Patents

Literature

95results about How to "Large amount of material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

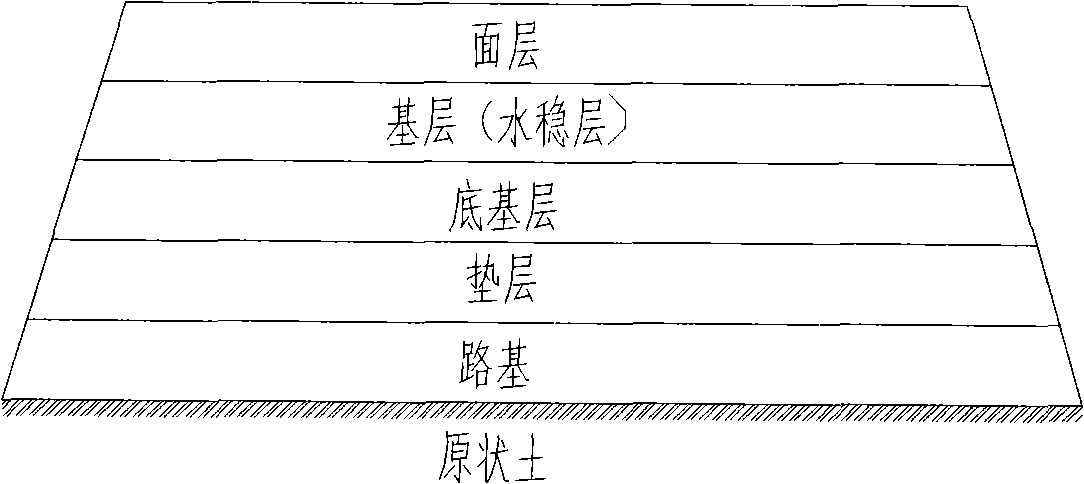

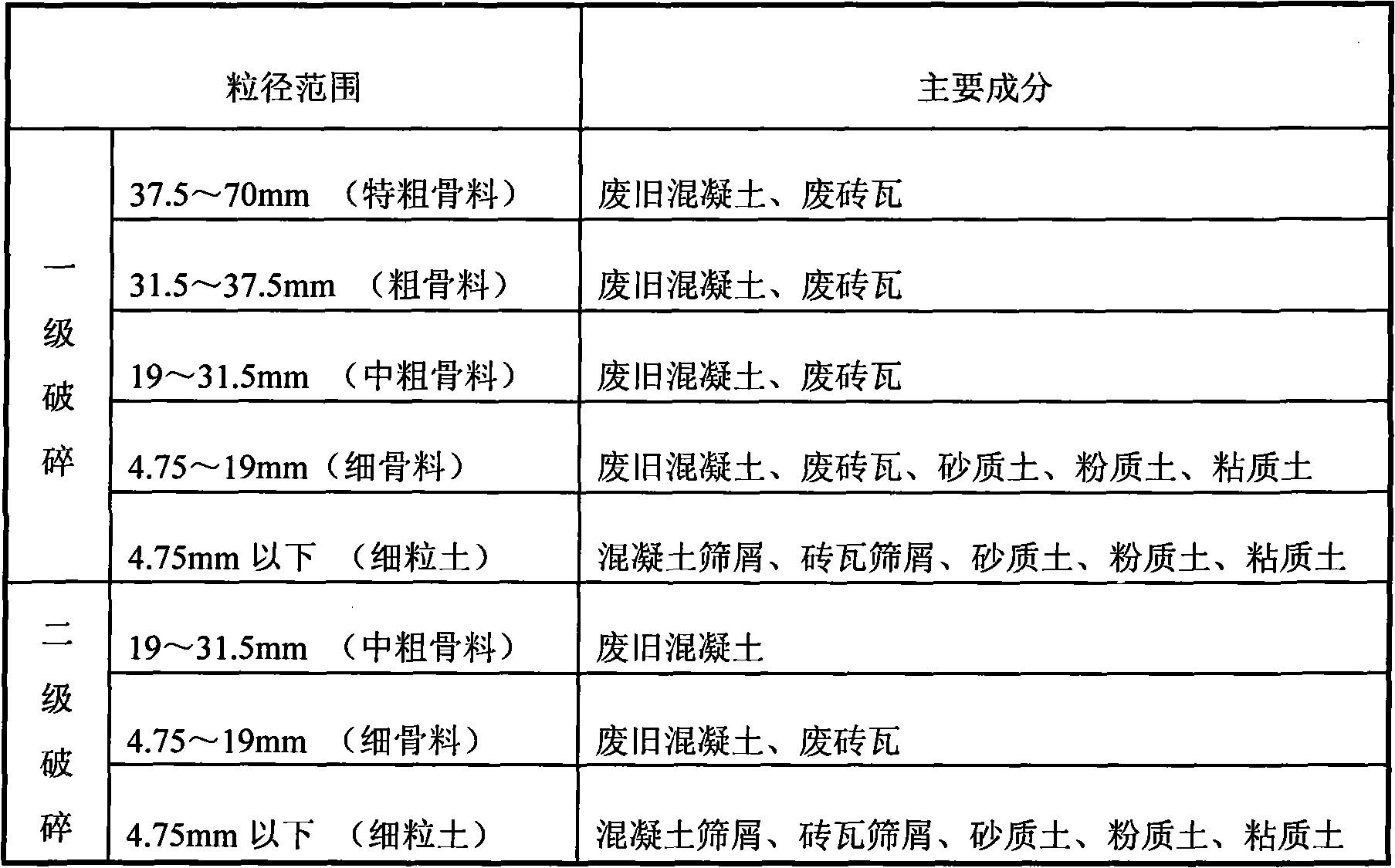

Method for preparing regenerative road material by using waste building material and construction method thereof

InactiveCN101255040ALarge amount of materialEasy to useSolid waste managementImpurityMaterials science

Owner:KUNMING UNIV OF SCI & TECH

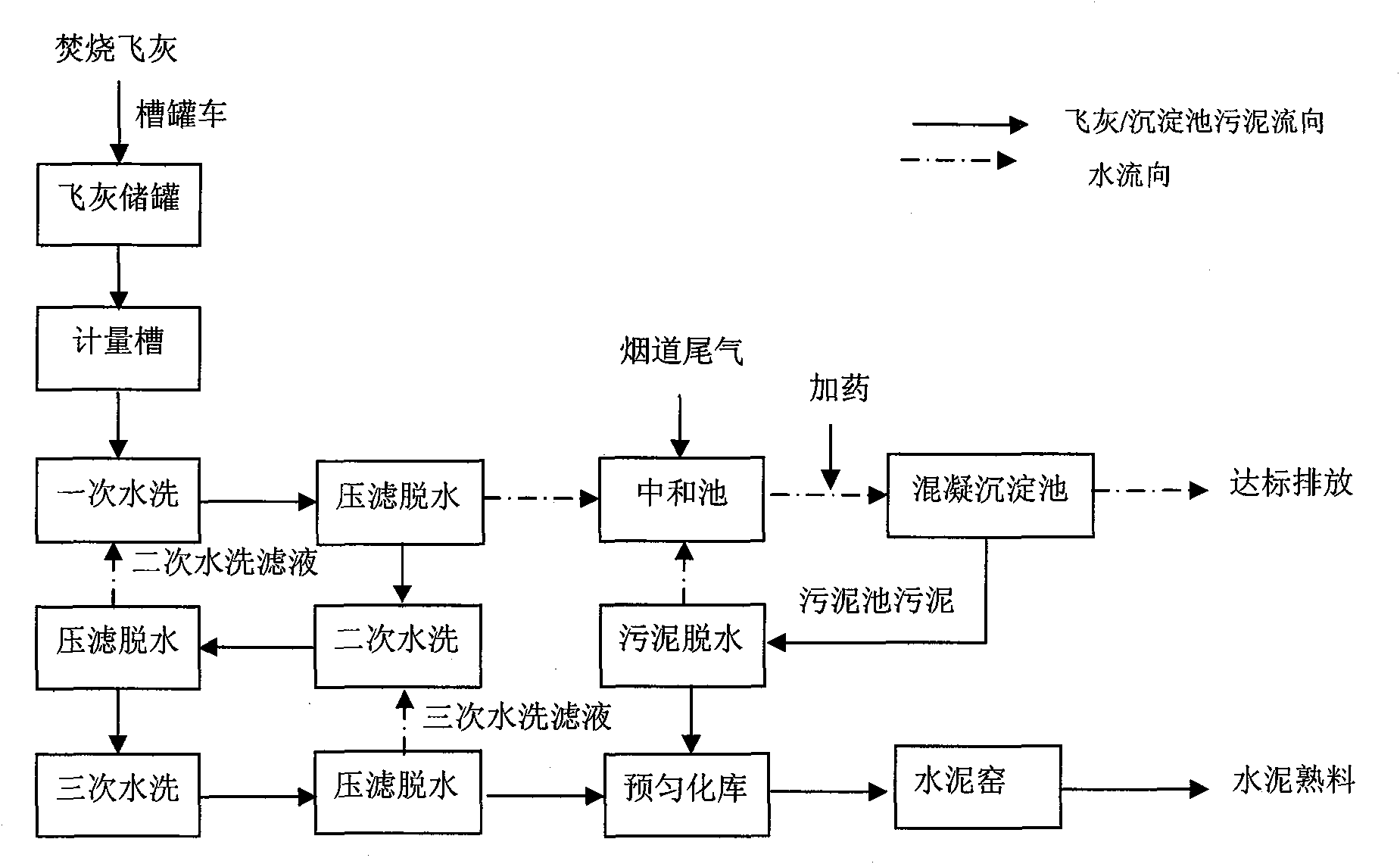

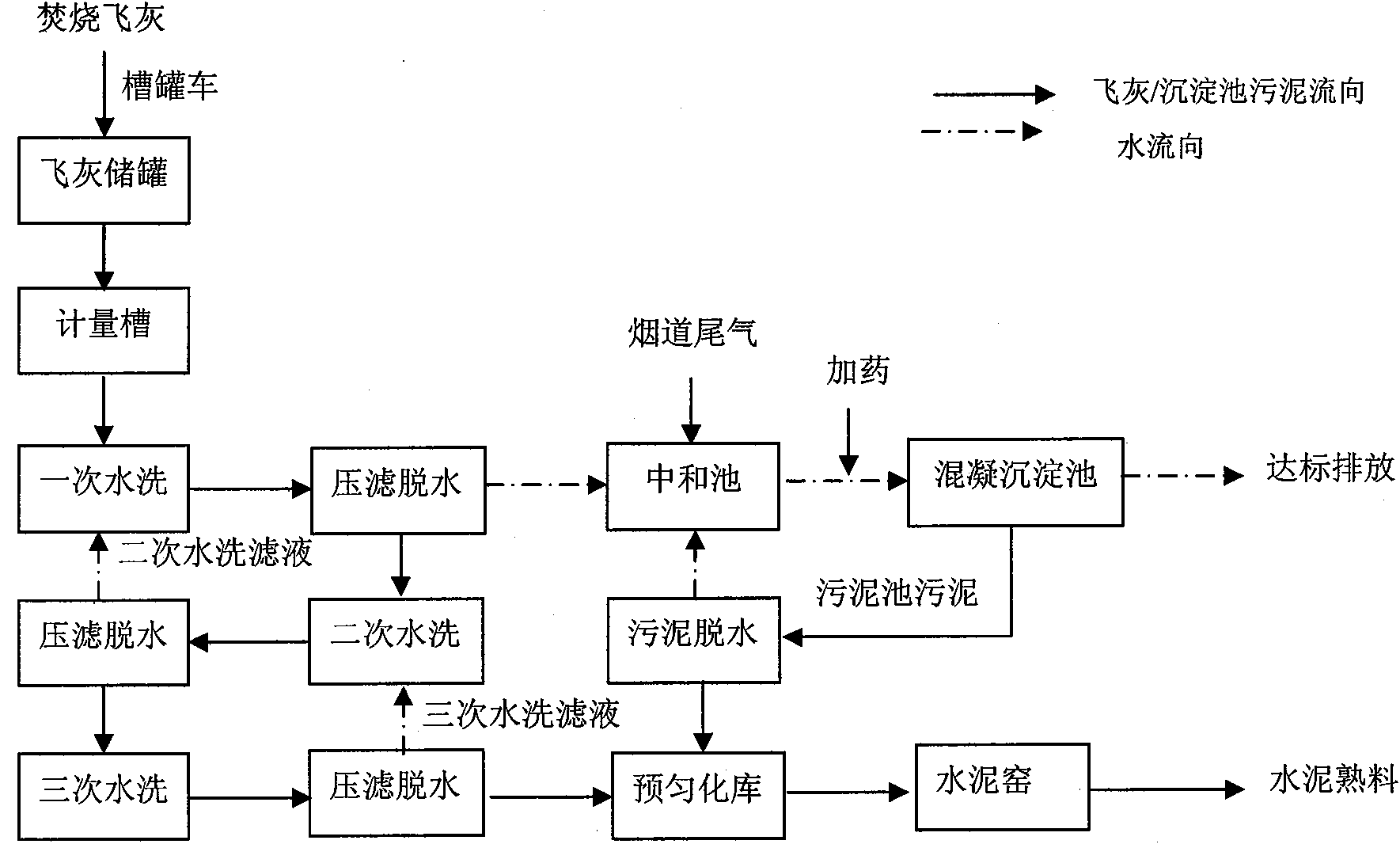

Incineration fly ash cement kiln synergic processing process

ActiveCN101913785AAvoid high energy consumptionReduce Chloride ContentCement productionIonHeavy metals

The invention provides an incineration fly ash cement kiln synergic processing process comprising the following steps of: a, carrying out washing treatment on incineration fly ash twice to three times; b, dewatering the incineration fly ash subjected to the washing treatment in a dewatering device to obtain a fly ash filter cake, wherein the water ratio of the fly ash filter cake is 25-30 percent, and the concentration of chloride ions is 0.3-0.6 percent; c, processing washing waste water generated in the step a through a carbonization-coagulating sedimentation process to obtain waste water processing precipitates; d, mixing the waste water processing precipitates and the fly ash filter cake with cement raw materials in proportion, wherein obtained materials are used as production raw materials of cement clinker; and e, calcining the production raw materials of the cement clinker under the condition of high temperature of 1100-1450 DEG C. The incineration fly ash cement kiln synergic processing process has little energy consumption and can be used for efficiently treating heavy metal, overcomes the defect that a non-ferrous metal extraction technology can not eliminate organic pollutants contained in the fly ash and realizes the thorough harmlessness of the fly ash.

Owner:杭州易辉环保科技有限公司

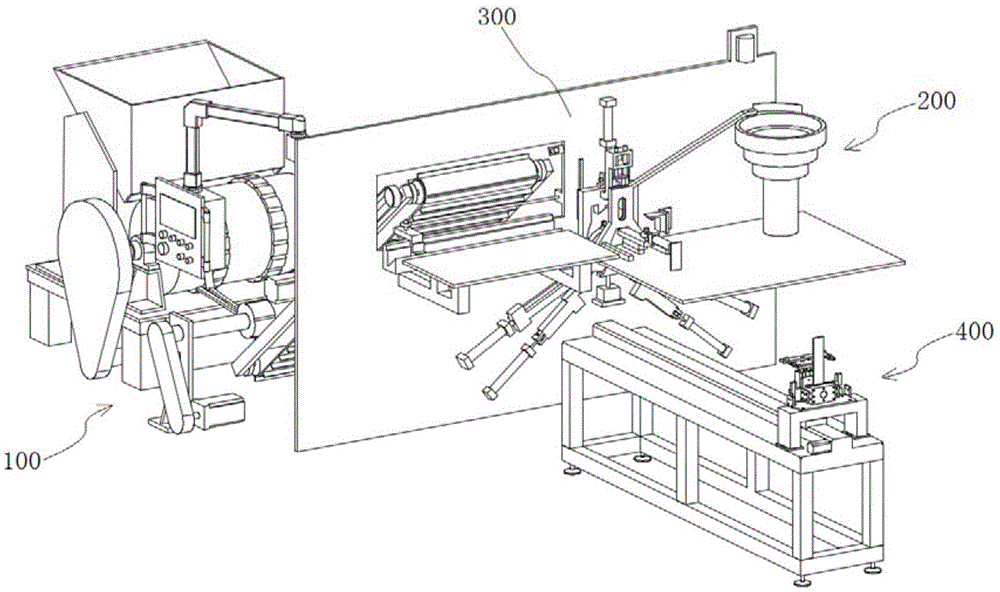

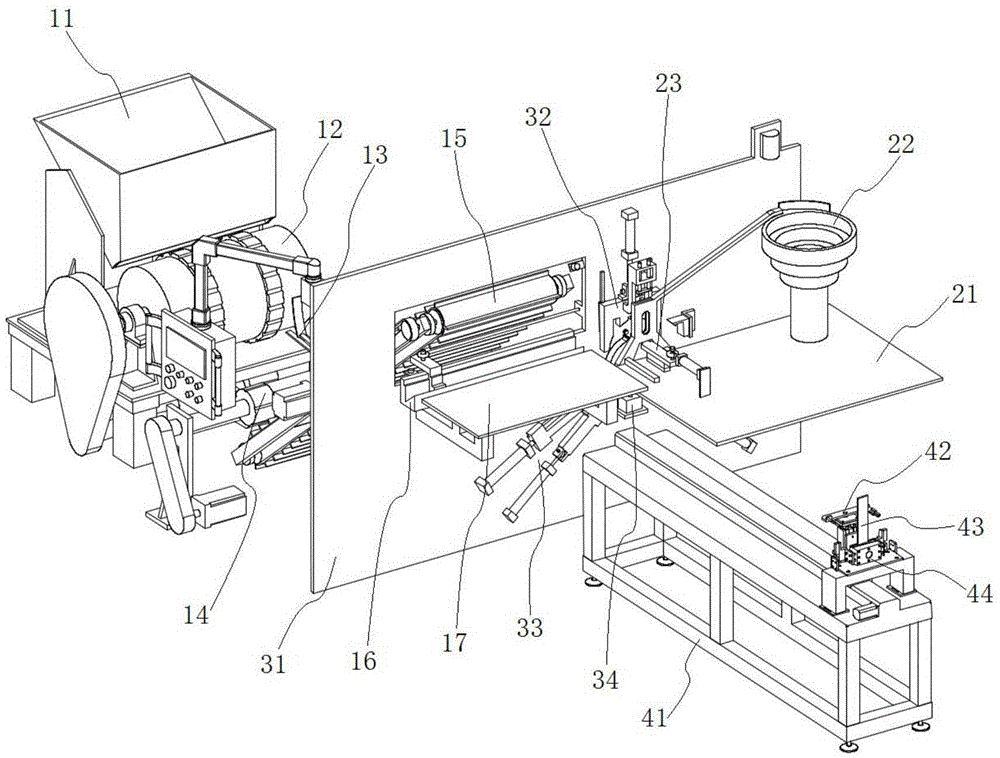

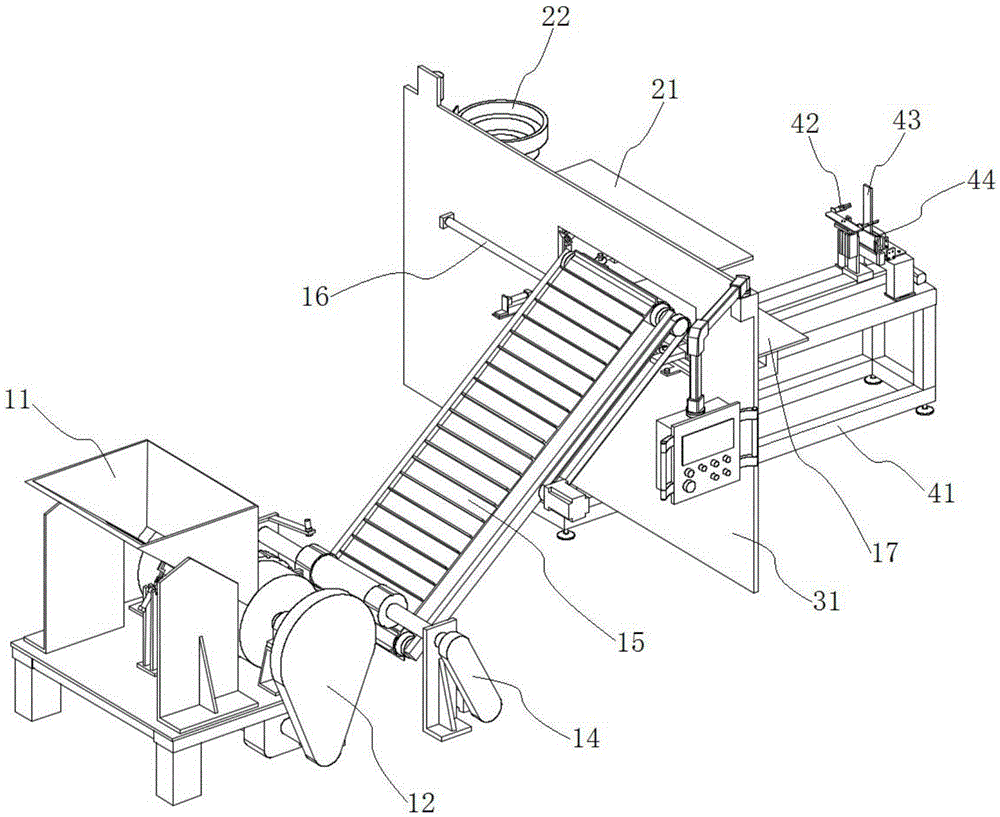

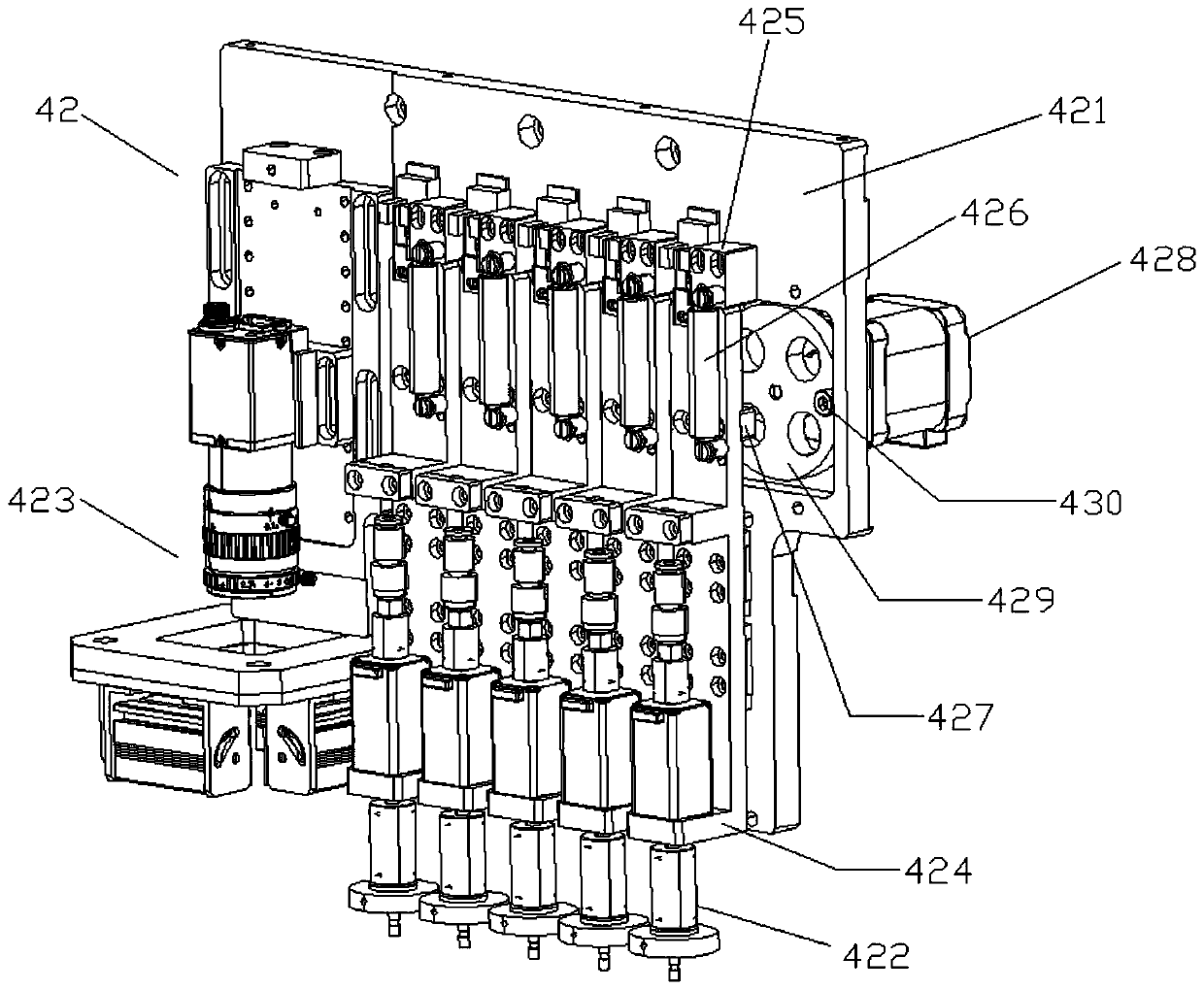

Fully-automatic round-head barrel hook forming machine

ActiveCN105414415AMeet production requirementsFulfill production requirementsWire articlesProduction lineControl system

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

Non-tube quick reproduction method for seedings of jatropha curcas L.

InactiveCN101057557AReduce in quantitySave germplasm materialHorticulture methodsPlant tissue cultureAxillary budNutrient solution

The invention discloses a non-tube method for fast breeding aleurite seedling, comprising: taking disinfected stem carrying axillary bud of 2-3cm length as explant; enclosing its morphological upper notch, immersing its morphological lower notch in indolebutyric acid solution, cutting it in sand disk, dressing nutritional solution to keep sand disk wet, culturing it for 16. 2-20. 2 days under conditions of 25-28 Deg. C, 70-80% of relative humidity, 2000-3000 lx lighting strength and light period of 12 hour lighting / 12 hour dark, and getting rooting and integral plant. The invention is characterized by fast breeding, free from influence of national factors such as season and region, low variation rate, simple process and low cost.

Owner:SUN YAT SEN UNIV

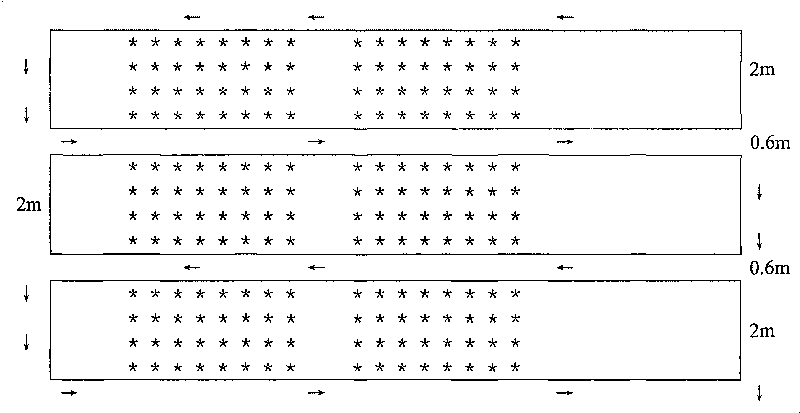

Ralstonia solanacearum disease resistance high density identification method in field

InactiveCN101690451AAccurate and reliable identification resultsIncrease planting densityPlant genotype modificationHorticultureFertilizerSite management

The invention discloses a ralstonia solanacearum disease resistance high density identification method in the field, comprising: 1) cultivating ralstonia solanacearum disease nursery; 2) tidying disease nursery field in due time: before tobacco in the disease nursery is transplanted, tidying land to reach the requirement of ridging, furrowing and covering with a mulching film due to finely divided soil; according to the requirement that the width of each furrow is 1.5-2.5m and the ditch width between furrows is 0.5-0.7m, making a furrow, levelling furrow surface, and adjusting length according to the size of a plot; 3) determining cultivating density, and adopting a parallel furrow transplant mode: transplanting more than 3-5 lines in each furrow with the row spacing of 0.2-0.4m; 4) reasonably applying fertilizer, and strengthening field management: at the weight ratio of 1:1-2:1-2 of nitrogenous fertilizer, phosphatic fertilizer and potassic fertilizer, adopting a mulching film covering mode, and paying attention to field irrigation; and 5) inspecting and grading state of illness. The invention has the advantages that the ralstonia solanacearum disease resistance high density identification method in the field improves large field identification efficiency of ralstonia solanacearum disease resistance, can be applied to identify ralstonia solanacearum disease resistance, can improve identification material for above 4-6 times under the condition of same capital and disease nursery area and can be applied to breed ralstonia solanacearum disease.

