Workpiece detection bench and workpiece detection transfer bench

A workpiece detection and mobile detection technology, applied in measuring devices, mechanical measuring devices, instruments, etc., to achieve the effect of simplifying the process flow, improving production efficiency and automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below.

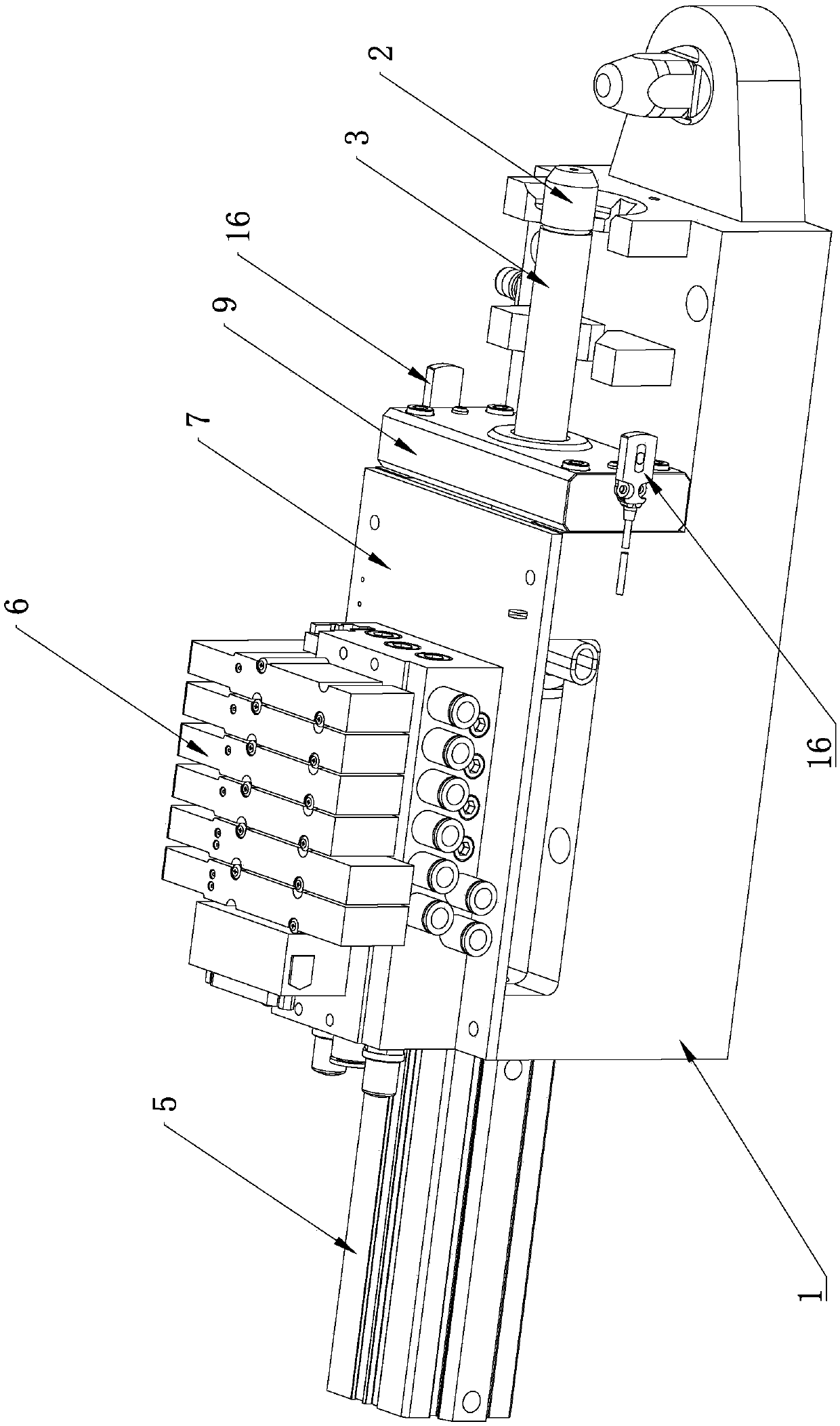

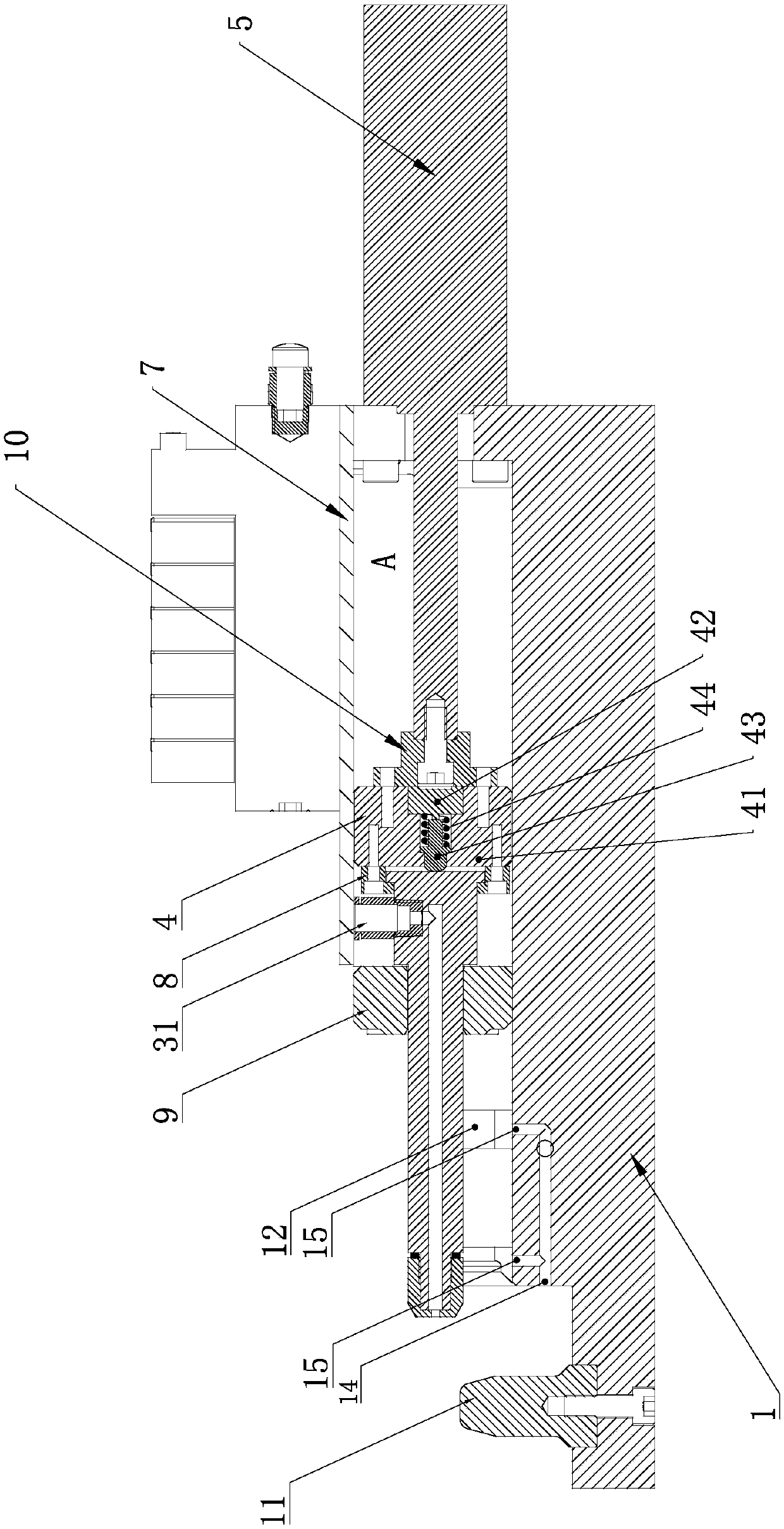

