Prefabricated reinforced concrete assembled column and its manufacturing method

A reinforced concrete, prefabricated assembly technology, applied in the direction of columns, pier columns, pillars, etc., can solve problems such as increased labor costs, and achieve the effect of reducing noise and environmental pollution, the number of personnel and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

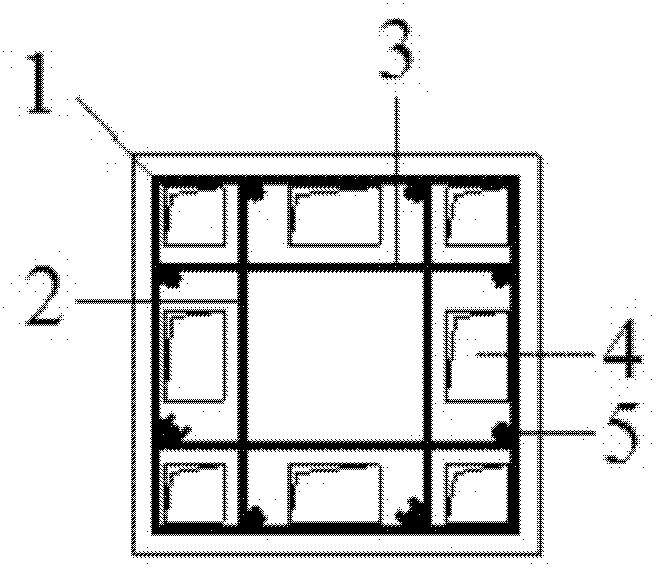

[0025] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

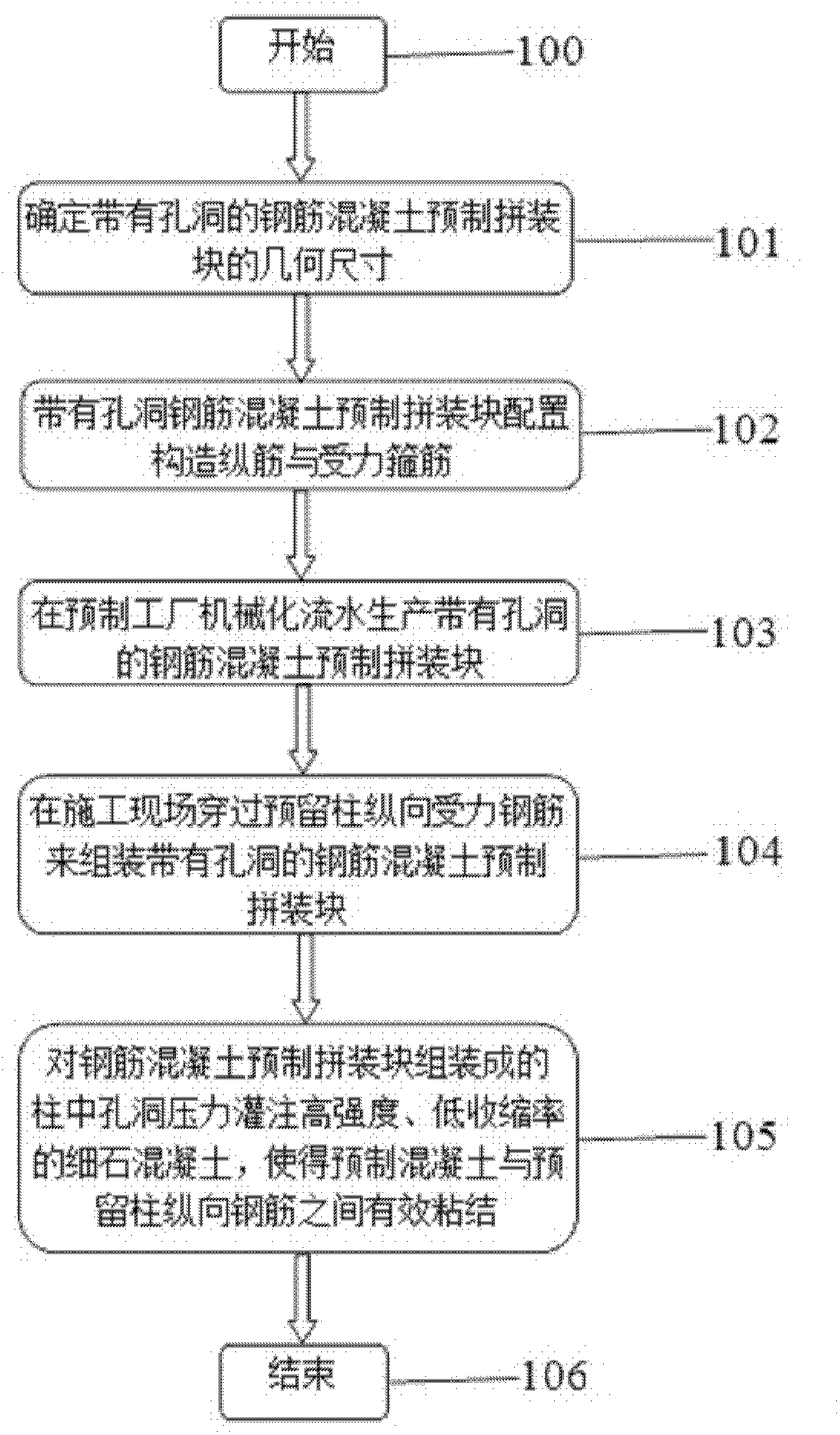

[0026] Such as figure 1 As shown, the manufacturing method of the reinforced concrete prefabricated assembled column of the present invention includes the following steps: 101. Determine the geometric size of the reinforced concrete prefabricated assembled block, and the transverse section size needs to be determined according to the design calculation; the vertical length is in order to meet the requirements of the prefabricated factory For mechanized flow production, an integer of 300mm is usually used, such as 600mm, 900mm, and 1200mm; 102. Configure longitudinal structural steel bars, transverse stress stirrups and longitudinal through holes of reinforced concrete prefabricated assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com