An automatic processing line for drum brake pads

A technology of automatic processing and brake pads, which is applied in the direction of metal processing equipment, manufacturing tools, grinding feed movement, etc., can solve the problems of unfavorable large-scale production, inability to standardize production and standardized operations, and difficulty in improving product quality. Large-scale production, the realization of standardized operations, and the effect of high-quality products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

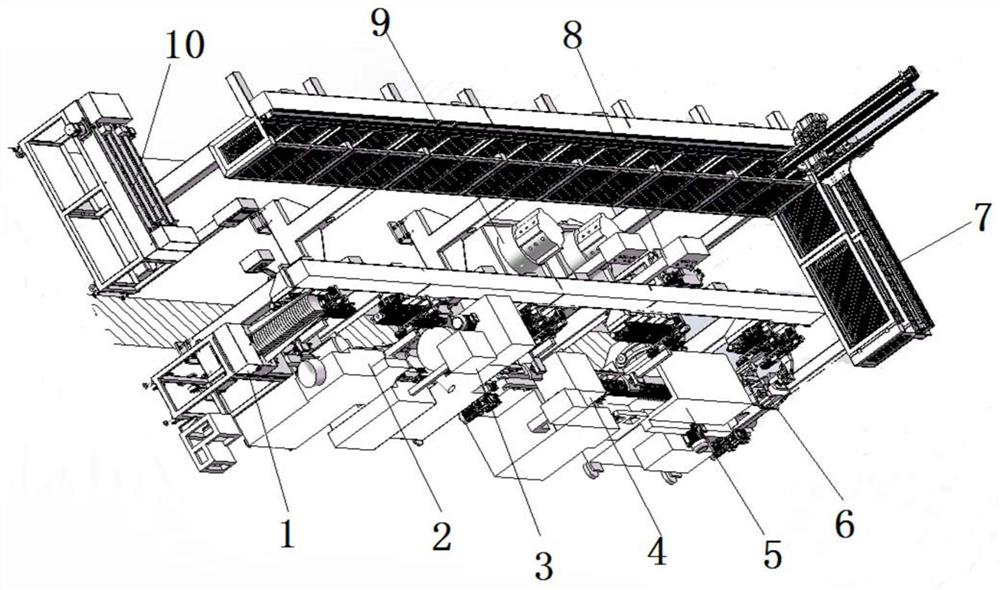

[0053] Refer to attached Figure 1-30 A drum-type brake pad automatic processing production line is shown. The production line is U-shaped as a whole, installed with a truss structure, and enters from one side of the U-shaped mouth. Grinding area 2, inner arc grinding area 3, end face grinding area 4, chamfering grinding loading area 5, chamfering grinding unloading device 6, transfer truss 7, drilling transfer area 8, drilling area 9 and automatic receiving device 10. Both the automatic feeding area 1 and the automatic receiving device 10 are set at the entrances at both ends of the U-shaped structure, and the transfer truss 7 is set at the turning point at the tail of the U-shaped structure.

