Automatic electrical drying chamber

An electrical automation, drying room technology, applied in drying, drying machine, non-progressive drying machine and other directions, can solve the problems of inability to realize electrical automatic drying, increase labor costs, affect work efficiency, etc., and achieve compact structure. , high energy-saving rate, the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention be further understood, the present invention will be further described below with reference to accompanying drawing and specific embodiment of description:

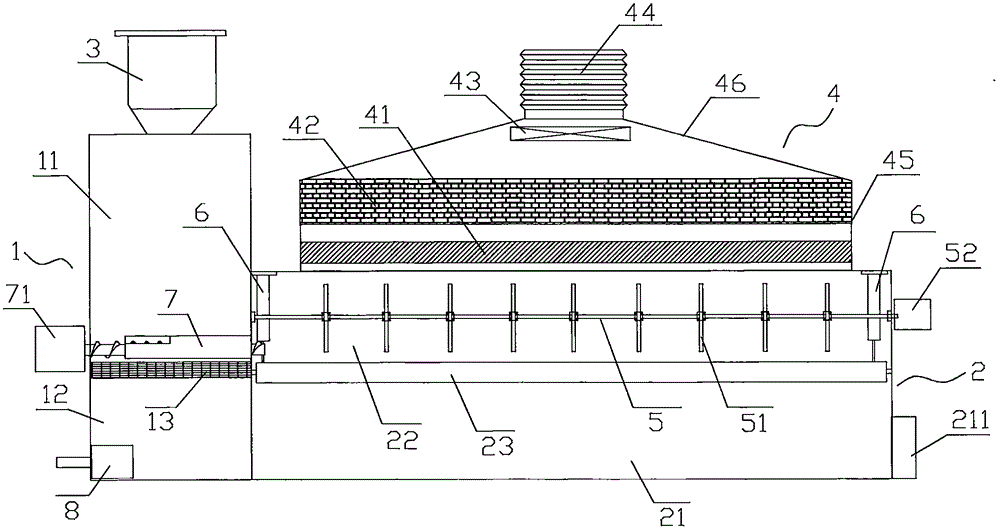

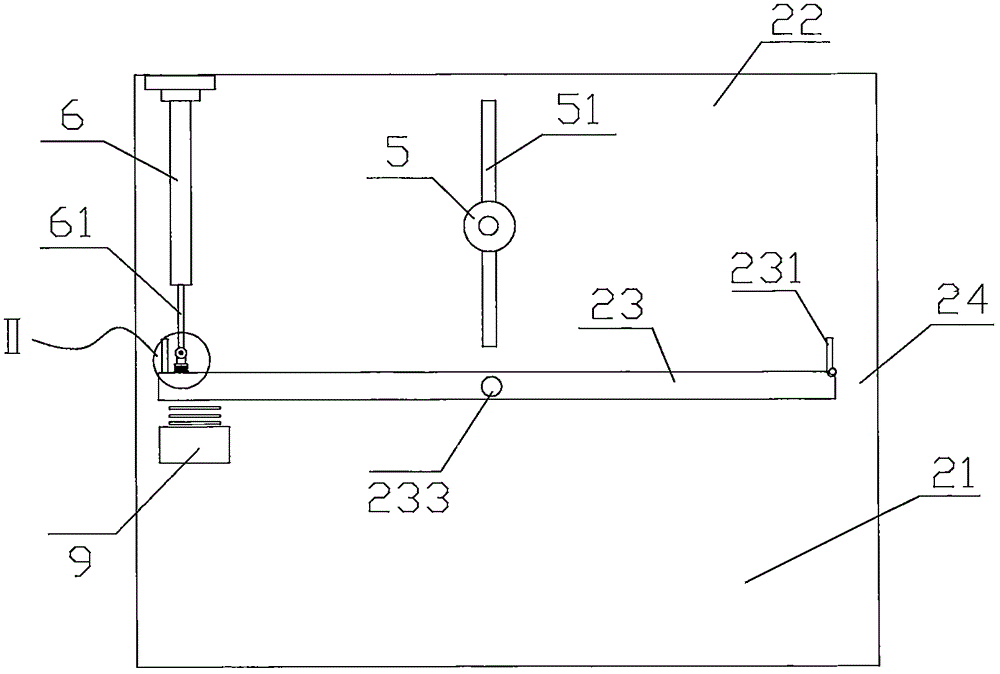

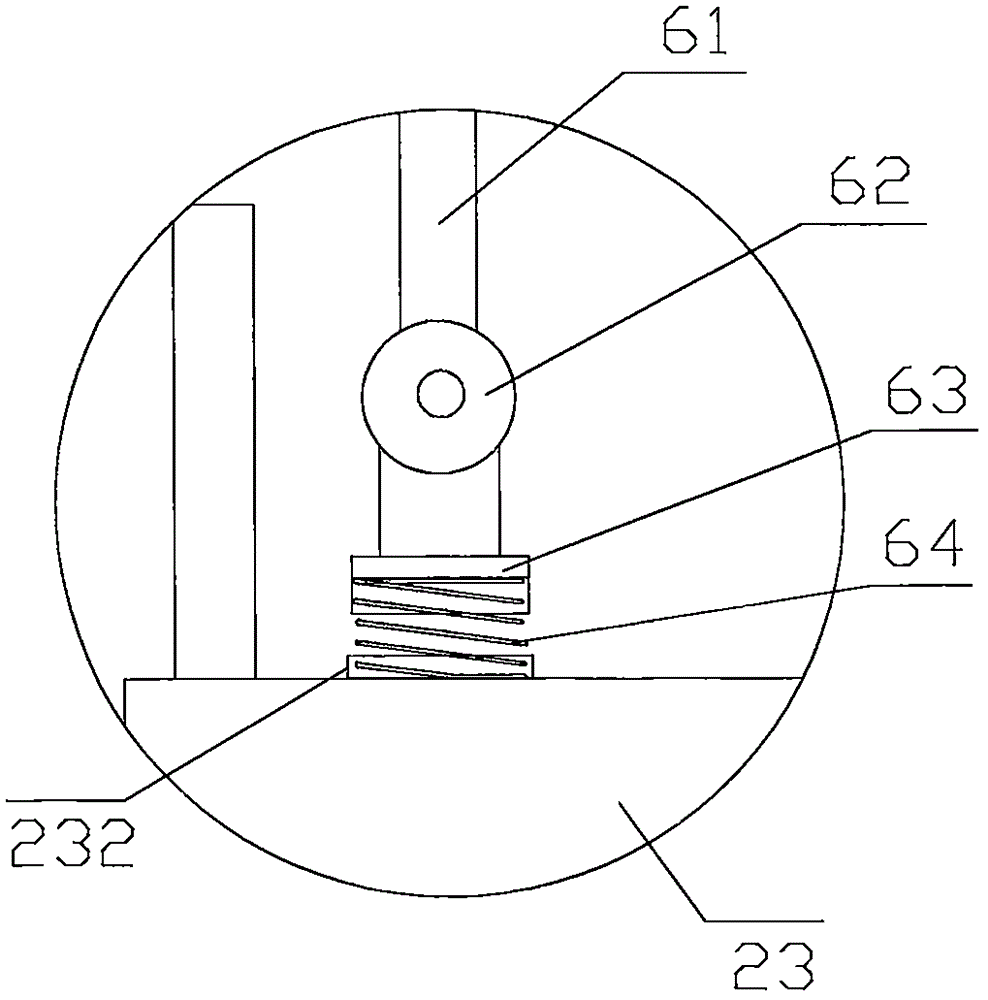

[0021] Such as Figure 1 to Figure 3 Shown, a kind of electrical automatic drying chamber, comprises drying chamber 2, is connected to the feed chamber 1 on one side of drying chamber 2 and is located at the deodorizing chamber 4 that is arranged on the top of drying chamber 2 and communicates with drying chamber 2, and feed chamber The top of 1 is provided with feed hopper 3. Wherein, as an improvement of the present invention, a flat high-frequency electromagnetic drying plate 23 is provided in the drying chamber 2, and the high-frequency electromagnetic drying plate 23 is rotatably connected in the drying chamber 2 through a rotating shaft 233, and its power is 40KW . The high-frequency electromagnetic drying plate 23 divides the chamber of the drying chamber 2 into an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com