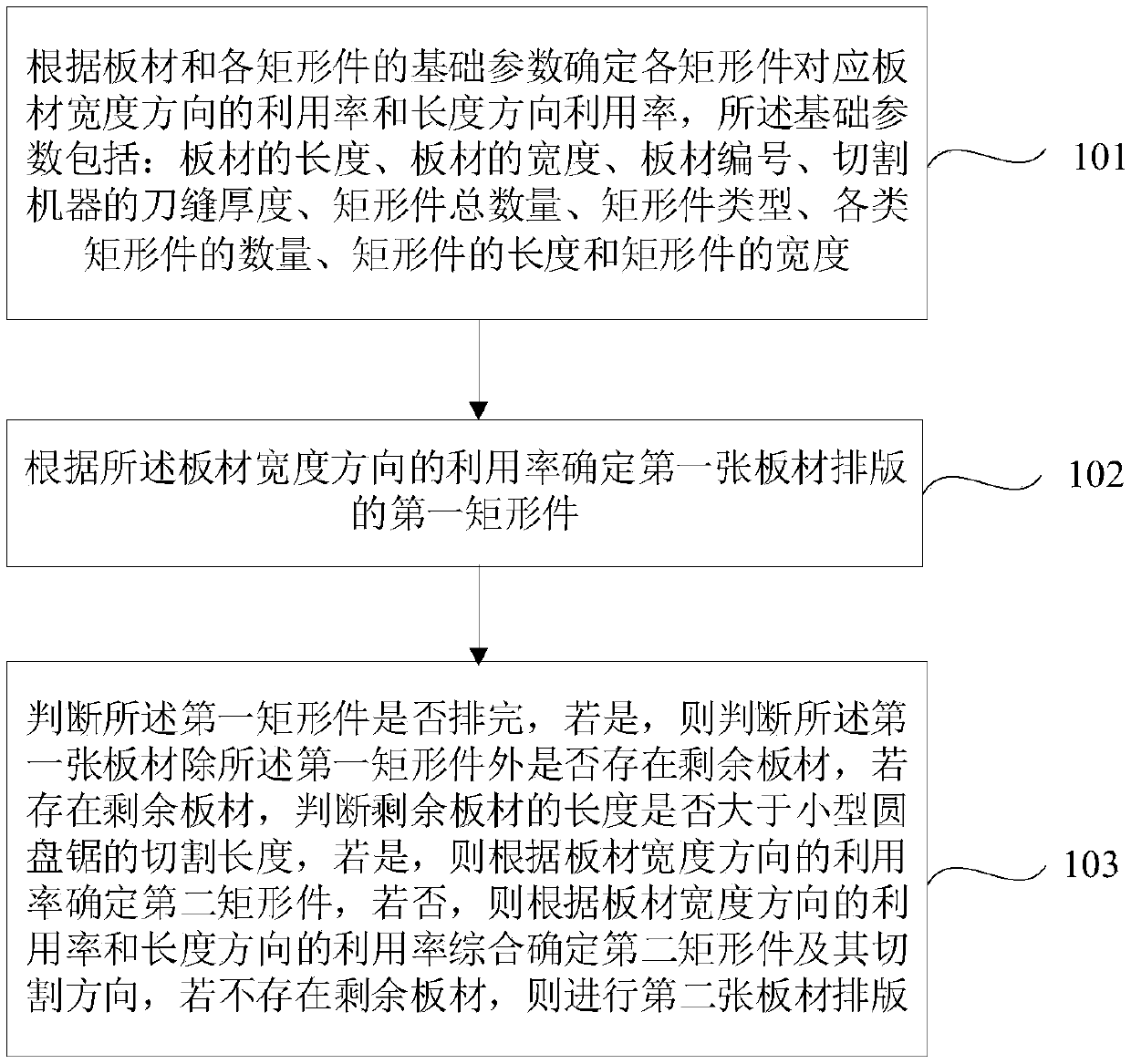

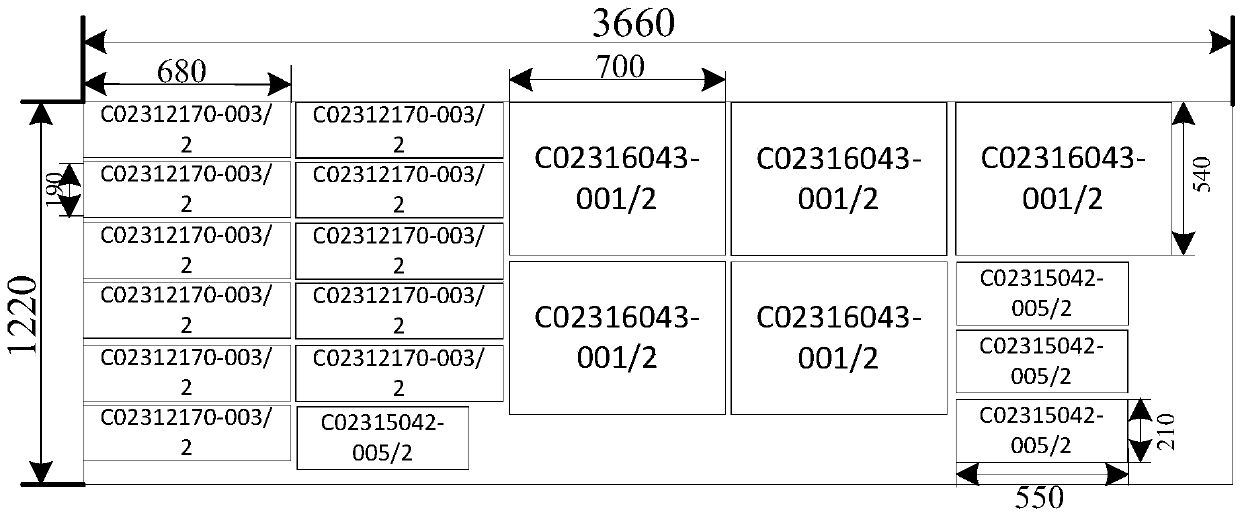

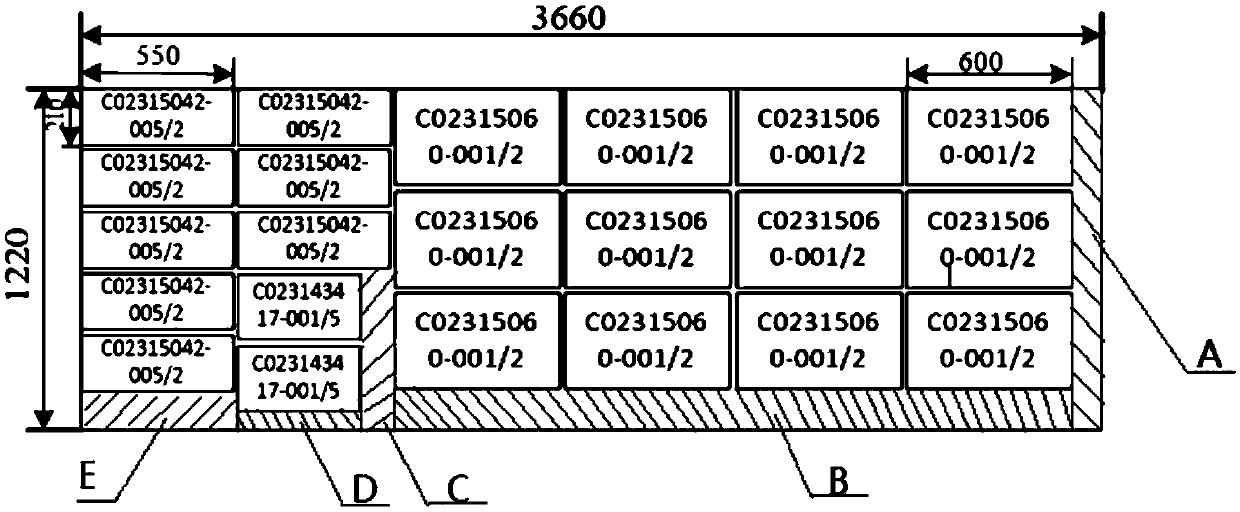

Rectangular optimal layout method for equalizing disk saw work and plate utilization rate

ActiveCN108681785AIncrease profitImprove work efficiencyForecastingManufacturing computing systemsCircular discGlobal distribution

The invention discloses a rectangular optimal layout method for equalizing disk saw work and plate utilization rate. The rectangular optimal layout method comprises the steps that the utilization rateof the plate width direction and the utilization rate of the plate length direction corresponding to each rectangular part are determined according to the basic parameters of the plate and each rectangular part; and each rectangular part of plate layout is determined according to the utilization rate of the plate width direction and the utilization rate of the length direction. Simultaneous workproduction of the large disk saw and the small disk saw can be equalized and global distribution of utilization of the plate can also be realized so that the utilization rate of the plate can be enhanced, the cutting loss in the blanking process can be reduced, the raw material can be saved, the production cost can be reduced, the working efficiency of plate cutting can be enhanced and the cuttingspeed can be accelerated.