Owner:INST OF TOBACCO ANHUI ACADEMY OF AGRI SCI

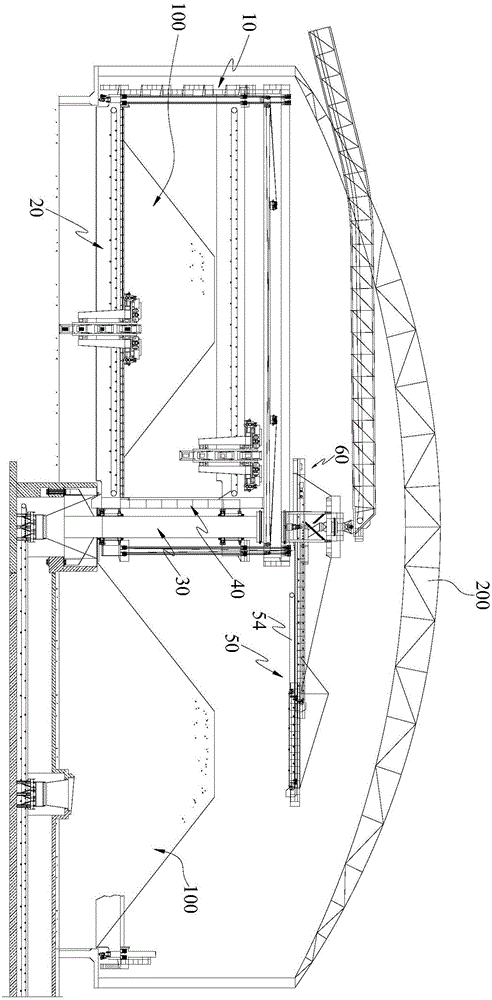

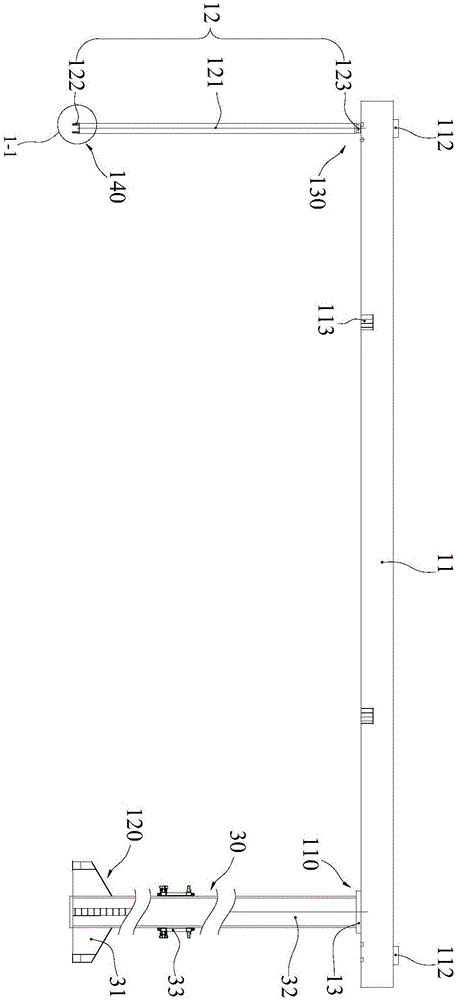

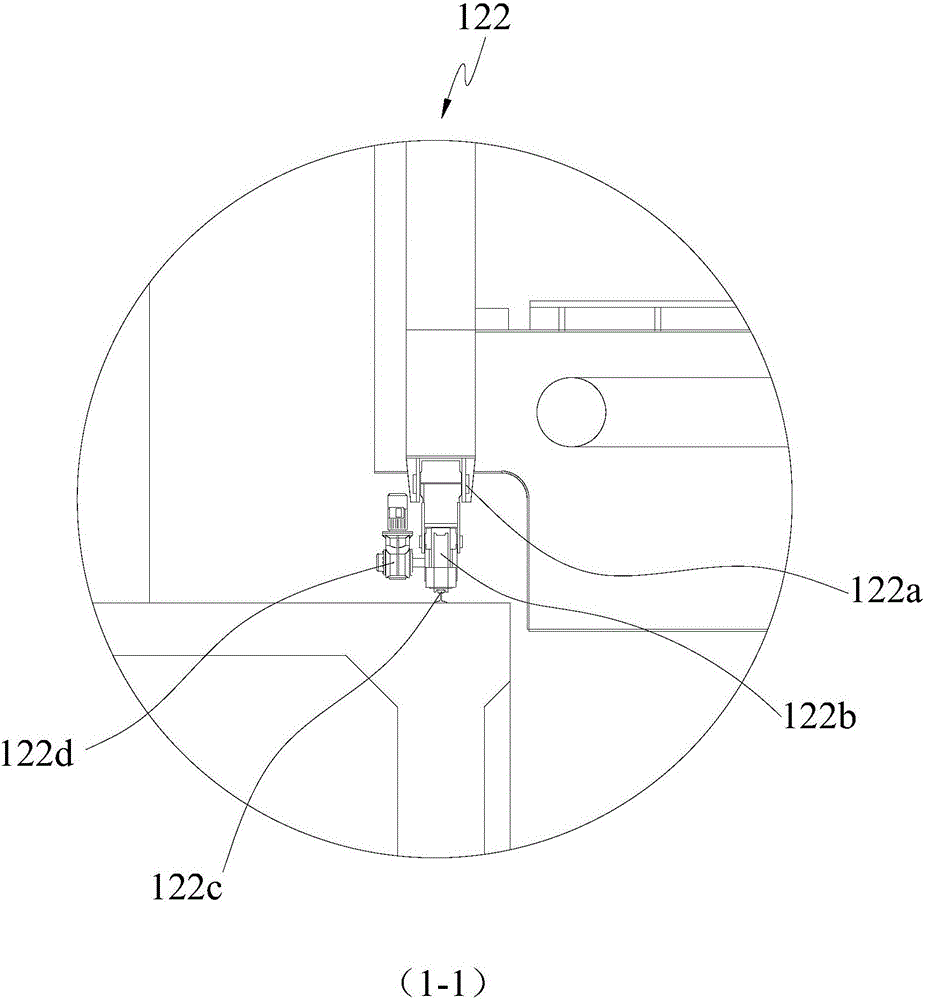

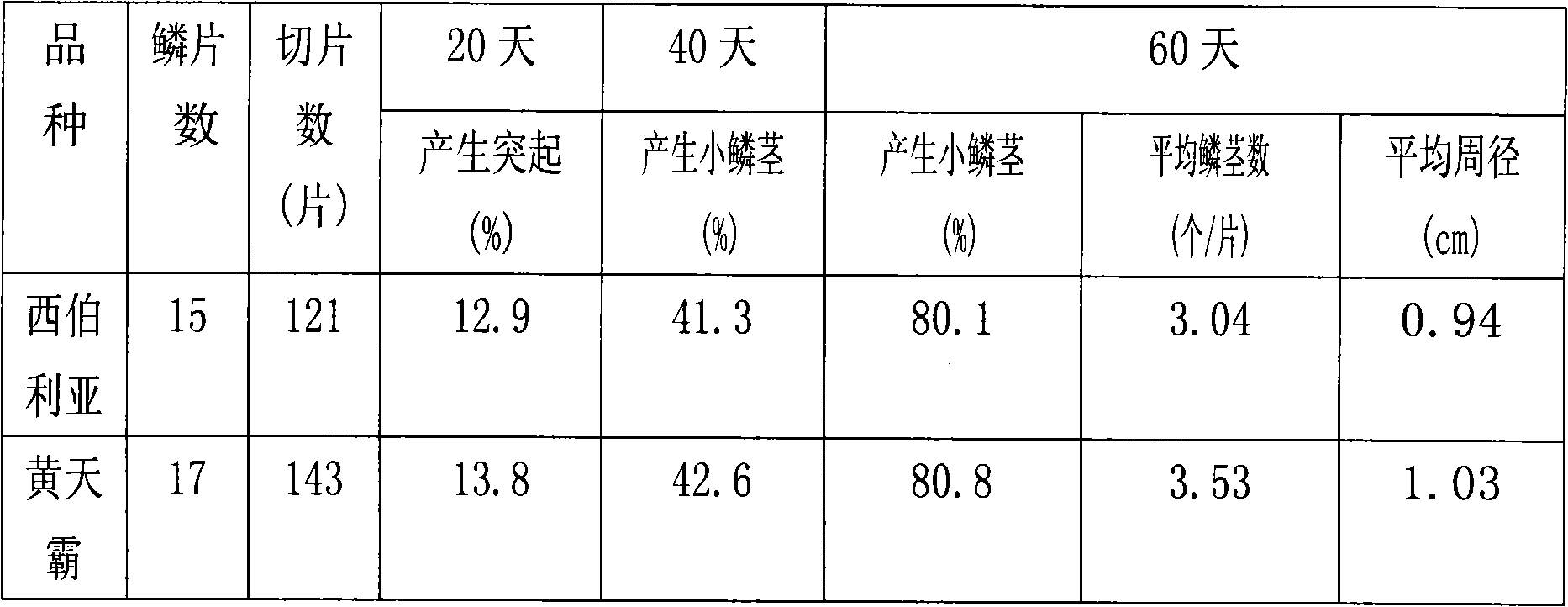

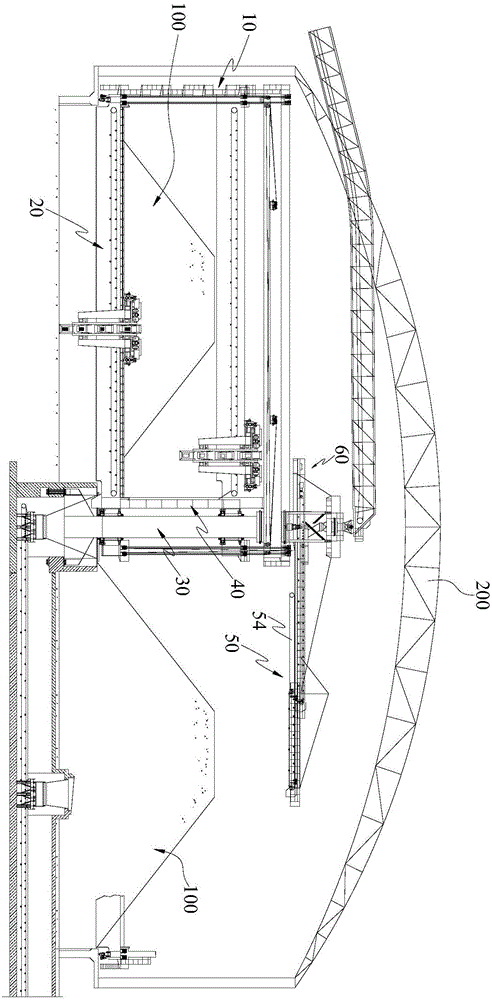

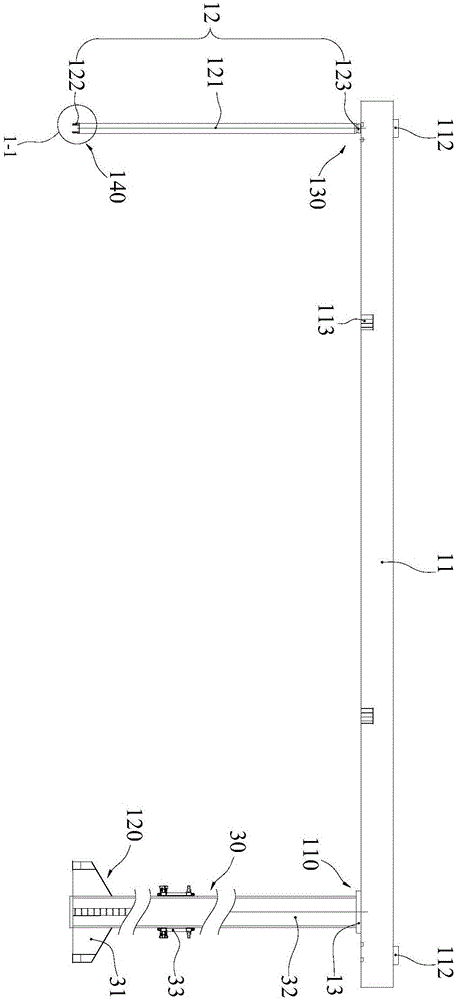

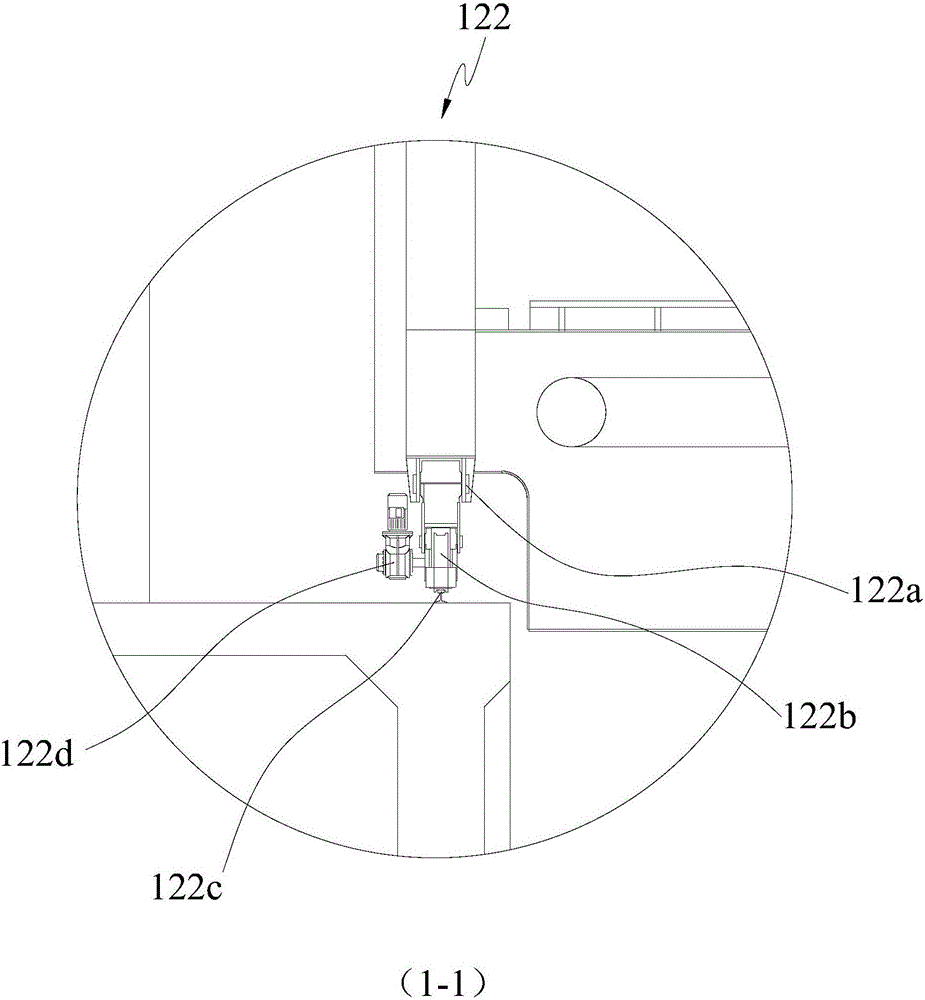

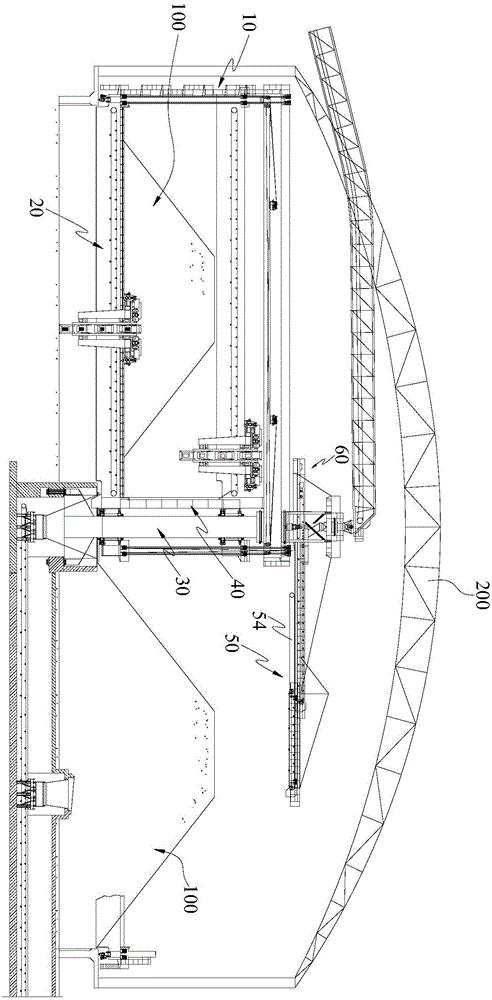

Round stockyard stacking and fetching machine

ActiveCN106219258ASolve the realization of stacking and reclaimingStacking adjustableLoading/unloadingEngineeringBelt conveyor

The invention discloses a round stockyard stacking and fetching machine which comprises a rotating portal portion, a bucket wheel fetching portion, a conveying portion and a centering swinging mechanism. The rotating portal portion rotates around the centering swinging mechanism by taking span of the rotating portal portion as a radius, the bucket wheel fetching portion and the conveying portion are connected with the rotating portal portion, and the conveying portion is composed of multiple belt conveyors and cooperates with the bucket wheel fetching portion to form a fetching logistics channel and / or a stacking logistics channel. Different from existing equipment, the round stockyard stacking and fetching machine takes the span of a portal as actual working range radius, and application of the stacking and fetching machine in a round stockyard is realized for the first time.

Owner:TIDFORE HEAVY IND

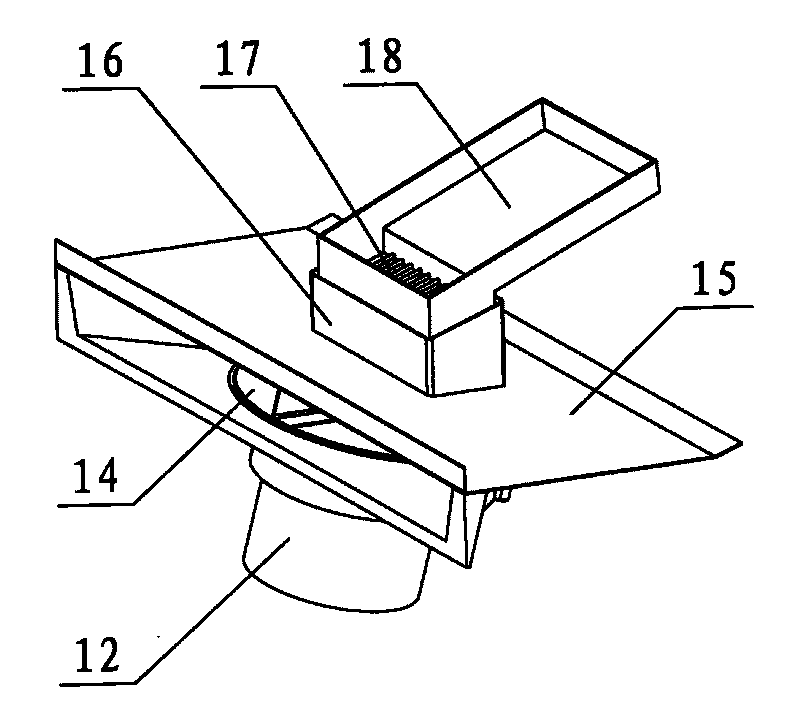

Feeding machine

ActiveCN101755701AWill not cause automatic slipControl the feeding amountPisciculture and aquariaBall bearingReciprocating motion

The invention provides a feeding machine, which mainly consists of a machine box, a controller, a baiting mechanism which carries out throwing movement, a material throwing motor, a material throwing disc, a box cover, a box bottom plate and the like, wherein a lower shaft is arranged at the baiting opening end of a material passing groove, the lower shaft is connected with an upper shaft through a connecting rod, the upper shaft is fixed under a material hopper, a bearing seat is arranged under the material passing groove, a roller bearing is arranged in the bearing seat and is connected with a motor shaft through an eccentric sleeve, and the motor shaft is supported on the middle of the material passing groove. The throwing movement refers to the movement that when the baiting motor rotates in the positive direction, the eccentric sleeve drives the roller bearing to revolute around the motor shaft, at the same time, the autorotation of the roller bearing drives the material passing groove to do the circumferential reciprocating movement, and an upper shaft and a lower shaft of the non-baiting end are hinged with the connecting rod for swinging, so the feedstuff is gradually thrown towards the baiting opening in the material passing groove to enter a material collector and to fall on the material throwing disc.

Owner:ZHEJIANG FORDY MACHINERY

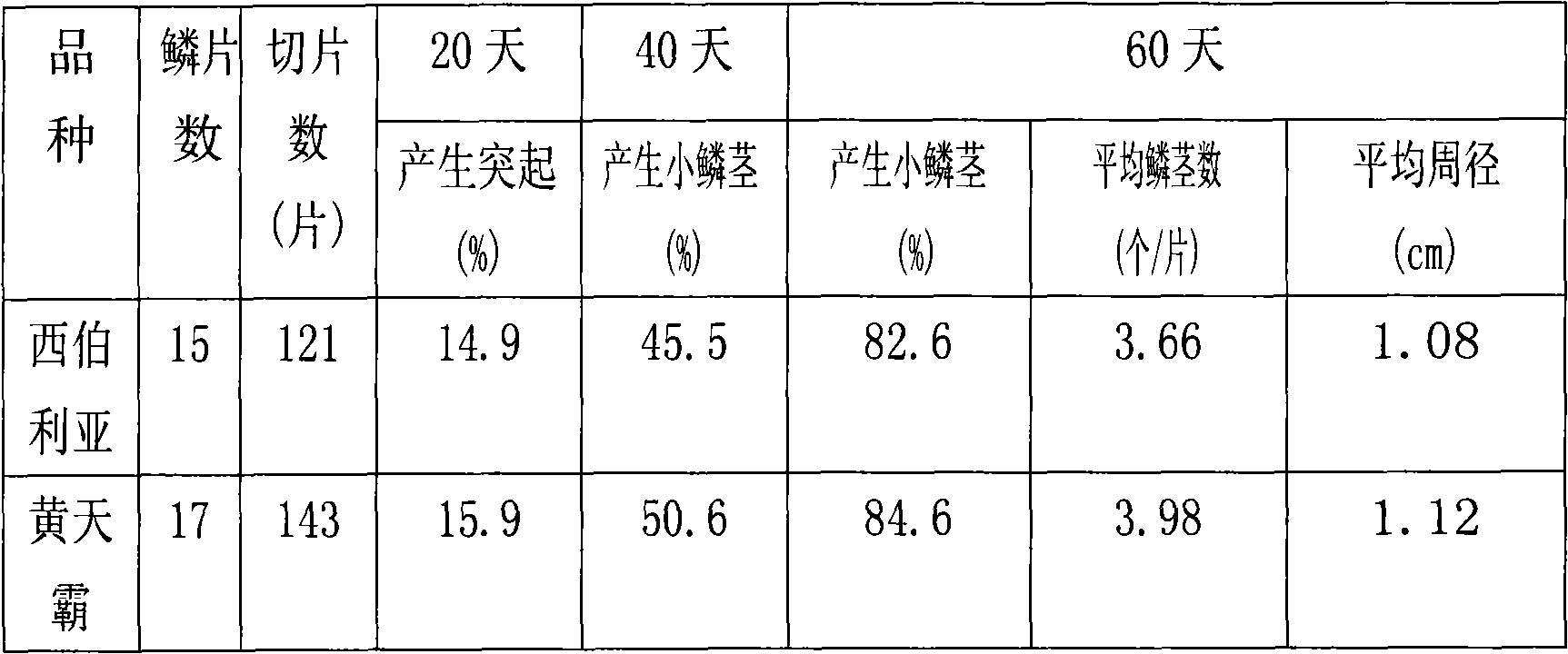

Method for quickly inducing bulblet by lily bulb scale slice

InactiveCN101554138AImprove productivityIncrease productionPlant tissue cultureHorticulture methodsBudCell budding

The invention provides a method for quickly inducing bulblet by lily bulb slice, which comprises the steps of seed ball low-temperature dormancy breaking treatment and scale disinfection treatment. The method is characterized in that the scale disinfection comprises the following treatments: scale pre-culture, scale slicing, bulblet inducing culture, bulblet culture, treatment before bulblet bottle-out and field setting. Each scale can produce 20 to 30 bulblets, each seed ball can produces more than 300 bulblets, the method not only can produce bulb-let with high yield and high efficiency rapidly, but also can form single bulblet directly and does not have the multi-pistil problem that the bulb-let is induced from adventitious bud; and the bulblet can be formed by direct inducing culture, thus reducing the process and the time for the callus tissues and the adventitious bud which require at least two times of secondary change over to form bulblet in the prior art, and simultaneously avoiding the mutation of the bulblet induced from bulblet. The bulblet induction and culture are performed in darkness, thereby effectively saving the energy source.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI

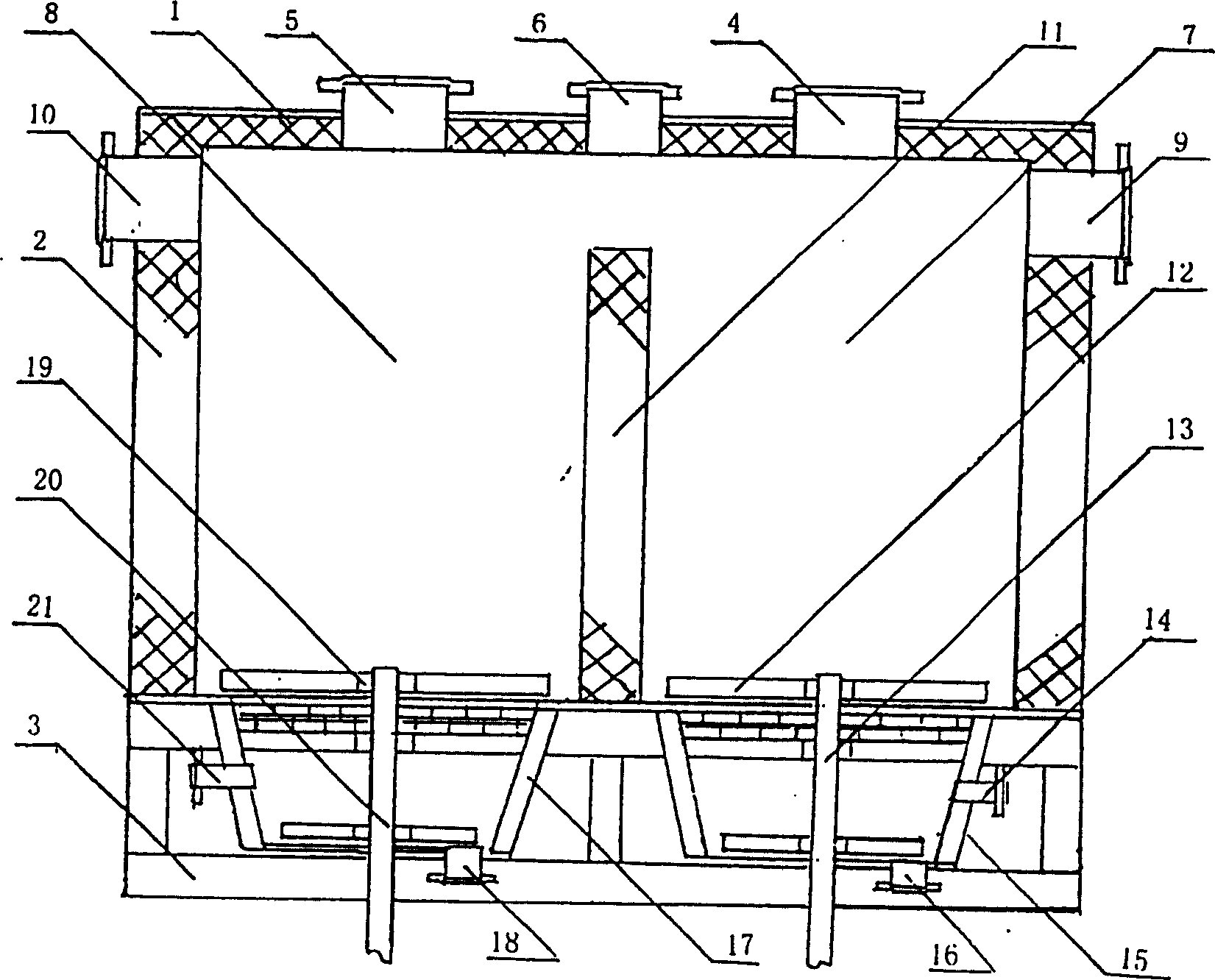

Door type bucket-wheel stacker-reclaimer

ActiveCN106219259ASolve the realization of stacking and reclaimingStacking adjustableLoading/unloadingEngineeringYard

The invention discloses a door type bucket-wheel stacker-reclaimer. The door type bucket-wheel stacker-reclaimer comprises a rotary door frame part, a bucket-wheel reclaiming part, a conveying part and a centered rotating mechanism, wherein the rotary door frame part rotates around the centered rotating mechanism with the span of the rotary door frame part as the radius, and the bucket-wheel reclaiming part and the conveying part are connected to the rotary door frame part. The conveying part is composed of a plurality of belt conveyers and forms a reclaiming logistics channel and / or a stacking logistics channel with the bucket-wheel reclaiming part. Different from existing equipment, the stacker-reclaimer can be applied to a round stock yard innovatively with the span of a door frame as the actual working range radius.

