Flat cut type plate-casting machine

A plate casting machine and flat cutting technology, which is applied in the field of lead alloy grid, can solve the problems of deformation of lead alloy grid size, difficulty in replacing valve core, quantitative lead supply of lead leakage, etc., so as to achieve reasonable structure and reduce production The effect of strength and operating cost, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

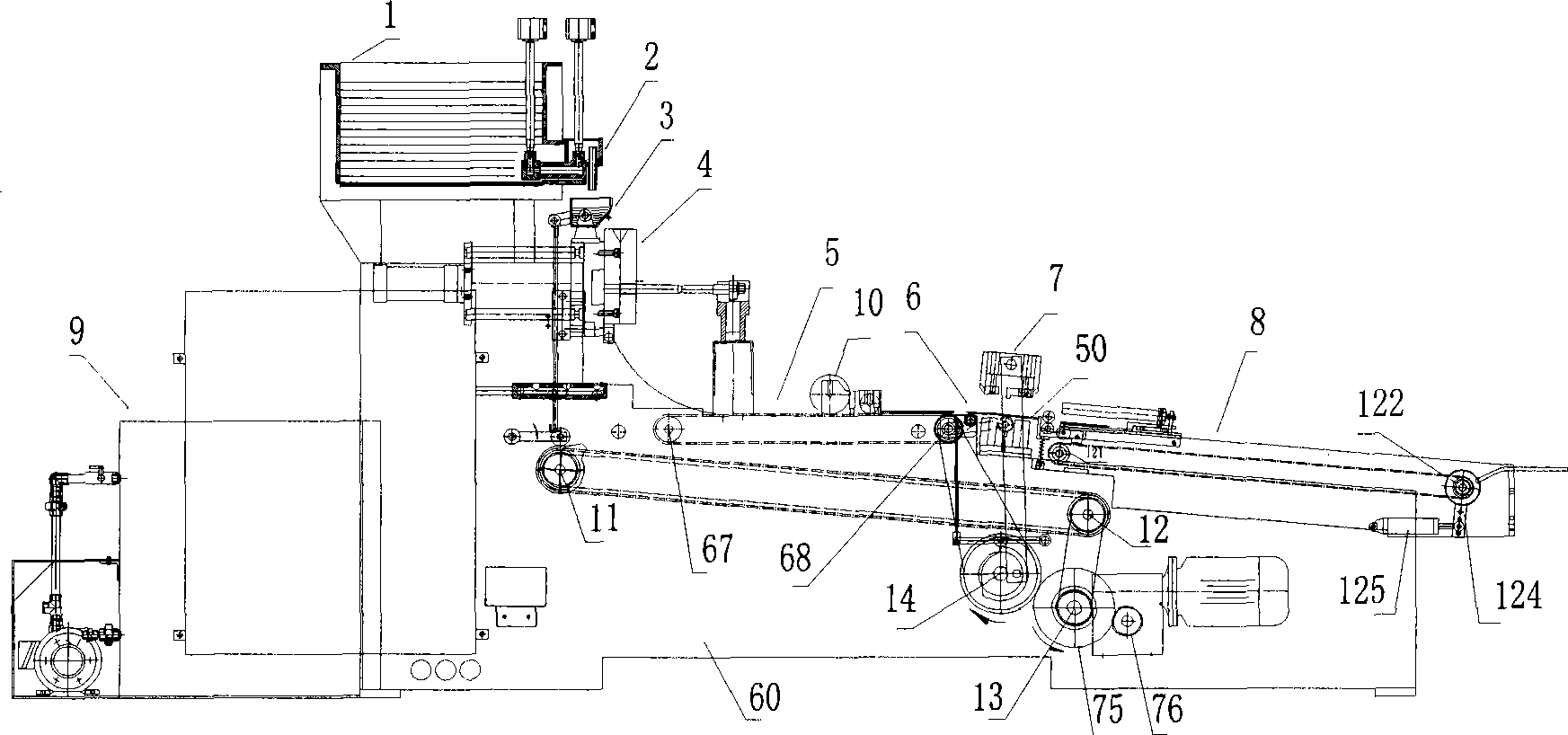

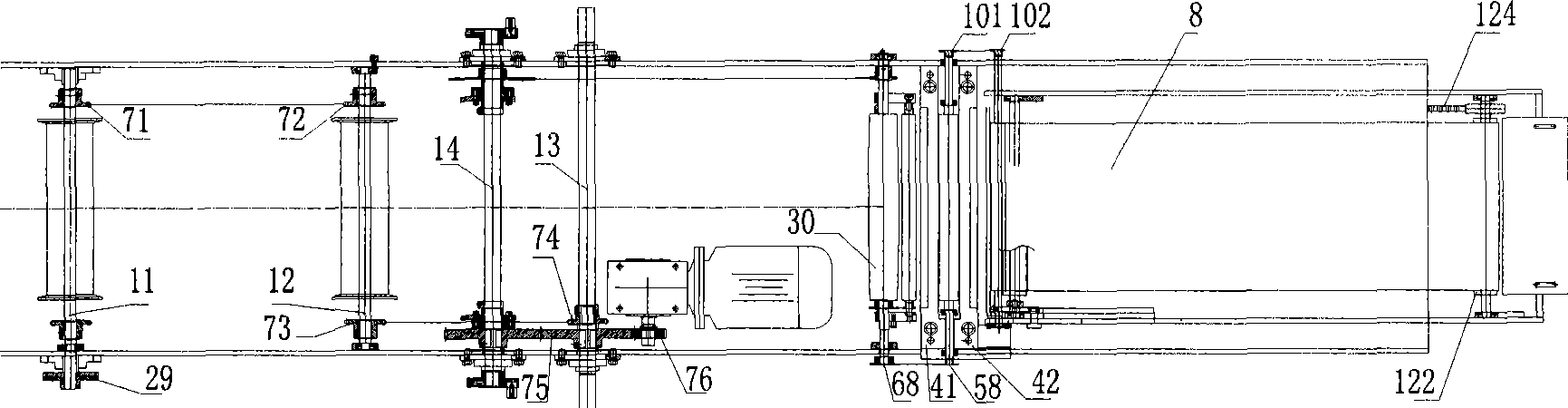

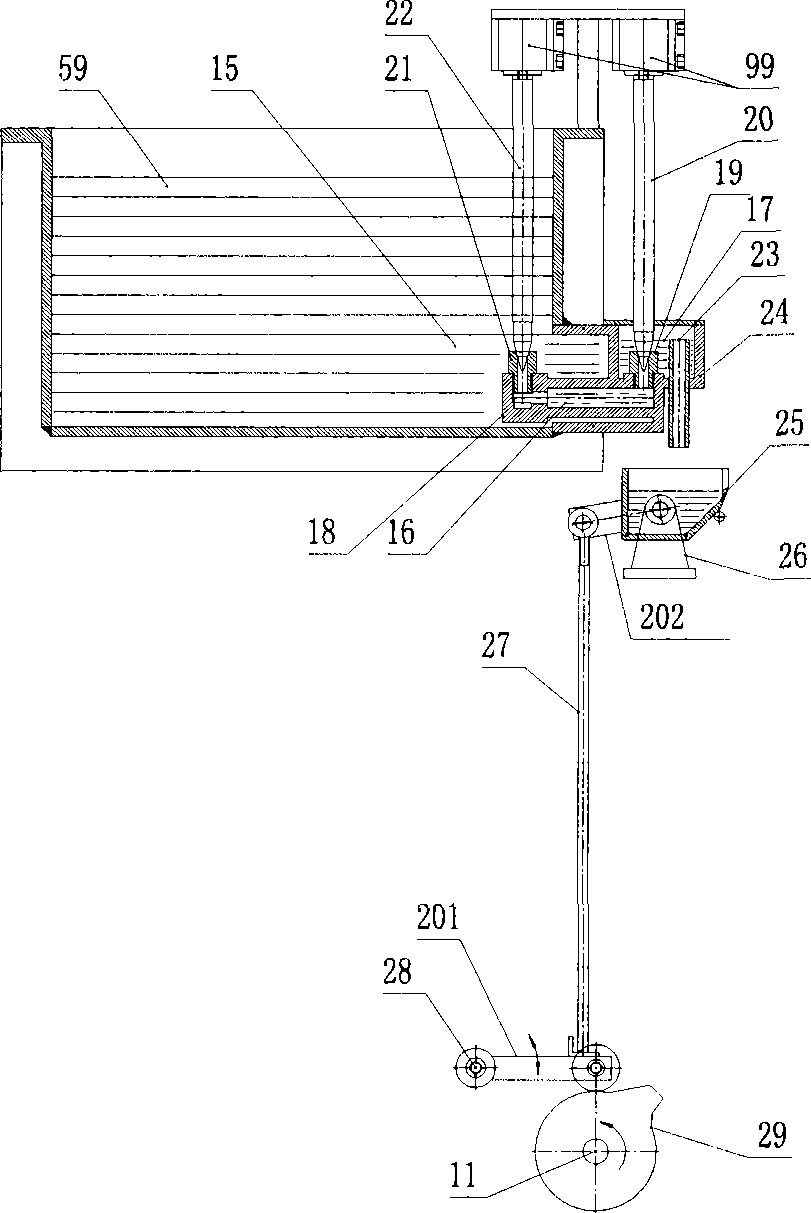

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] Figure 1A It is a schematic diagram of the overall structure of the flat-cut casting machine according to the present invention, including a high-level lead melting furnace 1 provided with a series lead valve device 2, and a lead spoon pouring mechanism 3 is arranged sequentially below the series lead valve device 2 And the mold opening and closing mechanism 4, the left side of the mold opening and closing mechanism 4 is provided with a circulating water tank 9, and the right side is successively provided with a shaping conveying mechanism 5, a grid horizontal positioning mechanism 6, a flat cutting knife mold 7 and a grid Film receiving mechanism 8; Wherein, three parts of serial lead valve device, plate grid horizontal positioning mechanism and flat cut-off type cutter mold are the key parts that the present invention overcomes the defect of prior ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com