Owner:DALIAN MARITIME UNIVERSITY

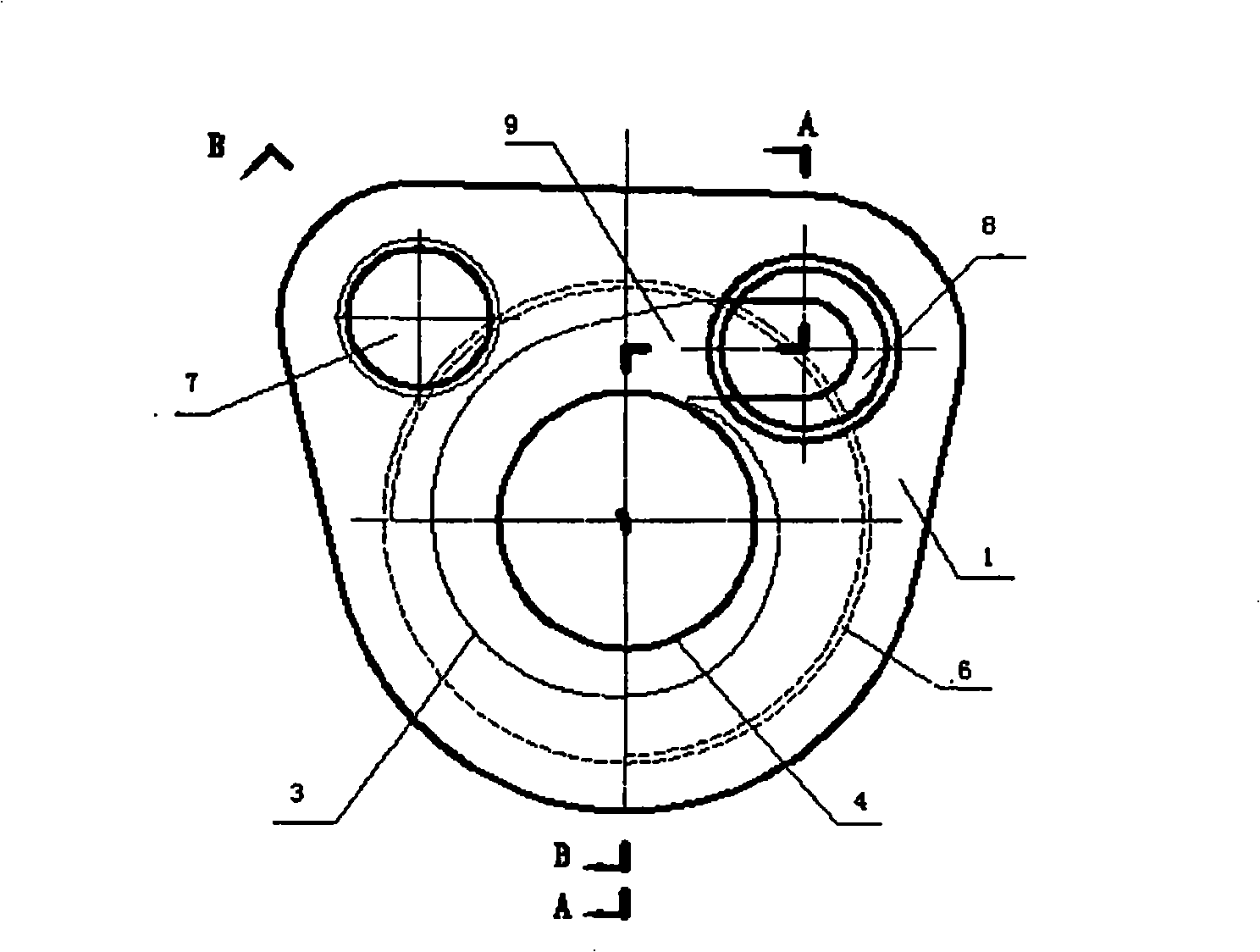

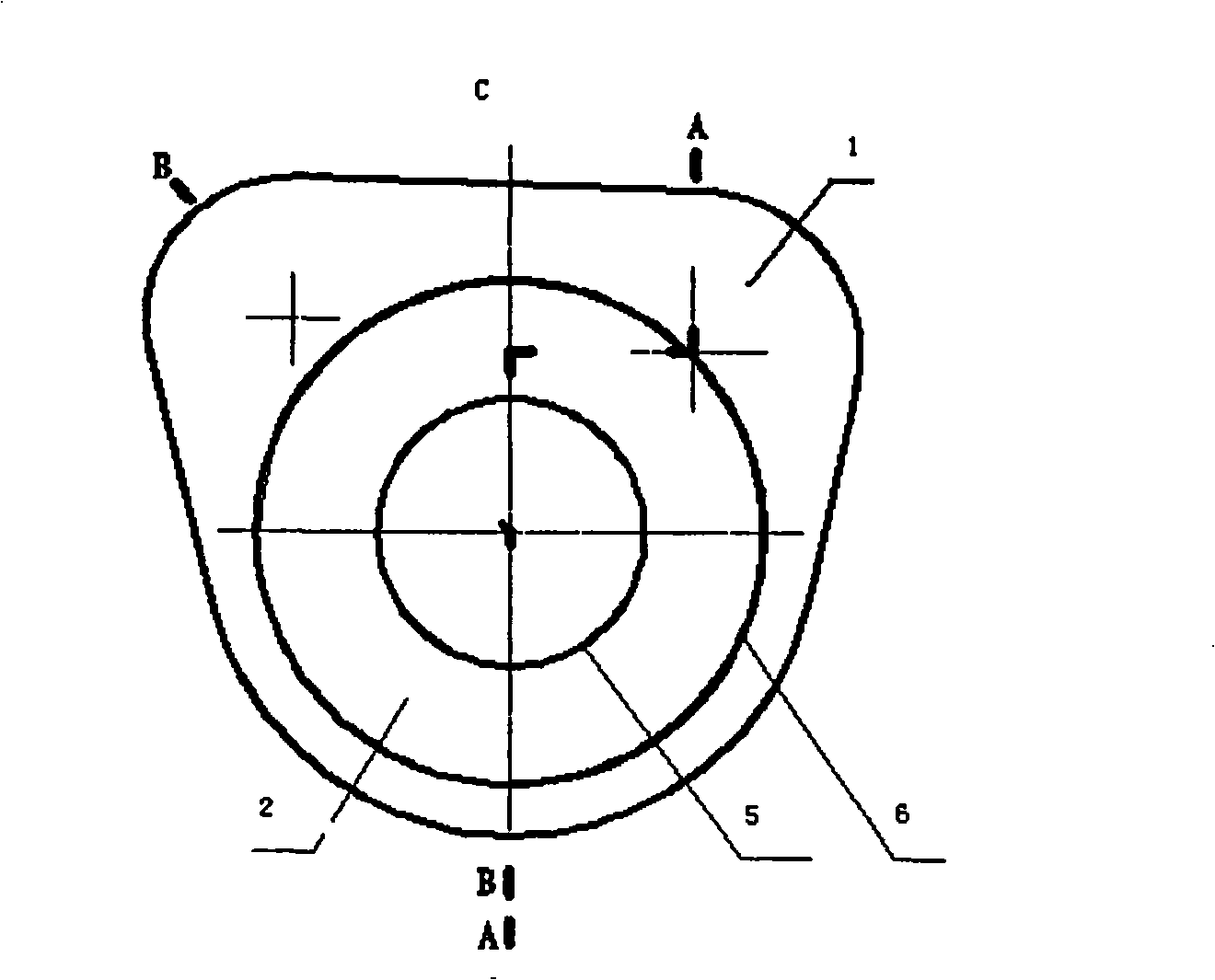

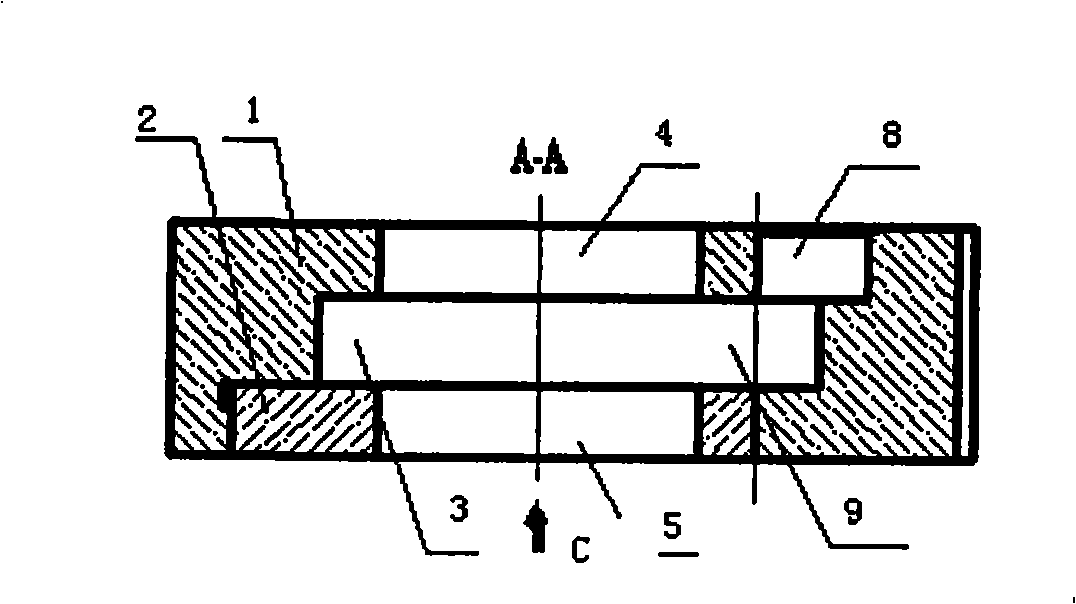

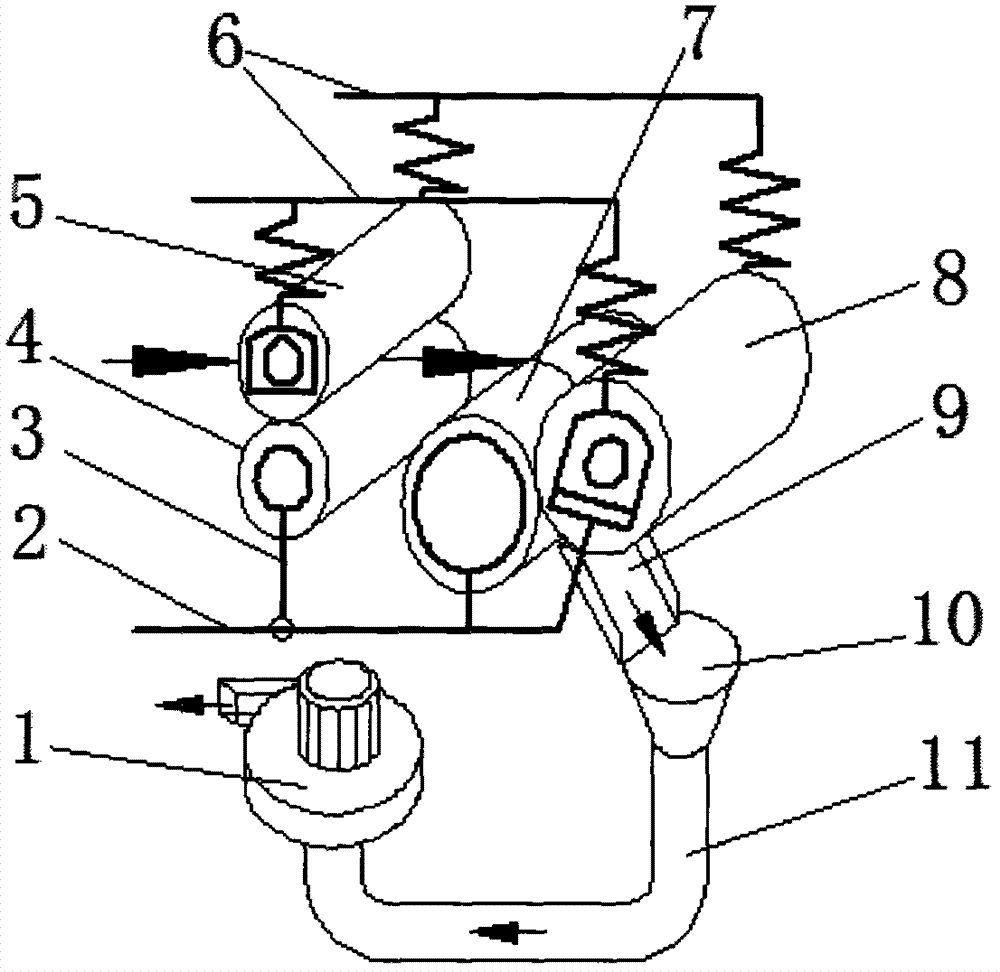

Method for preparing graphitic centrifugal pump spiral casing

InactiveCN101303026AAchieve mass productionSolve problems that cannot be processed by general machiningPump componentsPumpsNumerical controlEngineering

The invention discloses a manufacturing method of a centrifugal graphite pump shell. The manufacturing method of a pump shell body includes that a light hole A is cut at the position of a graphite pump shell blank, on which spiral channels are intended to be processed; the back of the blank, corresponding to the light hole A, is milled with screwed holes, the inner diameter of the screwed holes is larger than the maximum radius of the spiral channel; the spiral channel and an outlet of the spiral channel are processed by numerical control or common machining method; screw filling plugs matched with the screw holes are prepared for filling the screwed holes; a light hole B communicated with the light hole A is processed at the center of the screw filling plugs. The method solves the difficult problem that direct machining can not be adopted due to hidden channels in the existing centrifugal graphite pump, has the advantages of high efficiency, low energy consumption and low cost, and can realize job production and large-scale production of the centrifugal graphite pump shell.

