Method for preparing environmentally-friendly flame-retardant bio-based automobile chair polyurethane synthetic leather

A car seat, bio-based technology, applied in the direction of motor vehicles, road vehicles, transportation and packaging, etc., can solve the problems of poor seat covering performance, poor hand feeling and flexibility of non-woven fabrics, etc., and achieve improved flame retardancy Difficult, good surface skin-friendly performance, soft and full-feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

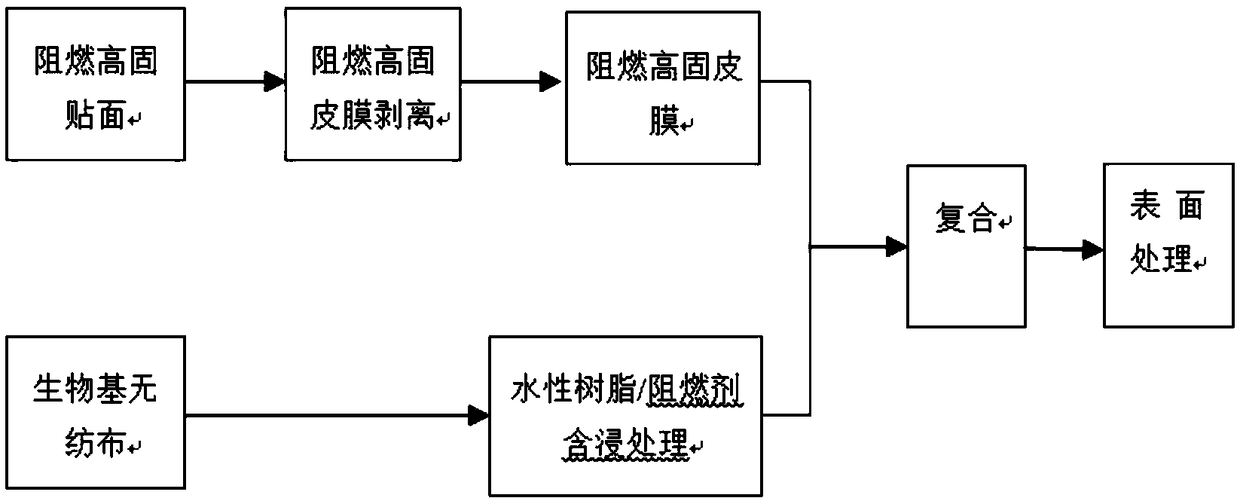

[0029] Such as figure 1 Shown, a kind of preparation method of environmental protection, flame-retardant bio-based car seat polyurethane synthetic leather, comprises the following steps:

[0030] (1) Co-spin bio-based raw materials and nylon to obtain a bio-based cloth base, then impregnate the bio-based cloth base with water-based polyurethane / halogen-free water-based flame retardant impregnating material, then squeeze and dry in sequence to obtain a Combustible bio-based substrates;

[0031] (2) Through the release paper film transfer method, the halogen-free flame-retardant high-solid polyurethane material is laminated to obtain a halogen-free flame-retardant high-solid polyurethane film, and then the release paper is peeled off to obtain a high-solid film with flame-retardant properties;

[0032] (3) Composite the flame-retardant bio-based substrate obtained in step (1) with the flame-retardant high-solid film obtained in step (2), and then perform surface treatment and m...

Embodiment 1

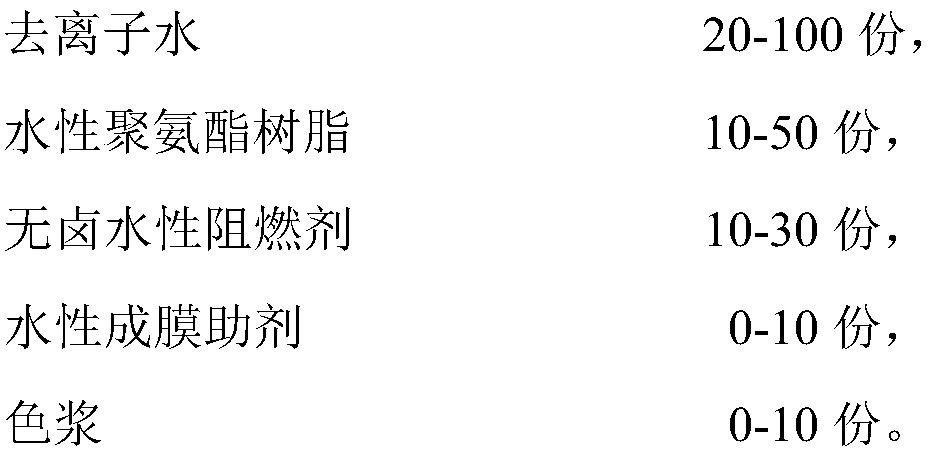

[0045] 1. Co-spinning bio-based raw materials and nylon to form a bio-based high-strength, high-elastic bio-based cloth base, which is impregnated with water-based polyurethane / halogen-free water-based flame retardant impregnation material, extruded, and dried to obtain a bio-based fabric with flame-retardant properties. Substrate, standby; wherein the preferred formula of water-based polyurethane / halogen-free water-based flame retardant impregnating material is as follows:

[0046]

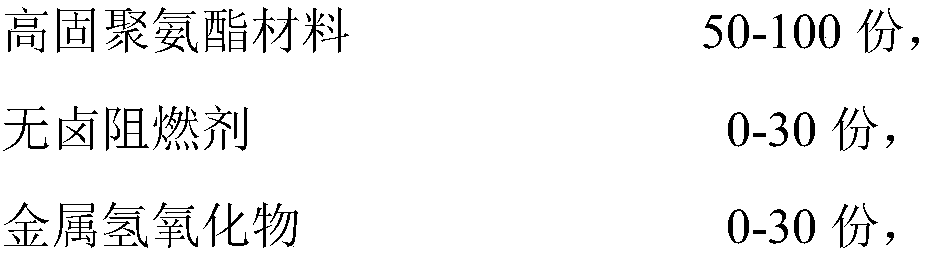

[0047] 2. Through the release paper film transfer method, the halogen-free flame-retardant high-solid polyurethane material is laminated to obtain a halogen-free flame-retardant high-solid polyurethane film, and then the release paper is peeled off to obtain a high-solid film with flame-retardant properties; among them, the halogen-free flame-retardant The preferred formula of burning high solid polyurethane material is as follows:

[0048]

[0049] 3. Composite the bio-based base material wi...

Embodiment 2

[0051] 1. Co-spinning bio-based raw materials and nylon to form a bio-based high-strength, high-elastic bio-based cloth base, which is impregnated with water-based polyurethane / halogen-free water-based flame retardant impregnation material, extruded, and dried to obtain a bio-based fabric with flame-retardant properties. Substrate. Among them, the preferred formula of water-based polyurethane / halogen-free water-based flame retardant impregnation material is as follows:

[0052]

[0053] 2. Through the release paper film transfer method, the halogen-free flame-retardant high-solid polyurethane material is laminated to obtain a halogen-free flame-retardant high-solid polyurethane film, and then the release paper is peeled off to obtain a high-solid film with flame-retardant properties; among them, the halogen-free flame-retardant The preferred formula of burning high solid polyurethane material is as follows:

[0054]

[0055] 3. Composite the bio-based base material with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com