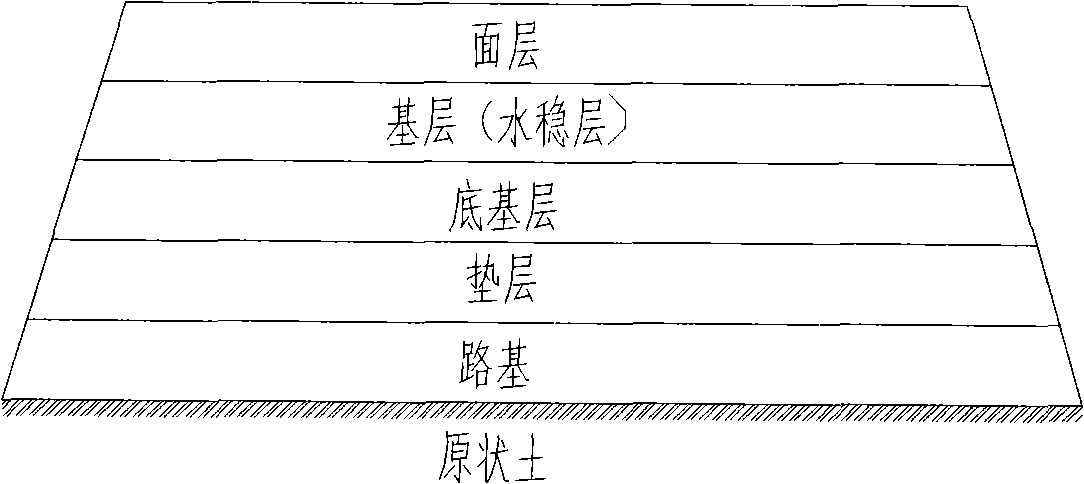

Method for preparing regenerative road material by using waste building material and construction method thereof

A technology for construction waste and construction access roads, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., and can solve problems such as inability to guarantee construction quality and service life of roads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Sorting construction waste to remove metal, wood and impurities.