Owner:CENT SOUTH UNIV

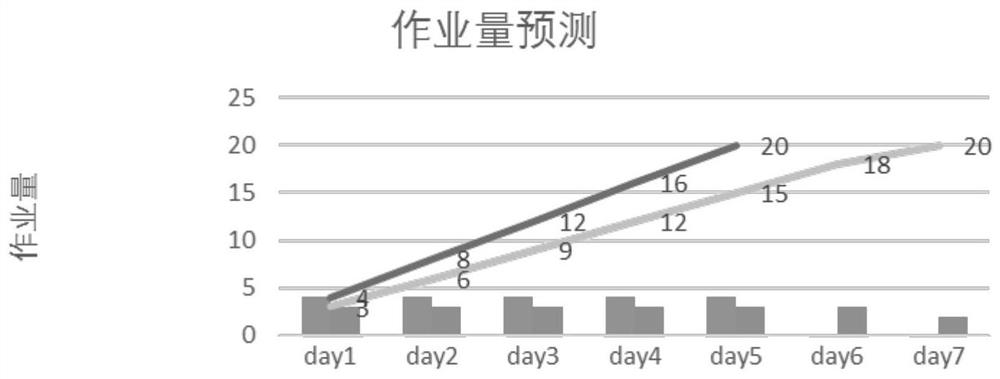

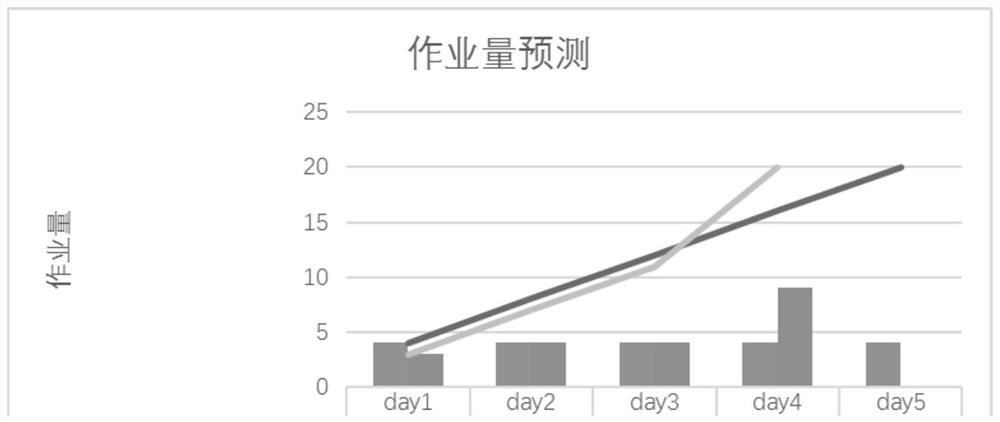

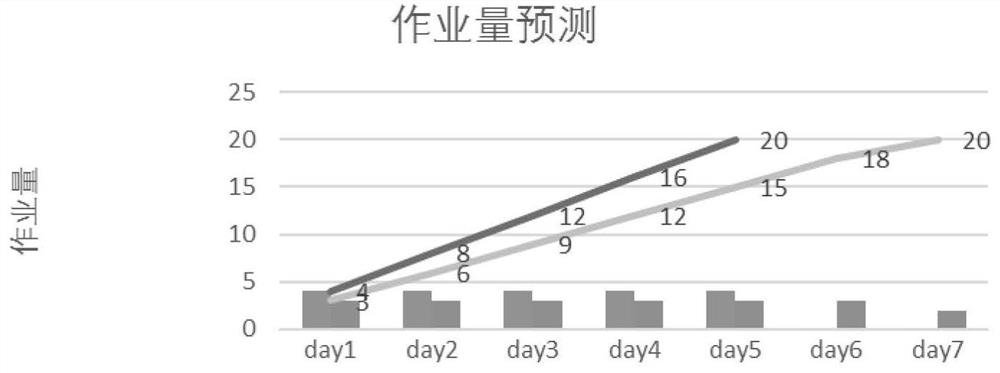

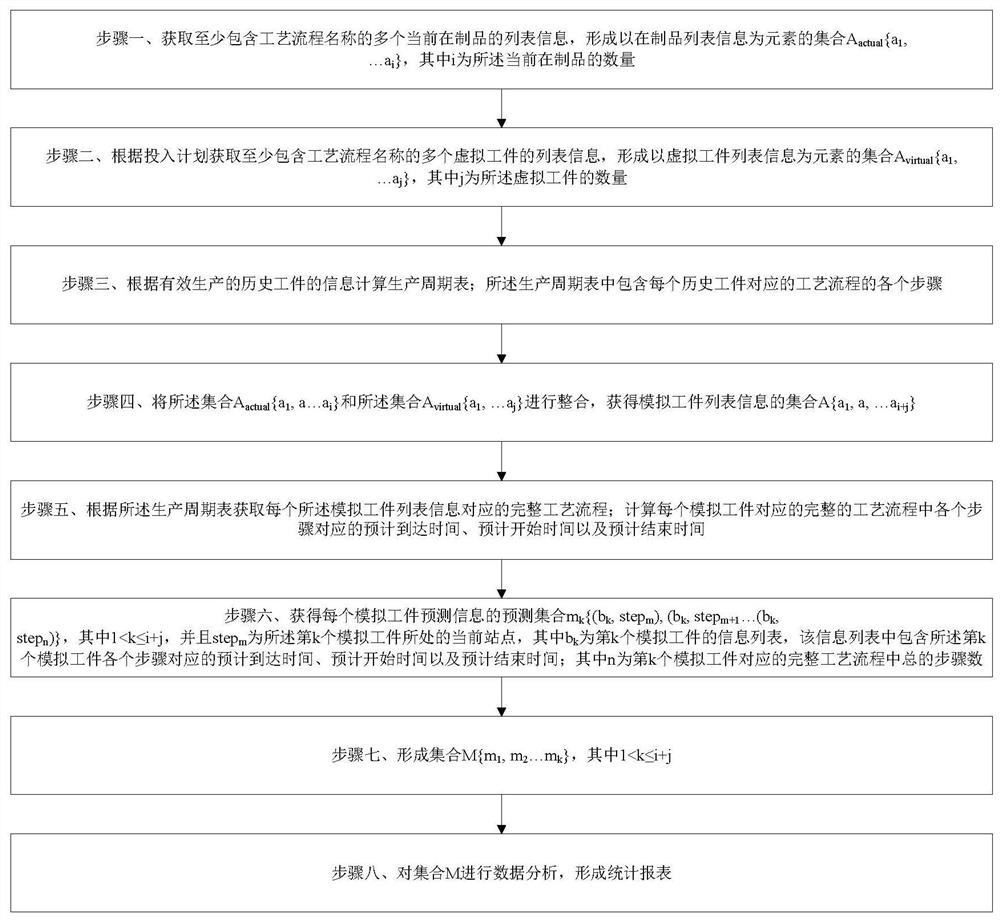

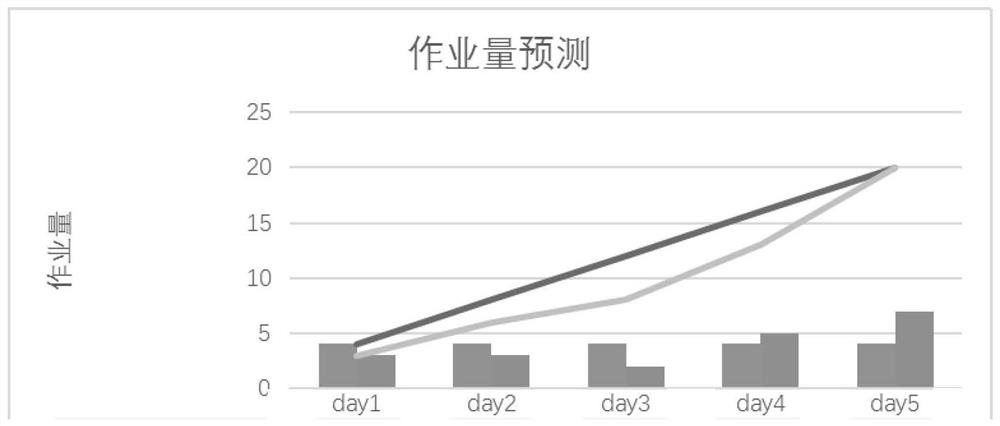

Line production line workload prediction method based on delivery date

PendingCN111784035AAchieve job scheduling and other control purposesForecastingOffice automationOperation schedulingWork in process

The invention provides a line production line workload prediction method based on a delivery date. The method comprises the steps of forming an in-process product list information set; forming a virtual workpiece list information set; calculating a production periodic table according to the historical workpiece information; integrating the in-process product list information and the virtual workpiece list information as a set of elements to obtain a simulated workpiece list information set; obtaining a complete technological process of each simulation workpiece; calculating estimated shipmenttime according to the time of arriving at the current station, the operation time, the waiting time and the stagnation time, and calculating a coefficient according to the estimated shipment time; calculating estimated arrival time, estimated start time and estimated end time of each step according to the coefficients; and obtaining a prediction set of prediction information for each simulated workpiece. According to the method, the coefficient value is used for correcting the production period, the future workload prediction of the whole production line is quickly realized, the data are analyzed, and the regulation and control purposes of production regulation and control, productivity early warning, operation scheduling and the like are achieved in combination with the condition of the actual production line.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

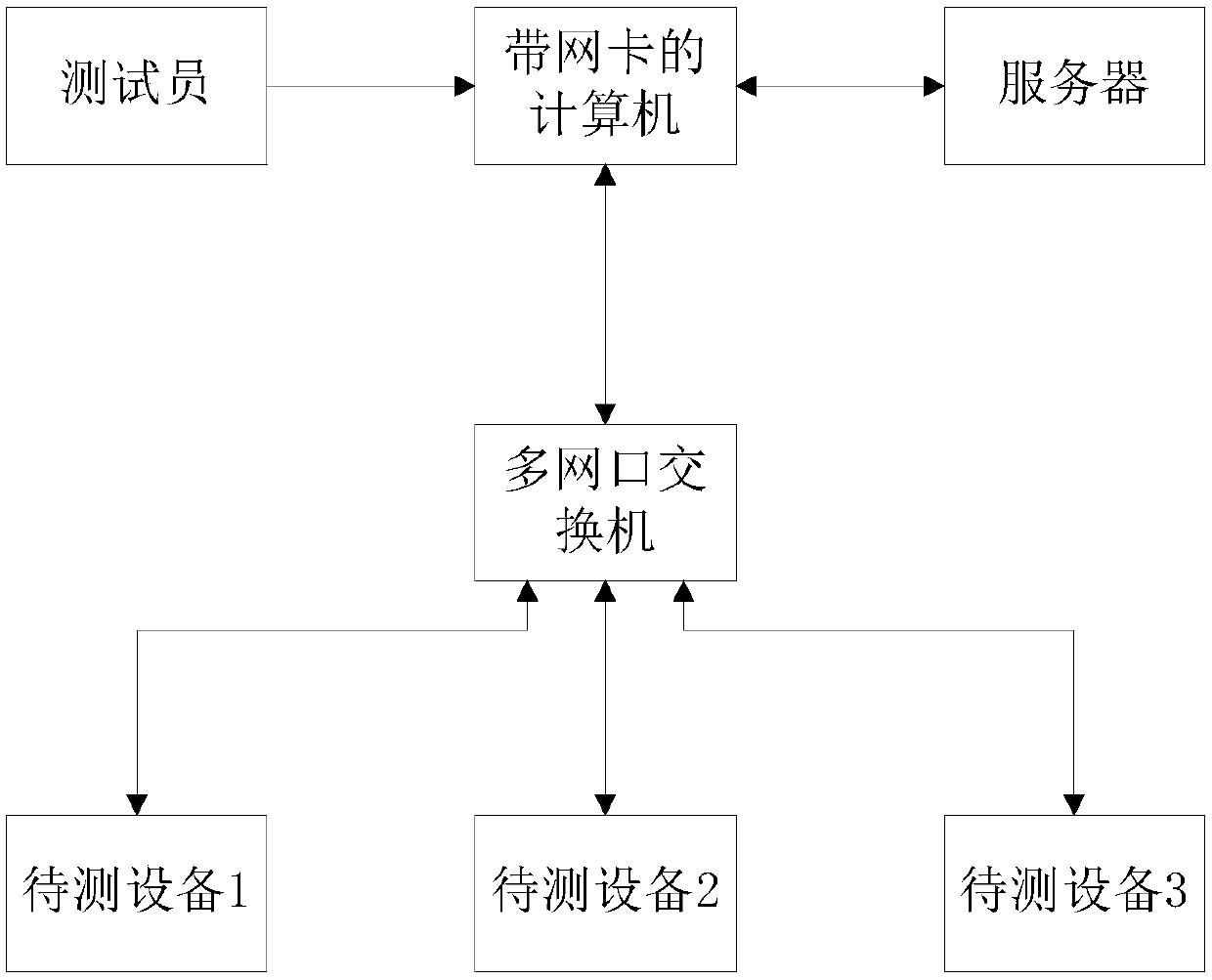

Multi-machine test method and system based on telnet protocol

InactiveCN109560980AEasy to identifyImplement multi-machine testingData switching networksMulti machineMulti port