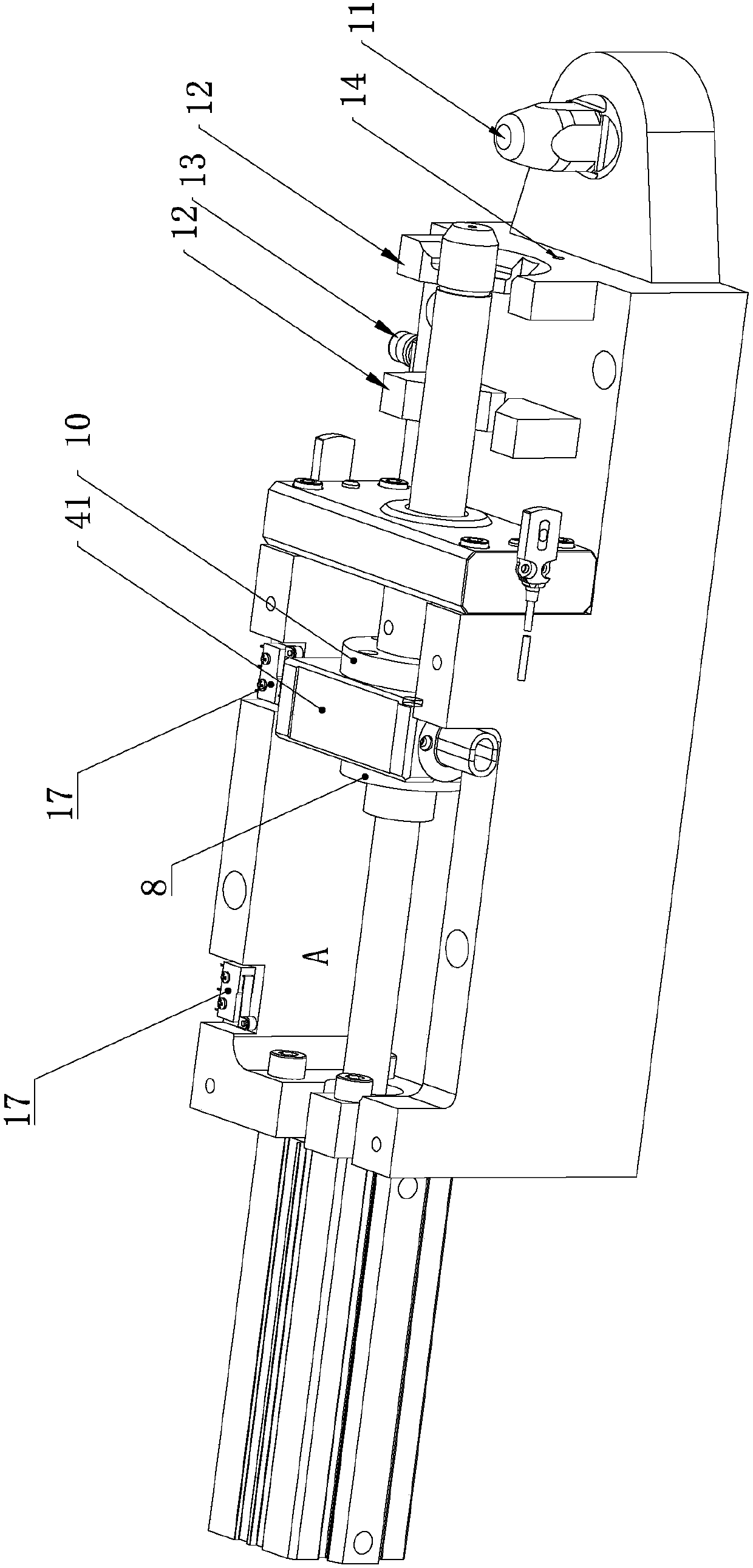

[0046] see Figures 1A to 1C , a workpiece detection platform of the present invention includes a base 1 and a positioning device installed on the base 1, a fixed guide plate 9, and a cylinder 5,

[0047] The electromagnetic valve 6 is installed above the base 1 through the support plate 7, the support plate 7, the fixed guide plate 9, and the base 1 jointly form a cavity A, and the force measuring mechanism 4 is arranged in the cavity A. One end of the mandrel 3 is placed in the fixed block 8 and the end can move a certain distance in the fixed block 8 , and the other end passes through the fixed guide plate 9 and is connected with the through gauge 2 . The two sides of the force measuring mechanism 4 are fixedly connected with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com