Owner:TIDFORE HEAVY IND

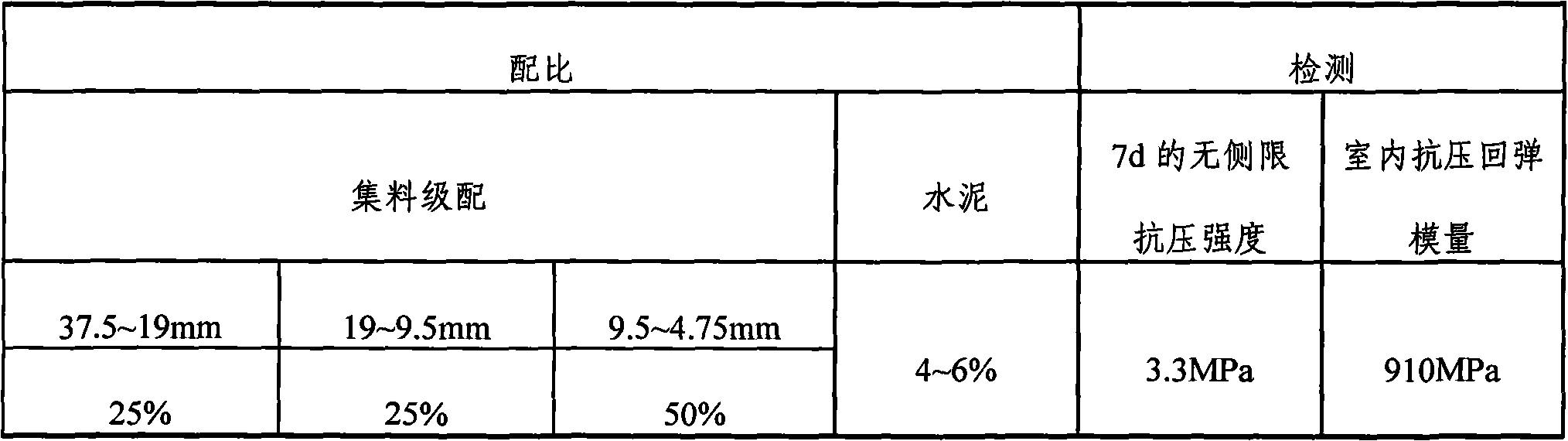

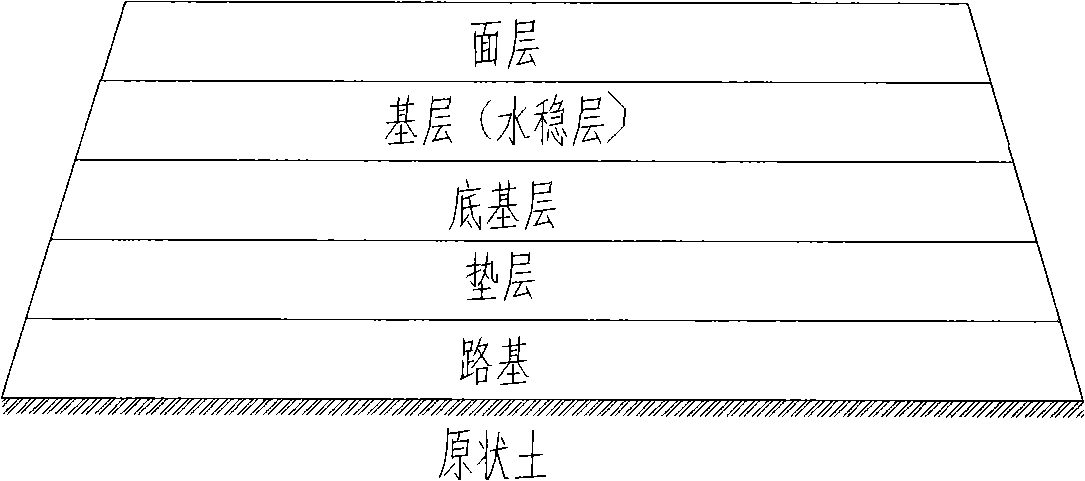

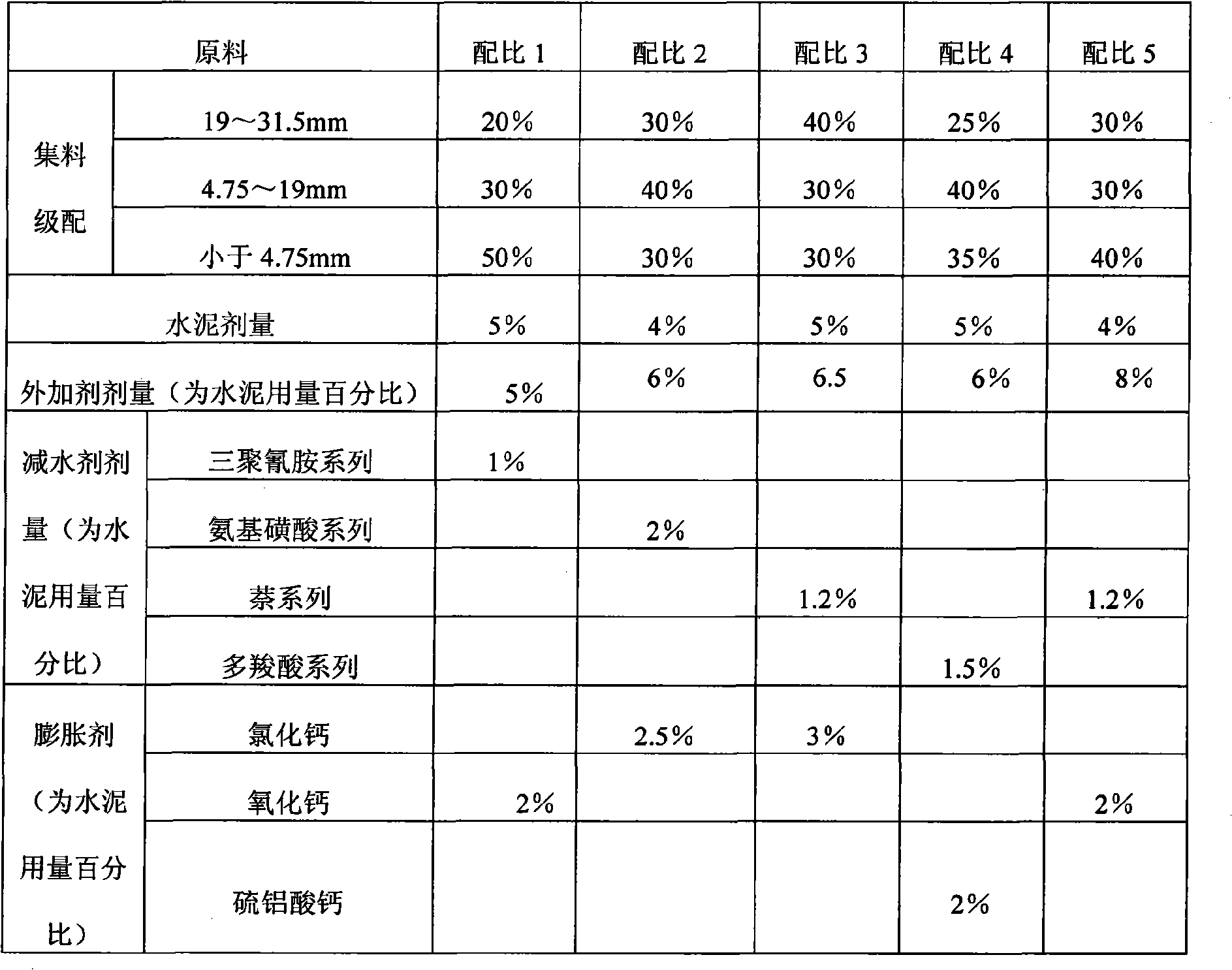

Method for preparing regenerative road material by using waste concrete and construction method thereof

InactiveCN101255044AImprove performanceLarge amount of materialSolid waste managementContinuous/uninterruptedWater reducer

A regeneration road material produced with waste concrete is used as a subbase material of roads and construction service roads and comprises waste concrete particles, cement, admixture, water reducer, expansion agent and water. The preparation method includes: separating; removing impurities, removing waste concrete contaminated by radioactive materials, heavy metals and other harmful impurities; crashing and screening; adding admixtures, water reducer, expansion agents, cement and water for mixing into a cement stable waste cement regeneration road material. The construction method of the regeneration road material produced with waste concrete includes: preparing feed according to the designed particle size and evenly mixing the cement and regeneration materials after adding water and paving in equilibrium continuously and uninterruptedly; rolling by using rollers to roll and shape the paving surface and compacting to the design required compaction degree; sprinkling for curing and sweeping away the soil sundries from the subbase surface and spraying prime coat asphalt with asphalt spray car. The invention makes full use of waste concrete to produce road materials, thereby expanding the sources of construction materials and solving the problem of recycling of waste concrete, so that the environment pollution is reduced and the natural construction resources are fully utilized.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing biomass charcoal and charring furnace with double furnace chambers therefor

InactiveCN1632060AAlleviate water scarcityDelayed exhaustion timeBiofuelsSpecial form destructive distillationFossil fuelBiomass

The invention includes a method to produce biological carbon and its double-furnate charring furnace. The method is: shatter, filter, dry and place the materials meeting the requirements in to cavity of charring furnace separately, ignite the material in cavity of gasification furnace to make gasification, putout the biological carbon dry distilled and charred in the cavity of charring furnace through the outlet for product. The main structure of double-farnace charring furnace includes there are mouth of pipe in the middle of upper furnace, and cavity of gasification furnace and cavity of charring furnace in the furnace. Its has biological fuel gas with hest value of 800-1000kg / m3, can be reused, after being scatter and add into watersoluble high molecular sticker, is useful to prolong the time of exhaustion of delay the fossil fuel resure; it makes good use of waste in farming and forestry, saves energy, has simple and reasonable structure of double-furnace charring furnace, convenient operation and large quality of processing material, high speed and efficiency of caring in furnace.

Owner:韩璋鑫 +1

Method for regulating quality of dasheens through hot air energy-far infrared energy-microwave energy integration drying

ActiveCN105509416AAvoid localized overheatingImprove conditions with low moisture content that is difficult to dryDrying solid materials with heatHearth type furnacesMicrowaveEconomic benefits

The invention relates to a method for regulating quality of dasheens through hot air energy-far infrared energy-microwave energy integration drying, and belongs to the technical field of deep processing of agricultural products. The method mainly comprises the following steps: taking fresh dasheens as raw materials, selecting, cleaning and slicing the dasheens, carrying out blanching and color protection on the dasheens, soaking, freezing, carrying out hot air energy-far infrared energy-microwave energy integration drying, and packaging. A hot air energy-far infrared energy-microwave energy integration drying technology is adopted, water in materials is rapidly vaporized and transferred through early-stage high-power microwave heating, and a porous structure is generated; by later-stage low-power microwave drying, local overheating of the materials due to single-power heating is avoided; through far infrared radiation, water inside and outside the materials is removed by ducts formed by microwave heating; and blowing heating is carried out in a whole drying cavity, so that water on the surfaces of the materials and in air is removed rapidly. Obtained dasheen crisp chips are good in uniformity and high in quality. By the method, continuous and automatic production is realized, material treatment amount is large, and economic benefit is high.

Owner:JIANGSU ACAD OF AGRI SCI

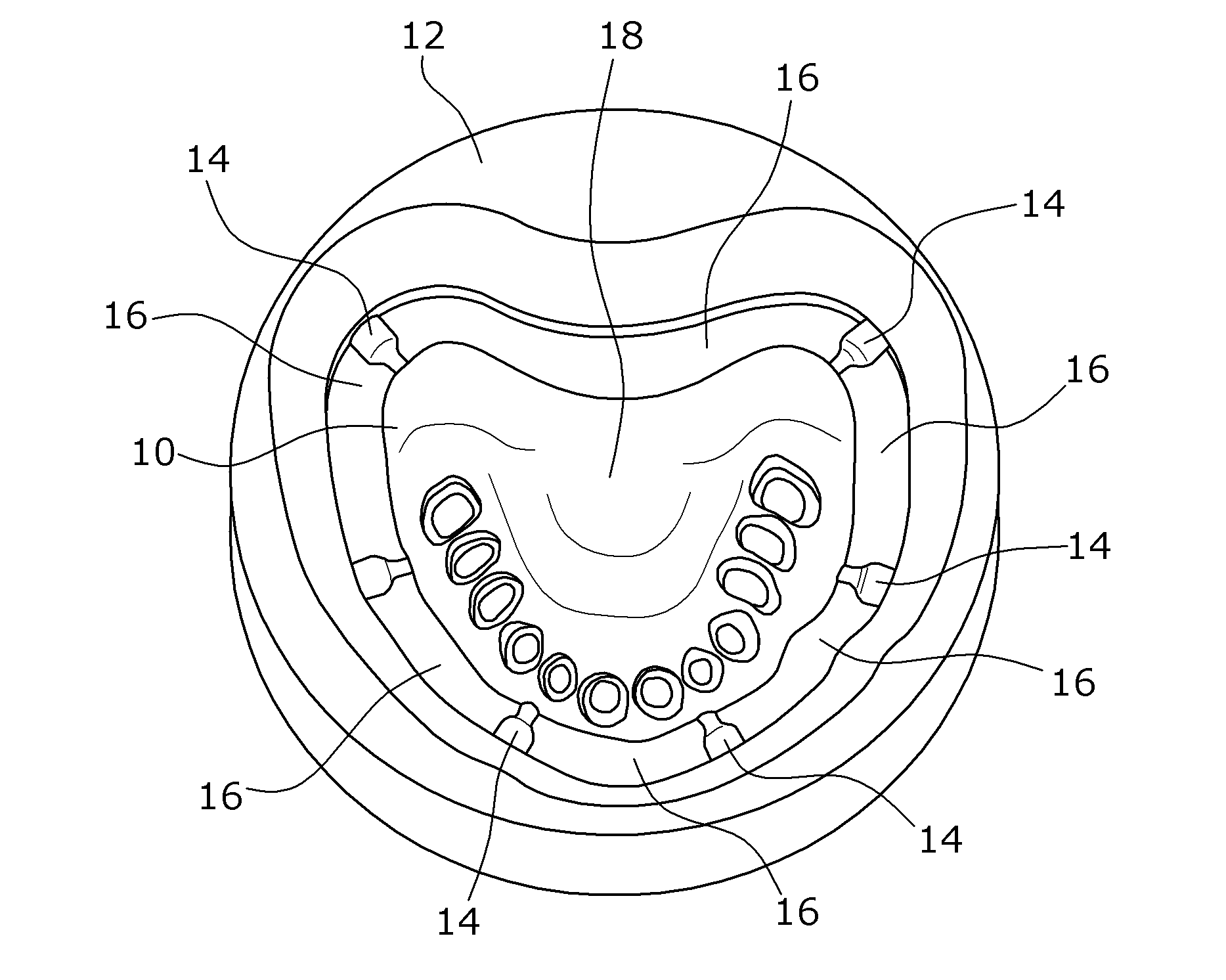

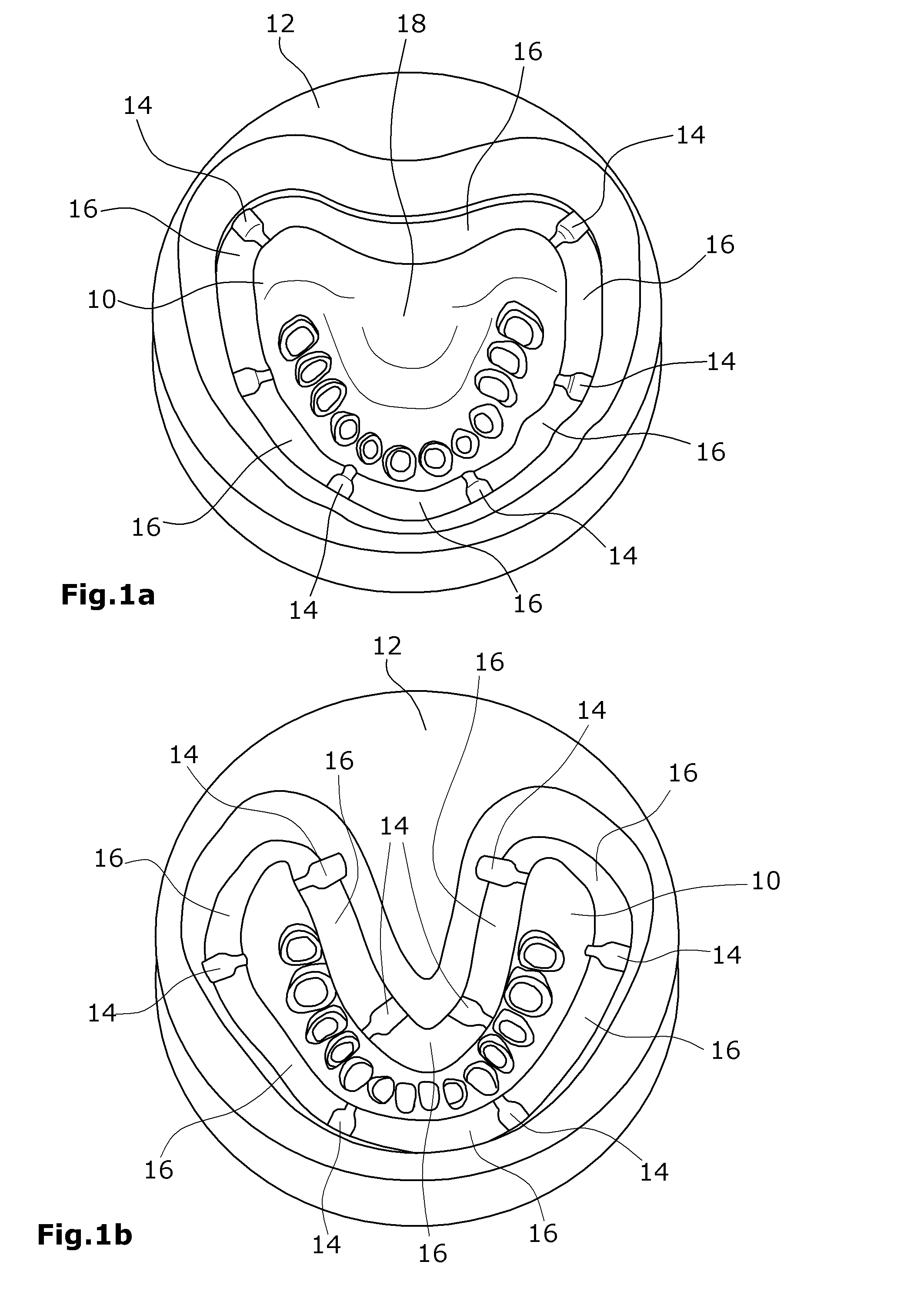

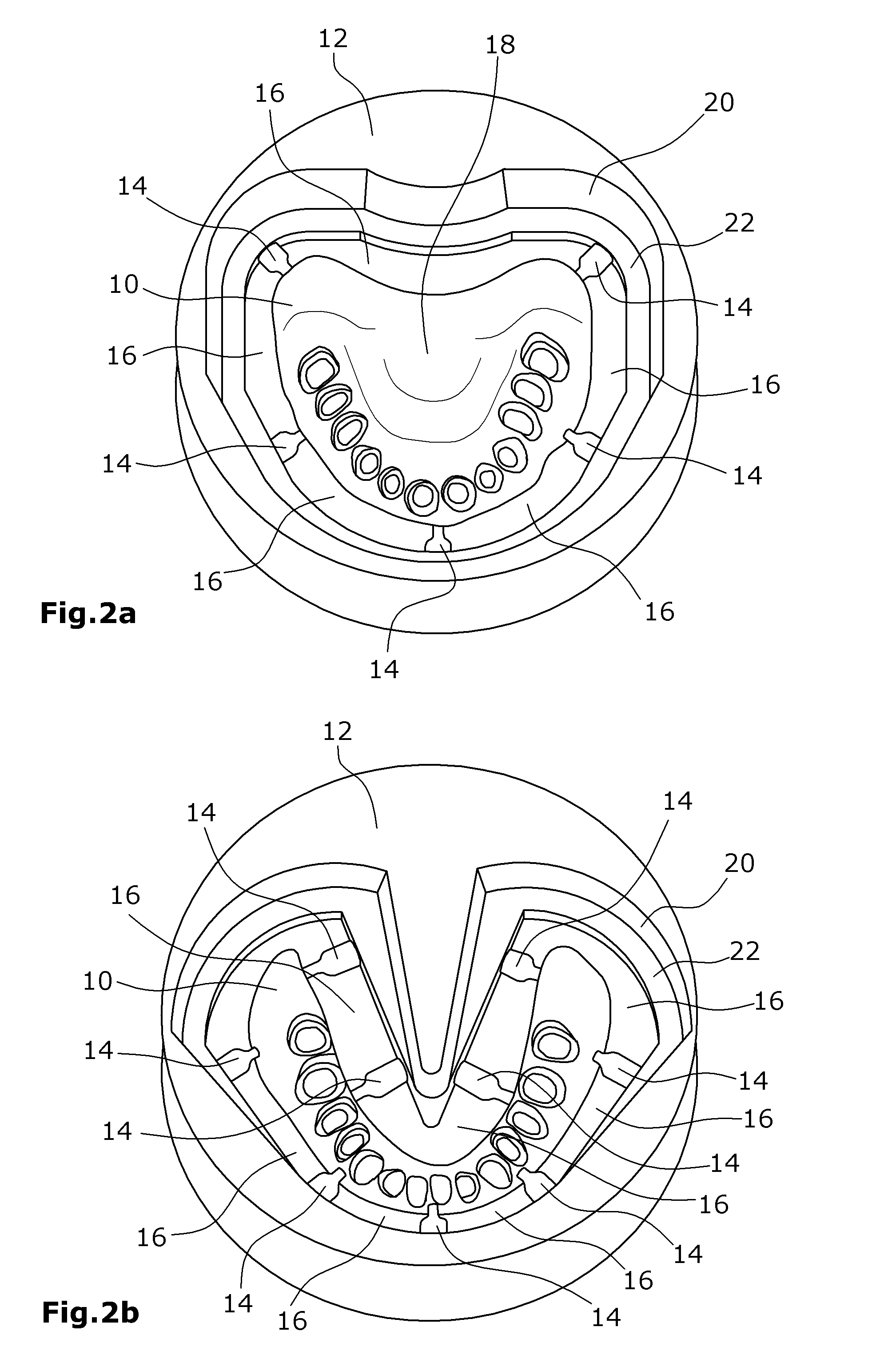

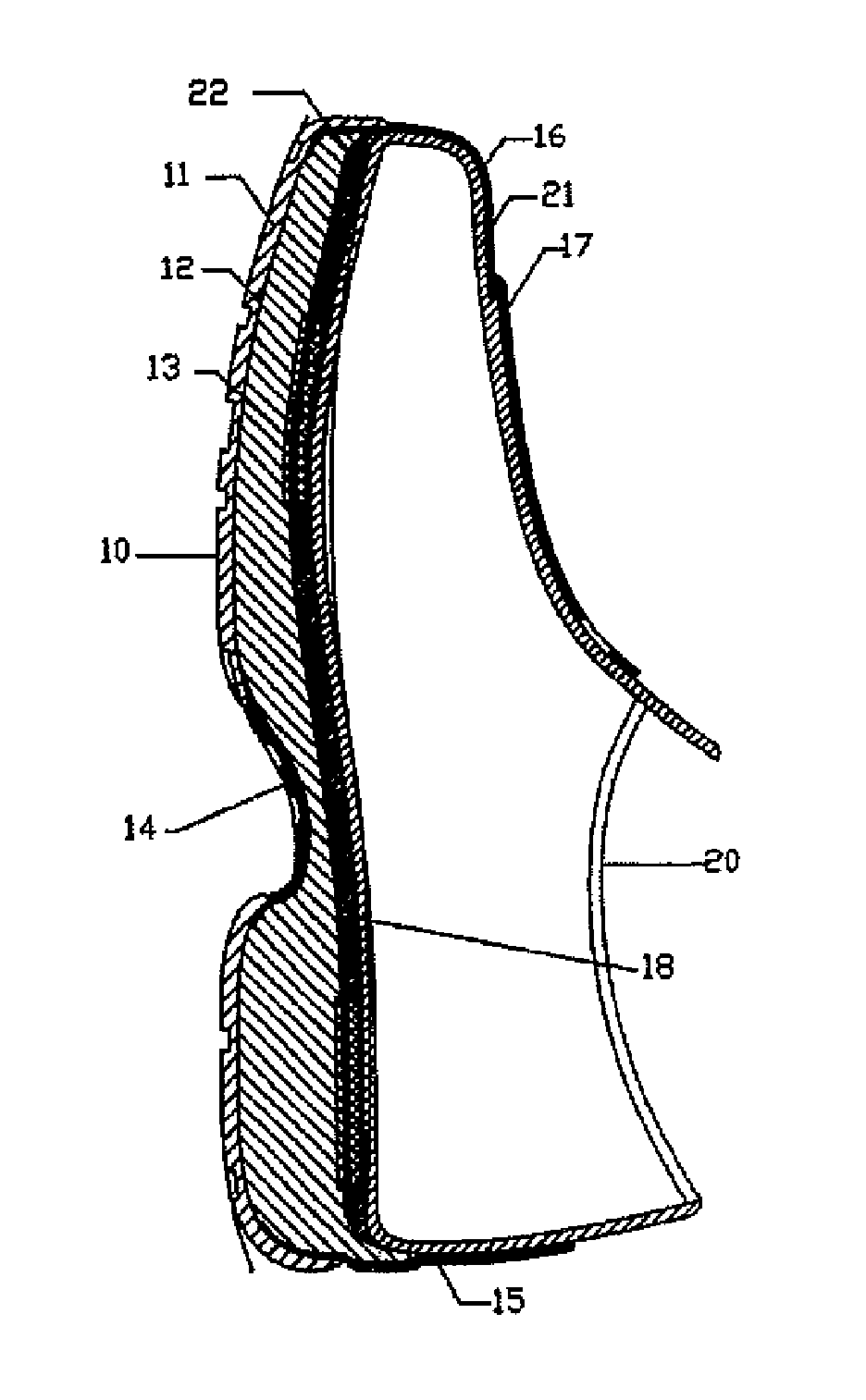

Prosthetic preform for producing a dental prosthetic body

ActiveUS20160128811A1Quality improvementLarge amount of materialImpression capsLayered productsProsthesisOrthodontics

To produce a dental prosthetic body for an upper or lower jaw prosthesis, a prosthetic preform is provided, the prosthetic preform having approximately the same shape as the prosthetic body. As a result, a high quality prosthetic body can be produced and customized, for example, by milling the prosthetic prebody.