The invention discloses a multi-machine test method and system based on a telnet protocol. The multi-machine test method comprises the steps of S1, using a computer with a vlan network card as a testterminal, connecting with devices under test through a multi-port switch so as to realize telnet protocol communication, and allocating an IP to each port of the switch; S2, controlling the multi-machine switch to log in the devices under test to read MAC / SN information through the test terminal, and testing the devices under test; and S3, displaying test results. The system comprises a computer with a vlan network card, a multi-port switch, a server and a plurality of devices under test. The multi-machine test method and system realize multi-machine testing and can reduce the cost and improvethe production testing efficiency in factory production; and it is convenient for employees to operate in the production testing process, and only product LAN ports need to be debugged when producingdifferent types of products, thereby being capable of saving the cost and waste of the personnel on the one hand, and being capable of saving the line changing time and effectively improving the production testing efficiency on the other hand.

Owner:SHENZHEN ATUE TECH CO LTD

Special-shaped plastic cover laser coding machine

The invention provides a special-shaped plastic cover laser coding machine. The coding machine comprises an outer frame, an inner frame is arranged in the middle of the outer frame, chain guide rails are arranged on two upper end surfaces of the inner frame, a conveying chain is arranged on the chain guide rail, the conveying chain is connected with a large chain wheel, the large chain wheel is arranged on a driven shaft, the driven shaft is connected with a servo motor through a synchronous belt, a small shaft is arranged on the lower end of the inner frame through a tensioning chain wheel fixing plate, the small shaft is connected with the tensioning chain wheel,a fixing plate is fixed on the outer frame, a guide pillar fixing seat and an air cylinder are arranged on the fixing plate, the guide pillar is arranged on the guide pillar fixing seat, a guide sleeve is arranged on the guide pillar, the guide sleeve is connected with an upper tool fixing plate, multiple upper tools are arranged on the upper tool fixing plate, the conveying chain is connected with a lower tool fixing plate, and a lower tool matched with the upper tool is arranged on the lower tool fixing plate. The coding machine provided by the invention is accurate in positioning, the marked two-dimension code colors are consistent, the sizes are the same, the production efficiency is high, the coding machine can realize large scale job production, the automation of the special-shaped plastic cover laser marking is realized, and the production efficiency is improved.

Owner:LIPENG PACKING YANTAI CITY

Line production line workload prediction method based on production cycle

PendingCN111784036AAchieve productivityTo achieve the purpose of production capacity early warning and other regulationForecastingOffice automationProduction lineStatistical Report

The invention provides a line production line workload prediction method based on a production cycle. The method comprises the steps of forming an in-process product list information set; forming a virtual workpiece list information set; calculating a production periodic table according to the historical workpiece information; integrating the in-process product list information and the virtual workpiece list information as a set of elements to obtain a simulated workpiece list information set; obtaining a complete process flow corresponding to each piece of simulated workpiece list informationaccording to the production periodic table; calculating the estimated arrival time, the estimated start time and the estimated end time of each step of each simulation workpiece; and obtaining a prediction set of the prediction information of each simulation workpiece to form a statistical report. According to the characteristics and known data of the flow production line, the prediction method is utilized to quickly realize workload prediction of the whole production line in a period of time in the future, detailed prediction data are reserved, analysis of each dimension is performed on thedata, and the regulation and control purposes of production regulation and control, productivity early warning and the like are achieved in combination with the condition of the actual production line.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

