Miniature strip cutting device and flow process method

A slitting and miniature technology, which is applied in the direction of deburring devices, fiber processing safety devices, fiber bundles into fiber slivers/yarns, etc., can solve the problems affecting delivery economy and corporate reputation, finished product return claims, low production efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

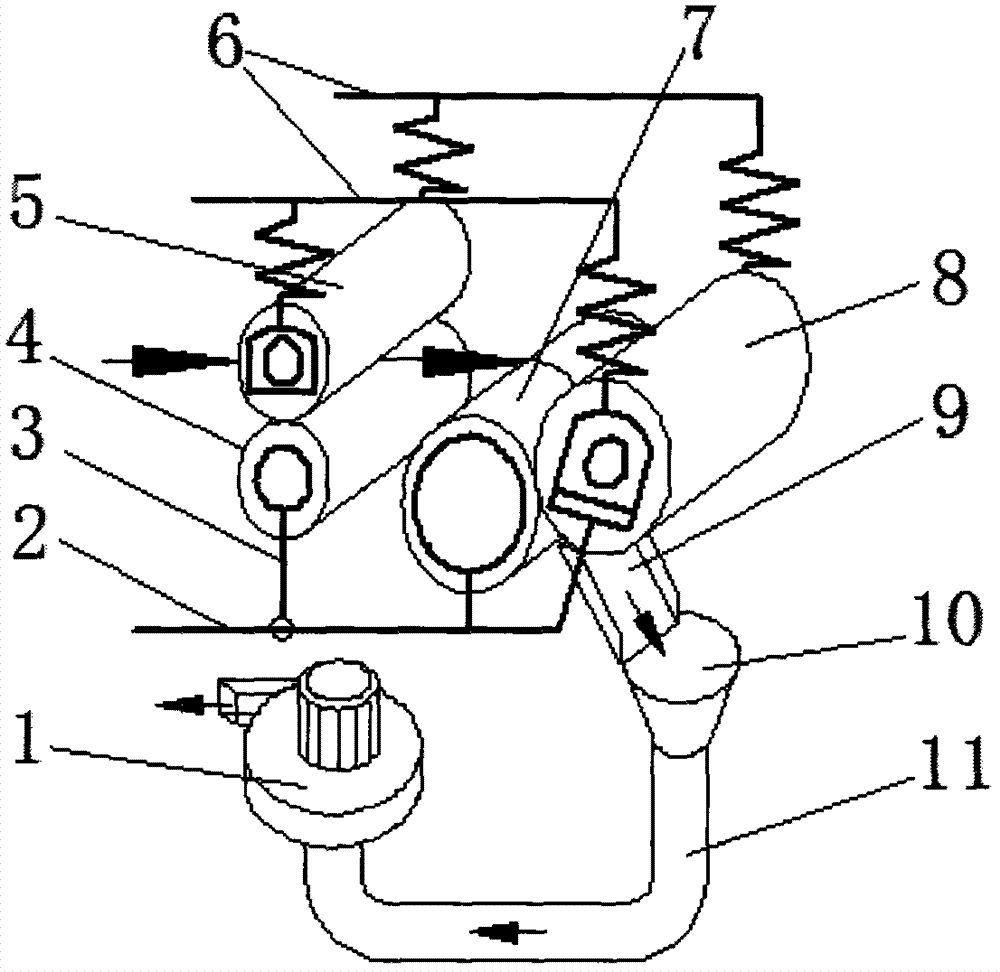

[0022] Figure 5 It is a colored cotton spinning mill that has installed a micro-sliver breaking device to form an excellent solidified fully mechanized pre-combing production flow chart. It can be seen from the flow chart: because the carding machine or combing machine is equipped with a micro-sliver breaking device , with the help of wind power and the connection of the fan cotton flow conveying device 13, the cleaning process 15, the carding machine 16, the combing machine 17, the annular cotton bin feeder 12, and the double-box baler 14 are easily integrated into an automatic contact production line , The labor intensity is greatly reduced, and the production efficiency is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com