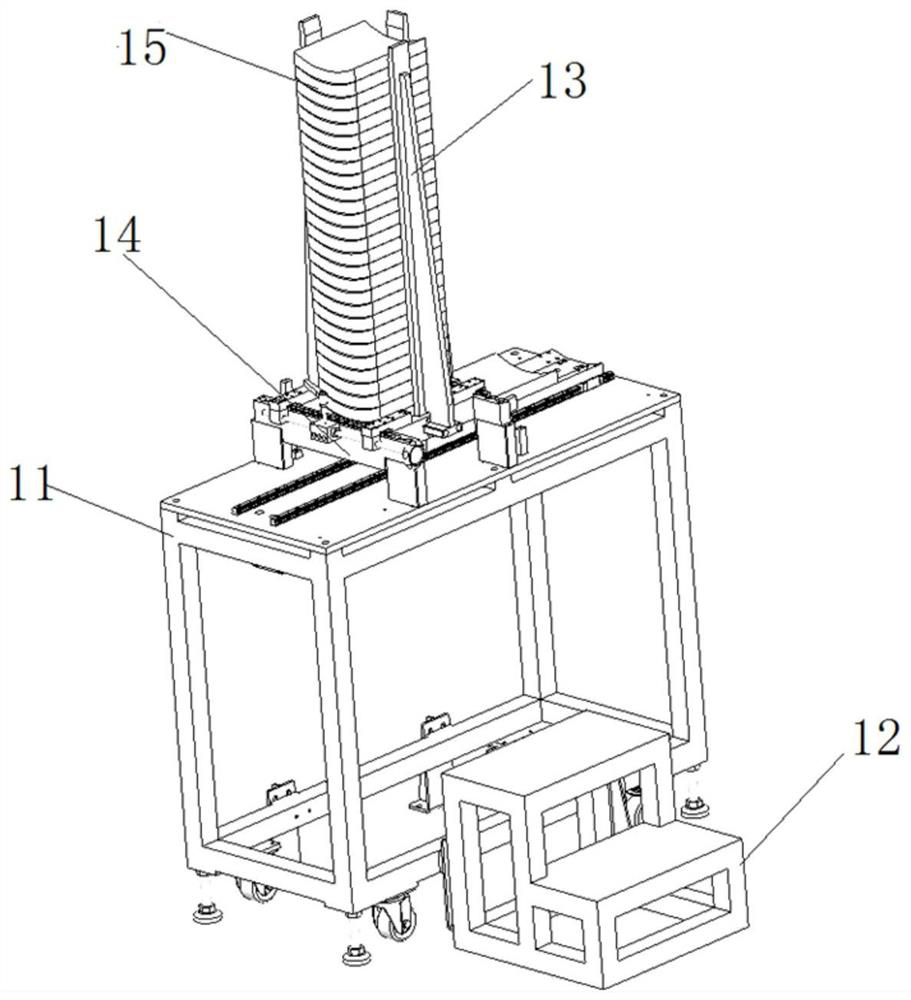

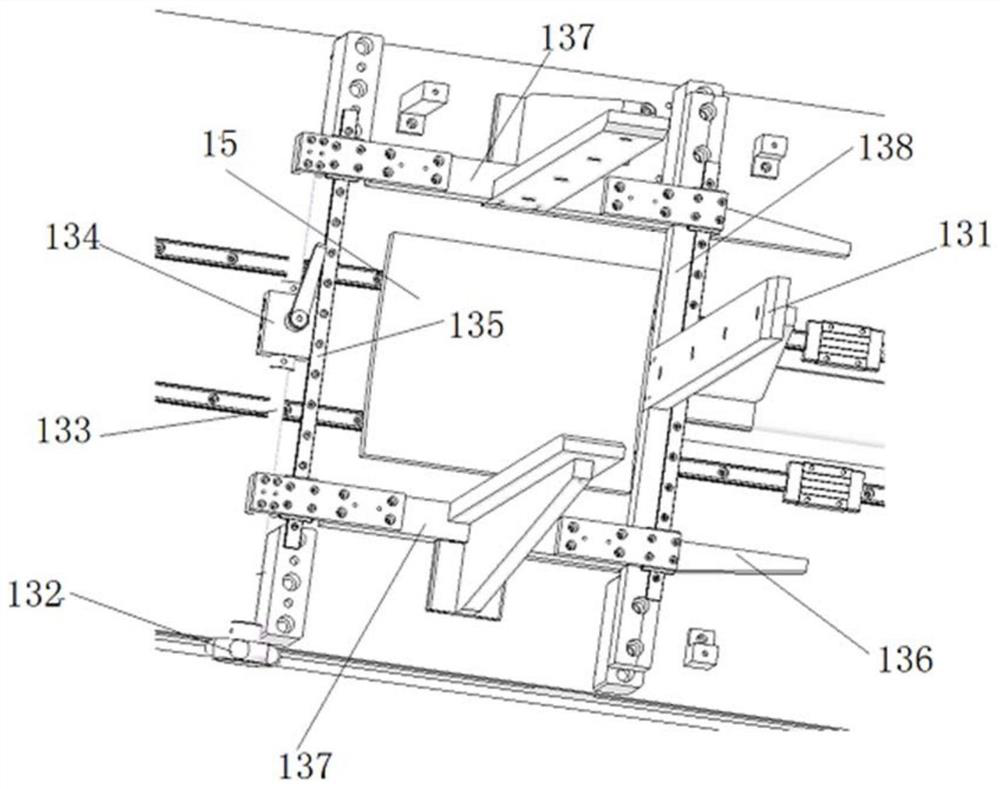

[0054] Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com