Owner:VITA ZAHNFABRIK H RAUTER GMBH & CO KG

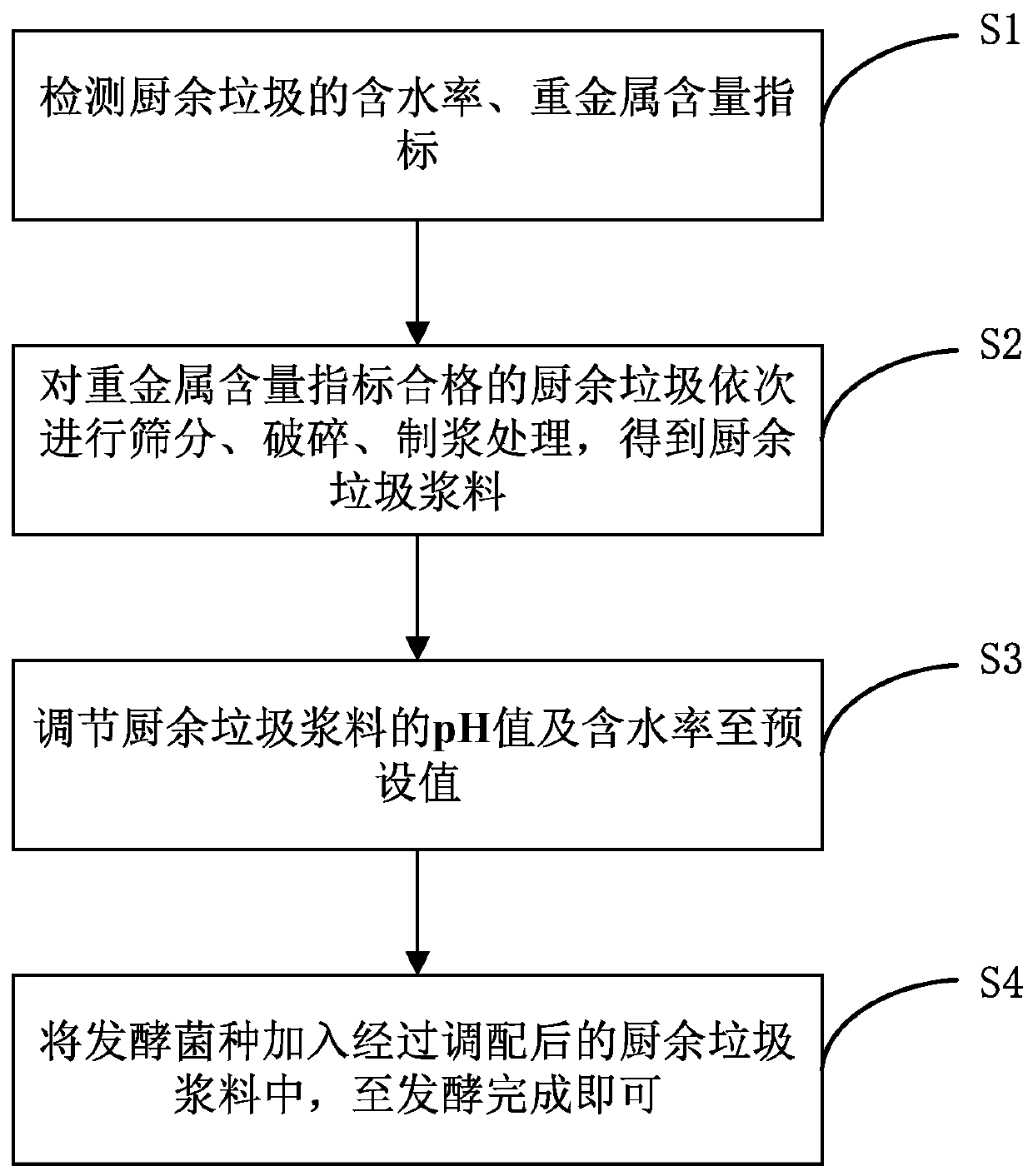

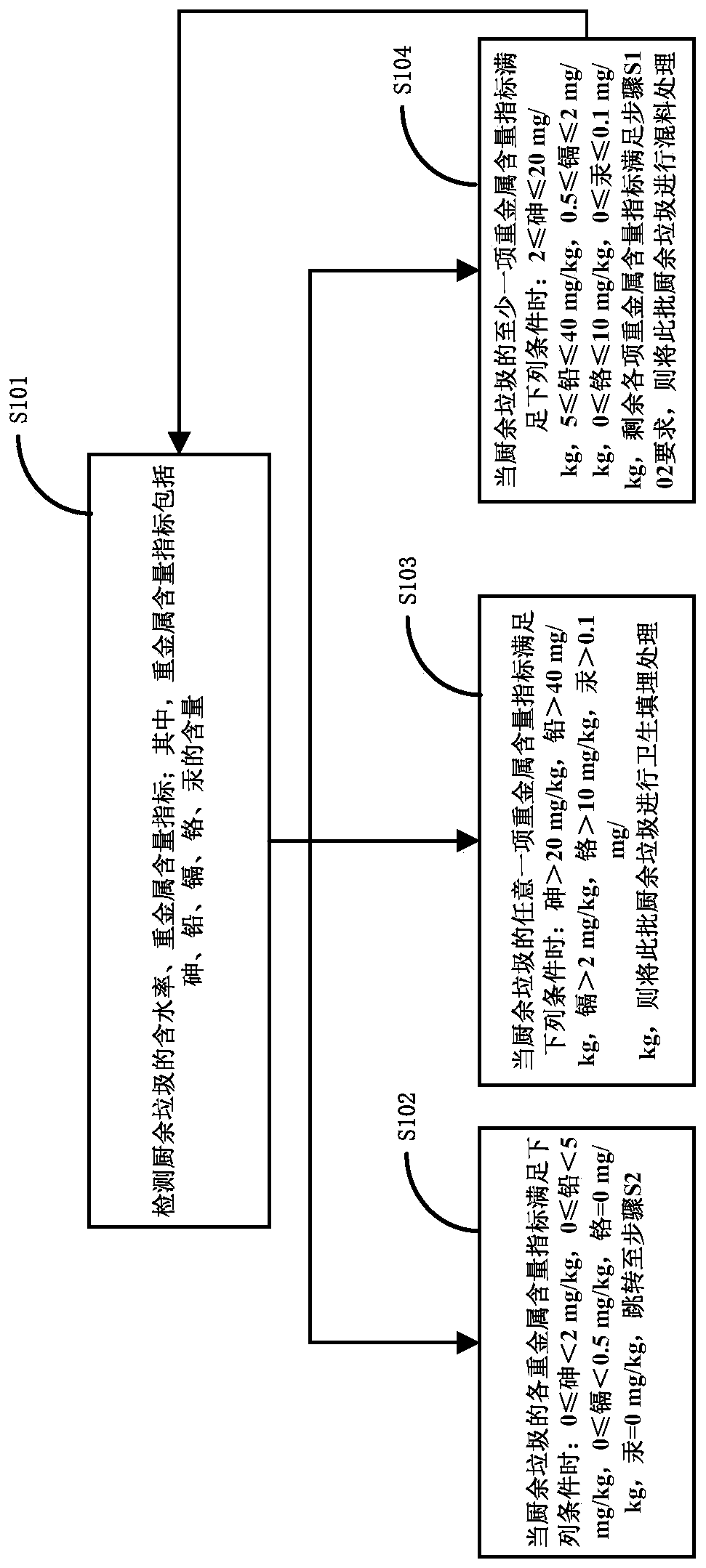

Feed treatment method of using kitchen garbage for culture of black soldier fly

InactiveCN110074286AEnsure safetyReduce moistureFood processingAnimal feeding stuffHydrogenResource utilization

The invention discloses a feed treatment method of using kitchen garbage for culture of a black soldier fly, and relates to the technical field of garbage treatment. The feed treatment method comprises the following steps of S1, detecting the water content and heavy metal content index of the kitchen garbage; S2, performing sequentially screening, crushing and pulping on the kitchen garbage with qualified heavy metal content index, so as to obtain the paste of the kitchen garbage; S3, adjusting the pH (potential of hydrogen) value and water content of the paste of the kitchen garbage to presetvalues; S4, adding fermenting strain into the regulated paste of the kitchen garbage until the fermenting is completed. The feed treatment method disclosed by the invention has the advantages that the continuous production is realized, the efficiency is high, the operation is intelligent and simple, and the safety and reliability are realized; the nutrient quality of the paste of the kitchen garbage is improved, and the high-value resource utilization of the kitchen garbage for the feeding of the black soldier fly is realized.

Owner:源创环境科技有限公司

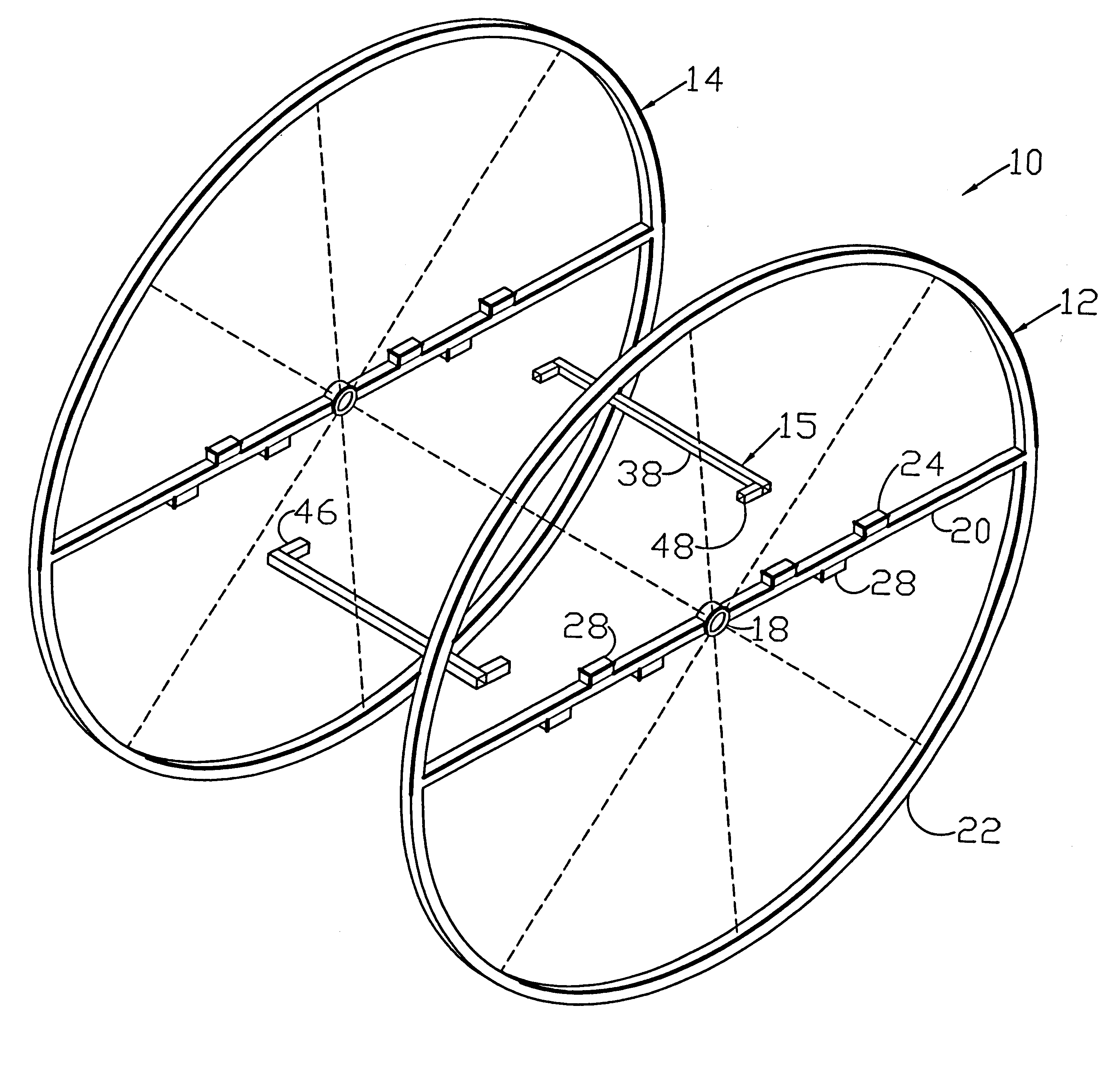

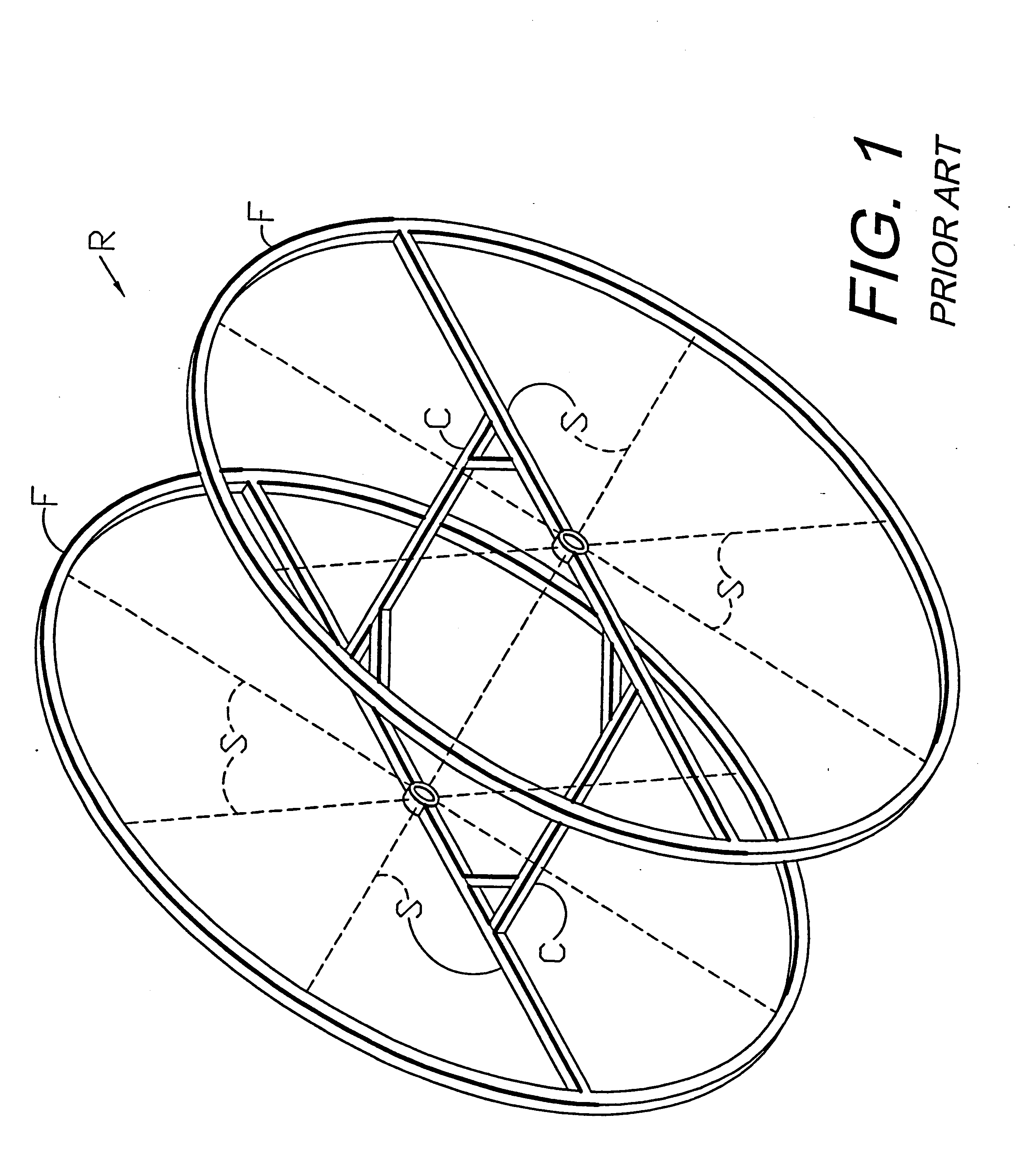

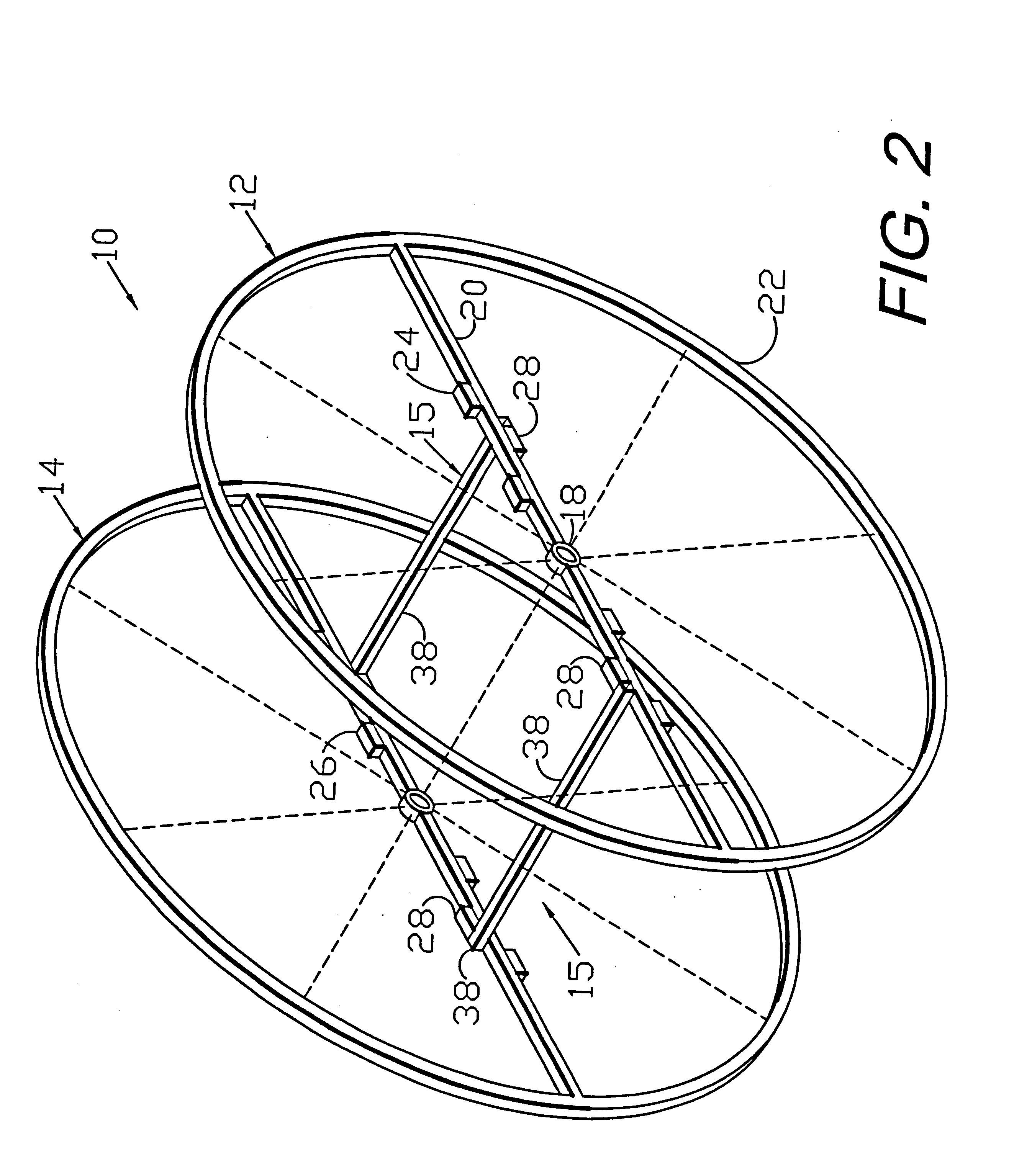

Knockdown, changeable reel system and method

InactiveUS6722607B2Efficient removalLarge amount of materialFilament handlingWebs handlingEngineeringFlange

Owner:PETROFLEX N A

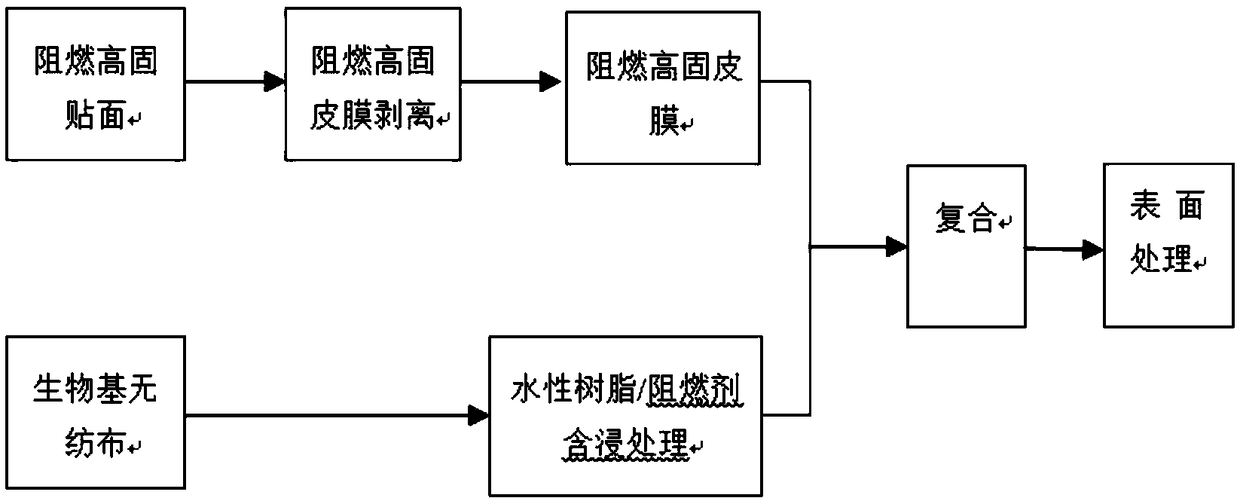

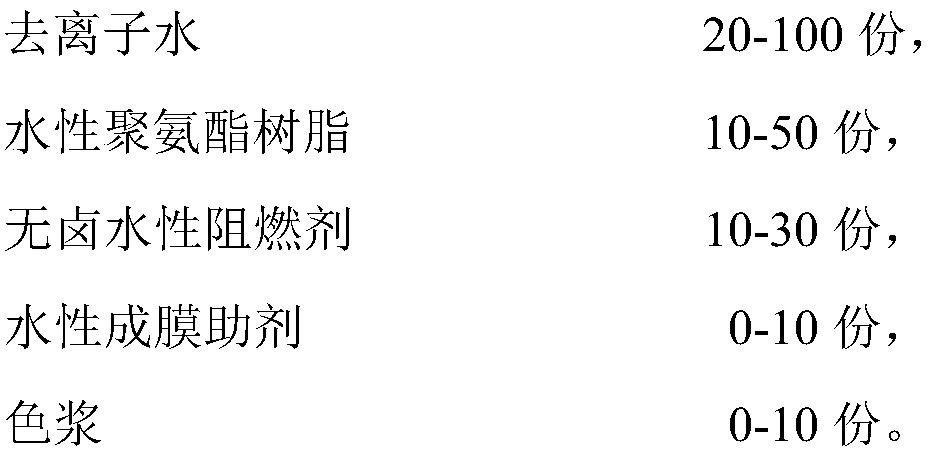

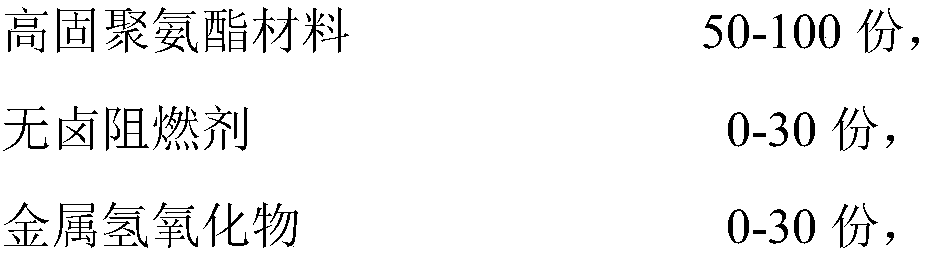

Method for preparing environmentally-friendly flame-retardant bio-based automobile chair polyurethane synthetic leather

InactiveCN109056356AMeet the processing performanceMeet the test requirementsRoad vehiclesTextiles and paperPolyurethane membranePhysical strength

The invention relates to a method for preparing environmentally-friendly flame-retardant bio-based automobile chair polyurethane synthetic leather. The method comprises the following steps: firstly, cospinning a bio-based raw material and chinlon to obtain bio-based base cloth, and carrying out dipping, extrusion and drying to obtain a bio-based basic material with flame retardancy; preparing a halogen-free flame-retardant high-solid polyurethane membrane in a release paper membrane transferring mode, and peeling off the release paper membrane to obtain a high-solid membrane with flame retardancy; finally compounding the bio-based basic material with the high-solid membrane, thereby obtaining a finished product. The environmentally-friendly flame-retardant bio-based automobile chair polyurethane synthetic leather prepared with the method has flame retardancy which meets requirements of grade B provided by 'GB 8410-2006 combustion property of automotive trim material'. Meanwhile, the leather has the advantages of low VOC (volatile organic compound), good environment protection, flexible and full hand feelings, good surface skin friendliness, high physical strength, oil resistance, aging resistance, and the like.

Owner:ANHUI ANLI MATERIAL TECH

Stacker-reclaimer

ActiveCN106315247ASolve the realization of stacking and reclaimingStacking adjustableLoading/unloadingEngineeringReclaimer

The invention discloses a stacker-reclaimer. The stacker-reclaimer comprises a rotary portal frame part, a bucket-wheel material taking part, a conveying part and a centering rotating mechanism, wherein the rotary portal frame part rotates around the centering rotating mechanism by taking a span of the rotating portal frame as the radius, and the bucket-wheel material taking part and the conveying part are connected to the rotating portal frame. The conveying part is composed of a plurality of belt conveyors and is matched with the bucket-wheel material taking part to form a material taking material flow channel and / or a material stacking material flow channel. Different from existing equipment, the stacker-reclaimer, taking the span of the portal frame as the actual working range radius, is applied to a round stockyard initiatively.