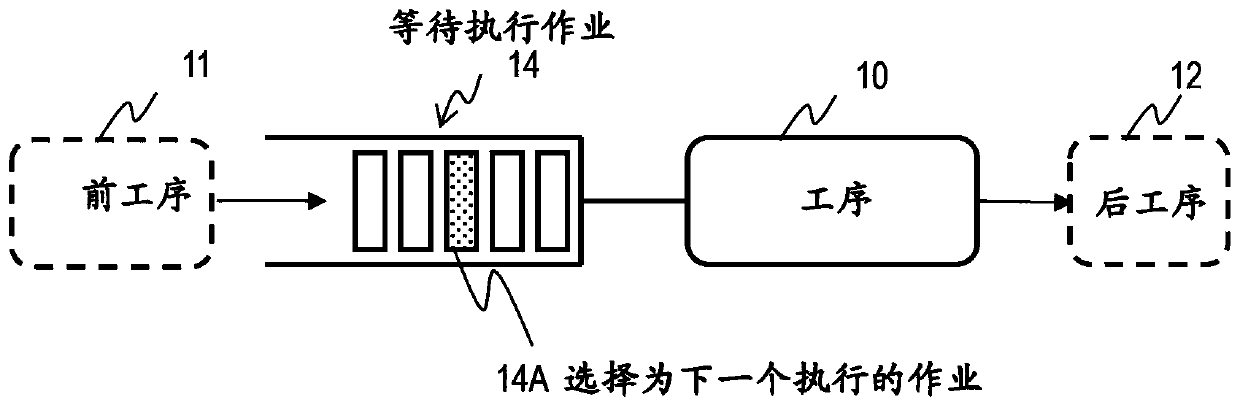

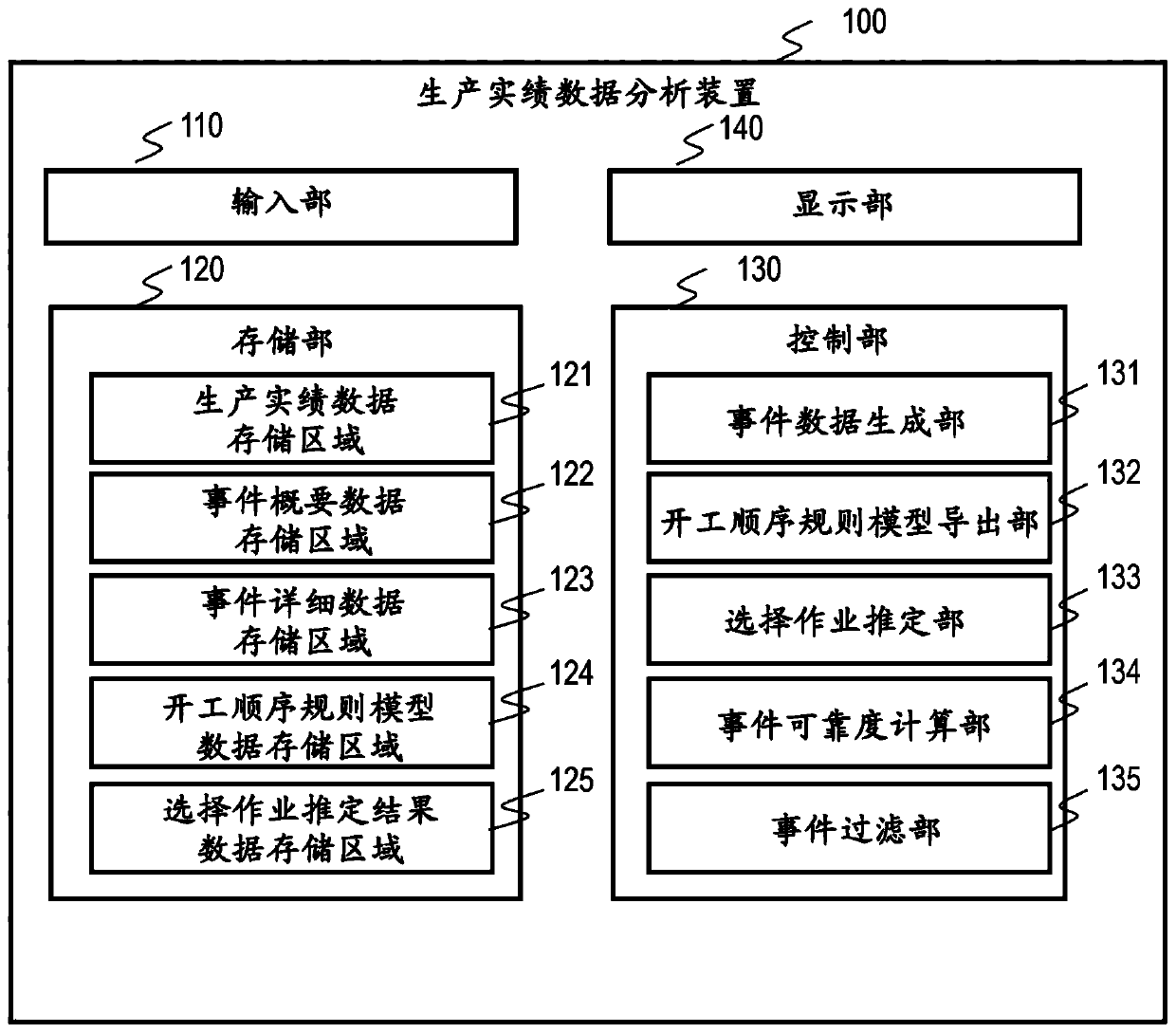

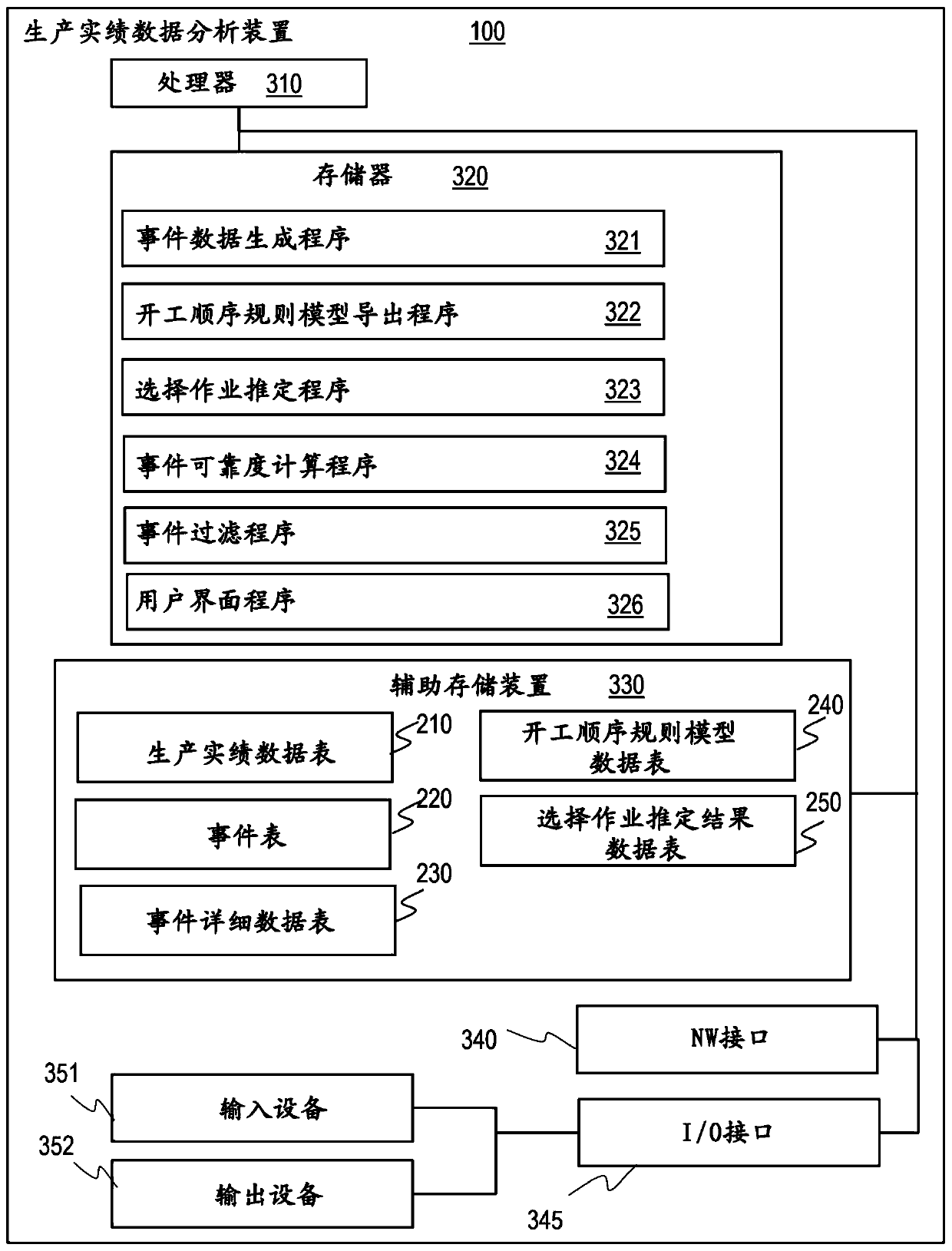

Production record data analyzer

According to the method, a startup sequence rule model conforming to an actual startup sequence rule of a production site is constructed. Event data of the production performance data includes information of an event in which a next job to be executed is selected from the jobs to be executed for each process.Each dispatching rule model in each dispatching rule model set is configured to anticipatea job to be selected next from waiting jobs in an event in a process associated with the dispatching rule model set. One or more processors are configured to: generate anticipation results of a selected event with the plurality of dispatching rule models associated with the process; determine reliability of the selected event based on whether each of the jobs indicated in the anticipation resultsis the same as the job actually selected in the selected event shown in the production record data in each of the plurality of processes; and determine whether to include the selected event to training data for generating a new dispatching rule model based on the reliability in each of the plurality of processes.

