Radio frequency coaxial cable assembly assembling automatic production system

A radio frequency coaxial cable, automatic production technology, applied in electrical components, circuit/collector parts, circuits, etc., can solve the problems of difficult to control the overall quality of assembled products, poor product quality consistency, long cycle time, etc. Guaranteed traceability, guaranteed uniformity and overall quality, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

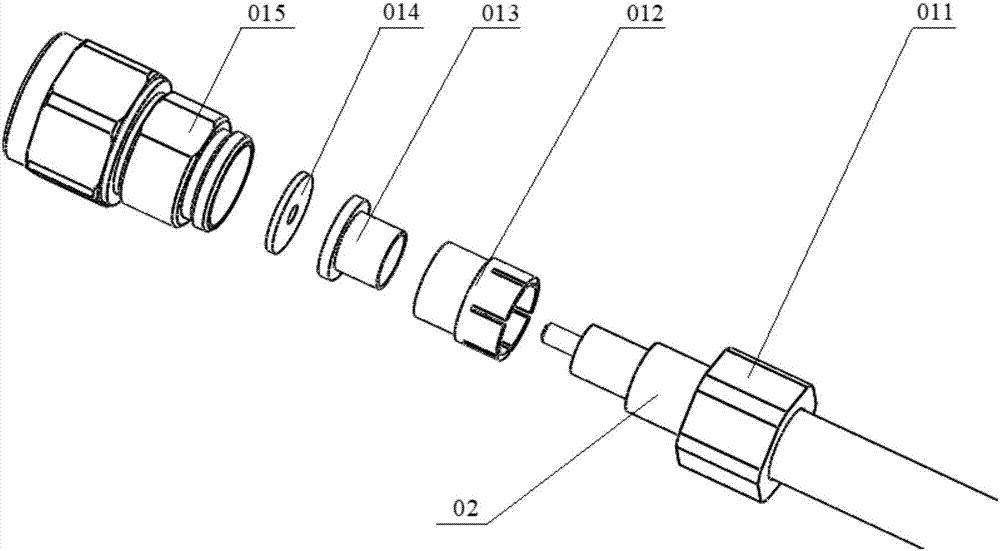

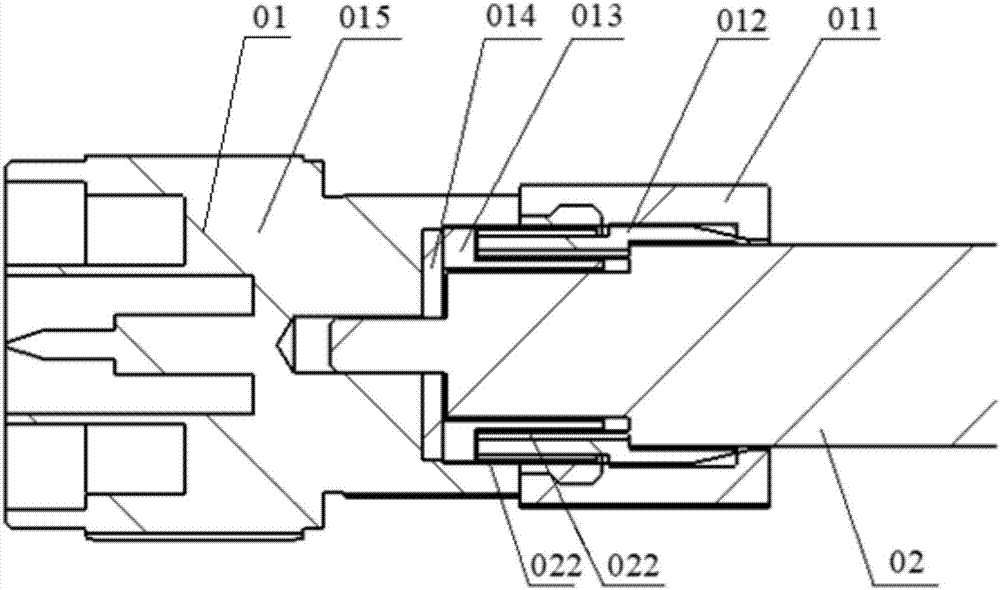

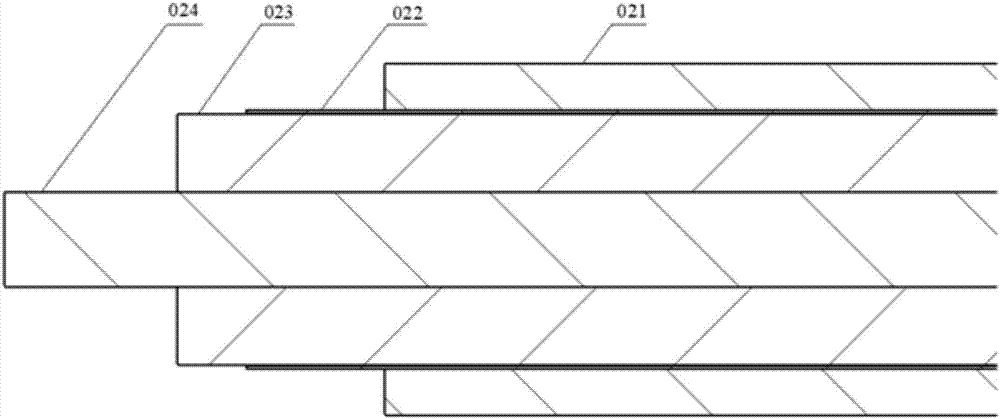

[0042] Figure 1~3 It is a schematic diagram of the structure of the RF coaxial cable assembly. Whether it is manual assembly in the prior art or the automatic production system of the present invention, the qualified products obtained after assembly have the same structure.

[0043] Fig. 4 is a schematic structural diagram of an automatic production system for assembling radio frequency coaxial cable assemblies. Figure 4a The leftmost end of the center is the upper carrier lifter. After the carrier rises, the RF coaxial cable 02 is manually fixed on the carrier. The carrier passes the assembly machines to the right along the assembly line. The carrier flows back to the upper carrier elevator from the lower carrier elevator at the far right and the carrier return line from right to left for the assembly of the next RF coaxial cable assembly.

[0044] From Figure 4b It can be seen that each device of the radio frequency coaxial cable assembly automatic production system co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com