Owner:TIDFORE HEAVY IND

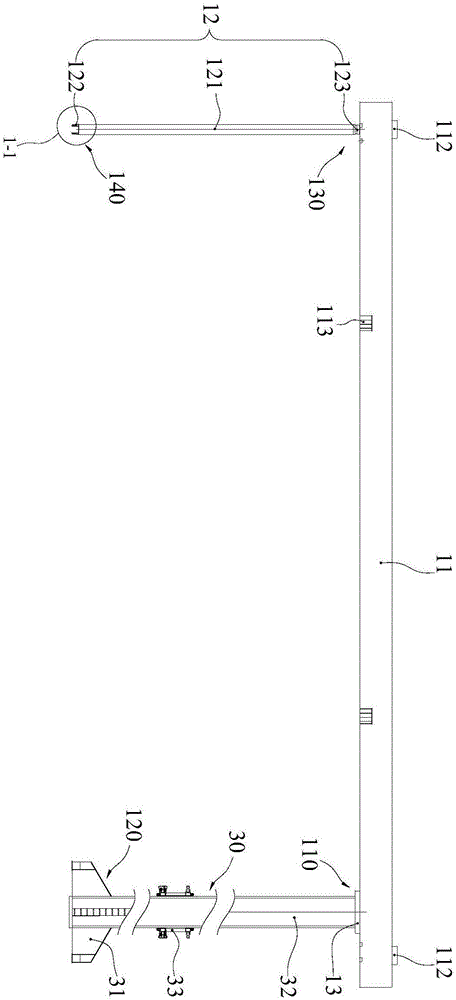

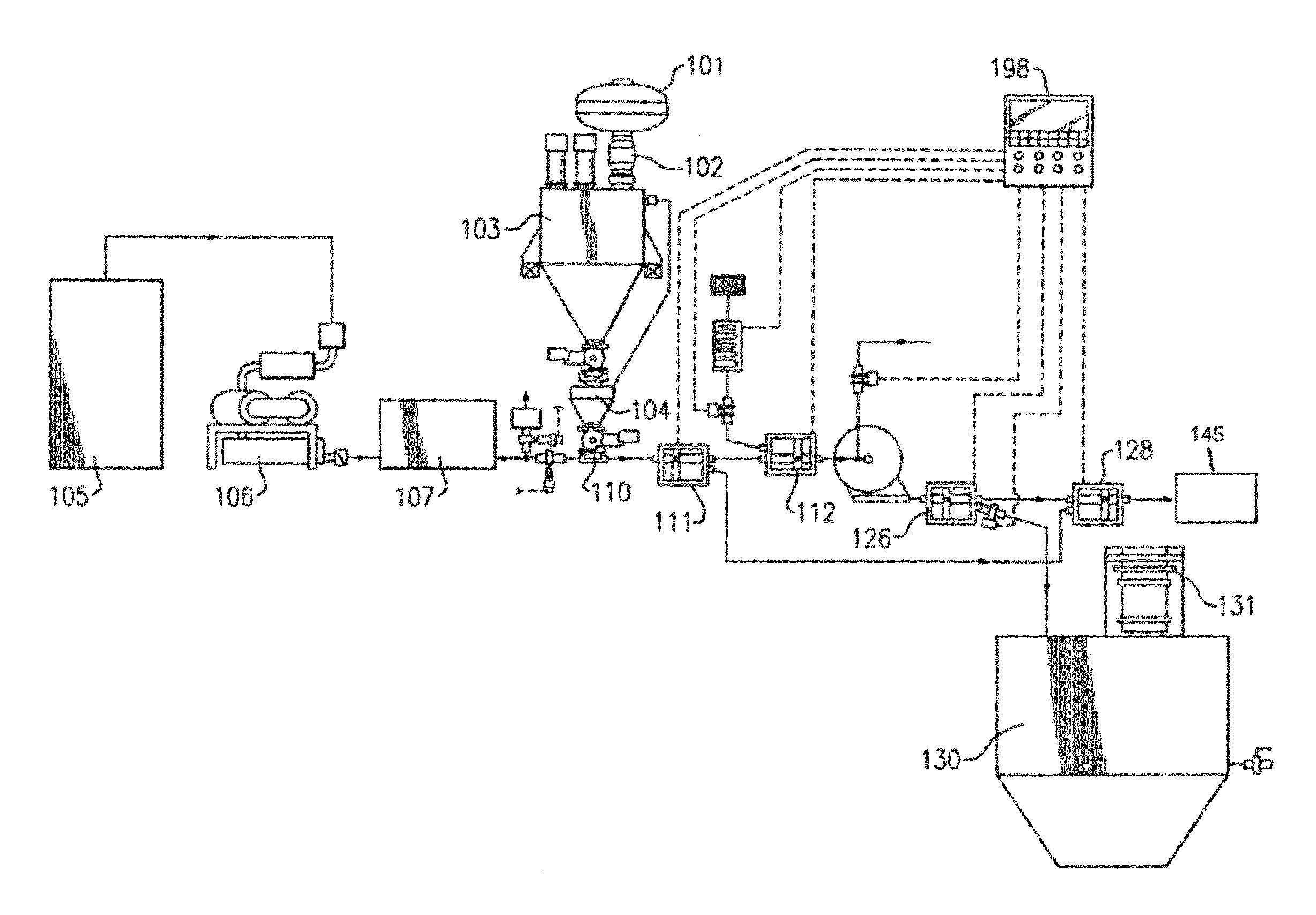

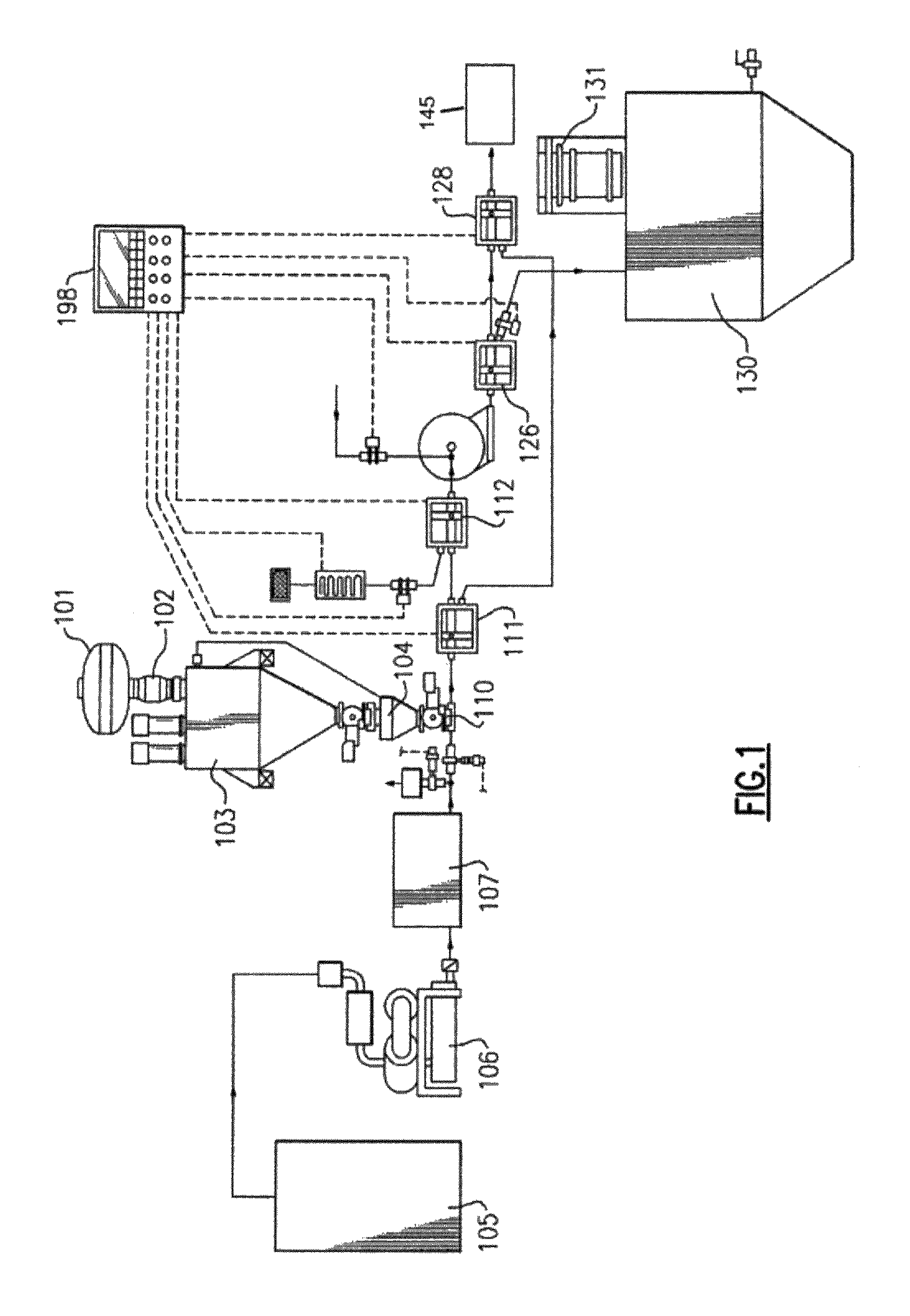

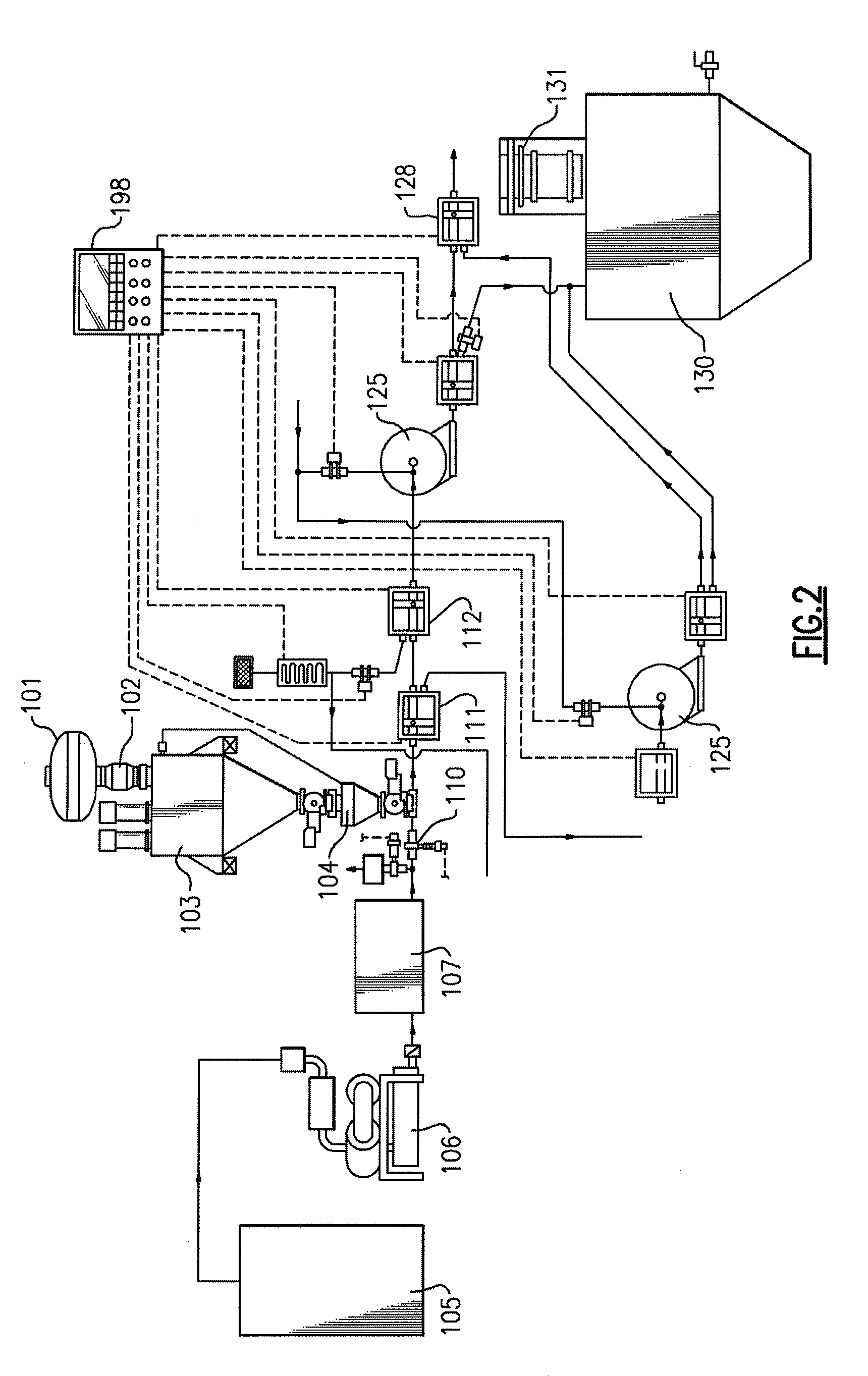

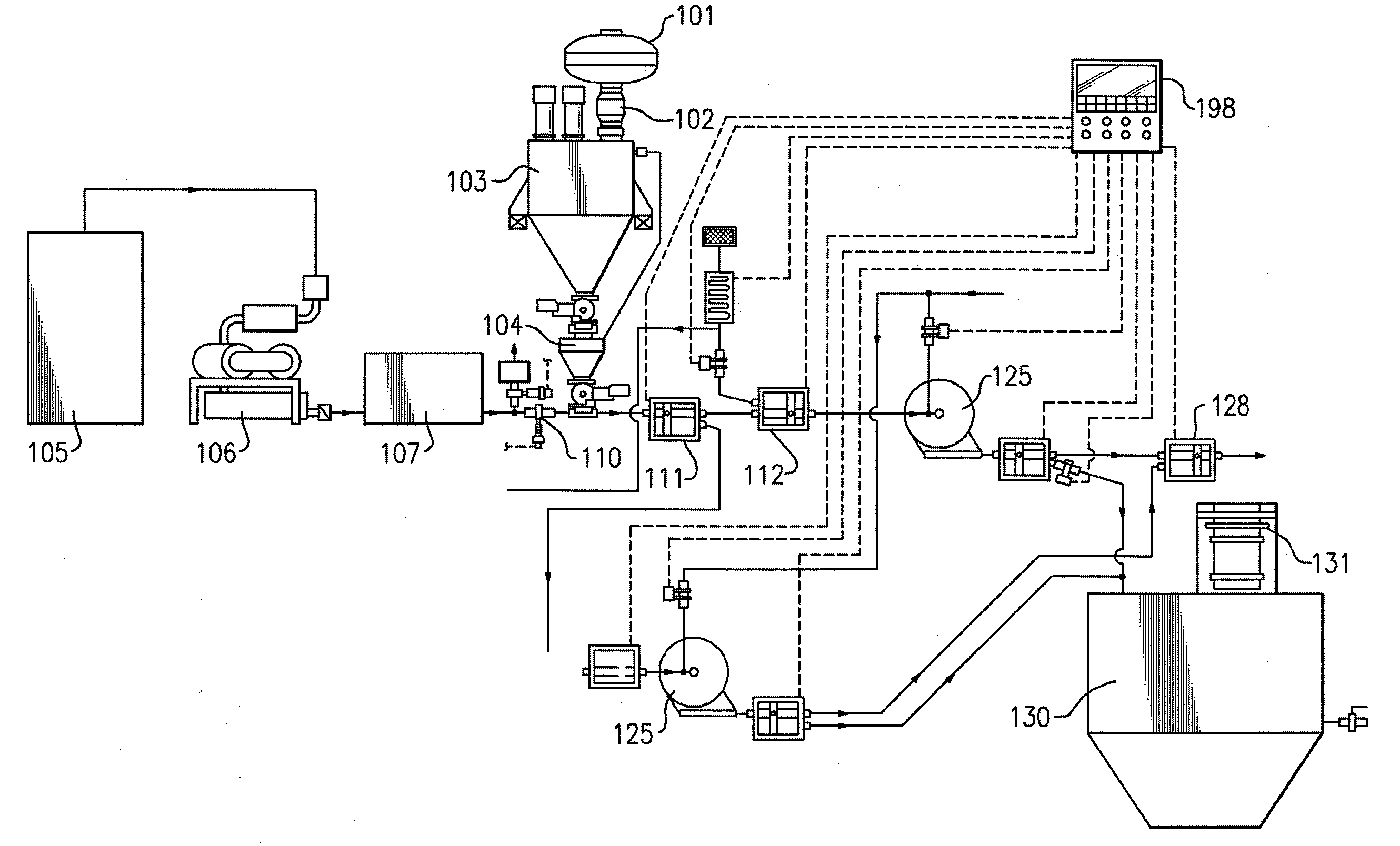

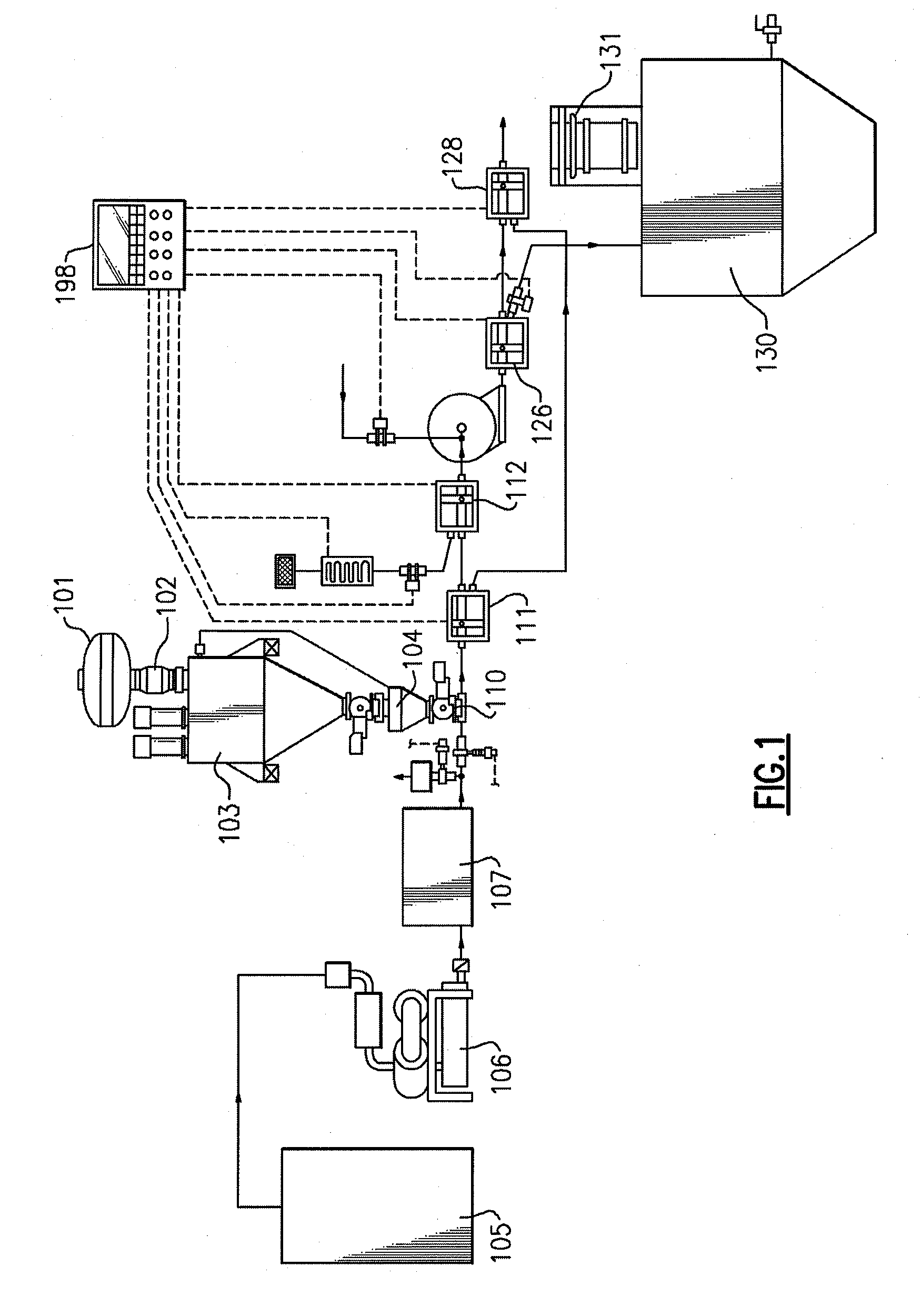

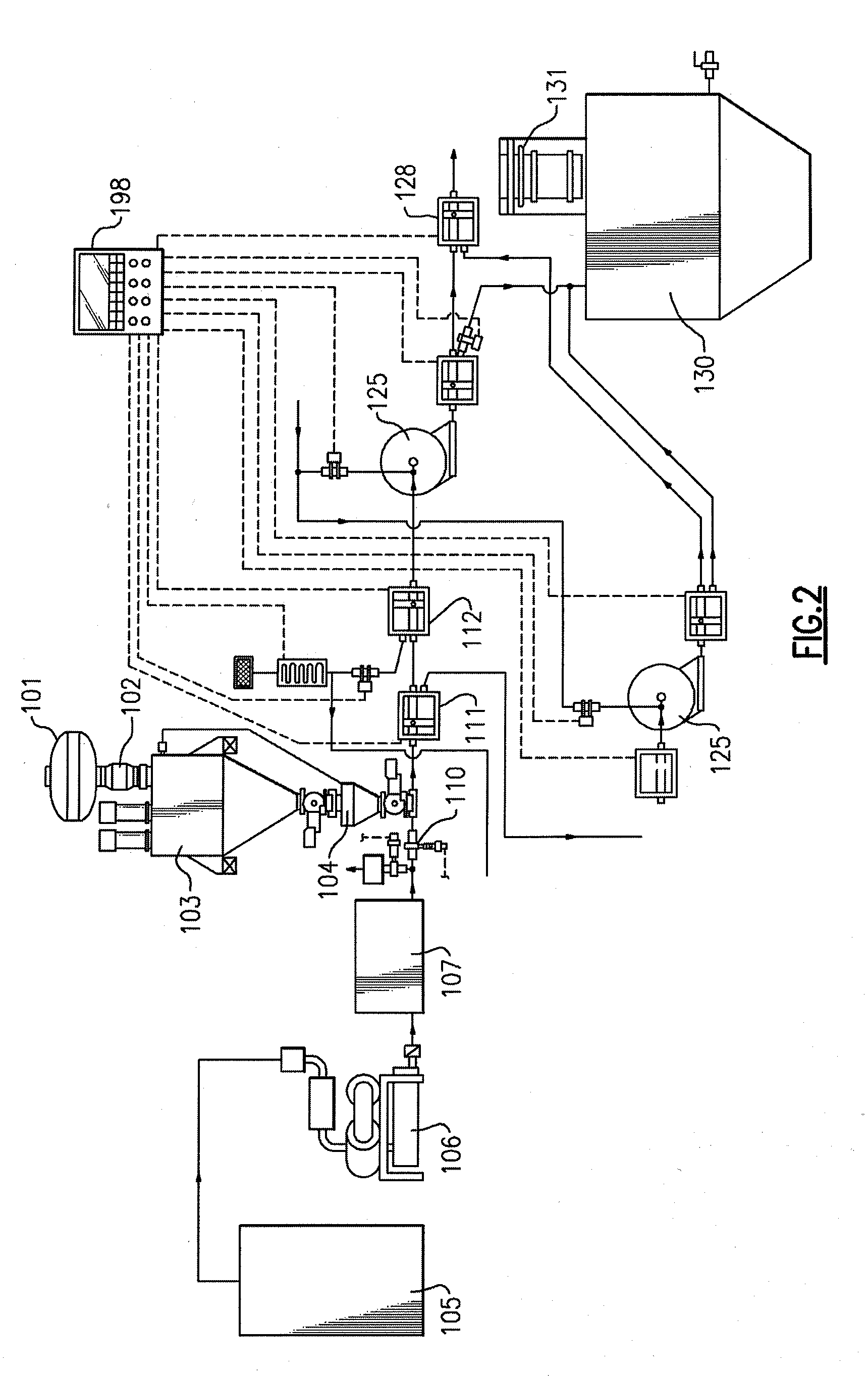

In-line milling system

Owner:OBRIEN & GERE ENGINEERS +1

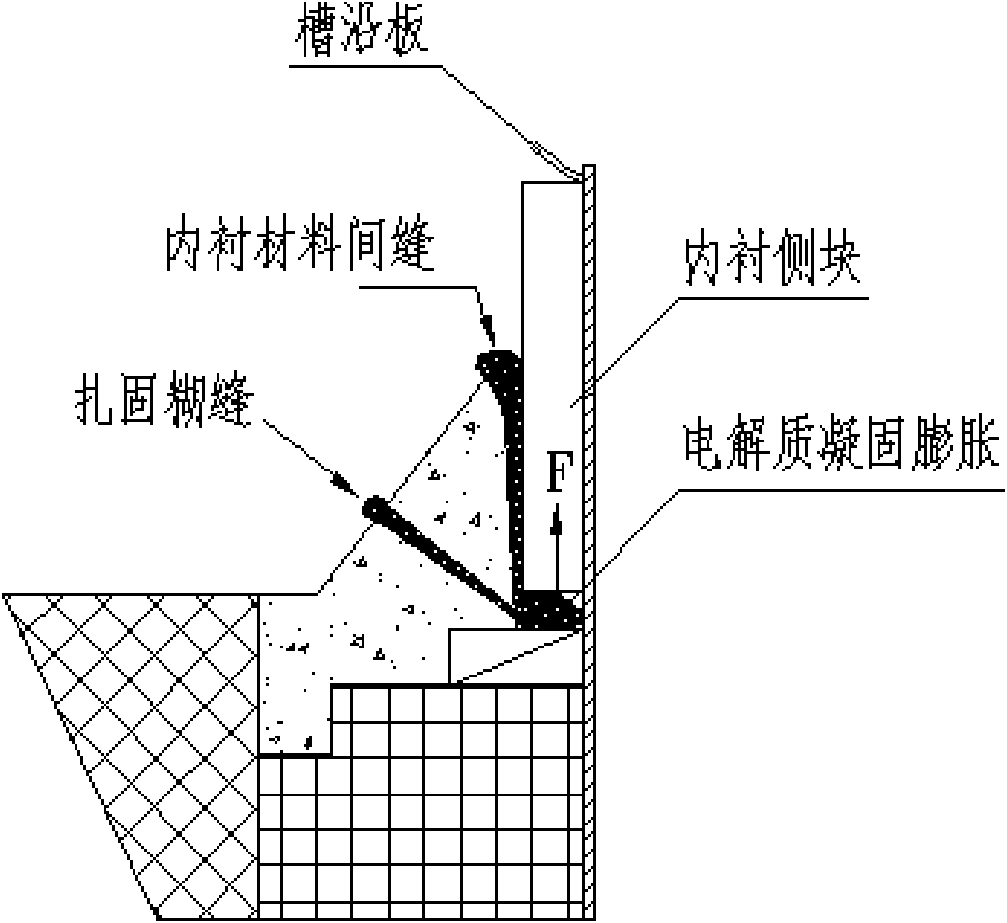

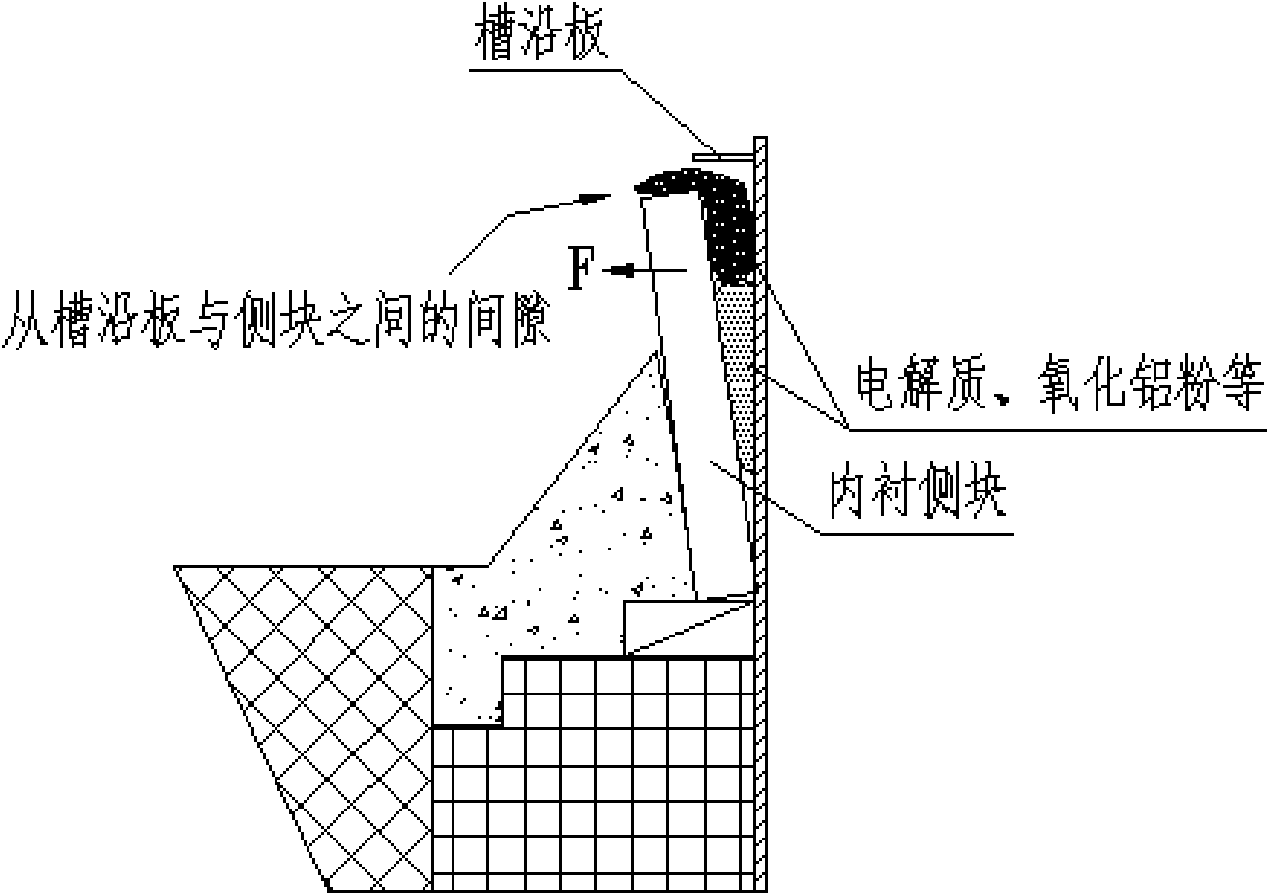

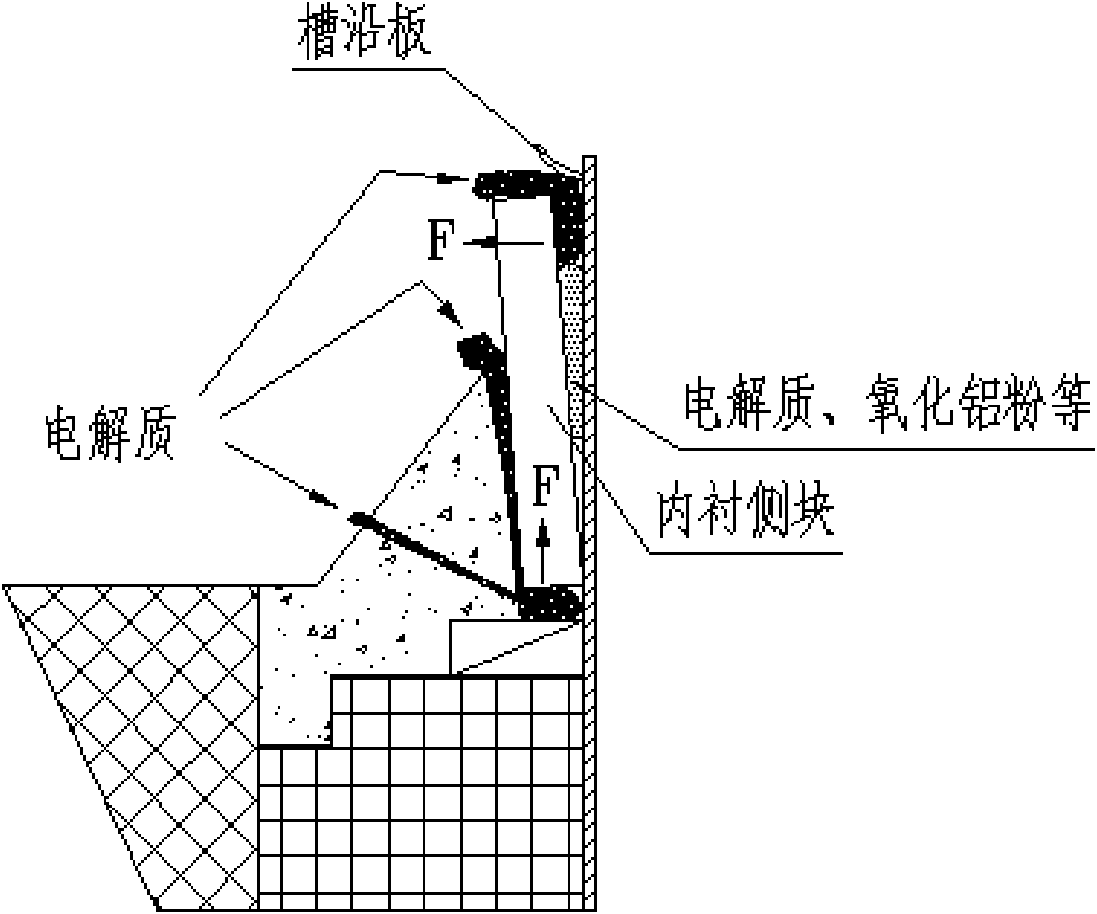

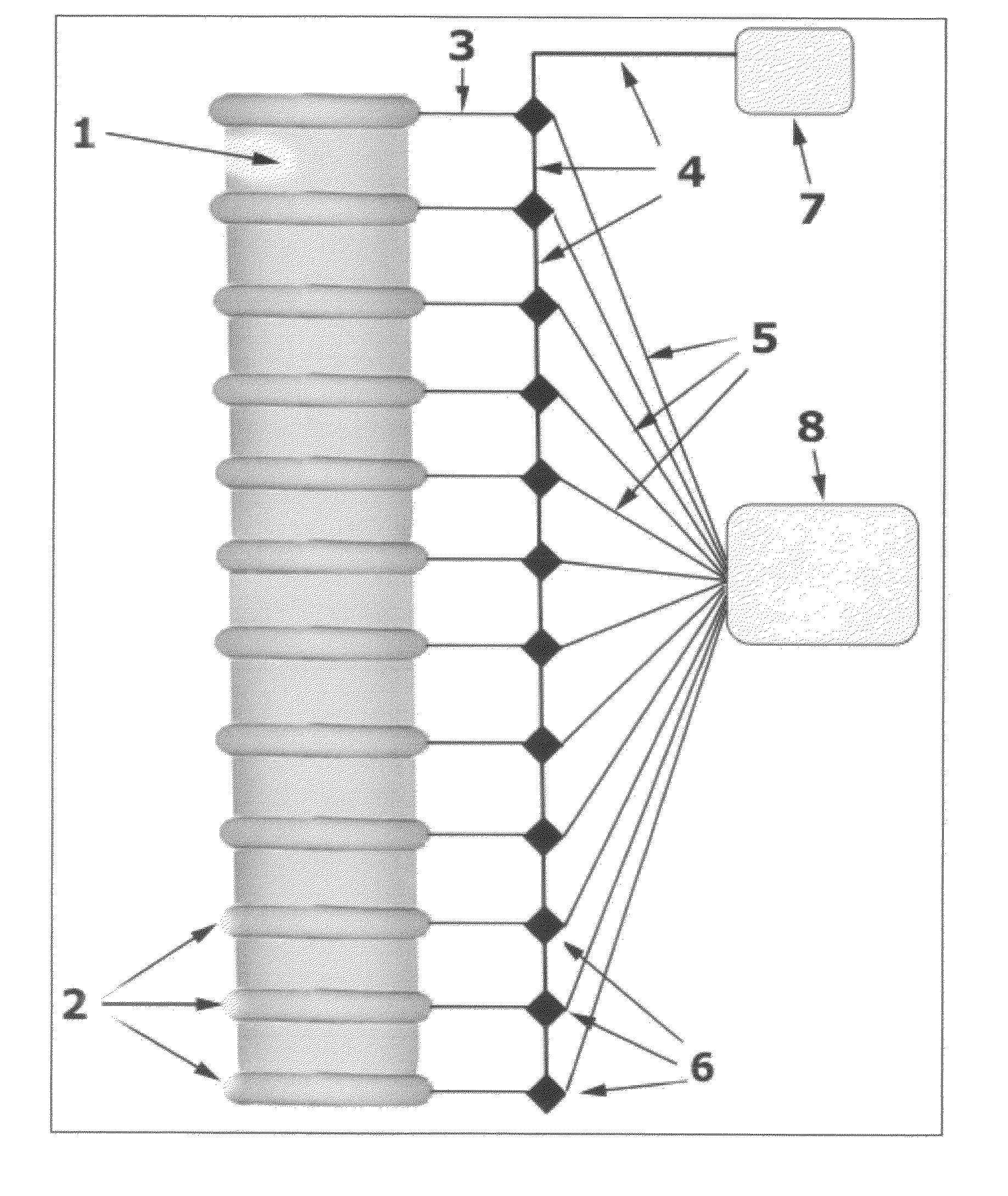

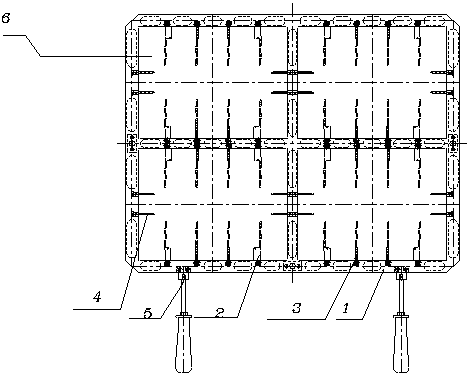

Restraining structure of lateral lining of electrolytic cell

The invention discloses a restraining structure of the deformation of a lateral lining of an electrolysis cell, with low cost and convenient installation. The restraining structure comprises an original cell edge plate (3), a cell shell side plate (4) and a cell shell boarding (5), and a hook-shaped rib plate (1) and a side guard plate (2) are respectively connected with the cell edge plate (3), the cell shell side plate (4) and the cell shell boarding (5). A ramming paste (7) is filled between the bottom surface of the cell edge plate (3) and the top surface of an original lining side block (6). The space between the bottom surface of the cell edge plate (3) and the top surface of the original lining side block (6) is 20-40mm. Compared with the prior art, the invention can effectively restrain the deformation of the lateral lining of the electrolysis cell, thereby preventing the side block from arching up, obliquely arching up or dropping caused by the deformation; the invention can prevent materials of electrolytes, electrolyte and the like from entering space between the side wall of the cell shell and the lining side block; when the pole changing operation is carried out, the invention can also play a role of protecting the lining side block and can greatly reduce the edge sealing workload.

Owner:GUIYANG AL-MG DESIGN & RES INST

Preparation method for genuine leather-imitated braided belt

The invention relates to the field of braided belt dyeing technologies, and provides a preparation method for a genuine leather-imitated braided belt which is uniform to dye and not likely to cause color mixing. The preparation method comprises the following steps: (1) pretreatment; (2) dyeing, namely delivering the braided belt pretreated in the step (1) into a dye vat for dyeing, and adding a deepening agent OP-2, wherein the OP-2 comprises polysiloxane emulsion A and polysiloxane emulsion B, the polysiloxane emulsion A comprises 20-25 parts of octamethylcyclotetrasiloxane, 20-25 parts of an emulsifier, and 0.5 part of a catalyst according to weight parts, and the polysiloxane emulsion B comprises 20-25 parts of octamethylcyclotetrasiloxane, 20-25 parts of an emulsifier, and 5 parts of a catalyst according to weight parts; controlling the pressure at 55-65N in the dyeing process; (3) infrared treatment; (4) drying treatment.

