Loading frame for lead frame with staggered pins

A technology of lead frame and staggered pins, which is applied in the field of loading frame, can solve the problems of small batch loading of loading frame and low utilization rate of mold surface, and achieve the effect of improving the utilization rate of mold surface and placing it stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

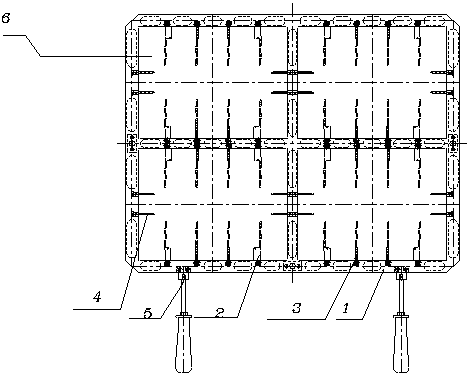

[0015] Such as figure 1 As shown, the present invention includes a frame body 1 and two handles 5 affixed to one side of the frame body 1, and the frame body 1 is provided with several support frames for supporting lead frames with staggered pins 6. A support bar is fixedly connected to the horizontal frame line of the support frame 6, and the shape of the support bar is consistent with the shape of the gap between the staggered pins of the lead frame.

[0016] The support frame 6 can be one, two, four, preferably four, evenly distributed in the frame body 1, so that the amount of material loaded at one time is more, and more than eight ultra-wide and ultra-dense staggered arrays can be loaded at a time Lead frames, of course, can also be divided into smaller grids, which can accommodate more lead frames at a time.

[0017] Since the products on the lead frame are cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com