Combined Shoe

a combined shoe technology, applied in the field of footwear, to achieve the effect of avoiding the diffusion of foot odor, reducing costs, and saving a large amount of materials and work hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

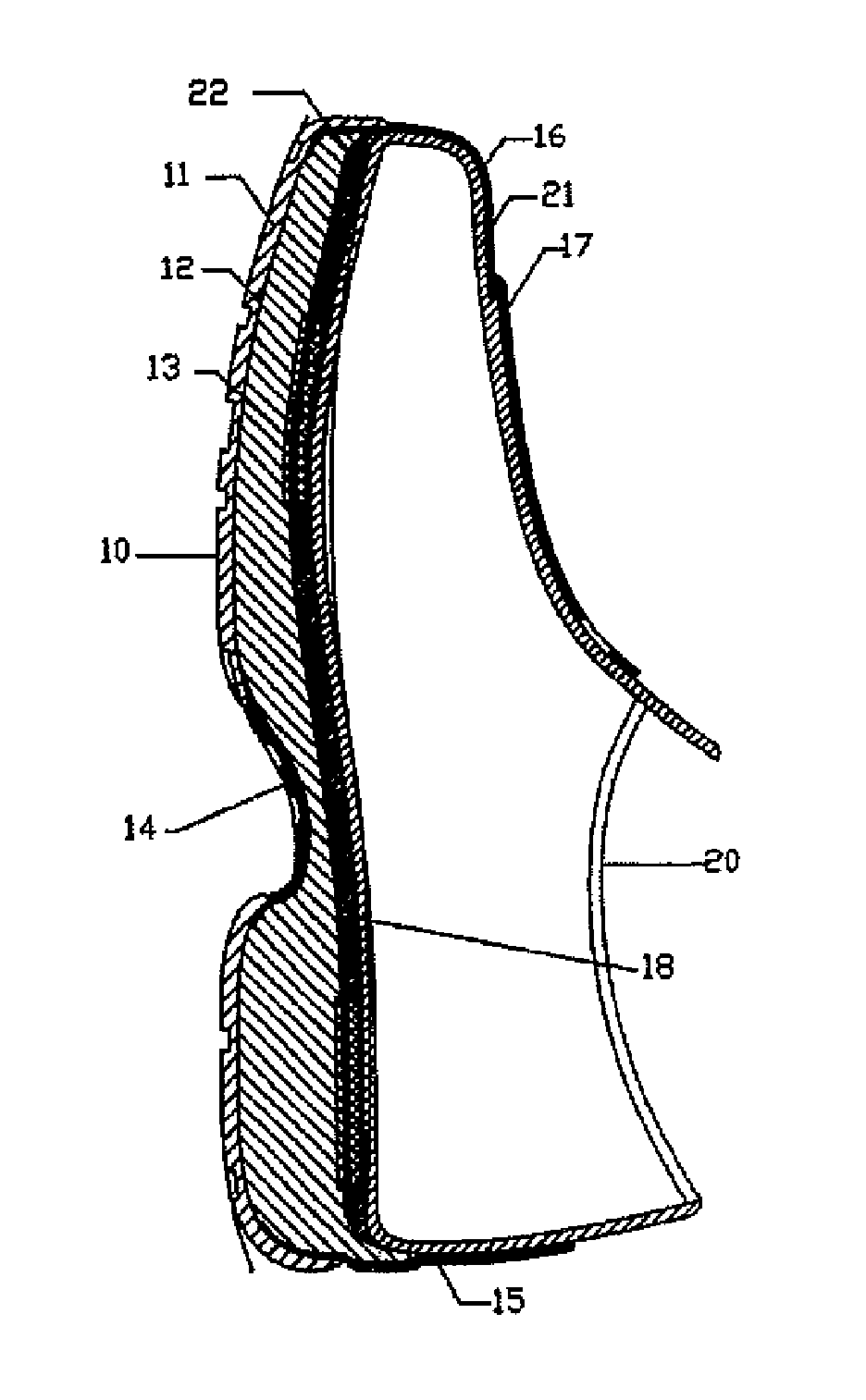

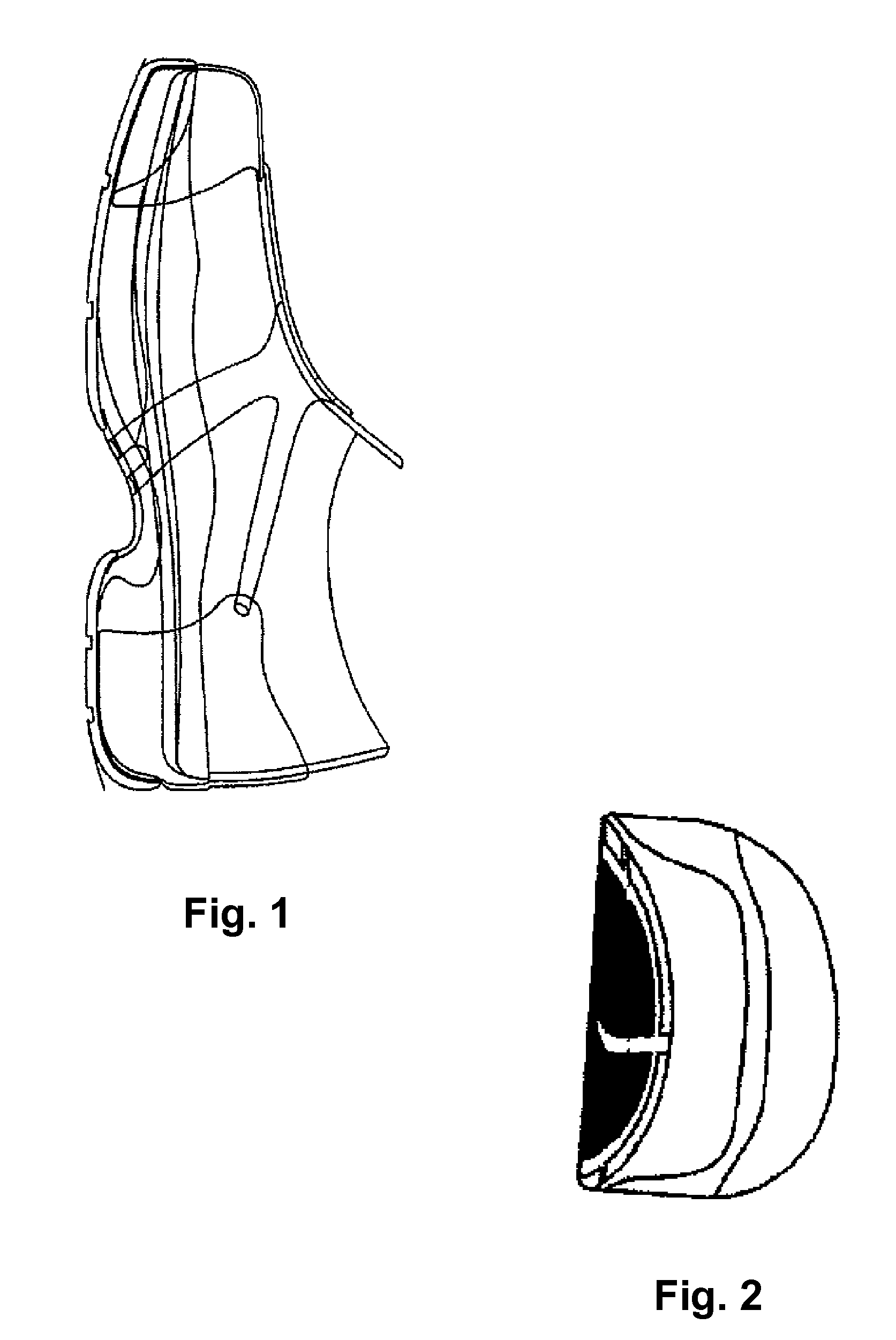

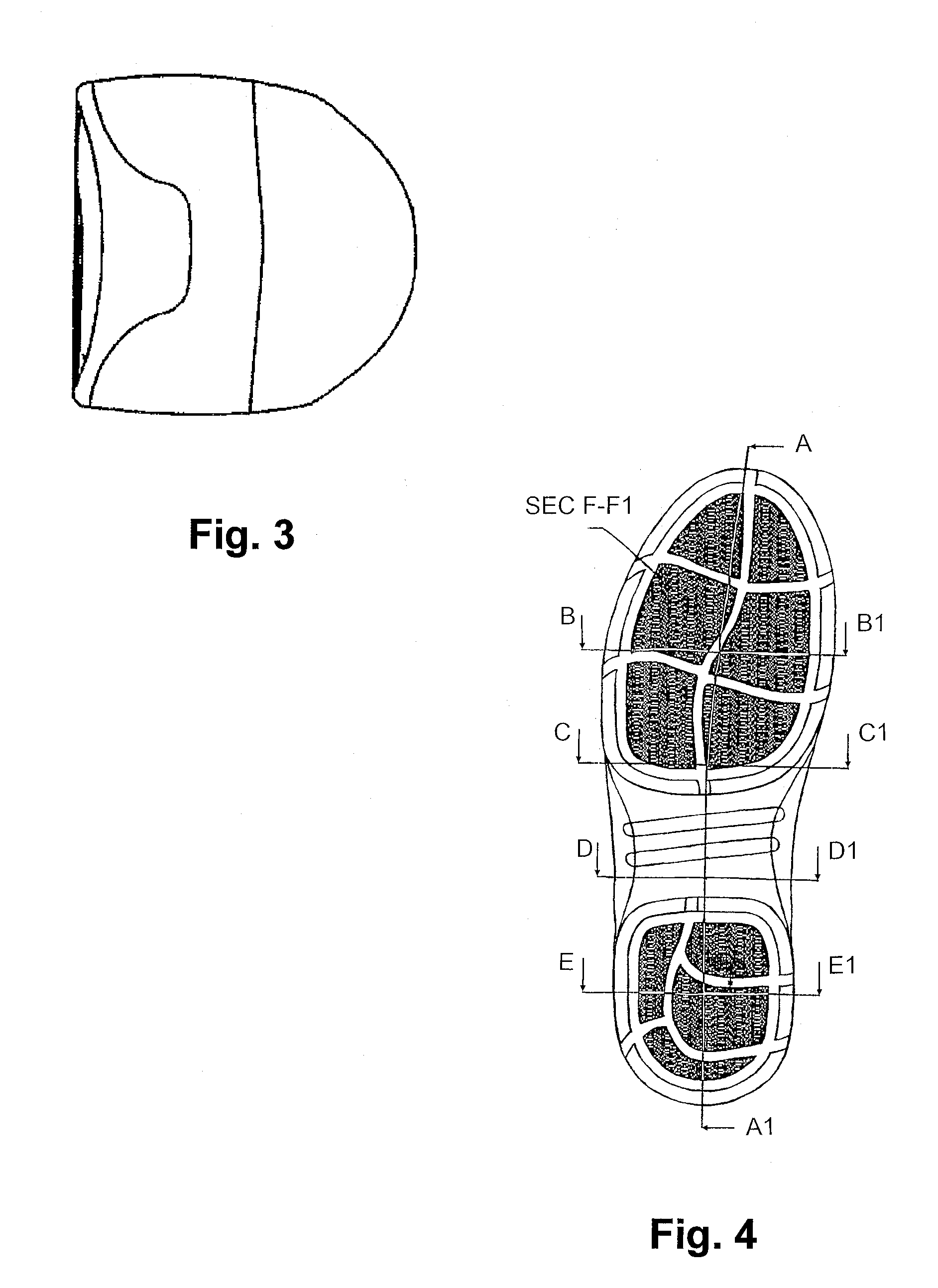

The description of the embodiments will be carried out with drawings as follows. Firstly, refer to FIG. 1, FIG. 2, FIG. 3 and FIG. 4; in which, FIG. 1 is an assembly drawing of finished product of the combined shoes; FIG. 2 is a top view of FIG. 1; FIG. 3 is a bottom view of FIG. 1; and FIG. 4 is A-A1 section of FIG. 1. In section A-A1 , it is shown that the combined shoe comprises a sole 10; a vamp 20; a front cap 16 located on front of the sole 10 for buckling the heel of the vamp 20; two pairs of matched anti-slide plates 13, each of them located on the half-soles / heels respectively for preventing relative sliding between the vamps and the soles; and a plurality of pressing means for pressing the vamps tightly on the soles. Each of the soles 10 includes an outer sole 11, a middle sole 12 and an inner sole 22. Between the middle sole 12 and the inner sole 22, there is a layer of EVA filling 18. In the drawings, 11 is the rubber outer sole; 12 is the EVA middle sole and 13 is the T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| colors | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com