Owner:XINSHENGDA HLDG GRP

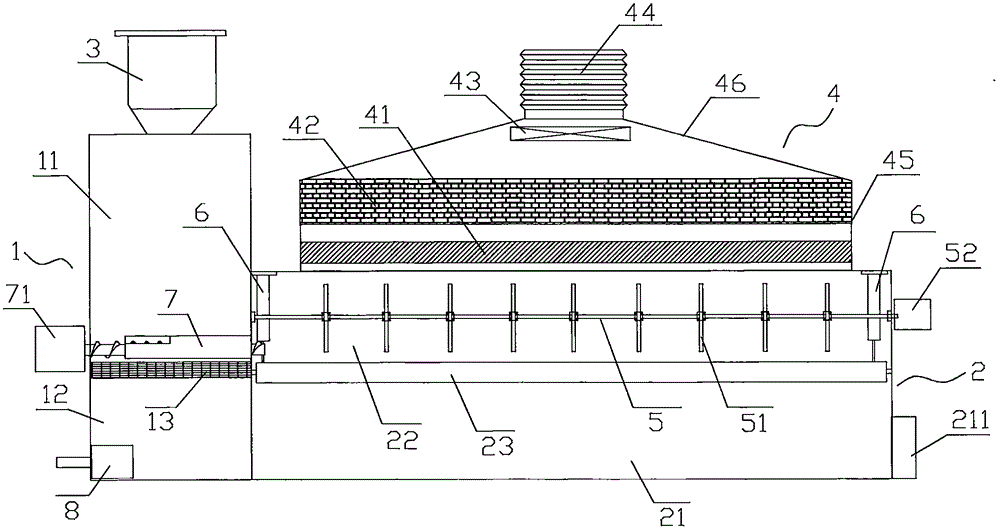

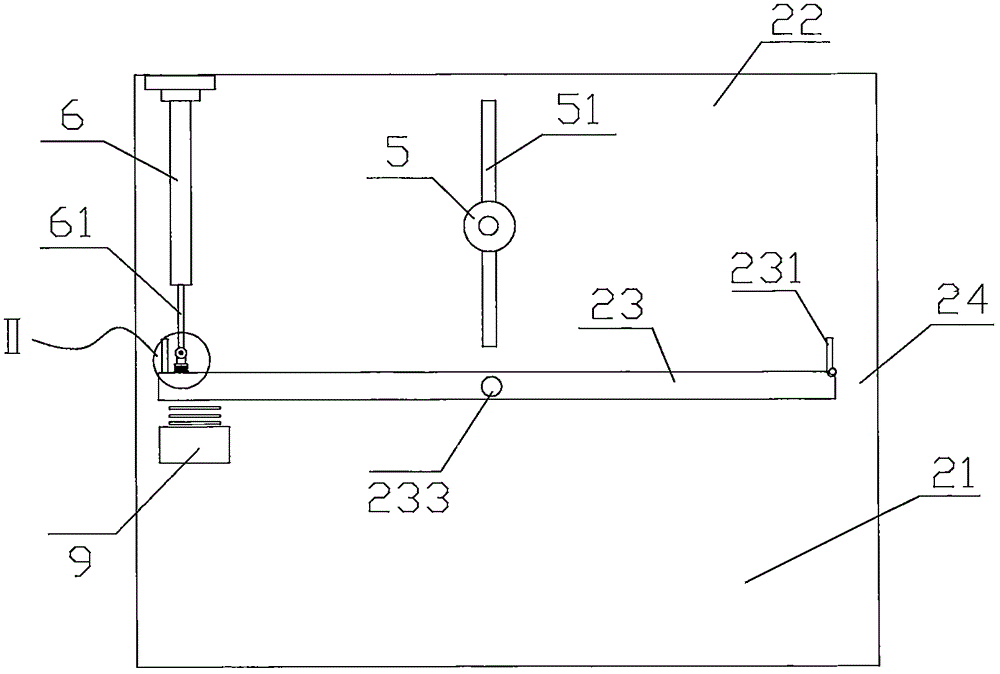

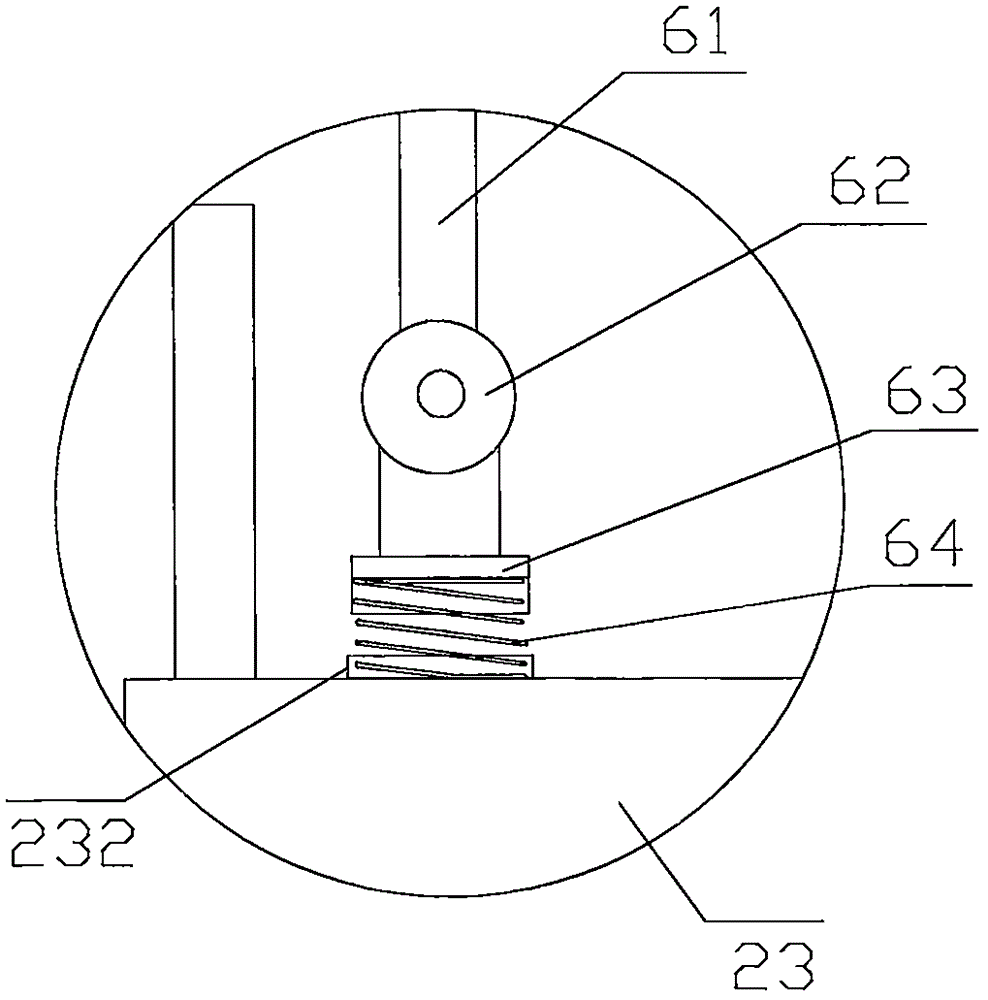

Automatic electrical drying chamber

InactiveCN106196951ALost quicklyAccelerated destructionFireproof paintsAnti-corrosive paintsWater filterEvaporation

The invention discloses an automatic electrical drying chamber. The automatic electrical drying chamber comprises a drying room, a feeding chamber connected to one side of the drying room, and a deodorization chamber arranged on the top of the drying room and communicating with the drying room. A flat-plate-shaped high-frequency electromagnetic drying plate is arranged in the drying room. The high-frequency electromagnetic drying plate divides a cavity of the drying room into an upper evaporation cavity and a lower dry material storage cavity. A guide rod air cylinder is connected between the inner side edge of the high-frequency electromagnetic drying plate and the room roof of the drying room. A high-frequency vibration device is arranged below the inner side edge of the high-frequency electromagnetic drying plate. A buffering device is arranged between a guide rod of the guide rod air cylinder and the plate face of the high-frequency electromagnetic drying plate. The tail end of the guide rod is rotationally connected with the buffering device. A water filtering plate is arranged in the feeding chamber, and the feeding chamber is divided into an upper wet material storage cavity and a lower dirt water storage cavity. A spiral feeding rod is arranged at the position, close to the upper end face of the water filtering plate, of the wet material storage cavity, and a deodorization plate and a water absorbing plate are arranged in the deodorization chamber. The drying chamber is compact in structure and high in drying efficiency.

Owner:LIAONING INST OF SCI & TECH

In-line milling system

ActiveUS20090194618A1Minimize downtimeImprove throughputGas treatmentElectric controllersProcess engineeringMechanical engineering

The present invention provides an in-line system for milling sorbent material to be used in a pneumatic conveying system. The system provides for optimal particle size in a duct injection system, regardless of the original sorbent particle size, and is designed to prevent clogging of the milled material through the system. Methods of operation for milling, as well as cleaning the mills while providing various sorbent material by-pass configurations to minimize system down-time while enhancing material throughput and that support the unique aspects of the system, are also described in detail below.