Owner:HITACHI LTD

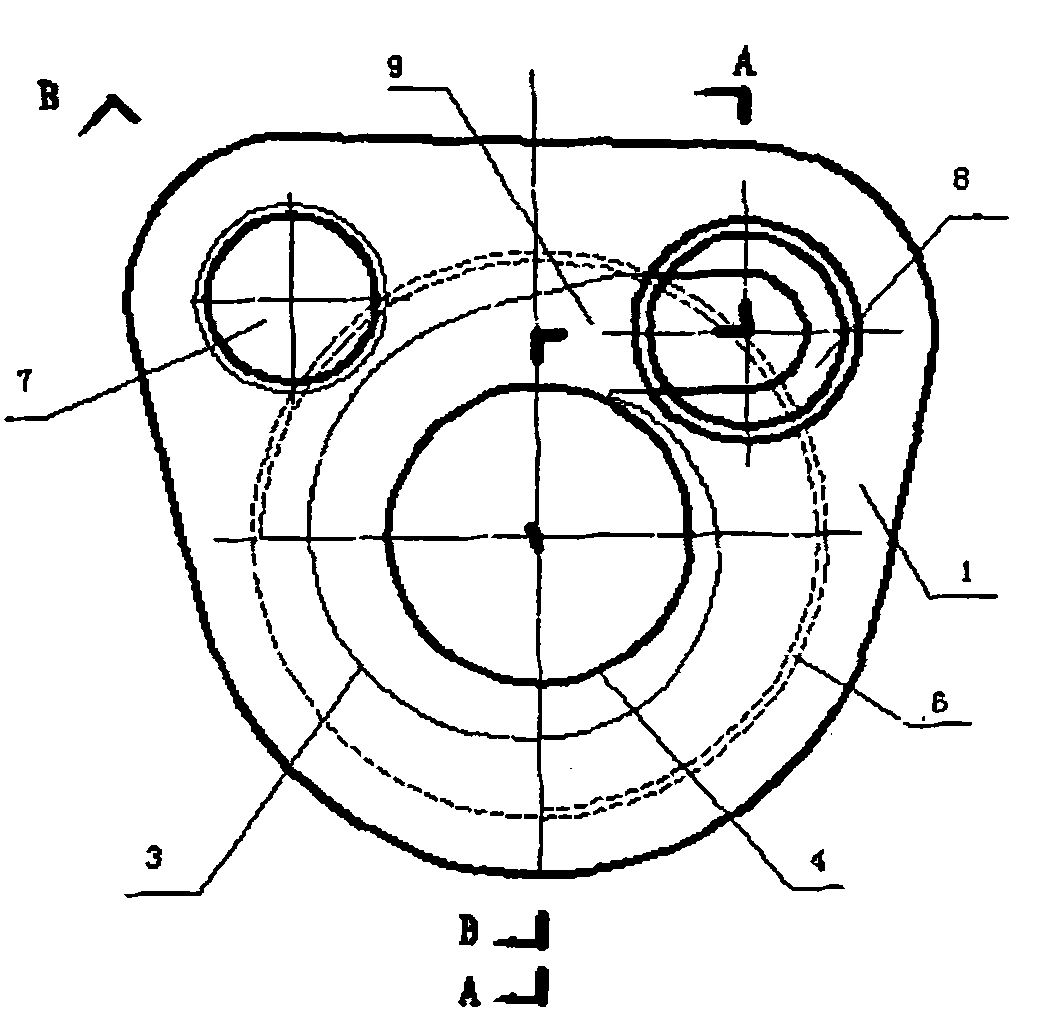

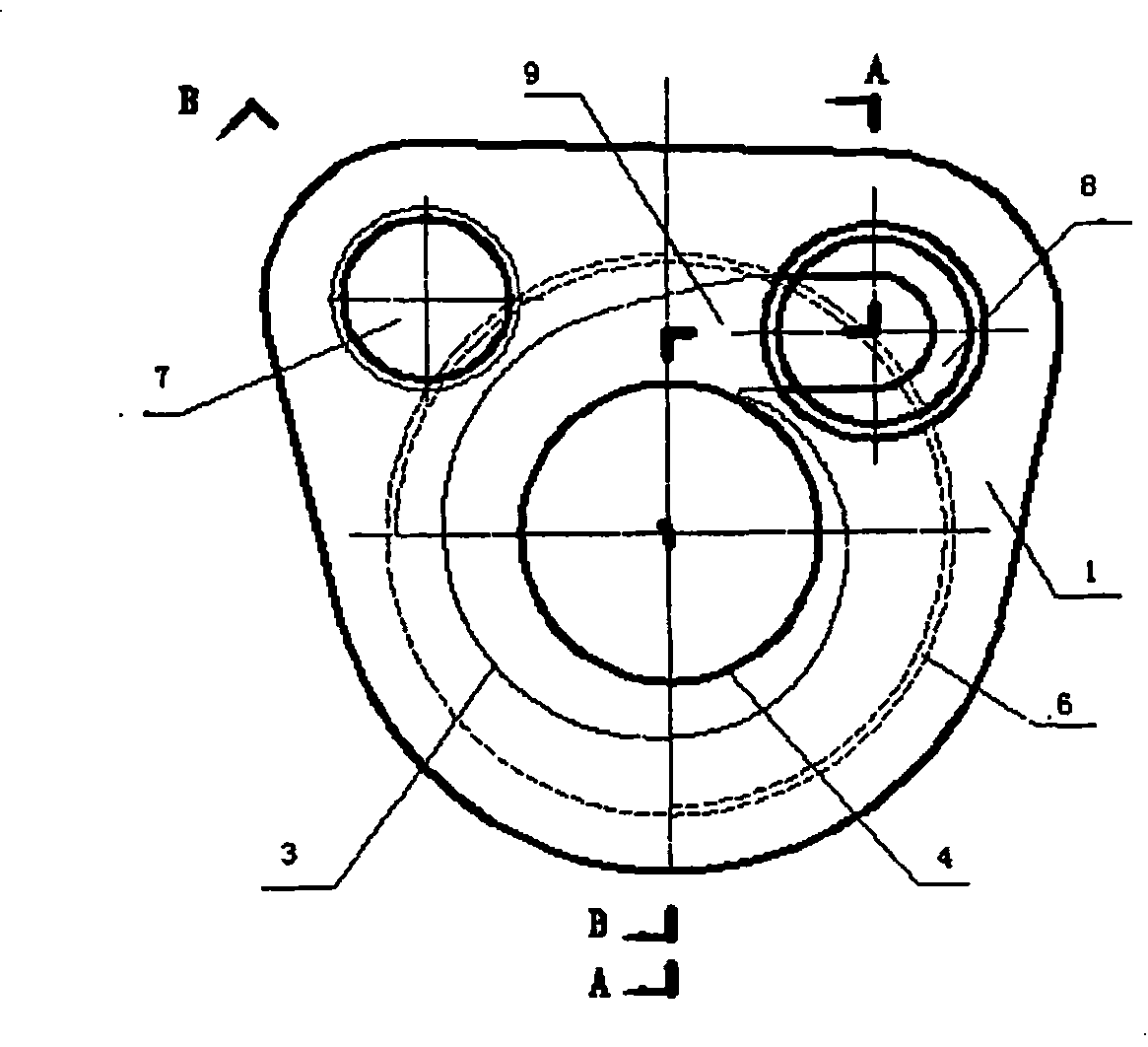

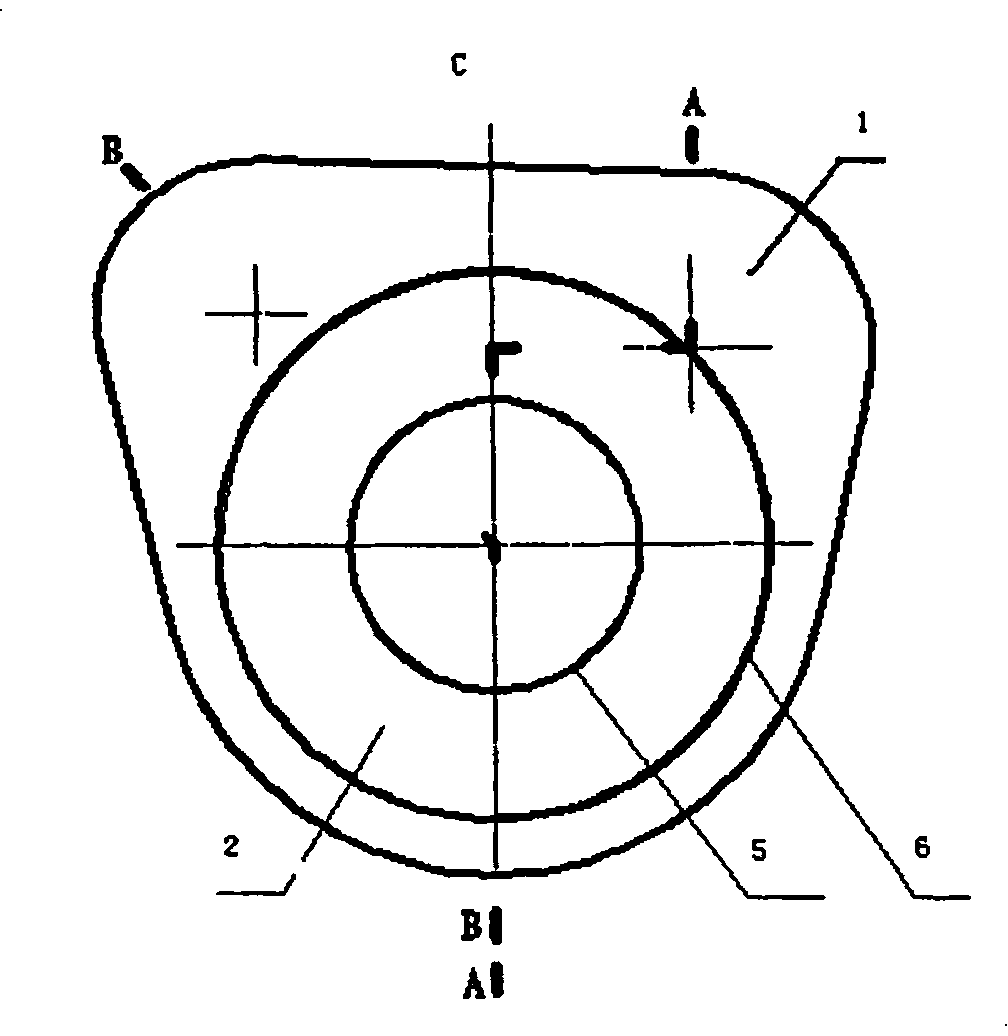

Method for preparing graphitic centrifugal pump spiral casing

InactiveCN101303026BAchieve mass productionSolve problems that cannot be processed by general machiningPump componentsPumpsNumerical controlEngineering

The invention discloses a manufacturing method of a centrifugal graphite pump shell. The manufacturing method of a pump shell body includes that a light hole A is cut at the position of a graphite pump shell blank, on which spiral channels are intended to be processed; the back of the blank, corresponding to the light hole A, is milled with screwed holes, the inner diameter of the screwed holes is larger than the maximum radius of the spiral channel; the spiral channel and an outlet of the spiral channel are processed by numerical control or common machining method; screw filling plugs matched with the screw holes are prepared for filling the screwed holes; a light hole B communicated with the light hole A is processed at the center of the screw filling plugs. The method solves the difficult problem that direct machining can not be adopted due to hidden channels in the existing centrifugal graphite pump, has the advantages of high efficiency, low energy consumption and low cost, and can realize job production and large-scale production of the centrifugal graphite pump shell.

Owner:CENT SOUTH UNIV

Workpiece detection bench and workpiece detection transfer bench

PendingCN107655379ASimple processIncrease productivityMechanical measuring arrangementsMachineIndustrial engineering

A workpiece detection transfer bench comprises an underframe, two workpiece detection benches and a defective product groove. The underframe is equipped with a lead screw guide rail, a linear track and a drag chain erected on an outer side of the linear track. One workpiece detection bench is a mobile detection bench. The mobile detection bench is cooperated with the lead screw guide rail and thelinear track so as to realize manual random spot check. Another workpiece detection bench is a fixed detection bench. The fixed detection bench is fixedly arranged on the underframe so as to realize automatic full inspection of a machine. The defective product groove is installed below the two detection benches. The workpiece detection transfer bench possesses the following advantages that duringan automation production process, a robot can put a workpiece on the transfer bench, and two functions of the automatic full inspection of the machine and the manual random spot check can be realized;the detection benches detect the workpiece, after being detected to be qualified, the workpiece can be taken, and work production of a next process is performed; and after being detected to be defective, the workpiece enters into the defective product groove, technology processes are simplified, and production efficiency and an automation level are increased.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

Miniature strip cutting device and flow process method

The invention relates to a miniature strip cutting device and a flow process method, and belongs to the technical field of spinning. The method has the technical scheme that in the colored cotton spinning process, the miniature strip cutting device adopts a measure of changing the notch roller intermittent traction strip pulling and cutting work into the combination of the conventional roller continuous traction and the airflow winding effect in the traditional fiber pre-combing cotton strip production. The device is additionally arranged at the tail part of a cotton combing machine or a fine combing machine, so that the device can synchronously work along with the cotton combing machine or the fine combing machine, fragmentary cotton strips or scattered fiber type small cotton blocks are outwards conveyed, then, through the airflow conveyance, the fragmentary cotton strips or the scattered fiber type small cotton blocks are fed to a baler by annular cabin collecting equipment, the technical production flow process of fully mechanical production of pre-combing scattered fiber, collection and feeding and baling is realized, the original manual operation production with the defects of high production work intensity, complexity and low efficiency is greatly liberated, the production efficiency is improved, the production noise is reduced, and time, labor and resources are saved.

Owner:江苏三州机械科技有限公司

PCB double-sided board cutting system

ActiveCN108271316AReduce production processing timeSolve the problem of process integrationInsulating layers/substrates workingSingle processProcess integration

The invention belongs to the field of circuit board processing, and in particular relates to a PCB double-sided board cutting system. Through connection of a three-dimensional warehouse, a cutting machine, a pin hole drilling machine, an edge grinding round-corner machine, a water washing and drying machine, a pad placing machine, a TWO PIN gluing machine and an AGV storage location, the system directly produces semi-finished products to be drilled from raw materials and greatly shortens the production and processing time. The problem of process integration is solved, the redundant procedure of manual material transfer is removed, and the procedures of the line connection production can be integrated to achieve continuous operation and production. Complete system signal transmission between the procedures described in the invention is performed, such that, when a single process is completed, a completion signal is transmitted to a next station and the automatic identification and automatic production of the next station are realized. The system has a great market prospect and an economic value.

Owner:江西景旺精密电路有限公司

A pcb double panel cutting system

ActiveCN108271316BReduce production processing timeSolve the problem of process integrationInsulating layers/substrates workingProcess integrationManufactured material

The invention belongs to the field of circuit board processing, and in particular relates to a PCB double-sided board cutting system. Through connection of a three-dimensional warehouse, a cutting machine, a pin hole drilling machine, an edge grinding round-corner machine, a water washing and drying machine, a pad placing machine, a TWO PIN gluing machine and an AGV storage location, the system directly produces semi-finished products to be drilled from raw materials and greatly shortens the production and processing time. The problem of process integration is solved, the redundant procedure of manual material transfer is removed, and the procedures of the line connection production can be integrated to achieve continuous operation and production. Complete system signal transmission between the procedures described in the invention is performed, such that, when a single process is completed, a completion signal is transmitted to a next station and the automatic identification and automatic production of the next station are realized. The system has a great market prospect and an economic value.

Owner:江西景旺精密电路有限公司

A micro-strip breaking process

Owner:江苏三州机械科技有限公司

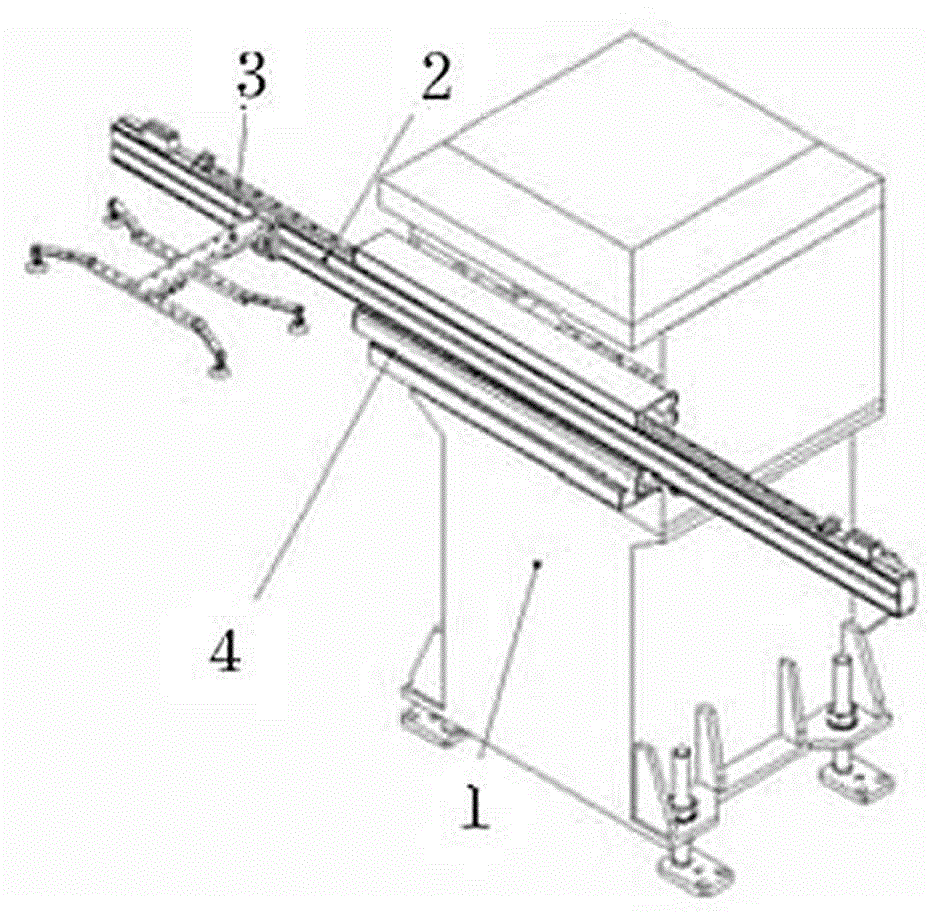

Novel multi-station punch mechanical hand

InactiveCN105583816ARealize automatic pick and placeIncrease production capacityProgramme-controlled manipulatorMetal-working feeding devicesProduction linePunch press

The invention discloses a novel multi-station punch mechanical hand. The mechanical hand mainly consists of a mechanical hand mainframe box 1, a translation rod 2, a mechanical hand end actuator 3 and a guide rail 4. The novel multi-station punch mechanical hand can be used among 8 punches, can realize unloading and unloading actions of stamped parts, and can realize automatic taking and replacing of stamped parts among the punches; taking a stamping automatic production line consisting of 8 punches as an example, the mechanical hand can be operated by only needing one person while the conventional operation production mode at least needs more than 8 persons, so that the labor cost can be greatly saved; and meanwhile, the operation environment is improved to certain extent, potential safety hazards are reduced, and user-friendly production and management are realized.