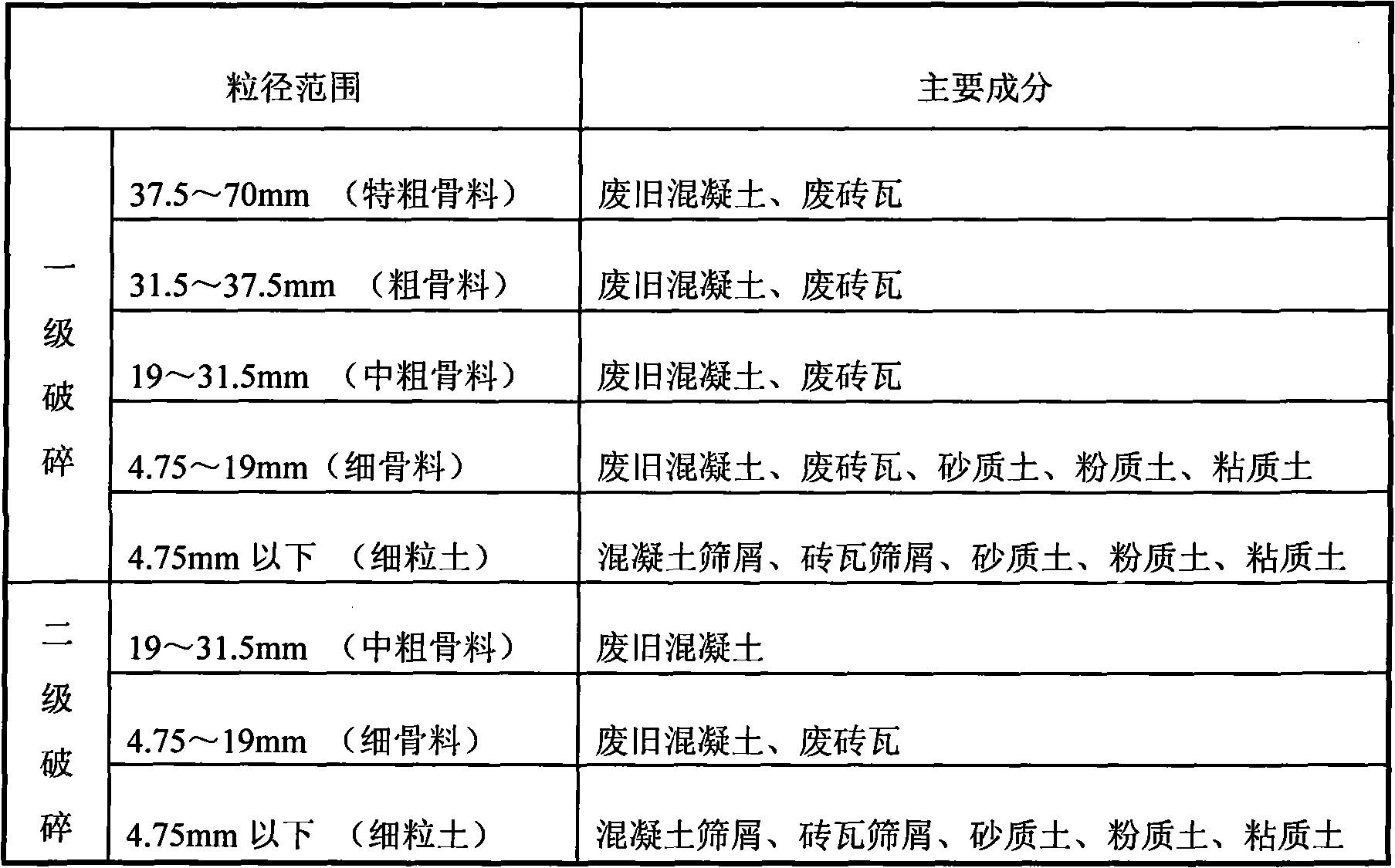

[0030] 2. The crushing of construction waste in the project adopts the principle of centralized crushing, and primary crushing or secondary crushing can be adopted according to specific conditions. Sieve by grade to get special coarse aggregate, coarse aggregate, medium coarse aggregate, fine aggregate, fine-grained soil, among the aggregates, waste brick: waste concrete is about 3:1; aggregate: fine-grained soil is about 3:1 It is 6:4, and the water content is less than 5%.

[0031] Particle composition and particle size requirements of construction waste and soil after crushing and screening

[0032]

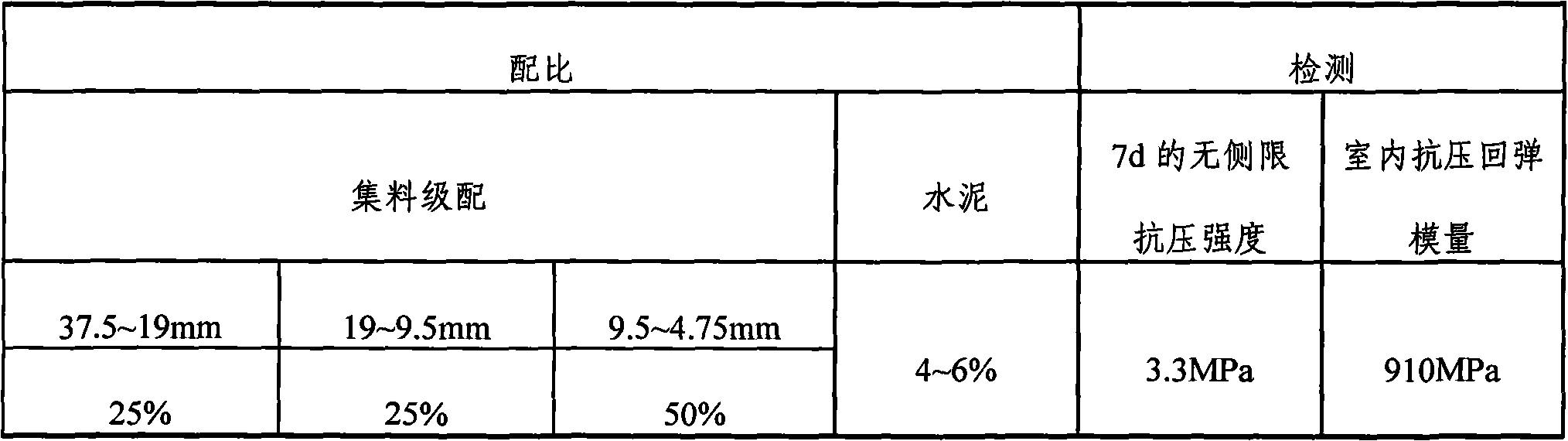

[0033] Formed test pieces; maximum dry density and optimum moisture content: determined by heavy-duty compaction tests.

[0034] 3. Prepare materials,

[0035] According to design requirements, special coarse aggregate, coarse aggregate, medium coarse aggregate, fine aggregate and fine-grained s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com