Owner:OBRIEN & GERE ENGINEERS +1

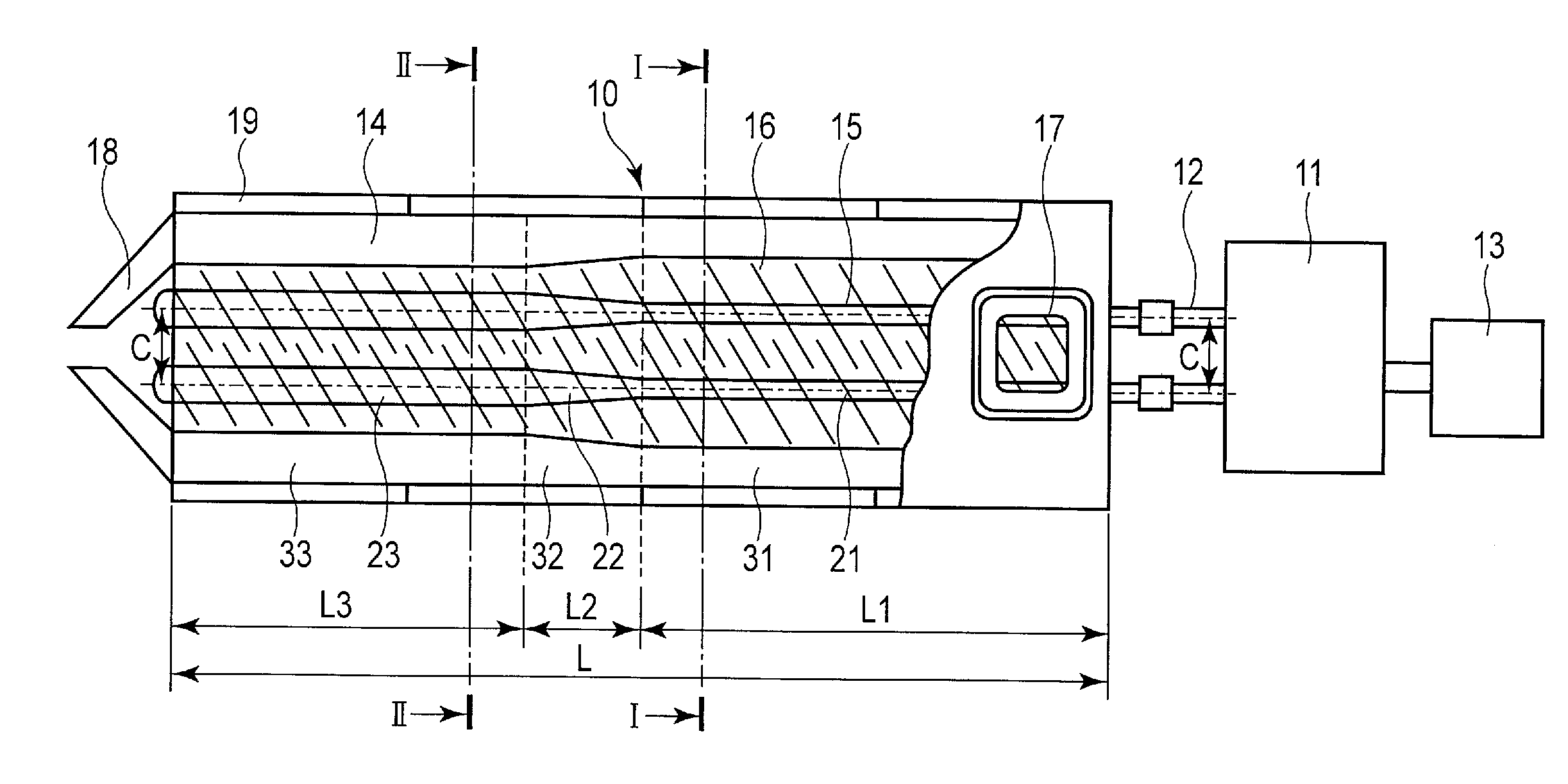

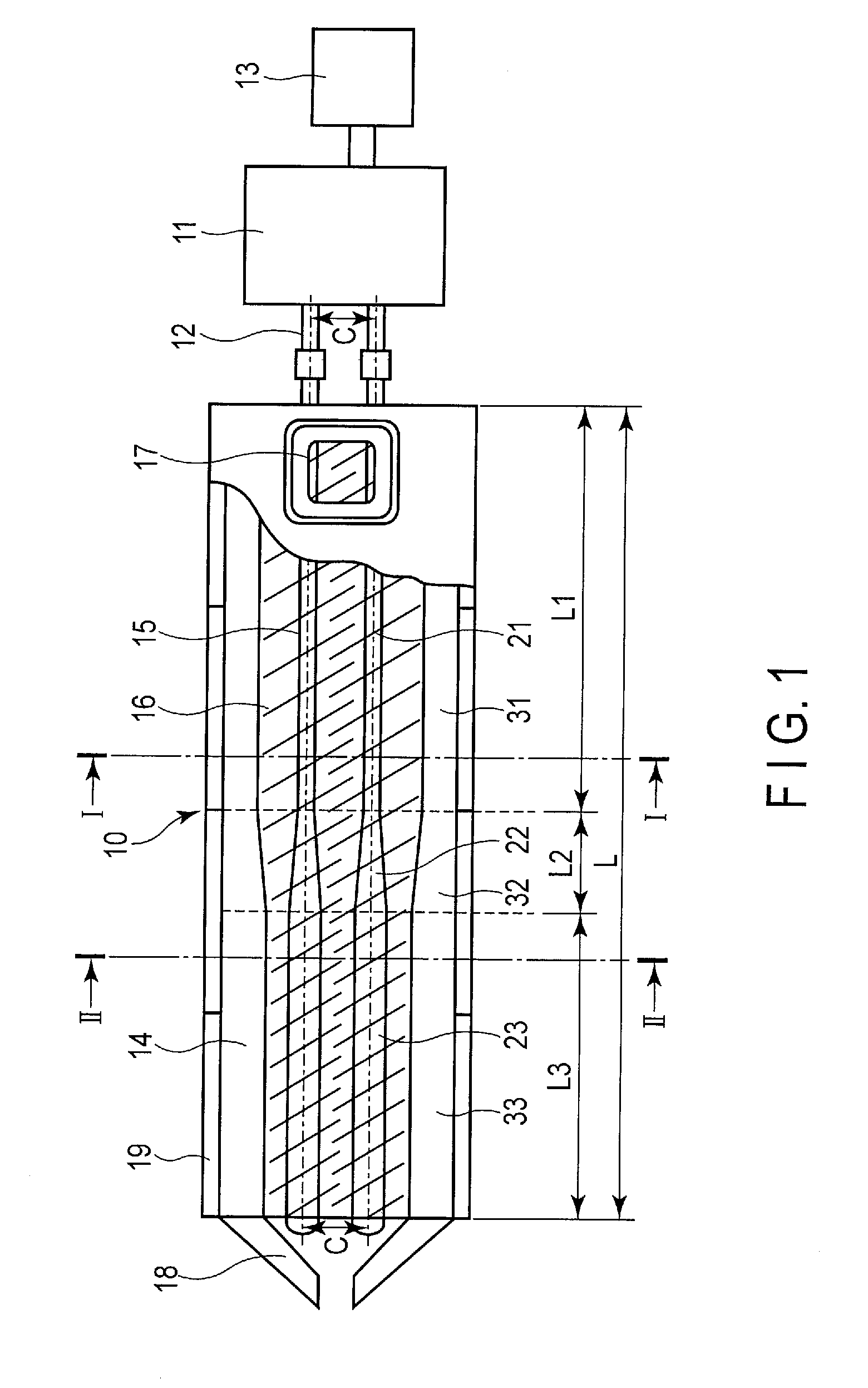

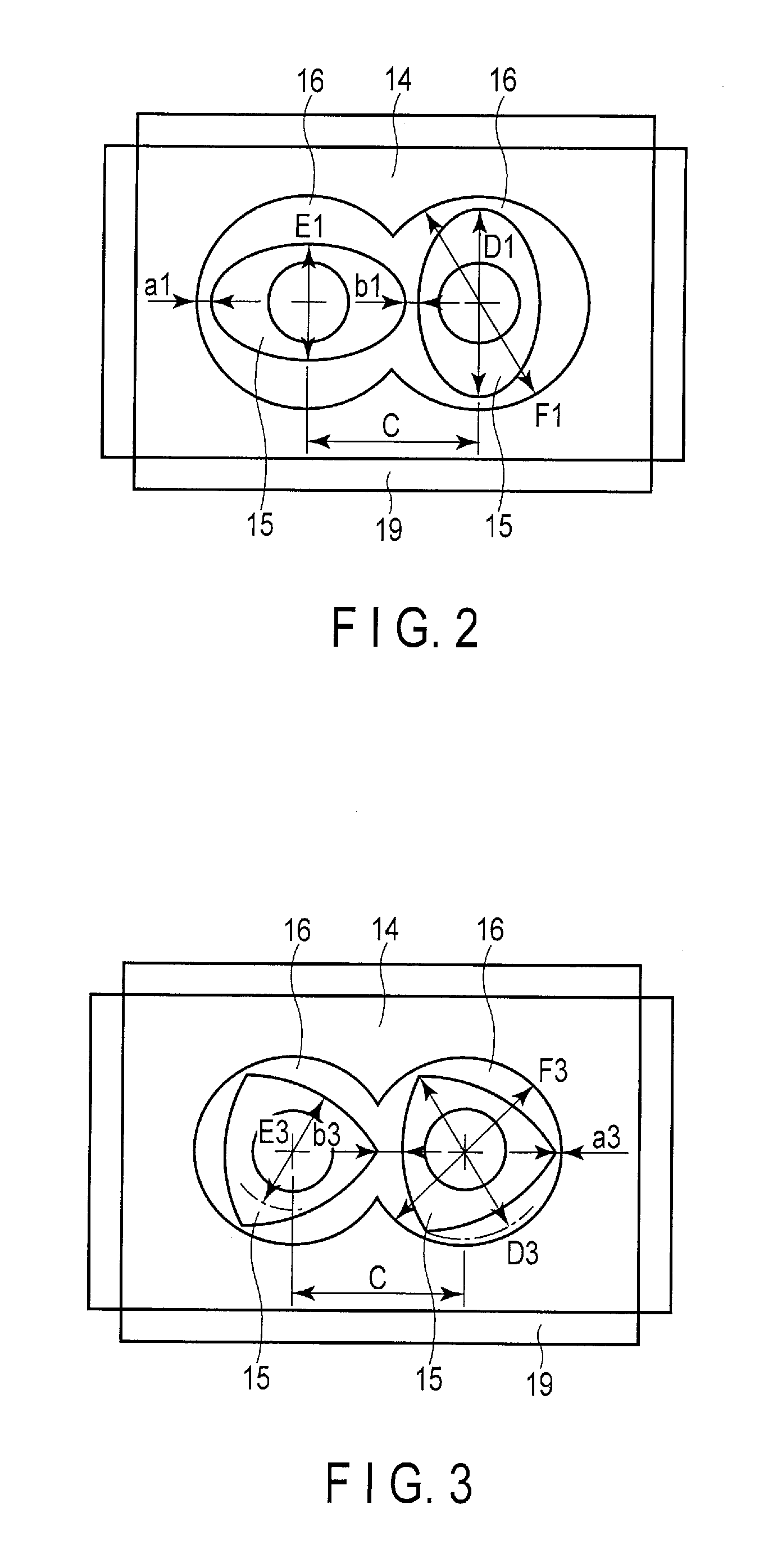

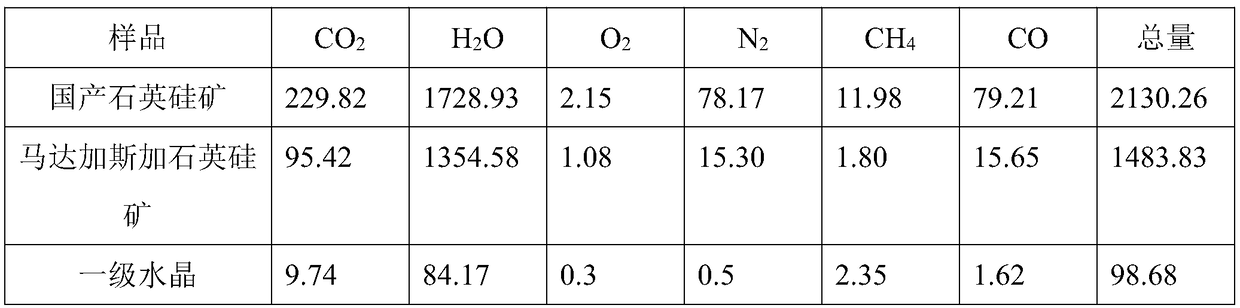

Twin-screw extruder and kneading method using twin-screw extruder

ActiveUS20160207225A1Large amount of materialImprove productivityConfectioneryCeramic shaping apparatusProduction rateEngineering

One embodiment provides a twin-screw extruder which is used to knead materials and has excellent productivity. The twin-screw extruder includes screws. The screws include double thread screws in which first screw portions engage with each other. Ratio D1 / C of external diameter D1 of the first screw portion to a shaft distance C ranges from 1.25 to 1.40. The screws further include triple thread screws in which third screw portions engage with each other. Ratio D3 / C of external diameter D3 of the third screw portion to the shaft distance C ranges from 1.05 to 1.10. External diameter D2 of a second screw portion decreases gradually from the first screw portion toward the third screw portion.

Owner:TOSHIBA MASCH CO LTD

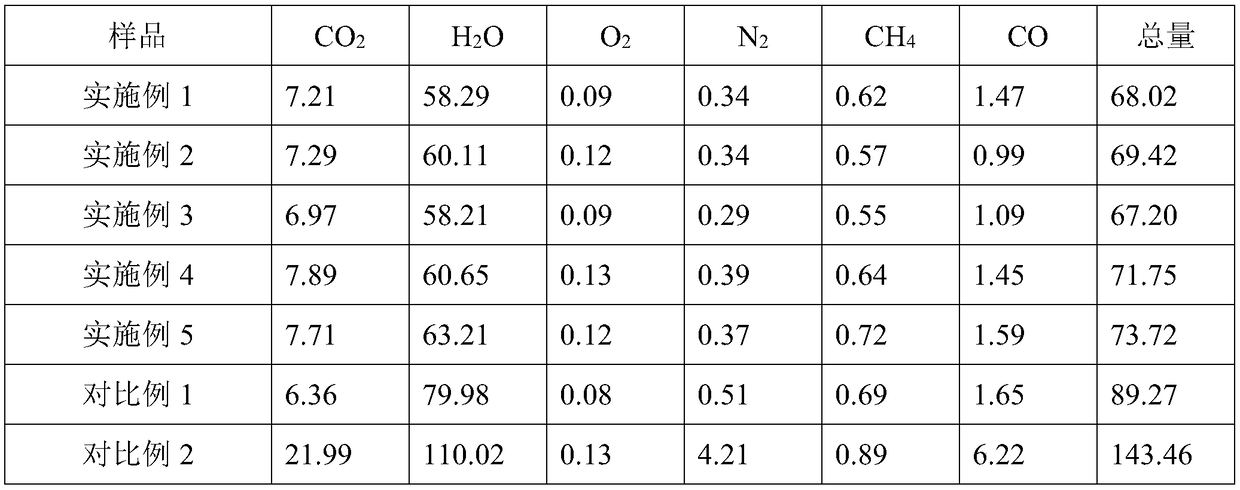

Ultra-pure color-spot-free high-end fully-transparent quartz material and preparation method and application thereof

The invention discloses an ultra-pure color-spot-free high-end fully-transparent quartz material and a preparation method and application thereof. Domestic quartz silicon ores are subjected to purification treatment through the processing steps of concentration of quartz silicon ores, water quenching, aqua regia impurity removing, esterification, floatation, magnetic separation, high-temperature vacuum treatment, ultrasonic purification and the like, and the ultra-pure quartz material for preparing color-spot-free high-end fully-transparent quartz glass ingots can be obtained. According to theultra-pure color-spot-free high-end fully-transparent quartz material and the preparation method and the application thereof, by combining the requirement for industrial production scales, the technological conditions for microwave processing and production of the ultra-pure color-spot high-end fully-transparent quartz material are further improved; particularly for the source of ultra-pure quartz raw materials in China, the production technological conditions for producing the ultra-pure quartz raw materials by the domestic quartz silicon ores are truly provided, the production technologicalconditions are mature and reasonable and have a stable technical effect, and technological supports are provided for scale production of the ultra-pure quartz glass ingots, and truly lowering of theproduction cost of the ultra-pure quartz glass ingots.

Owner:HUNAN UNIV OF TECH

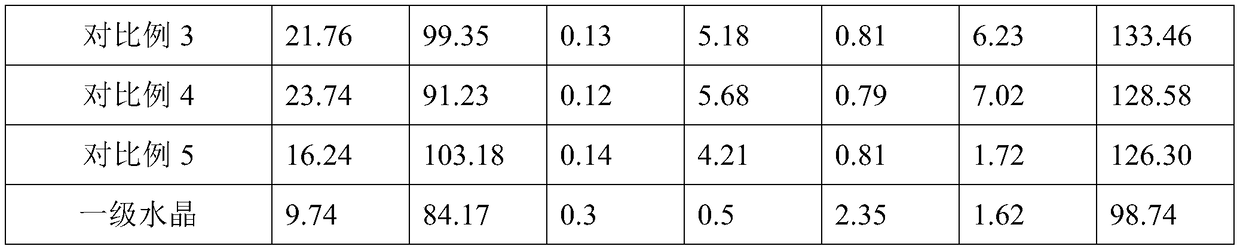

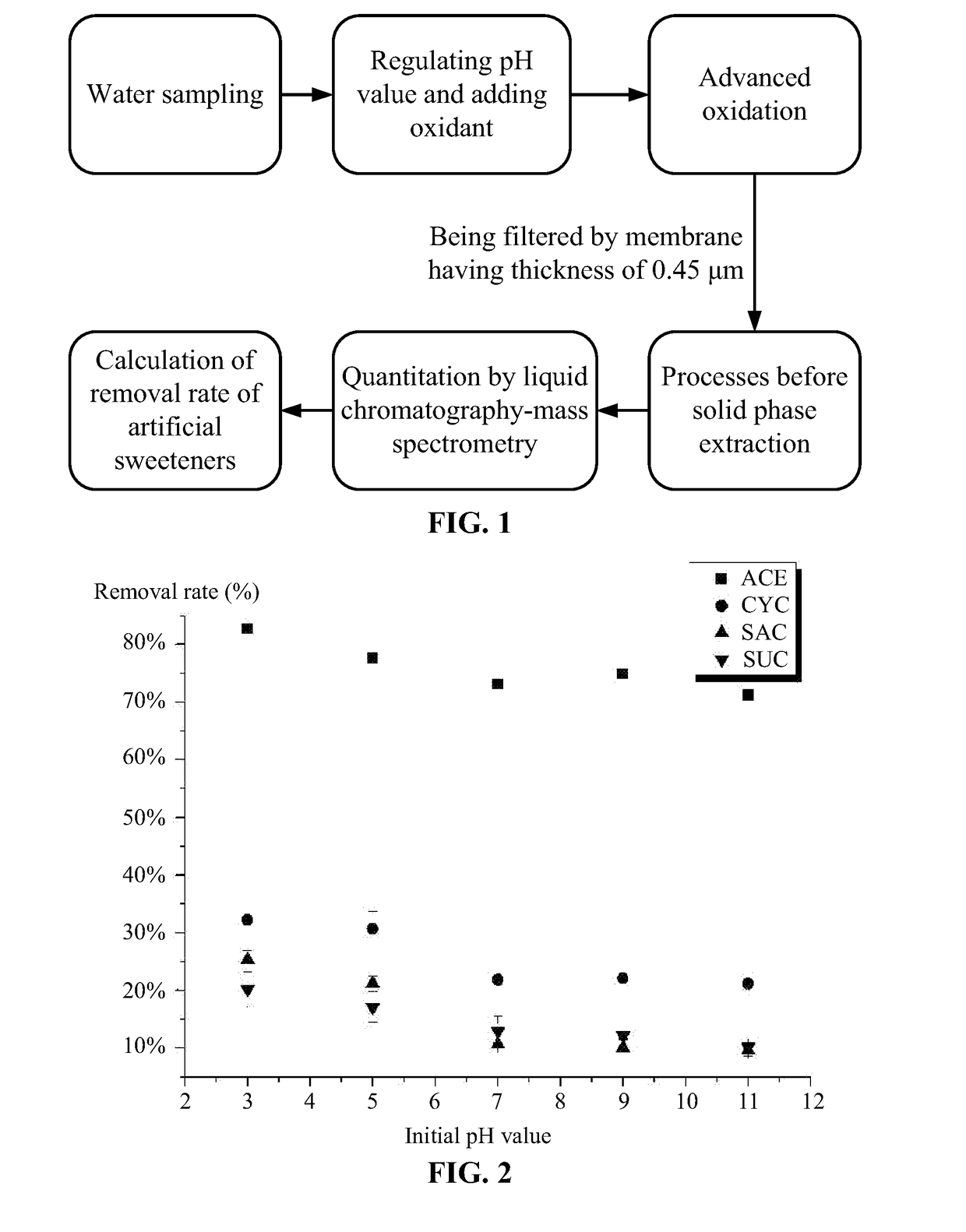

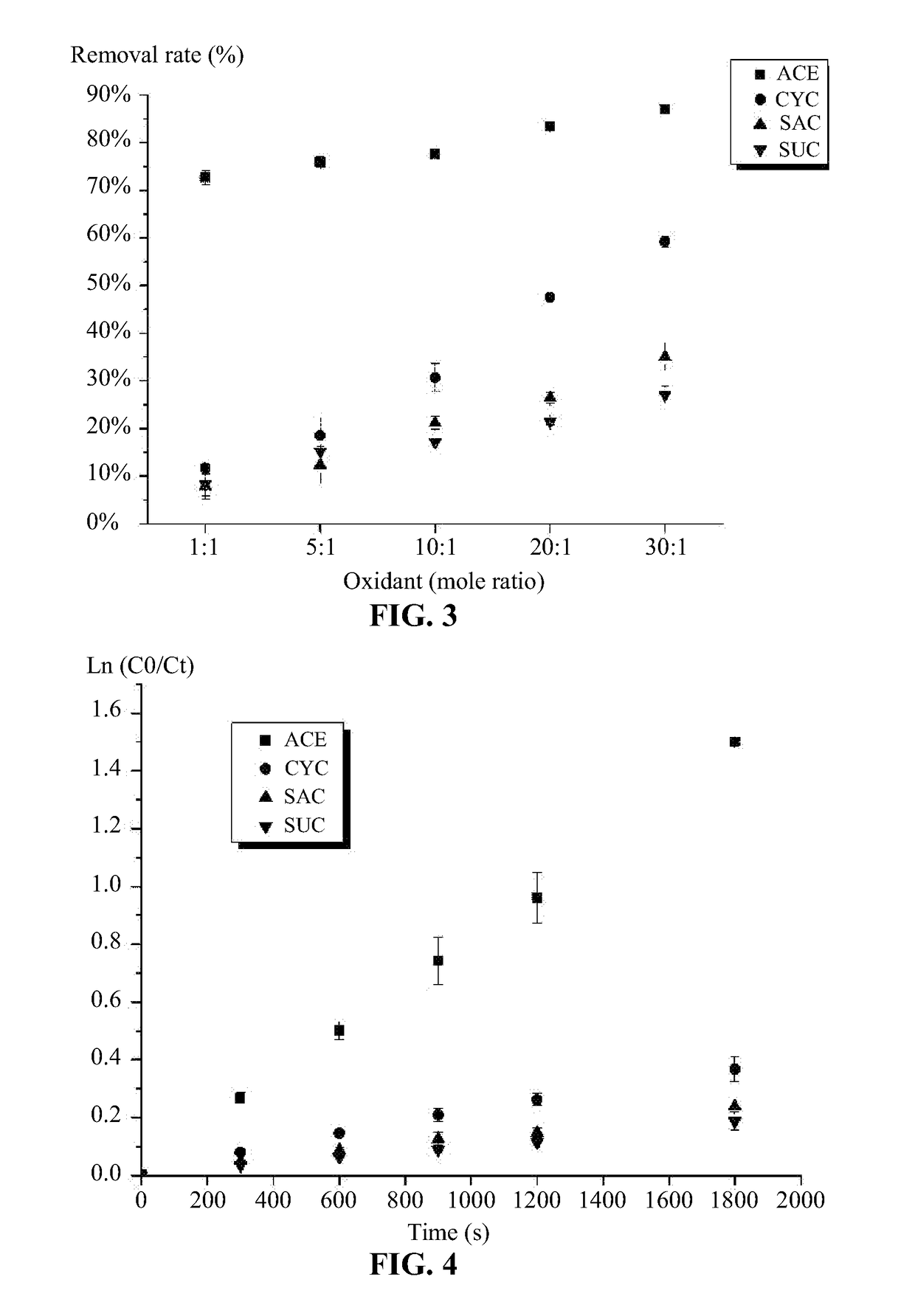

Method for degrading artificial sweeteners from sewage

InactiveUS20170267564A1Large amount of materialInefficient in degrading artificial sweeteners.Water/sewage treatment by irradiationWater treatment compoundsUltraviolet lightsSewage

A method for degrading artificial sweeteners from sewage, the method including: 1) introducing sewage to a secondary sedimentation tank and precipitating sediments; 2) collecting a supernatant from the secondary sedimentation tank, adding a NaOH solution or a perchloric acid solution to regulate the pH; adding an H2O2 solution to the supernatant to adjust a ratio of a molar concentration of H2O2 to a molar concentration of the sweetener in the resulting mixed solution to be between 1:1 and 30:1; transferring the resulting mixed solution to a photoreactor, irradiating the mixed solution by ultraviolet light, and stirring the mixed solution for between 5 and 30 min; and adding a 1.5% w / w aqueous NaNO2 solution to the mixed solution; and 3) collecting and analyzing an effluent obtained from 2), contacting the effluent with ClO2 for reaction in a disinfecting tank, and discharging the product.

Owner:NANJING UNIV

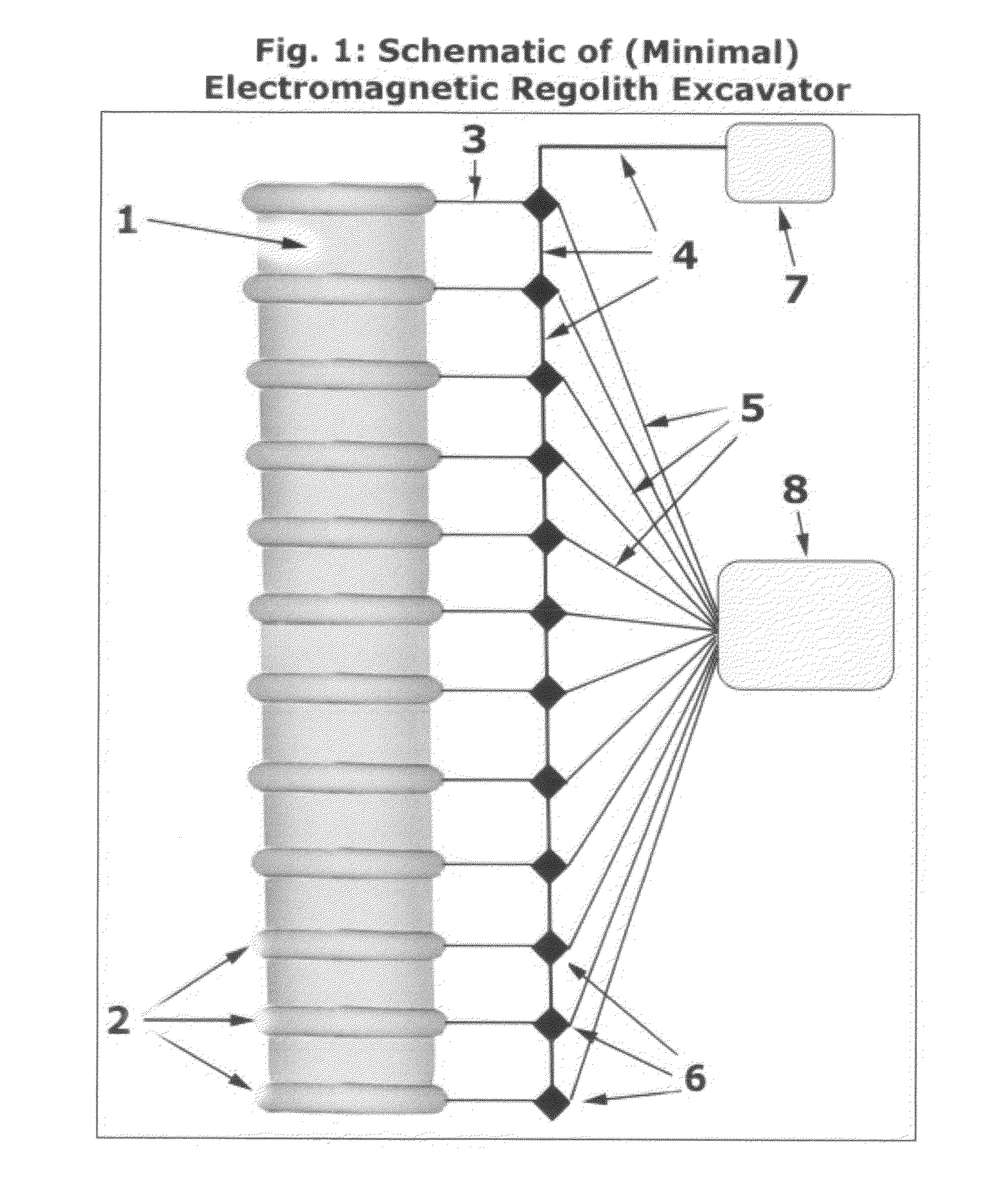

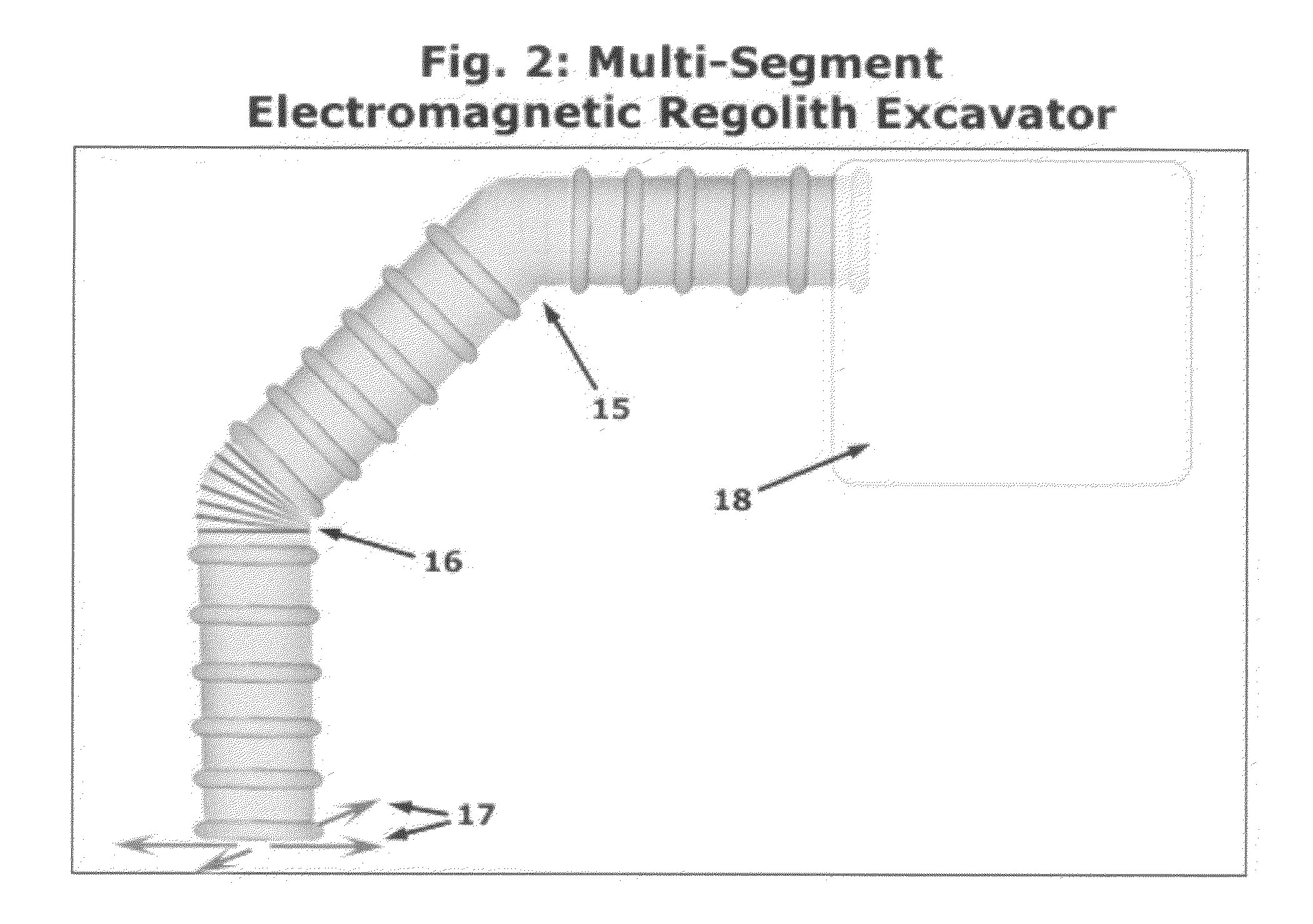

Electromagnetic Regolith Excavator

InactiveUS20140345168A1Large amount of materialMove quicklyMachines/dredgers working methodsMechanical machines/dredgersMagnetiteNon magnetic

Decades of research and development have been invested in various forms of railguns, coilguns and mass drivers. See http: / / settlement.arc.nasa.gov / 75SummerStudy / Table_of Contents1.htmlResearch at the Space Studies Institute in the 1980s refined the mass driver concept. See http: / / ssi.org / introduction-to-research / research-report / # mass-driver-iiiThe innovation of the Electromagnetic Regolith Excavator is to eliminate the use of a bucket or other container that is accelerated by the magnetic fields. Instead, magnetic particles in the regolith itself (nickel-iron grains and / or magnetite) are put into motion and they carry along with them a to-be-determined fraction (perhaps all) of the co-resident non-magnetic regolith particles.The Electromagnetic Regolith Excavator applies only attractive forces: no anchoring is required. This enables robotic and crewed spacecraft to safely collect surface material from asteroid targets that may be tumbling. Because no hard connection is required, no strong hazardous forces can be imparted to the collection apparatus aboard the spacecraft.

