Ultra-pure color-spot-free high-end fully-transparent quartz material and preparation method and application thereof

A technology of transparent quartz and quartz materials, which is applied in the field of ultra-pure non-color spot high-grade fully transparent quartz materials and its preparation, can solve the problems of blue spots in quartz glass ingots, inability to remove hydroxyl groups, high impurity content, etc., and achieve simple operation, environmental protection, super The effect of pure high-grade fully transparent quartz material without color spots, large amount and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

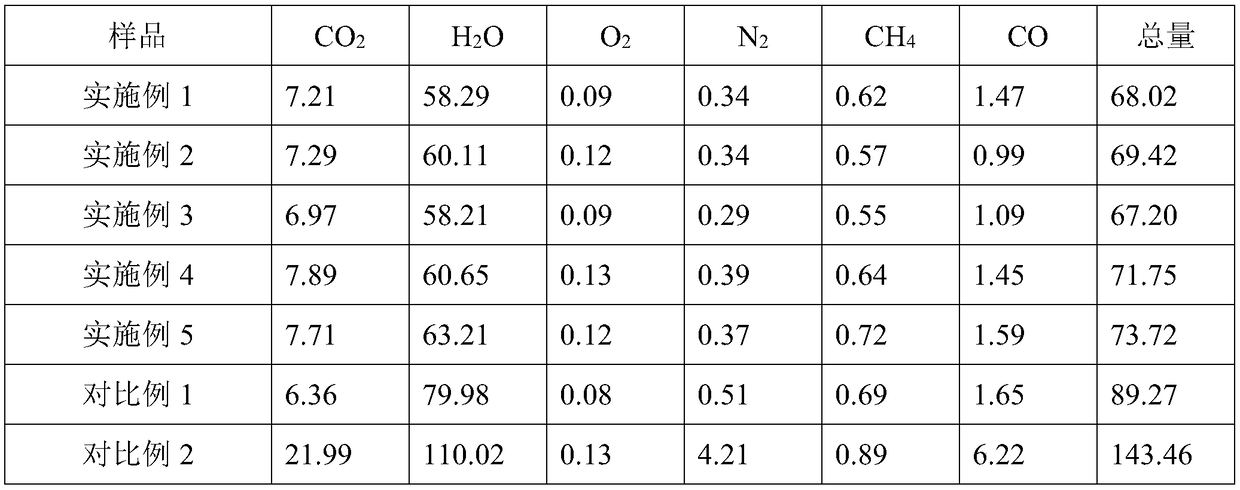

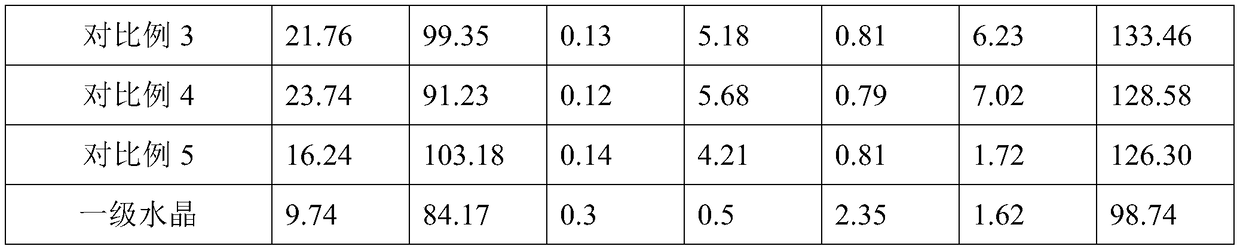

Embodiment 1

[0042] Example 1 Preparation of ultra-pure high-grade fully transparent quartz material without color spots

[0043] S1. Selected quartz silicon ore: Repeated ICP analysis and comparison of domestic quartz silicon ore, screened out that the total content of alkali metals is less than 320mg / kg, the total content of gas-liquid inclusions is less than 2000mg / kg, and the total content of B and P is less than 38mg / kg of quartz silica ore, soak the quartz silica ore with 1% hydrochloric acid at 60°C for 2 hours, and then quickly rinse with a large amount of deionized water to obtain the crude quartz silica ore;

[0044] S2. Water quenching: acid leaching the crude quartz silicon ore obtained in step S1, heating it to 600°C, and then quickly putting it into water to explode for 5 seconds, removing a large amount of gas-liquid inclusions, and obtaining crude product particles;

[0045] S3. Acid leaching: pulverize the crude product particles obtained in step S2 through a Raymond mill,...

Embodiment 2

[0051] Example 2 Preparation of ultra-pure high-grade fully transparent quartz material without color spots

[0052] S1. Selected quartz silicon ore: Repeated ICP analysis and comparison of domestic quartz silicon ore shows that the total content of alkali metal is 350mg / kg, the total content of gas-liquid inclusions is 2310mg / kg, and the total content of B and P is 21mg / kg The quartz silica ore is soaked in hydrochloric acid with a concentration of 2% at 60°C for 2 hours, and then quickly rinsed with a large amount of deionized water to obtain a crude quartz silica ore;

[0053] S2. Water quenching: acid leaching the crude quartz silicon ore obtained in step S1, heating it to 630°C, and then quickly putting it into water for 5 seconds to explode when it is cooled, to remove a large amount of gas-liquid inclusions, and obtain crude product particles;

[0054] S3. Acid leaching: pulverize the crude product particles obtained in step S2 through a Raymond mill, pass through a 100...

Embodiment 3

[0060] Example 3 Preparation of ultra-pure high-grade fully transparent quartz material without color spots

[0061] S1. Selected quartz silicon ore: After repeated ICP analysis and comparison of domestic quartz silicon ore, the total content of alkali metal is 354mg / kg, the total content of gas-liquid inclusions is 2256mg / kg, and the total content of B and P is 21.6mg / kg. kg of quartz silicon ore, soak the quartz silicon ore at 70°C for 1 hour with phosphoric acid with a concentration of 3%, and then quickly wash it with a large amount of deionized water to obtain the crude quartz silicon ore;

[0062] S2. Water quenching: acid leaching the crude quartz silicon ore obtained in step S1, heating it to 650°C, and then quickly putting it into water for 8 seconds to explode when it is cooled, to remove a large amount of gas-liquid inclusions, and obtain crude product particles;

[0063] S3. Acid leaching: pulverize the crude product particles obtained in step S2 through a Raymond ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com