Owner:张桂春

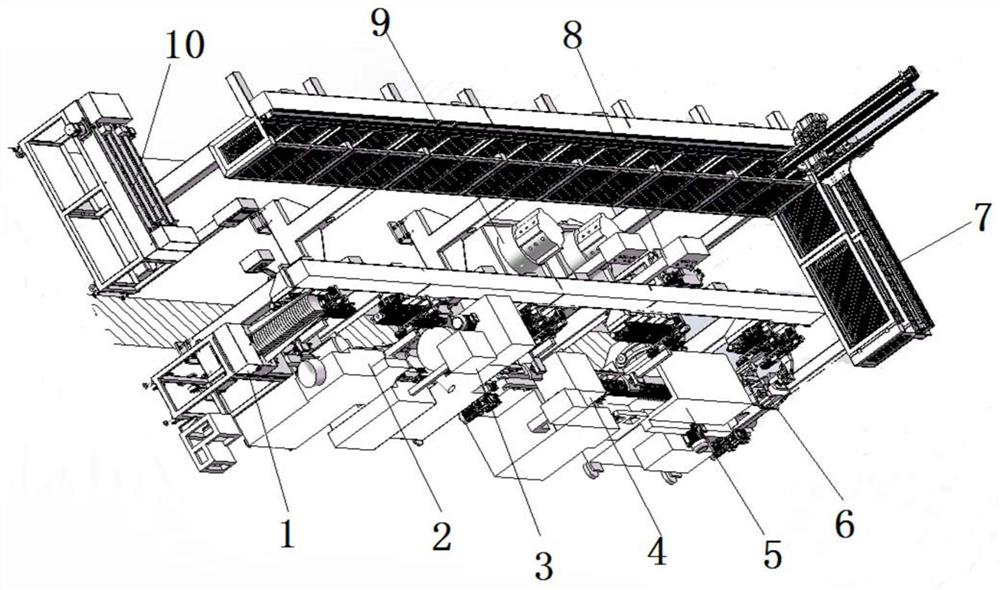

An automatic processing line for drum brake pads

ActiveCN112157549BReduce labor intensityReduce labor costsOther manufacturing equipments/toolsGrinding machinesProcess engineeringTransfer mechanism

The invention discloses a drum-type brake pad automatic processing production line. The production line is U-shaped as a whole, adopts a truss structure, and enters from one side of the U-shaped mouth. Arc grinding area, end face grinding area, chamfering mill loading area, chamfering mill unloading device, transfer mechanism, drilling transfer machine, drilling area and automatic receiving device, the automatic feeding area and automatic receiving device They are all set at the entrances at both ends of the U-shaped structure, and the transfer truss is set at the turning point at the tail of the U-shaped structure; when in use, there is flow-through construction between the various devices, and workers do not need to follow them in real time to monitor and operate, and only need regular inspections. Yes, the labor intensity of workers is reduced, and the labor cost of the enterprise is saved at the same time; this assembly line uses fully automatic assembly line construction, with a high level of automation, and the whole process uses parametric control, high production capacity, convenient for large-scale production, and can achieve standardization Operation, high quality products.