Owner:COVEY STEPHEN D

Loading frame for lead frame with staggered pins

ActiveCN102709218APlace stableIncreased die surface utilizationSemiconductor/solid-state device manufacturingEngineeringLead frame

The invention discloses a loading frame for a lead frame with staggered pins. The loading frame comprises a frame body (1) and two handles (5), wherein the two handles (5) are fixedly connected to one side of the frame body (1); a plurality of support frames (6) which are used for supporting the lead frame with the staggered pins are arranged in the frame body (1); support strips are fixedly connected to horizontal frame lines of the support frames (6); and the shape of each support strip is consistent with that of a gap between every two staggered pins of the lead frame. The support strips, each of which the shape is consistent with that of the gap between every two staggered pins of the lead frame, extend to the staggered pins of the lead frame to support the lead frame, so that the modular surface utilization rate is increased; the lead frame can be placed more stably by a support plate; and due to adoption of four lead frames, the loading amount is larger, and 8 lead frames can be loaded once.

Owner:TONGLING SANJIA YAMADA TECH

Bucket-wheel stacker-reclaimer

ActiveCN106315246ASolve the realization of stacking and reclaimingStacking adjustableLoading/unloadingMechanical conveyorsReclaimerPortal frame

The invention discloses a bucket-wheel stacker-reclaimer. The bucket-wheel stacker-reclaimer comprises a rotary portal frame part, a bucket-wheel material taking part, a conveying part and a centering rotating mechanism, wherein the rotary portal frame part rotates around the centering rotating mechanism by taking a span of the rotating portal frame as the radius, and the bucket-wheel material taking part and the conveying part are connected to the rotating portal frame. The conveying part is composed of a plurality of belt conveyors and is matched with the bucket-wheel material taking part to form a material taking material flow channel and / or a material stacking material flow channel. Different from existing equipment, the stacker-reclaimer, taking the span of the portal frame as the actual working range radius, is applied to a round stockyard initiatively.

Owner:TIDFORE HEAVY IND

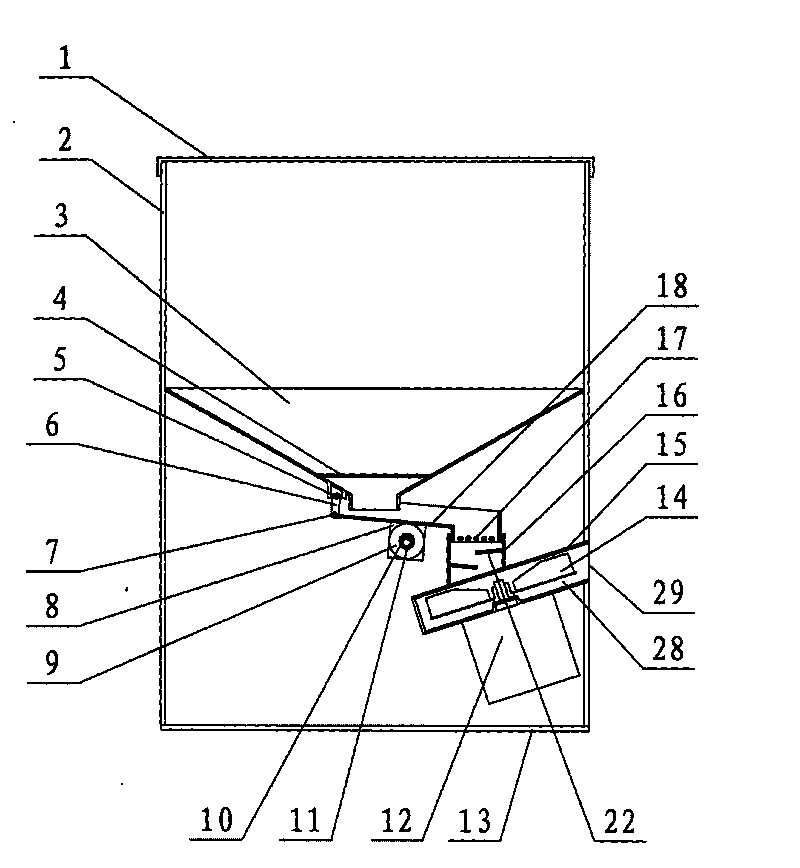

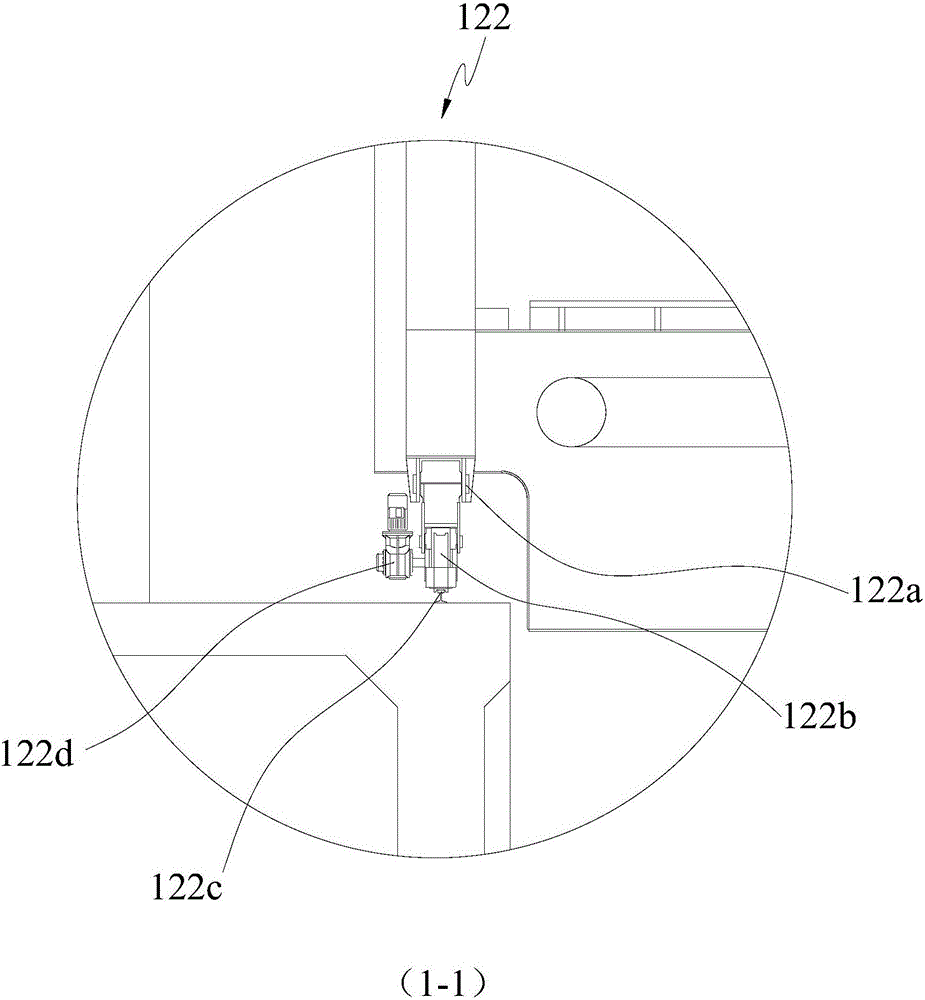

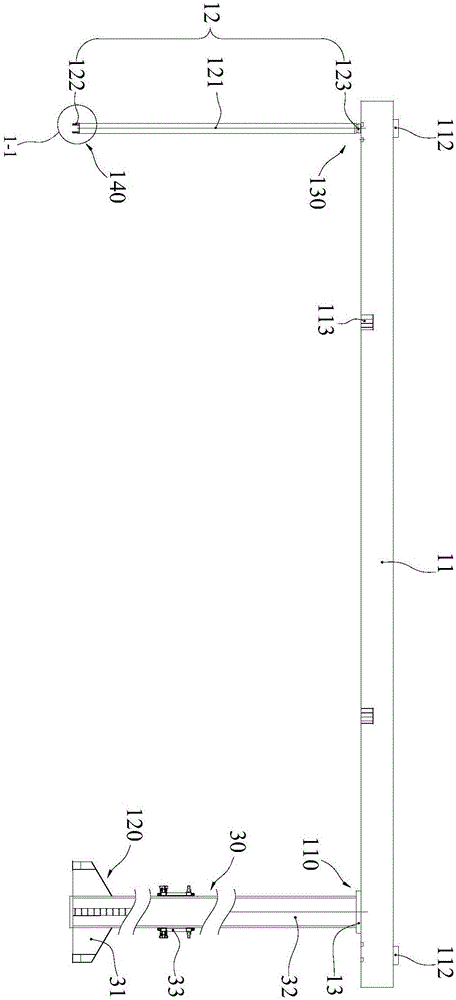

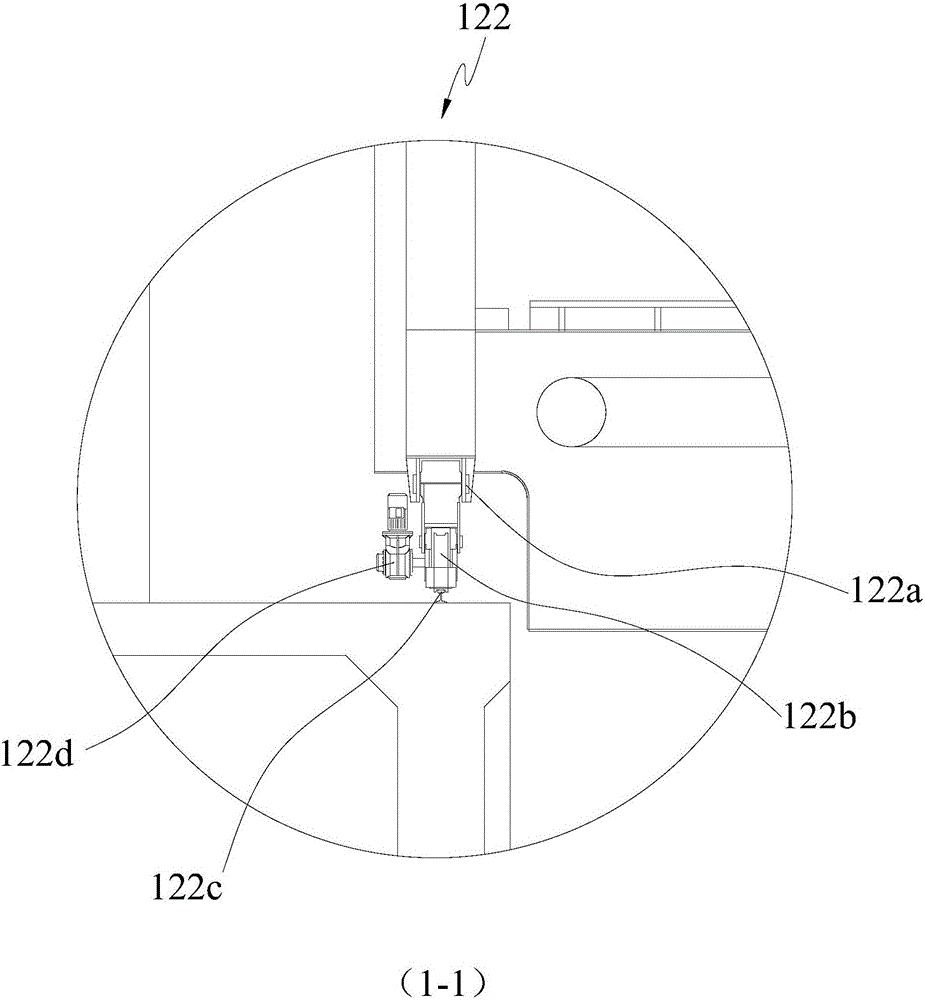

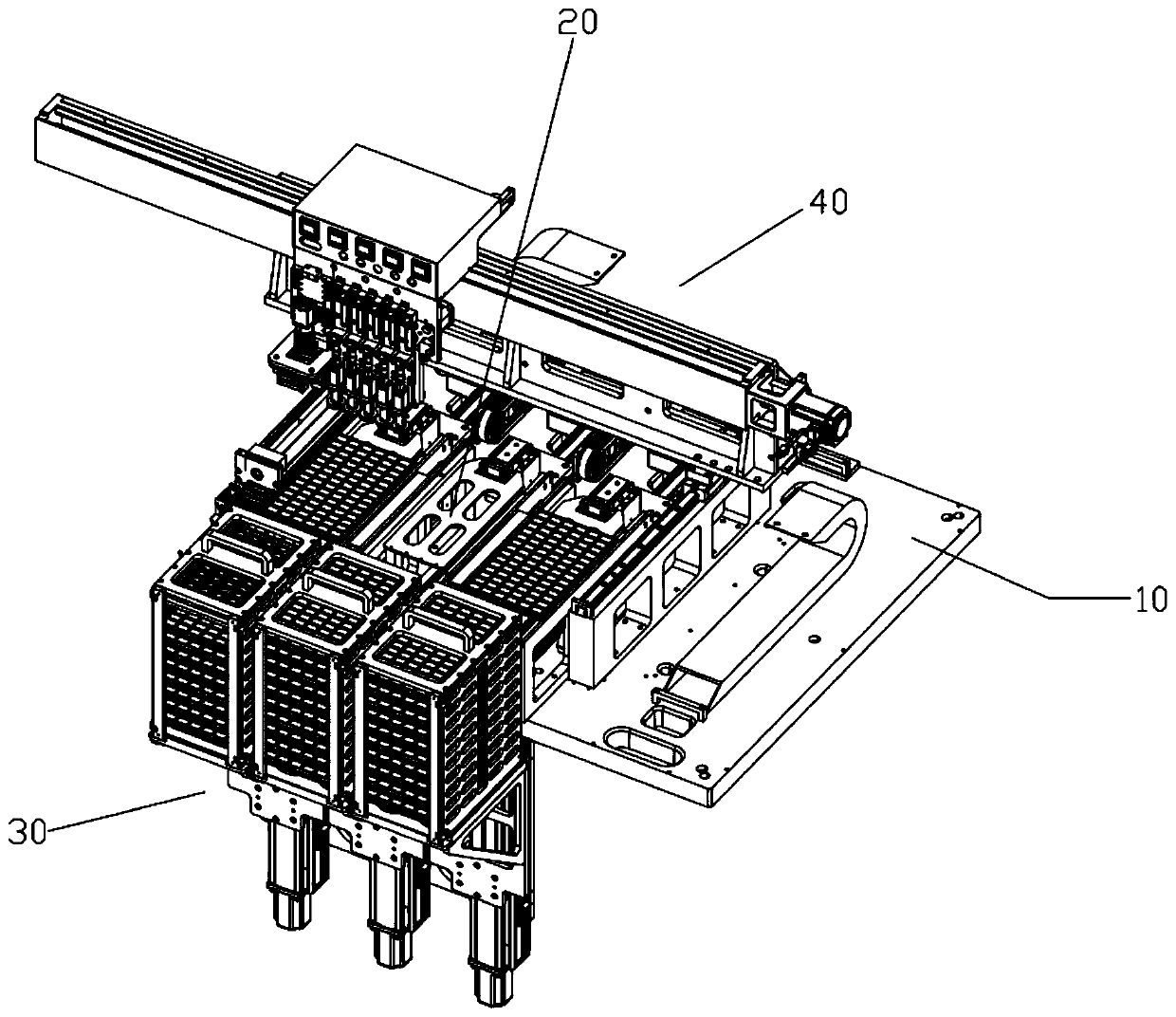

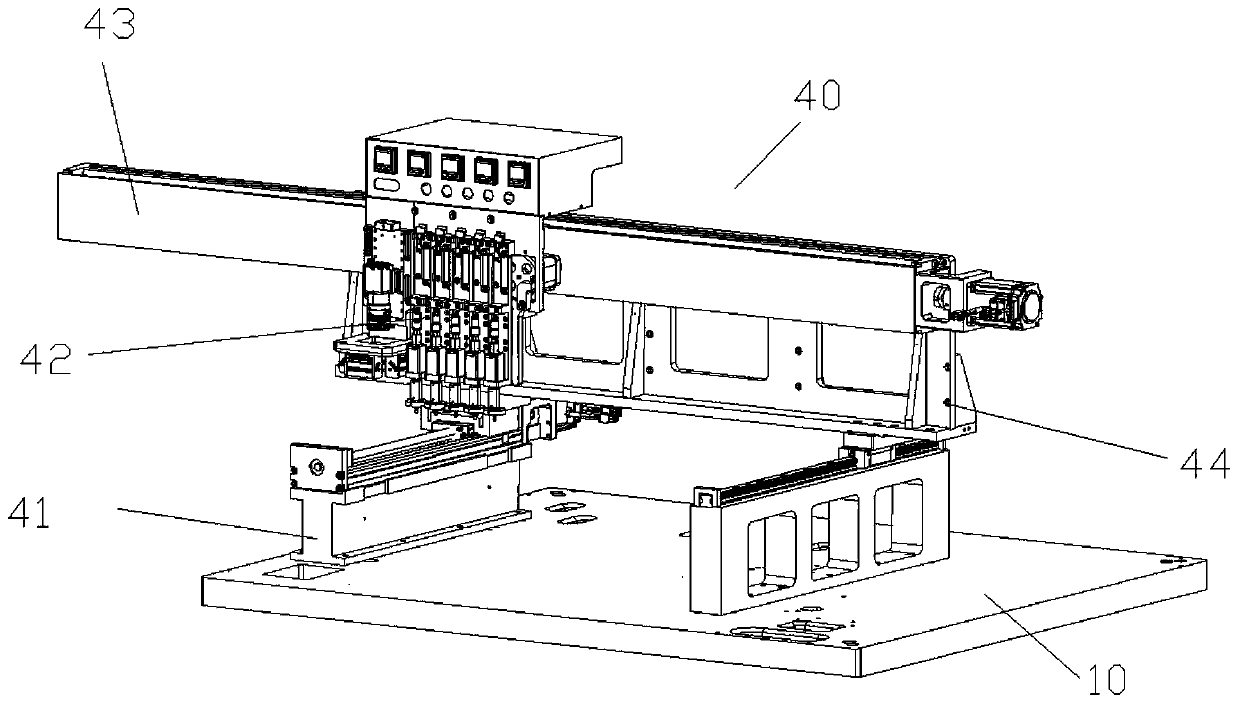

Automatic feeding and discharging mechanism for testing mobile phone camera module equipment

PendingCN111003506AImprove test efficiencyLarge amount of materialConveyor partsEngineeringCamera module

The invention discloses an automatic feeding and discharging mechanism for testing mobile phone camera module equipment. The automatic feeding and discharging mechanism comprises a mounting table, multiple sets of conveying mechanisms which are transversely arranged on the mounting table side by side, a bin lifting mechanism which is vertically arranged on one side of the mounting table corresponding to the conveying mechanism and is positioned at the feeding end of the conveying mechanism, and a material taking and placing mechanism which is longitudinally erected above the conveying mechanisms and provided with a plurality of sets of air suction nozzles arranged side by side and used for taking and placing materials from the conveying mechanism. By adopting the above technical scheme, asthe multiple sets of conveying mechanisms are transversely arranged on the mounting table side by side, the bin lifting mechanism is vertically arranged on one side of the mounting table corresponding to the conveying mechanism and is positioned at the feeding end of the conveying mechanism, the material taking and placing mechanism is longitudinally erected above the multiple sets of conveying mechanisms, material taking and placing are conducted on the multiple camera modules on the conveying mechanisms through the multiple sets of air suction nozzles which are arranged on the material taking and placing mechanism side by side, the feeding amount each time is large, the feeding and discharging time is shortened, and the testing efficiency of the camera modules is improved.

Owner:佛山市旭研自动化科技有限公司

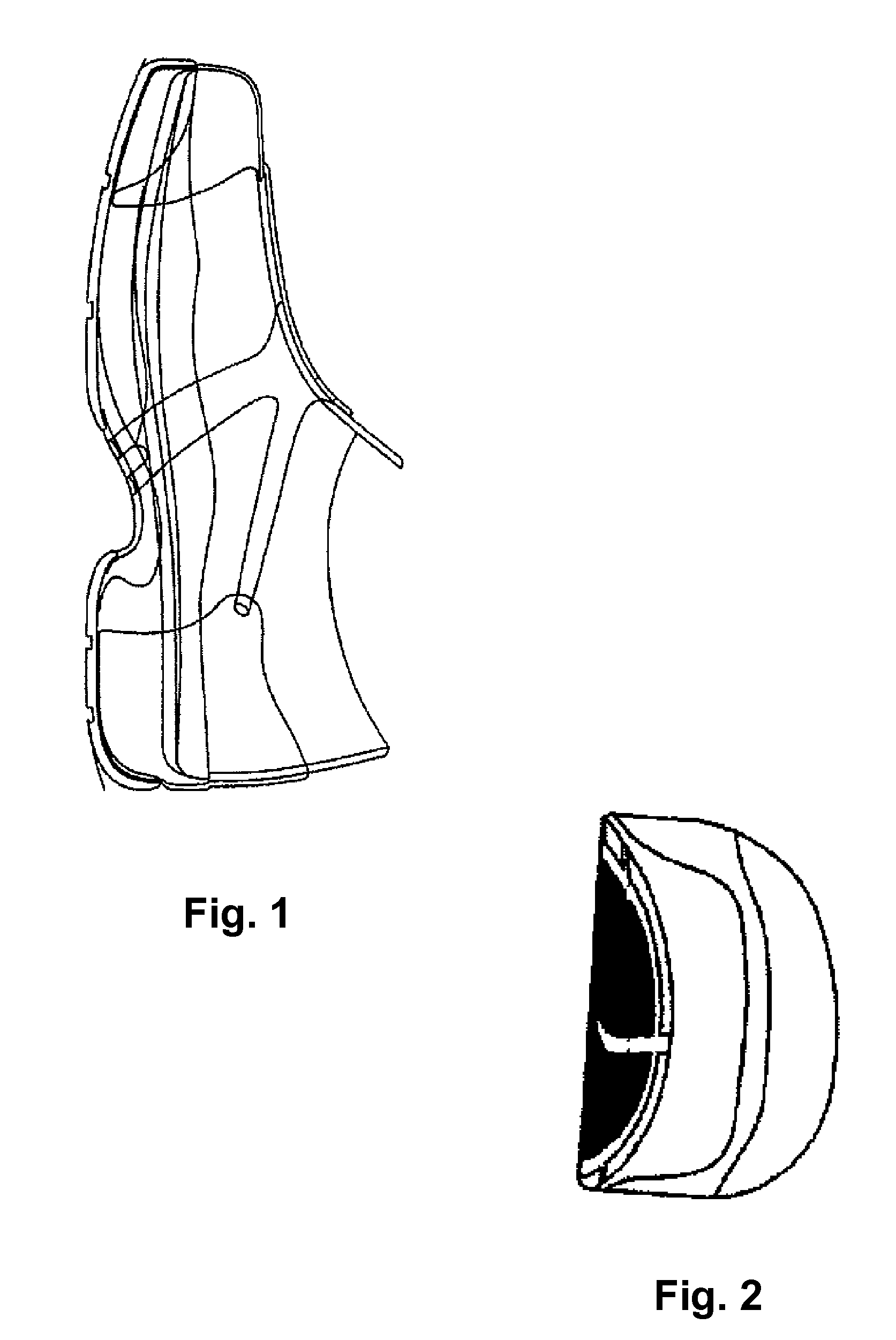

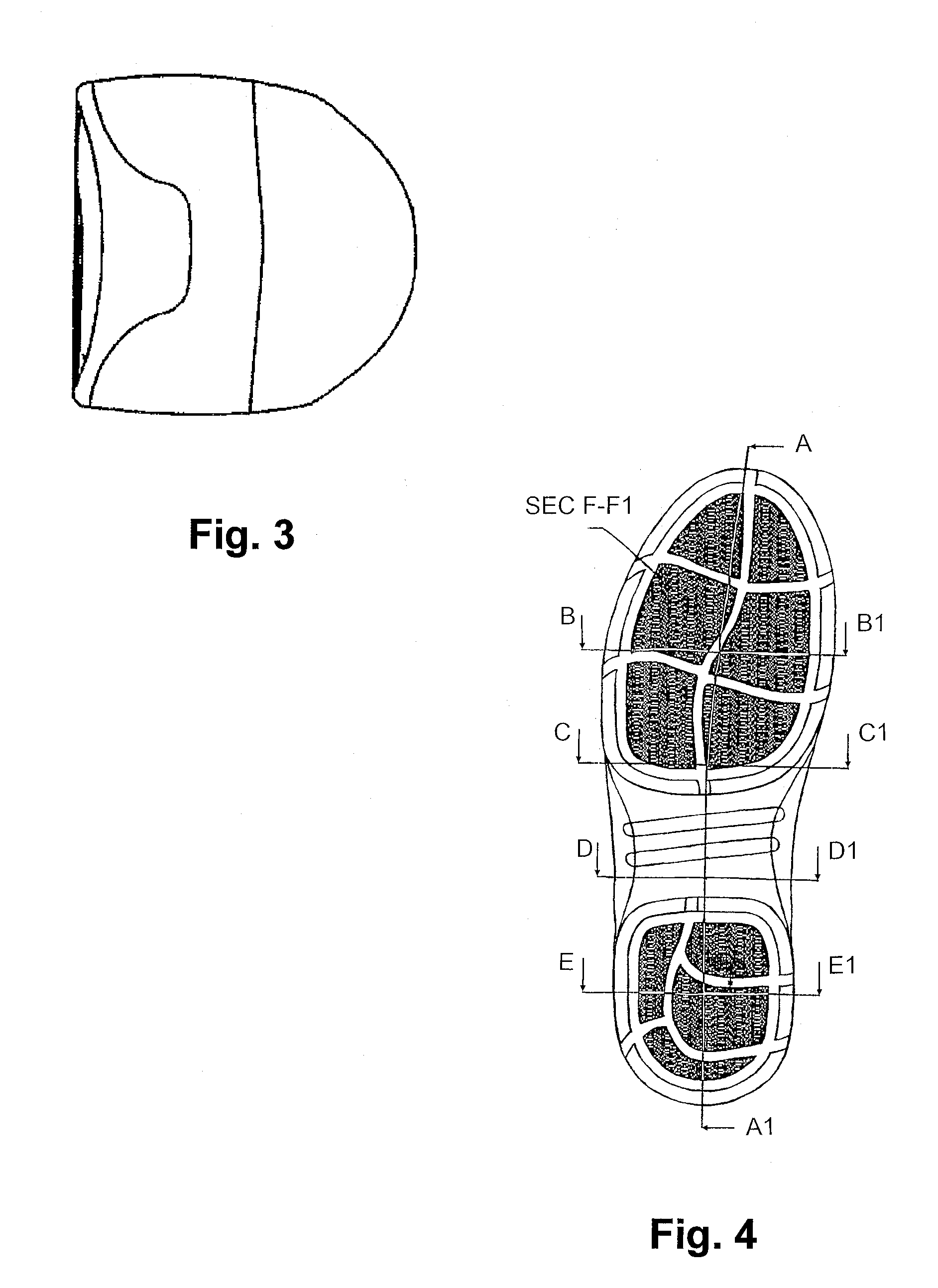

Combined Shoe

A combined shoe formed by a selected vamps and soles with different functions and appearances at any time, comprises a sole, a vamp and attaching means used to quick-connect the vamp and the sole for forming a whole shoe. The attaching means includes a front cap located in front of the sole for buckling the tip of the vamp; a hind cap located in the hind of the sole for buckling the heel of the vamp; two pairs of matched anti-slide plates located in half-soles / heels of both vamp and sole for preventing relative sliding between the vamp and the sole; and a plurality of pressing means used for pressing the vamp on the sole tightly. The combined shoes provide a multitude of combinations and reduce the shoe purchasing cost. Since the vamp and the sole can be disassembled and assembles quickly, when the wearer enters a room, he needs only remove the sole for keeping the cleanliness of the room and still can keep his feet warm and / or prevent the diffusion of foot odor.

Owner:CREATIVE WORKSHOP INTL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com