Owner:DONGGUAN POLYTECHNIC

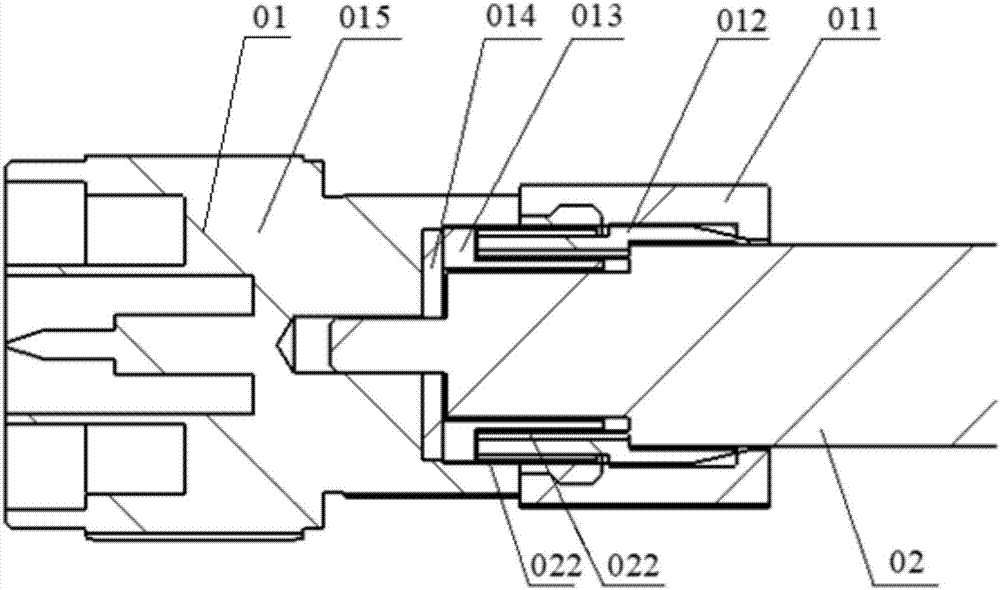

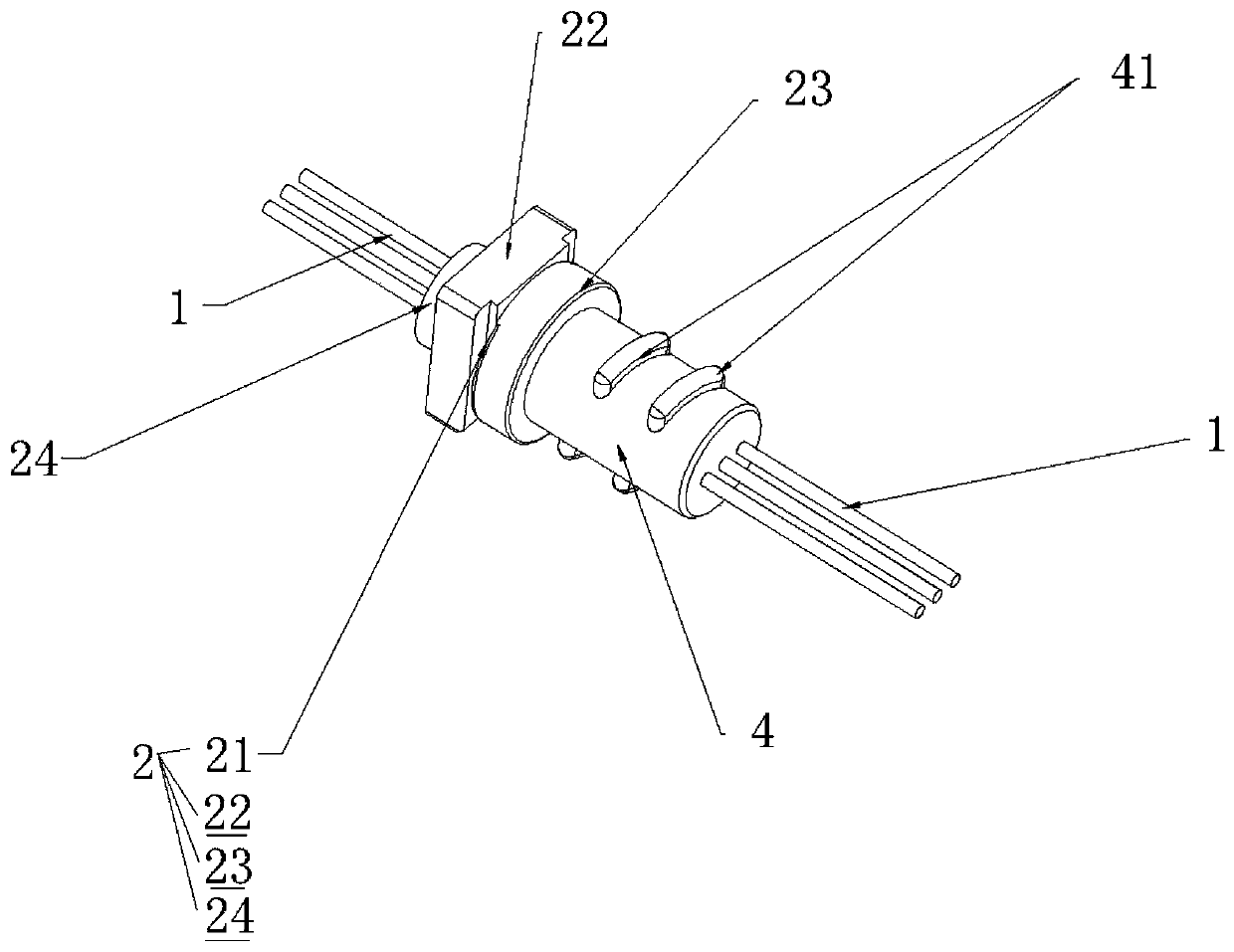

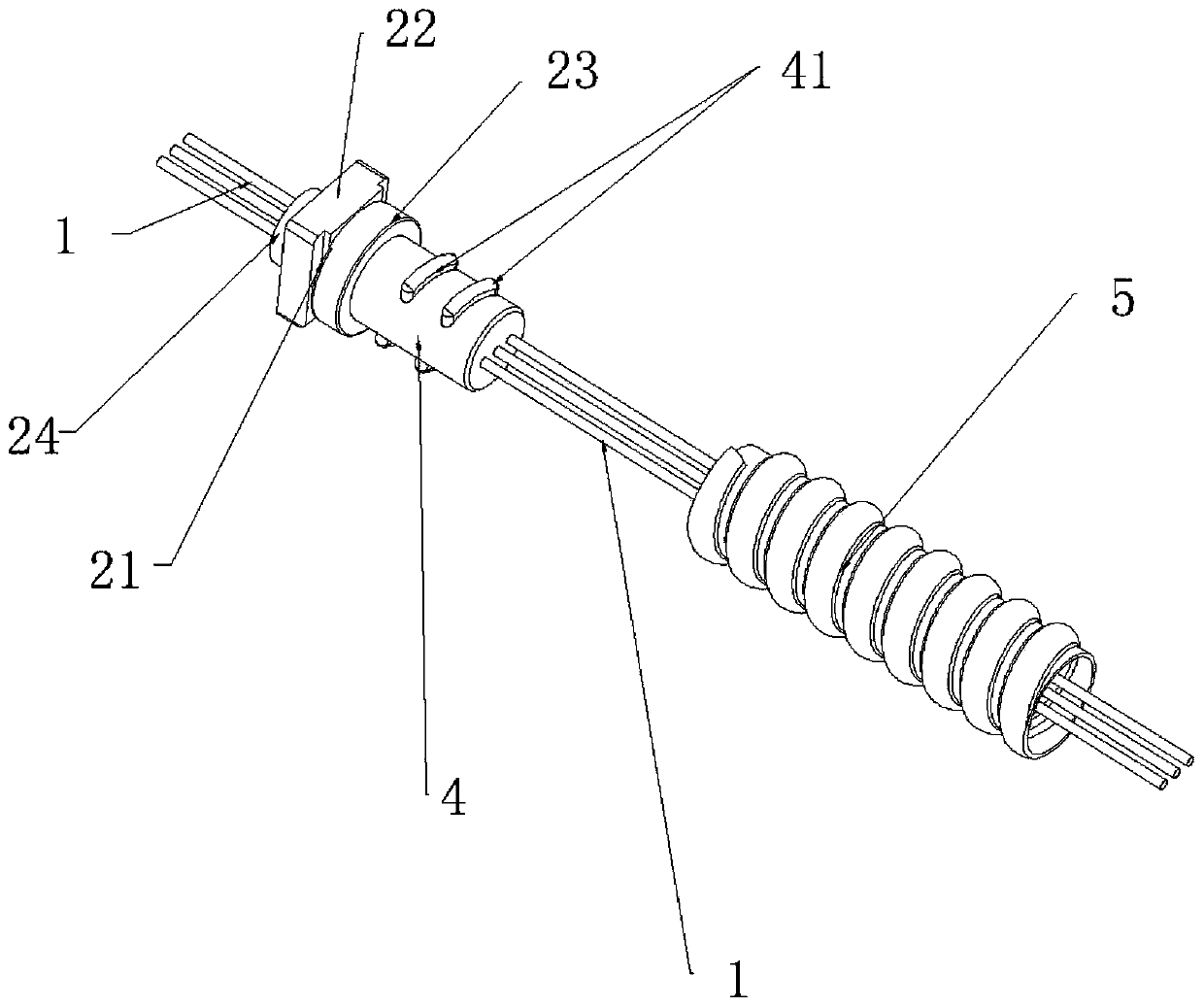

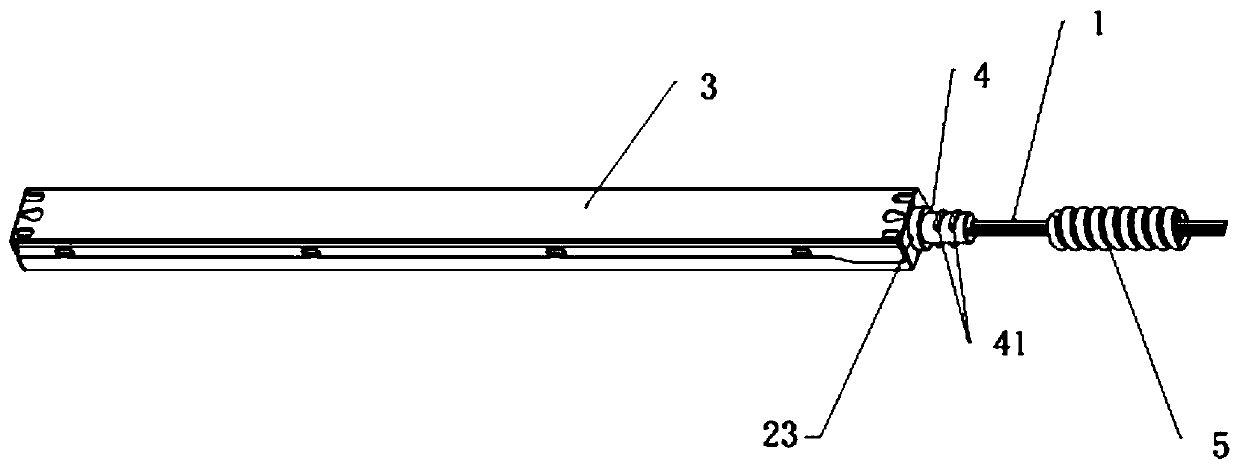

Connector with wire and emergency power supply box with same

PendingCN110391637AAchieve electrical connectionMeet wiring requirementsCable junctionsElectricityEmergency situations

The invention discloses a connector with a wire and an emergency power supply box with the same. The connector is arranged on the outlet end of the emergency power supply box. The connector comprisesa conductive portion and a fixed portion. The fixed portion is fixed on the outlet end of the emergency power supply box. The fixed portion extends to one end away from the emergency power supply boxto form a connecting portion. The outer wall of the connecting portion is provided with a screwing portion screwed to a corrugated hose. One end of the conductive portion runs through the fixed portion and extends out of the fixed portion to be electrically connected with the control board of the emergency power supply box. The other end of the conductive portion extends out of the connecting portion to be connected with an electrical appliance. The portion, which extends out of the connecting portion, of the conductive portion is covered by soft rubber. According to the emergency power supplybox provided by the invention, due to the outer soft rubber of the wire and the screwing portion of the connecting portion, the emergency power supply box can meet the wiring requirement of China, and can be screwed to the corrugated hose to meet the wiring requirement of the United States; and the risk of job production is avoided.

Owner:SHENZHEN BILLDA TECH CO LTD

Punching and cutoff mold for left support and right support of automobile

InactiveCN111085611AAchieve punchingReduce in quantityShaping toolsVehicle componentsIndustrial engineeringJob production

The invention discloses a punching and cutoff mold for a left support and a right support of an automobile. The punching and cutoff mold comprises a supporting mechanism, a lower mold mechanism, an upper mold mechanism, guide sleeves and guide columns. According to the punching and cutoff mold, through the arrangement of the upper mold mechanism and the lower mold mechanism, a left support blank and a right support blank are placed between the upper mold mechanism and the lower mold mechanism, and punching, cutoff and edge cutting work of the left support blank and the right support blank canbe achieved at the same time; the mold is adopted for doing machining work of the left support and the right support, few production procedures are needed, the number of adopted molds is small, production and management of the left support and the right support of an automobile front cross beam are convenient, the labor intensity of workers is reduced, the production period is shortened, and wideapplication and popularization value is achieved in the industry; through the arrangement of the supporting mechanism, a lower mold seat achieves a supporting function on the lower mold mechanism, itis guaranteed that the lower mold mechanism is placed stably, and lifting of the lower mold mechanism can be achieved conveniently through lifting lugs; and the machining efficiency of the left support and the right support is improved, the production input is small, production cost is low, and large-scale production of the left support and the right support of the automobile front cross beam is facilitated.

Owner:湖南忠元红快速充电有限公司

Prefabricated reinforced concrete assembled column and its manufacturing method

InactiveCN102352668BReduce in quantityReduce labor costsStrutsCeramic shaping apparatusReinforced concreteArchitectural engineering

Belonging to the technical field of structural engineering in the civil engineering industry, the invention discloses a prefabricated reinforced concrete assembled column and its manufacturing method. The prefabricated reinforced concrete assembled column comprises over two prefabricated reinforced concrete assembled blocks which are provided with vertical through holes and are in columnar stacking. And the prefabricated reinforced concrete assembled blocks are integrated through vertical stressed steel bars passing through the vertical through holes. Meanwhile, the gaps between the vertical stressed steel bars and the vertical through holes are pressure perfused slurry layers. Installation of the vertical stressed steel bars is carried out on site. Therefore, the method of the invention can realize prefabricated reinforced concrete assembled block production through mechanized flow production in prefabrication factories. Due to the employment of on-site mechanical lifting, very few people are needed for cooperation so as to produce assembled columns safely, so that the labor cost is effectively reduced and the production efficiency is improved.

Owner:SOUTHEAST UNIV

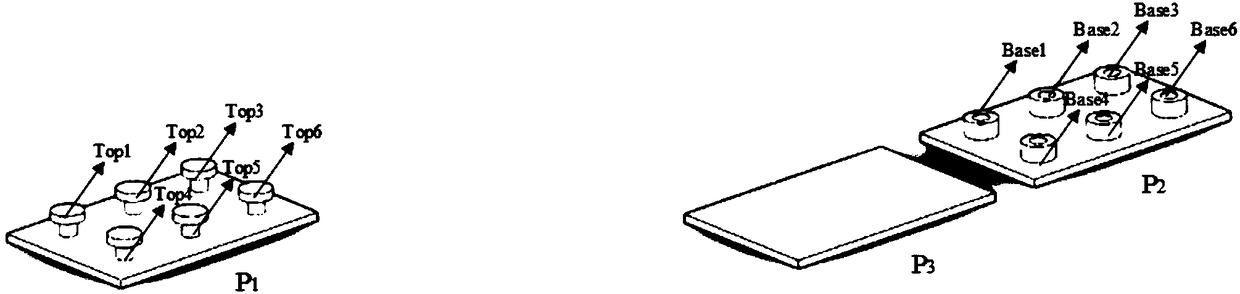

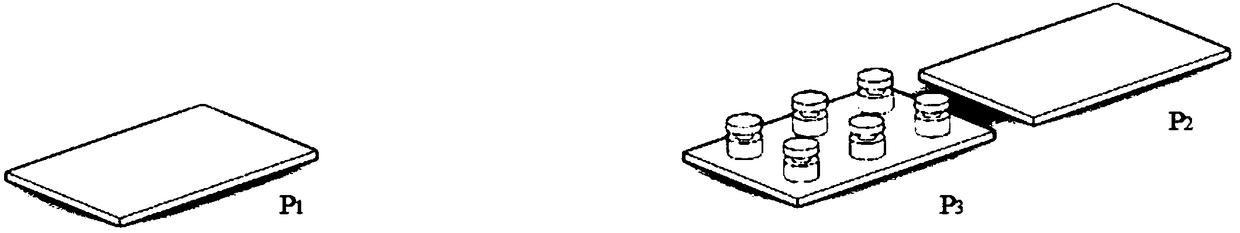

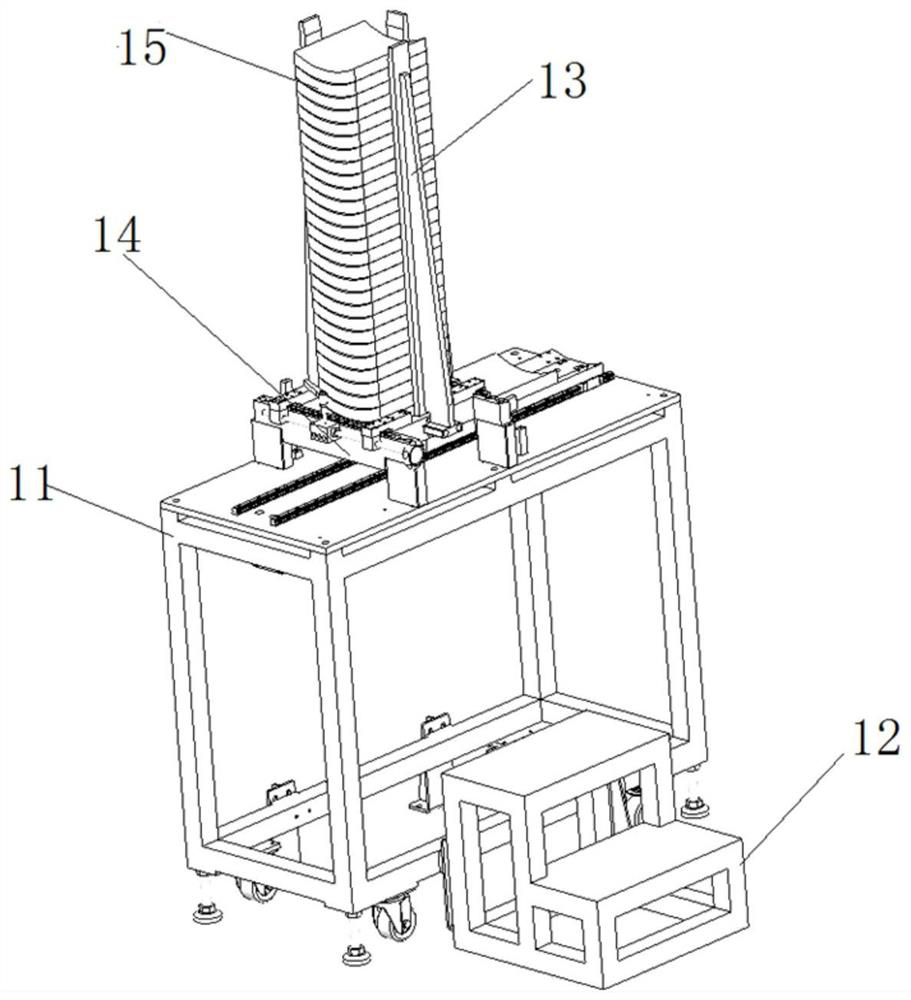

Automatic production line for unsaturated resin button blanks

PendingCN111070517AFully automatedRealize mechanized productionDomestic articlesWorking environmentManufacturing line

The invention discloses an automatic production line for unsaturated resin button blanks. The automatic production line for the unsaturated resin button blanks comprises a machine frame, a mold pipe bent frame, a bar conveying belt and a conveying mechanism, wherein the machine frame is integrally in a concentric-square shape, and a washing station, a rinsing station, a drying station, a wax dipping station, a first cooling station, a second cooling station and a waiting station are sequentially arranged on the rear of the machine frame; and the front of the machine frame is sequentially provided with a filling station and a finished product discharging station, and after passing through the finished product discharging station, the mold pipe bent frame returns to the washing station through the conveying mechanism. By means of the technical scheme, manual operation can be completely avoided, the production line can carry out mold pipe cleaning, mold pipe control drying, mold pipe waxing, mold pipe bottom sealing filling, cooling demolding and bar slicing, so that full-automatic and mechanized production is achieved, operation of seven persons or more is changed into operation production of two persons at present, the yield is changed from one ton per shift to five tons per shift, the working environment is changed, and productivity is greatly improved.

Owner:永嘉东庆服装辅料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com